Beruflich Dokumente

Kultur Dokumente

Classification of Man-Made Fibers and Their Codes

Hochgeladen von

Falgon Islam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

59 Ansichten2 SeitenClassification of fiber

Originaltitel

Classification of Fibers

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenClassification of fiber

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

59 Ansichten2 SeitenClassification of Man-Made Fibers and Their Codes

Hochgeladen von

Falgon IslamClassification of fiber

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Classification of man-made fibers and their codes

The Classification of man-made fibers

Man-made fibers are classified into three classes, those made from natural polymers, those made

from synthetic polymers and those made from inorganic materials.

FIBERS

Natural Man-made

Organic Inorganic

By transformation From synthetic

of natural polymers polymers

Acetate CA Acrylic PAN Carbon CF

Alginate ALG Aramid AR Ceramic CEF

Cupro CUP Chlorofibre CLF Glass GF

Elastodiene 1 ED Elastane 2 EL Metal MTF

Lyocell CLY Elastodiene 2 ED

Modal CMD Fluorofibre PTFE

Triacetate CTA Modacrylic MAC

Viscose CV Polyamide PA

Polyester 3 PES

Polyethylene 2 PE 1. Previously called elastofibers

2. Sometimes called polyolefins

Polyimide PI 3. Same code for polyether sulfone in ISO 1043

Polypropylene 2 PP 4.

Vinylal PVAL

Fibers from Natural Polymers

The most common natural polymer fiber is viscose, which is made from the polymer cellulose obtained

mostly from farmed trees. Other cellulose-based fibers are cupro, acetate and triacetate, lyocell, and

modal. Less common natural polymer fibers are made from rubber, alginic acid and regenerated

protein.

Fibers from Syntetic Polymers

There are very many synthetic fibers i.e. organic fibers based on petrochemicals. The most common

are polyester, polyamide (often called nylon), acrylic and modacrylic, polypropylene, the segmented

polyurethanes which are elastic fibers known as elastanes (or spandex in the USA), and speciality

fibers such as the high performance aramids.

Fibers from Inorganic Materials

The inorganic man-made fibers are fibers made from materials such as glass, metal, carbon or

ceramic. These fibers are very often used to reinforce plastics to form composites.

Viscose Rayon

There are several fibres made from the Rayon, artificial textile material, composed of

naturally occuring polymer cellulose which is cellulose obtained from cotton linters or from

present in all plants. Mostly cellulose from the pulp of trees such as spruce. Since the

wood is used to produce the fibers but introduction of rayon about 1900, it has been

sometimes cellulose from short cotton fibres, used in many textile fields. At first rayon was

called linters, is the source. By far the most called silk because, in its filament form, it

common cellulosic fibre is viscose. somewhat resembles silk; however, this

comparision is misleading because the

Viscose is defined very simply by BISFA as chemical composition of rayon is entirely

being ”a cellulose fibre obtained by the different from that of silk.

viscose process”. It is known as rayon in the Rayon can be made by either the viscose

USA. Although several cellulosic fibres had process or the cuprammonium process; both

been made experimentally during the 19th produce fibre classified by the U.S. Federal

century, it was not until 1905 that what has Trade Commission as rayon. In the viscose

become the most popular cellulosic fibre, process purified cellulose is treated with

viscose, was produced. sodium hydroxide, then with carbon disulfide,

to form a viscous yellow liquid called viscose.

Production In the cupammonium process purified

Viscose fibres are made from cellulose from cellulose is treated with cuprammoniun liquor,

wood pulp. The cellulose is ground up and then with sodium hydroxide, to form viscose.

reacted with caustic soda. After a waiting The manufacture of rayon filaments – and all

period, the ripening process during which manufactured fibers – is done by means of

depolymerisation occurs, carbon disulphide is an extrusion process called spinning. In this

added. This forms a yellow crumb known as procedure the fiber-forming liquid is forced

cellulose xanthate, which is easily dissolved through tiny holes in a nozzle or spinneret

in more caustic soda to give a viscous yellow into a liquid bath containing chemicals that

solution. This solution is pumped through a produce filaments of pure cellolose, which

spinneret, which may contain thousands of can be spun into yarn. The filaments are

holes, into a dilute sulphuric acid bath where drawn together to form both fibers and yarn in

the cellulose is regenerated as fine filaments a single, continuous process.

as the xanthate decomposes.

Properties and End-Uses

Viscose fibres, like cotton, have a hight

moisture regain. It dyes easily, it does not

shrink when heated, and it is biodegradable.

It is used in most apparel end-uses, often

blended with other fibres, and in hygienic

disposables where its high absorbency gives

advantages. In filament yarn form it is

exellent for linings. It is used very little in

home furnishing fabrics but in the industrial

field, because of its thermal stability, a high

modulus version is still the main product used 2001/WP

in Europé to reinforce high speed tyres.

Das könnte Ihnen auch gefallen

- Classification of Man-Made Fibers and Their CodesDokument2 SeitenClassification of Man-Made Fibers and Their CodesNazmul-HassanNoch keine Bewertungen

- Tensile Strength of FibersDokument27 SeitenTensile Strength of FibersKaushik DwivediNoch keine Bewertungen

- BUBTDokument67 SeitenBUBTPrince RajNoch keine Bewertungen

- Tensile Strength of FibersDokument26 SeitenTensile Strength of FibersSandip Bakshi50% (2)

- Investigatory Project Chemistry - 1Dokument27 SeitenInvestigatory Project Chemistry - 1Jayesh ModiNoch keine Bewertungen

- FibresDokument13 SeitenFibresbillatkrNoch keine Bewertungen

- Tensile Strength of Fibers My SchoolDokument25 SeitenTensile Strength of Fibers My SchoolNatkhat londaNoch keine Bewertungen

- Classification of FibresDokument9 SeitenClassification of Fibres01917473787Noch keine Bewertungen

- Tensile Strength of FibersDokument15 SeitenTensile Strength of FibersBharat PatelNoch keine Bewertungen

- Nonwoven Fiber Materials and TechnologyDokument105 SeitenNonwoven Fiber Materials and TechnologydanielcocrgNoch keine Bewertungen

- Fiber or Fibre: Natural FibersDokument10 SeitenFiber or Fibre: Natural FibersMd. Sifat Ibna IslamNoch keine Bewertungen

- 38-character title for synthetic fibers documentDokument8 Seiten38-character title for synthetic fibers documentZAyedNoch keine Bewertungen

- Maharishi International Residential School: Chemistry Investigatory ProjectDokument27 SeitenMaharishi International Residential School: Chemistry Investigatory ProjectArun MurugavelNoch keine Bewertungen

- Dye IndustryDokument19 SeitenDye IndustryBarbie Ann Tampus Jurolan100% (1)

- Scheme of The EvaluationDokument6 SeitenScheme of The EvaluationSabihanaz InamdarNoch keine Bewertungen

- Types of FibersDokument7 SeitenTypes of FibersAbubakar JavedNoch keine Bewertungen

- Semi-synthetic fibers made from raw materialsDokument2 SeitenSemi-synthetic fibers made from raw materialskate trishaNoch keine Bewertungen

- Delhi Public School Varanasi: Chemistry Investigatory ProjectDokument26 SeitenDelhi Public School Varanasi: Chemistry Investigatory ProjectPriyansh SinghNoch keine Bewertungen

- Chemisty of Textile Fibers and Their PropertiesDokument21 SeitenChemisty of Textile Fibers and Their Propertiesnalaka.sampathNoch keine Bewertungen

- Subject-Chemistry: Tensile Strength of Fibre in Alkali & Acidic MediumDokument14 SeitenSubject-Chemistry: Tensile Strength of Fibre in Alkali & Acidic MediumLovesh KashyapNoch keine Bewertungen

- Chemistry Project Class 11 A3Dokument41 SeitenChemistry Project Class 11 A3ERROR ???Noch keine Bewertungen

- IntroductionDokument12 SeitenIntroductionompandit0xNoch keine Bewertungen

- Preparation of Rayon ThreadDokument20 SeitenPreparation of Rayon ThreadAkshaya SuruthiNoch keine Bewertungen

- 02.2 Textile Fibres Overview NotesDokument34 Seiten02.2 Textile Fibres Overview NotesFlorin ChiroscaNoch keine Bewertungen

- FiberDokument5 SeitenFiberEka Nanda PutrianiNoch keine Bewertungen

- Textile Fundamentals: Project On Fibre ClassificationDokument7 SeitenTextile Fundamentals: Project On Fibre ClassificationAnubhav kashyapNoch keine Bewertungen

- Synthetic FibersDokument16 SeitenSynthetic FibersDhiraj ChalseNoch keine Bewertungen

- Properties and uses of cotton fibreDokument20 SeitenProperties and uses of cotton fibreAlen Jose ThomasNoch keine Bewertungen

- Fiber: Fiber or Fibre (From Latin: FibraDokument4 SeitenFiber: Fiber or Fibre (From Latin: FibraCrow LordNoch keine Bewertungen

- CBSE Class 8 Science Chapter 3 NotesDokument5 SeitenCBSE Class 8 Science Chapter 3 NotesSree LuckyNoch keine Bewertungen

- FIBRE (Power Point)Dokument54 SeitenFIBRE (Power Point)MonirHossainNoch keine Bewertungen

- Them Investigatory ProjectDokument24 SeitenThem Investigatory ProjectRimjhim mathur50% (2)

- FibresDokument5 SeitenFibresu92445622Noch keine Bewertungen

- Lyocell Fibre DocumentDokument4 SeitenLyocell Fibre DocumentHossain RsfaNoch keine Bewertungen

- Man Made Fibres: Assignment: Fabric KnowledgeDokument37 SeitenMan Made Fibres: Assignment: Fabric Knowledgeangurdevi100% (2)

- L 1 F: T C C: Esson Ibres Heir Lassification AND HaracteristicsDokument11 SeitenL 1 F: T C C: Esson Ibres Heir Lassification AND HaracteristicsMuhamad RafiqNoch keine Bewertungen

- Training Report On Textile Wet ProcessingDokument38 SeitenTraining Report On Textile Wet ProcessingMunazza SohailNoch keine Bewertungen

- Chemistry Class 8 CH - 3 Synthetic Fibres and Plastics: FibreDokument3 SeitenChemistry Class 8 CH - 3 Synthetic Fibres and Plastics: FibreJayesh ParmarNoch keine Bewertungen

- Presentation On: Semi Synthetic or Regenerated FiberDokument8 SeitenPresentation On: Semi Synthetic or Regenerated Fibersazzad alaminNoch keine Bewertungen

- Synthetic FibersDokument18 SeitenSynthetic Fibersaayush_vijayvargiaNoch keine Bewertungen

- The Ultimate Thread Guide: Everything You Need to Know to Choose the Perfect Thread for Every ProjectVon EverandThe Ultimate Thread Guide: Everything You Need to Know to Choose the Perfect Thread for Every ProjectBewertung: 4 von 5 Sternen4/5 (4)

- Submitted By-Lili M.SC (C.T) 3 SemDokument23 SeitenSubmitted By-Lili M.SC (C.T) 3 Semvivek jangraNoch keine Bewertungen

- Textile Raw Materials-IIDokument2 SeitenTextile Raw Materials-IIMOJAHID HASAN Fall 19100% (1)

- Relations Between Fiber Structure and PropertiesDokument7 SeitenRelations Between Fiber Structure and PropertiesChikam BuraNoch keine Bewertungen

- Basic Netting TermsDokument6 SeitenBasic Netting TermsTine CajegasNoch keine Bewertungen

- Fibers Properties Textile MaterialsDokument19 SeitenFibers Properties Textile MaterialsGarmentLearner100% (1)

- Textile FibreDokument34 SeitenTextile Fibrekavi RAJ SenNoch keine Bewertungen

- Natural and Artifical FiberDokument2 SeitenNatural and Artifical FiberBhupesh TambeNoch keine Bewertungen

- Textile Industry - 01 LectureDokument40 SeitenTextile Industry - 01 Lectureisabelism100% (1)

- CGTPaper IIDokument130 SeitenCGTPaper IIMd. Humayun KabirNoch keine Bewertungen

- Modal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonDokument18 SeitenModal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonHrs Shihab100% (1)

- Textile Fibers 9 Mansoor IqbalDokument8 SeitenTextile Fibers 9 Mansoor IqbalMansoor IqbalNoch keine Bewertungen

- Chemistry of Textile Fibres & Their PropertiesDokument24 SeitenChemistry of Textile Fibres & Their PropertiesAsiri Vidul100% (3)

- Handbook of Textile Fibres: Man-Made FibresVon EverandHandbook of Textile Fibres: Man-Made FibresBewertung: 2 von 5 Sternen2/5 (1)

- Field Guide to Fabrics: The Complete Reference Tool to Understanding FabricVon EverandField Guide to Fabrics: The Complete Reference Tool to Understanding FabricBewertung: 5 von 5 Sternen5/5 (2)

- The Chemical Technology of Textile Fibres - Their Origin, Structure, Preparation, Washing, Bleaching, Dyeing, Printing and DressingVon EverandThe Chemical Technology of Textile Fibres - Their Origin, Structure, Preparation, Washing, Bleaching, Dyeing, Printing and DressingBewertung: 4 von 5 Sternen4/5 (1)

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentVon EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNoch keine Bewertungen

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineDokument4 SeitenMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamNoch keine Bewertungen

- Spare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckDokument12 SeitenSpare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckFalgon IslamNoch keine Bewertungen

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineDokument4 SeitenMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamNoch keine Bewertungen

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineDokument4 SeitenMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamNoch keine Bewertungen

- FLX30d: Spare Parts CatalogueDokument49 SeitenFLX30d: Spare Parts CatalogueFalgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: (MGS 7310 GCP)Dokument47 SeitenOperation & Maintenance Manual: (MGS 7310 GCP)Falgon IslamNoch keine Bewertungen

- VFD-M Series AC Motor Drive ManualDokument173 SeitenVFD-M Series AC Motor Drive ManualoarionIIINoch keine Bewertungen

- PIC For BeginnersDokument147 SeitenPIC For Beginnersapi-3695801100% (45)

- Untitled SpreadsheetDokument23 SeitenUntitled SpreadsheetFalgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: (MGS 7310 GCP)Dokument47 SeitenOperation & Maintenance Manual: (MGS 7310 GCP)Falgon IslamNoch keine Bewertungen

- Sheet No 12Dokument30 SeitenSheet No 12Falgon IslamNoch keine Bewertungen

- FLX30d: Spare Parts CatalogueDokument49 SeitenFLX30d: Spare Parts CatalogueFalgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Dokument123 SeitenOperation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Falgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: (MGS 560 Panel)Dokument53 SeitenOperation & Maintenance Manual: (MGS 560 Panel)Falgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: (S16R2-PTAW2-S)Dokument111 SeitenOperation & Maintenance Manual: (S16R2-PTAW2-S)Falgon IslamNoch keine Bewertungen

- Operation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Dokument123 SeitenOperation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Falgon IslamNoch keine Bewertungen

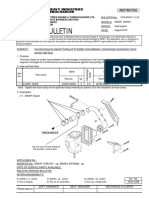

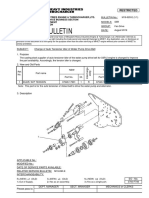

- Service BulletinDokument2 SeitenService BulletinFalgon IslamNoch keine Bewertungen

- Filter Offer PaikaneDokument1 SeiteFilter Offer PaikaneFalgon IslamNoch keine Bewertungen

- Service BulletinDokument3 SeitenService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument4 SeitenService BulletinFalgon IslamNoch keine Bewertungen

- FLX30d: Spare Parts CatalogueDokument49 SeitenFLX30d: Spare Parts CatalogueFalgon IslamNoch keine Bewertungen

- Service BulletinDokument3 SeitenService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument2 SeitenService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- Service BulletinDokument1 SeiteService BulletinFalgon IslamNoch keine Bewertungen

- History of Photography - by Doug - NickelDokument18 SeitenHistory of Photography - by Doug - NickelThomaz SimoesNoch keine Bewertungen

- Drifter OP - Guitar Tab Full - AndrosDokument3 SeitenDrifter OP - Guitar Tab Full - AndrosSahrul AgustianNoch keine Bewertungen

- English 393B: Environmental CriticismDokument4 SeitenEnglish 393B: Environmental CriticismLuis RomanoNoch keine Bewertungen

- Dear YouDokument6 SeitenDear YouSue SandraNoch keine Bewertungen

- All Summer in A Day Comprehension TestDokument4 SeitenAll Summer in A Day Comprehension TestnispalNoch keine Bewertungen

- 1-Bombardino C PDFDokument3 Seiten1-Bombardino C PDFJose HerreroNoch keine Bewertungen

- A Christmas Carol - Charles DickensDokument93 SeitenA Christmas Carol - Charles DickensiisPublishNoch keine Bewertungen

- Edgar E. Garcia Deped-BataanDokument46 SeitenEdgar E. Garcia Deped-BataanJohnson SungaNoch keine Bewertungen

- The Nun's Priest's Tale AnalysisDokument6 SeitenThe Nun's Priest's Tale AnalysisAdam ParkerNoch keine Bewertungen

- Ana & Dino Demicheli, Salona AD 541 PDFDokument34 SeitenAna & Dino Demicheli, Salona AD 541 PDFAnonymous hXQMt5Noch keine Bewertungen

- Mechanical Movements enDokument8 SeitenMechanical Movements enbogdanNoch keine Bewertungen

- Indus ValleyDokument37 SeitenIndus ValleySwati Shukla100% (1)

- Pearl Academy Case StudyDokument1 SeitePearl Academy Case Studyadnan khanNoch keine Bewertungen

- JESTROVIC, S. From Brecht To BelgradeDokument10 SeitenJESTROVIC, S. From Brecht To BelgradeMarcela MariaNoch keine Bewertungen

- Kyle Kledzik - Module 4 Paper Ogl 350Dokument6 SeitenKyle Kledzik - Module 4 Paper Ogl 350api-522554262Noch keine Bewertungen

- Blithe Spirit ResumenDokument3 SeitenBlithe Spirit ResumenYael SqueoNoch keine Bewertungen

- Underground: by Ika NatassaDokument5 SeitenUnderground: by Ika NatassaKhalida Zia SiregarNoch keine Bewertungen

- Marketing Galeri Luxton Layout Plans 3D Perspectives Furniture DimensionsDokument16 SeitenMarketing Galeri Luxton Layout Plans 3D Perspectives Furniture DimensionsYustisia KatriniNoch keine Bewertungen

- Cortot Edition Chopin Etudes Alexander Technique Facilitate PerformanceDokument102 SeitenCortot Edition Chopin Etudes Alexander Technique Facilitate PerformanceMiguel Angel Aguirre Igoa50% (2)

- Monsters & Hacienda LuisitaDokument15 SeitenMonsters & Hacienda LuisitaErvic AngelesNoch keine Bewertungen

- "Haiti" by Henry Louis Gates, Jr.Dokument34 Seiten"Haiti" by Henry Louis Gates, Jr.NYU Press100% (2)

- Desire ReviewDokument3 SeitenDesire ReviewSherilyn Closa Bunag0% (1)

- Steedman 11Dokument24 SeitenSteedman 11RolandoNoch keine Bewertungen

- NayeonieejeongyeonsanajihyooooominadahyuuuuuunyyyDokument5 SeitenNayeonieejeongyeonsanajihyooooominadahyuuuuuunyyyNayeon LimNoch keine Bewertungen

- Bangalore Business Samples 250Dokument18 SeitenBangalore Business Samples 250dpkraja100% (3)

- Anomalous Eras - H - Illig Toronto 2005Dokument11 SeitenAnomalous Eras - H - Illig Toronto 2005András Beöthy-MolnárNoch keine Bewertungen

- Cbse 10TH NotesDokument2 SeitenCbse 10TH NotesManoj KumarNoch keine Bewertungen

- Advertising in Selling Real Estate by C.C.C. TatumDokument7 SeitenAdvertising in Selling Real Estate by C.C.C. Tatumreal-estate-historyNoch keine Bewertungen

- Awards List - Gujpex - 2015, Gujarat State Level Philatelic ExhibitionDokument4 SeitenAwards List - Gujpex - 2015, Gujarat State Level Philatelic ExhibitionYash ChudasamaNoch keine Bewertungen

- Credai list in Andhra PradeshDokument106 SeitenCredai list in Andhra PradeshDIKSHA VERMA100% (6)