Beruflich Dokumente

Kultur Dokumente

Mechanics of Deformable Bodies

Hochgeladen von

arjunOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechanics of Deformable Bodies

Hochgeladen von

arjunCopyright:

Verfügbare Formate

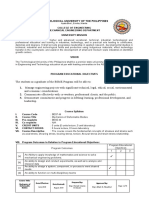

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

SUBJECT CODE: 18CSE13

SUBJECT NAME: MECHANICS OF DEFORMABLE BODIES

PROGRAMME/COURSE: M.Tech (STRUCTURAL ENGINEERING)

DEPARTMENT: CIVIL

NAME OF THE STUDENT: ARJUN RATHOD

REG. NO: 2VX18CSE02

SEMESTER/YEAR: 1ST SEM/ 1ST YEAR

SUBJECT LEADER: Dr. SATISH A ANNIGERI

VISVESVARAYA TECHNOLOGICAL UNIVERSITY

JNANA SANGAMA, SANTIBASTAWADN ROAD,VTU CAMPUS BELAGAVI 590018

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

STRAIN GAGE

Definition:

When a force is applied to body, the body deforms. In the general case, the deformation is called strain.

Introduction:

Strain gauges measurements play an important role in many industrial sectors. Appropriate

measurements systems can define the strain level occurring in different construction from biomechanics

to civil engineering

The most commonly used strain gauge is an electrical resistance strain gauge.

Working Principle [1]:

A Strain gauge (Figure 1) is a sensor used to measure strain. It has a conductive grid, which changes its

electrical resistance when is deformed. Grid deformation is caused by forces coming from loaded object

to which strain gauge is mounted by bonding. Strain gauge produces as output change of resistance

corresponding to a physical change of the investigated object.

Figure 1. Stain gauge construction

The strain gauge principle of operation is based on Equation (1). When the strain gauge is subjected to

tensile or compressive forces, it changes its length and cross-section which affects change of the

resistance.

𝑙

𝑅 = 𝑆 ∗ 𝜌------------------------------------------------------------------------------------------------------ (1)

Where,

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

R – Electrical Resistance (Ω)

𝜌 –Electrical resistivity (Ω. 𝑚)

𝑙 - Length (m)

S – Cross section Area 𝑚2

The change of resistance is proportional to the change of the length, Equation (2).

∆𝑅 ∆𝐿

𝑅

~𝐿 ------------------------------------------------------------------------------------------------------- (2)

𝑂

Where,

∆𝐿 - Difference between initial Length 𝐿𝑂 and final length

𝐿𝑂 – Initial Length

∆𝑅 – Resistance (Ω)

The difference between absolute and relative change in length presents belowFigure .

∆𝑳 = 𝑳 − 𝑳𝑶 Absolute change in length

∆𝑳

𝑳𝑶

Relative change in length

Strain is the ratio of length change to the initial length of sample, Equation (3).

∆𝐿

𝜖=𝐿 ------------------------------------------------------------------------------------------------------ (3)

𝑂

Based on Equation (2) and Equation (3) we obtained Equation (4)

∆𝑅

𝑅

~𝜖 -------------------------------------------------------------------------------------------------------- (4)

Where,

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

𝜖 − strain (μm/m)

The proportional sign in Equation (4) can be replaced by a constant k, which is characteristic for the

individual stain gauge and gives connection between resistance change and strain, Equation (5).

∆𝑅

= 𝑘 ∗ 𝜖 ----------------------------------------------------------------------------------------------- (5)

𝑅

Because ∆𝑳 is very small, the magnitude10−6 for strain ε common unit is𝛍𝐦/𝐦 .When selecting strain

gauge following criteria should be taken in consideration:

Material to which the strain gauge temperature response is matched

Measuring grid resistance

Maximum permissible effective bridge excitation voltage

Number of measuring grid, their dimensions and positions to each other’s.

When the strain gauge has been selected, another important aspect is to use suitable adhesive and

covering material adapted to working conditions, mainly in terms of the operating temperature. Figure 2

presents fully installed strain gauge on the object.

Figure 2. Properly installed strain gauge on object

How They Work [2]:

The strain gauge has been in use for many years and is the fundamentalsensing element for many types of sensors,

including pressure sensors,load cells, torque sensors, position sensors, etc.The majority of strain gauges are

foil types, available in a wide choiceof shapes and sizes to suit a variety of applications. They consist of

apattern of resistive foil which is mounted on a backing material. Theyoperate on the principle that as

the foil is subjected to stress, theresistance of the foil changes in a defined way.

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

The strain gauge is connected into a Wheatstone bridge circuit with a combination of four active gauges

(full bridge), two gauges (half bridge), or, less commonly, a single gauge (quarter bridge). In the half and

quarter circuits, the bridge is completed with precision resistors.

Figure 3. Wheatstone bridge

The complete Wheatstone bridge is excited with a stabilised DC supply and with additional conditioning

electronics, can be zeroed at the null point of measurement. As stress is applied to the bonded strain

gauge, a resistive change takes place and unbalances the Wheatstone bridge.

This results in a signal output, related to the stress value. As the signal value is small, (typically a few

millivolts) the signal conditioning electronics provides amplification to increase the signal level to 5 to 10

volts, a suitable level for application to external data collection systems such as recorders or PC Data

Acquisition and Analysis Systems.

STRAIN ROSETTES:

Definition:

A strain gauge rosette is, by definition, an arrangement of two or more closely positioned gauge

grids, separately oriented to measure the normal strains along different directions in the underlying

surface of the test part.

Introduction[3]:

Rosettes are designed to perform a very practical and important function in experimental stress

analysis. It can be shown that for the not-uncommon case of the general biaxial stress state, with the

principal directions unknown, three independent strain measurements (in different directions) are

required to determine the principal strains and stresses. And even when the principal directions are

known in advance, two independent strain measurements are needed to obtain the principal strains and

stresses

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

In common with single-element strain gauges, rosettes are manufactured from different combinations

of grid alloy and backing material to meet varying application requirements. They are also offered in a

number of gauge lengths, noting that the gauge length specified for a rosette refers to the active length

of each individual grid within the rosette.

To meet the foregoing requirements, the Micro-Measurements Division manufactures three basic types

of strain gauge rosettes (each in a variety of forms):

1. Tee (0-90 degree)

Two mutually perpendicular grids.

Figure 4.Tee Rosette

2. Rectangular (0-45-90 degree)

Three grids, with the second and third grids angularly displaced from the first grid by 45 degrees

and 90 degrees, respectively.

Figure 5.Rectangular Rosette

3. Delta (0-60-120 degree)

Three grids, with the second and third grids 60 degrees and 120 degrees away,

Respectively, from the first grid.

Figure 6.Delta Rosette

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

4. Stacked

Co-location of the gauges requires mounting each individual gauge on top of the others in what

is called a “stacked” rosette, but this leads to a complicated and often inaccurate type of gauge.

Figure 7.Stacked Rosette

STRAIN TRANSFORMATION EQUATION AND THIER USE TO OBTAIN STRAIN COMPONENTS FROM

STRAIN ROSSET READINGS[4]

CASE 1: UNIAXIAL STATE OF STRESS

In this problem shown in Figure 8, only 𝜎𝑥𝑥 is present. In this case, a single element strain gage is placed

with its axis coincident with the x axis. Then

𝜎𝑥𝑥 = 𝐸𝜖𝑥𝑥 ---------------------------------------------------------------------------------------- (1)

Figure 8. Uniaxial state of stress

CASE 2: ISOTROPIC STATE OF STRESS

For this case, as shown in Figure 9, the state of stress at a given point is givenas

𝜎𝑥𝑥 = 𝜎𝑦𝑦 = 𝜎1 = 𝜎2 = 𝜎 𝑎𝑛𝑑 𝛾𝑥𝑦

Figure 9. Isotropic state of stress

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

In this case, to determine the state of stress at a given point a single element strain gage may be placed

in any direction and the magnitude of stresses may be established from:

𝐸∗𝜖

𝜎𝑥𝑥 = 𝜎𝑦𝑦 = 𝜎1 = 𝜎2 = 𝜎 = 1−𝑣 2 ------------------------------------------------------- (2)

CASE 3: PURE TORSION(𝜎𝑥𝑥 = 𝜎𝑦𝑦 = 0 𝑎𝑛𝑑 𝑜𝑛𝑙𝑦 𝜏𝑥𝑦 present)

In this case as shown in Figure 10, a single strain gage is placed with its axis coincident with one of the

principal stress direction (45 degree with the x axis). The maximum shearing stress is calculated from:

𝜏𝑥𝑥 = 𝜏𝑦𝑦 = 𝐺𝛾𝑥𝑦 --------------------------------------------------------------------------------------- (3)

Where

𝜏𝑥𝑦= 2𝜖( ε is the strain measured strain from the gage)

Figure 10. Pure torsion loading and shearing strain

CASE 4: BIAXIAL STATE OF STRESS

a) If less is known about the state of stress, but directions of principal stresses are known, then two-

element rectangular rosette is placed on the specimen with its axes coincident with principal directions.

Two strains ε1 and ε2 are obtained from the gage and the corresponding principal stresses are as

calculated as:

𝐸 𝐸

𝜎1 = 1−𝑣2 (𝜖1 + 𝑣𝜖2 ) and 𝜎2 = 1−𝑣 2 (𝜖2 + 𝑣𝜖1 )-------------------------------------------- (4)

These relations give the complete state of stress since the principal directions are known a priori.

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

Figure 11. Biaxial state of stress and 2-element strain gage

b) If knowledge of the stress field or principal directions is not available, then a three-element rosette is

needed. To show that three measurements are sufficient, consider three strain gages placed along axes

A, B, and C, as shown in Figure 12.

Figure 12. Three-element rosette

Then the following transformation relations are valid for strain readings 𝜖𝐴 , 𝜖𝐵 and 𝜖𝐶 from gages A, B

and C, respectively;

𝜖𝐴 = 𝜖𝑥𝑥 𝑐𝑜𝑠 2 𝛼𝐴 + 𝜖𝑌𝑌 𝑠𝑖𝑛2 𝛼𝐴 + 𝛾𝑥𝑦 𝑐𝑜𝑠𝛼𝐴 𝑠𝑖𝑛𝛼𝐴

𝜖𝐵 = 𝜖𝑥𝑥 𝑐𝑜𝑠 2 𝛼𝐵 + 𝜖𝑌𝑌 𝑠𝑖𝑛2 𝛼𝐵 + 𝛾𝑥𝑦 𝑐𝑜𝑠𝛼𝐵 𝑠𝑖𝑛𝛼𝐵

𝜖𝐶 = 𝜖𝑥𝑥 𝑐𝑜𝑠 2 𝛼𝐶 + 𝜖𝑌𝑌 𝑠𝑖𝑛2 𝛼𝐶 + 𝛾𝑥𝑦 𝑐𝑜𝑠𝛼𝐶 𝑠𝑖𝑛𝛼𝐶 -------------------------------------------------- (5)

The Cartesian components of strain, 𝜖𝑥𝑥 , 𝜖𝑦𝑦 and ,𝛾𝑥𝑦 can be determined from a simultaneous solution

of above equations. The principal strains and the principal directions may then be established by

employing;

𝜖1 = 0.5(𝜖𝑥𝑥 + 𝜖𝑦𝑦 ) + 0.5√(𝜖𝑥𝑥 − 𝜖𝑦𝑦 )2 + 𝛾 2 𝑥𝑦 ------------------------------------------------------ (6a)

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

𝜖2 = 0.5(𝜖𝑥𝑥 + 𝜖𝑦𝑦 ) − 0.5√(𝜖𝑥𝑥 − 𝜖𝑦𝑦 )2 + 𝛾 2 𝑥𝑦 ---------------------------------------------------------------- (6b)

𝛾𝑥𝑦

tan 2𝜃 = 𝜖 ---------------------------------------------------------------------------------------- (7)

𝑥𝑥 −𝜖𝑦𝑦

The solution of Eq. 7 yields two values for the angle θ. These are 𝜃1 , which refers to the angle between

the x-axis and the axis of the maximum principal strain 𝜖1 , and 𝜃2 , which is the angle between the x-

axis and the axis of the minimum principal strain 𝜖2 .

The principal stresses can then be calculated from the principal strains by utilizing Eqs. 4 as;

𝐸 𝐸

𝜎1 = 1−𝑣2 (𝜖1 + 𝑣𝜖2 ) and 𝜎2 = 1−𝑣 2 (𝜖2 + 𝑣𝜖1 ) -------------------------------------------------- (7a)

In practice, three-element rosettes with fixed angles (that is, ∝𝐴 , ∝𝐵 , and ∝𝐶 are fixed at specified

values) are employed to provide sufficient data to completely define the strain and stress fields. These

rosettes are defined by the fixed angles as the rectangular rosette, and the delta rosette.

THREE-ELEMENT RECTANGULAR ROSETTE

The three-element rectangular rosette employs gages placed at 0°, 45°, and 90° positions, as indicated

in Figure 13.

Figure 13. Three-element rectangular rosette

For this particular rosette:

∝𝐴 = 0° cos ∝𝐴 = 1 𝑠𝑖𝑛 ∝𝐴 = 0

∝𝐵 = 0° cos ∝𝐵 = 0.707 𝑠𝑖𝑛 ∝𝐶 = 0.707

∝𝐶 = 90° cos ∝𝐶 = 0 𝑠𝑖𝑛 ∝𝐶 = 1

It is clear from Eq. 5 that

𝜖𝐴 = 𝜖𝑥𝑥

𝜖𝐵 = 0.5(𝜖𝑥𝑥𝐵 + 𝜖𝑦𝑦 + 𝛾𝑥𝑦 )

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

𝜖𝑐 = 𝜖𝑦𝑦 ------------------------------------------------------------------------------------------------- (8)

From above equations:

𝜖𝑥𝑥 = 𝜖𝐴

𝜖𝑦𝑦 = 𝜖𝑐

𝜖𝐵 = (2𝜖𝐵 + 𝜖𝐴 + 𝜖𝑐 )----------------------------------------------------------------------------------- (9)

Thus, by measuring the strains, 𝜖𝐴 , 𝜖𝐵 and 𝜖𝑐 , the Cartesian components of strains 𝜖𝑥𝑥 , 𝜖𝑦𝑦 and 𝛾𝑥𝑦 can

be determined by using Eq. 9. Next, by utilizing Eqs. 6 and 7, the principal strain 𝜖1 and 𝜖2 and the

principal angle θ can be

calculated. Finally, the principal stresses occurring in the component can be solved by employing Eq. 4.

DELTA ROSETTE:

Figure 14. Delta rosette for 2-D loading

For this particular rosette:

∝𝐴 = 0° cos ∝𝐴 = 1 𝑠𝑖𝑛 ∝𝐴 = 0

√3

∝𝐵 = 120° cos ∝𝐵 = −0.5 𝑠𝑖𝑛 ∝𝐶 =

2

√3

∝𝐶 = 240° cos ∝𝐶 = −0.5 𝑠𝑖𝑛 ∝𝐶 = −

2

It is clear from Eq. 5 that

𝜖𝐴 = 𝜖𝑥𝑥

𝜖𝐵 = (0.25𝜖𝑥𝑥 + 0.75𝜖𝑦𝑦 − 1.224𝛾𝑥𝑦 )

𝜖𝑐 = (0.25𝜖𝑥𝑥 + 0.75𝜖𝑦𝑦 + 1.224𝛾𝑥𝑦 )----------------------------------------------------------------- (10)

Solving Eq. 10 for𝜖𝑥𝑥 , 𝜖𝑦𝑦 𝑎𝑛𝑑 𝛾𝑥𝑦 interms of 𝜖𝐴 , 𝜖𝐵 , 𝜖𝐶 𝑦𝑖𝑒𝑙𝑑𝑠

𝜖𝐴 = 𝜖𝑥𝑥

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

𝜖𝐵 = 0.3(2(𝜖𝐵 + 𝜖𝐶 ) − 1.224𝛾𝑥𝑦 ))

𝛾𝑥𝑦 = 0.577(𝜖𝐶 − 𝜖𝐵 )-------------------------------------------------------------------------------- (11)

Next,by utilizing Eqs. 6 and 7, the principal strains 𝜖1 and 𝜖2 and the principal angle θ can be found.

Finally, the principal stresses occurring in the component can be calculated by employing Eq. 4

NUMERICAL PROBLEM:

A strain Gage rosette was applied at a point on the free surface of a structural member and resultantly

developed the state of strain on an element with components 𝜖𝑥 = 900𝜇 , 𝜖𝑦 = 400𝜇 , 𝛾𝑥𝑦 = 500𝜇.

If the material for the structural member has a modulus of elasticity of E=200Gpa and poisson’s ratio =

0.3.

Solution:

𝜖𝑥 = 900𝜇 = 0.0009

𝜖𝑦 = 400𝜇 = 0.0004

𝛾𝑥𝑦 = 500𝜇 = 0.005

Modulus of elasticity of (E)=200Gpa

Poisson’s ratio (v) = 0.3.

Calculate the principal strains 𝝐𝟏 , 𝝐𝟐 , 𝝐𝟑

Take equation From6a and 6b

𝜖1 = 0.5(𝜖𝑥𝑥 + 𝜖𝑦𝑦 ) + 0.5√(𝜖𝑥𝑥 − 𝜖𝑦𝑦 )2 + 𝛾 2 𝑥𝑦

𝜖2 = 0.5(𝜖𝑥𝑥 + 𝜖𝑦𝑦 ) − 0.5√(𝜖𝑥𝑥 − 𝜖𝑦𝑦 )2 + 𝛾 2 𝑥𝑦

𝜖3 = √𝜖1 2 + 𝜖2 2

Substitute the values in above equation then we get,

𝜖1 = 0.5(0.0009 + 0.0004) + 0.5√(0.0009 − 0.0004)2 + 0.00052

𝝐𝟏 = 𝟎. 𝟎𝟎𝟏𝟎𝟎𝟒

𝜖2 = 0.5(0.0009 + 0.0004) = 0.5√(0.0009 − 0.0004)2 + 0.00052

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

𝝐𝟐 = 𝟎. 𝟎𝟎𝟎𝟑

𝜖3 = √𝜖1 2 + 𝜖2 2

𝝐𝟑 = √𝟎. 𝟎𝟎𝟏𝟎𝟎𝟒𝟐 + 𝟎. 𝟎𝟎𝟎𝟑𝟐

Calculate the maximum inplane shear strain.

𝛾𝑖𝑛𝑝𝑙𝑎𝑛𝑒 = 𝑙𝑎𝑟𝑔𝑒𝑟 𝑜𝑓 (𝜖3 − 𝜖2 )1 𝑎𝑛𝑑 (𝜖1 − 𝜖2 )1

𝛾𝑖𝑛𝑝𝑙𝑎𝑛𝑒 = (𝝐𝟑 − 𝝐𝟐 )𝟏

Substitute the values in equation

𝛾𝑖𝑛𝑝𝑙𝑎𝑛𝑒 = (0.00105 − 0.003)1

𝜸𝒊𝒏𝒑𝒍𝒂𝒏𝒆 = 𝟎. 𝟎𝟎𝟎𝟕𝟓

Calculate the principal stresses.

From equation (7a)

𝐸

𝜎1 = (𝜖 + 𝑣(𝜖2 + 𝜖3 )

1 − 𝑣2 1

𝐸

𝜎2 = (𝜖 + 𝑣(𝜖1 + 𝜖3 )

1 − 𝑣2 2

𝐸

𝜎3 = (𝜖 + 𝑣(𝜖2 + 𝜖1 )

1 − 𝑣2 3

Substitute the values in above Equation

200 ∗ 109

𝜎1 = (0.001004 + 0.3(0.0003 + 0.00105)

1 − 0.32

𝝈𝟏 = 𝟑𝟐𝟎. 𝟓𝟏𝑴𝑷𝒂

200 ∗ 109

𝜎2 = (0.0003 + 0.3(0.001004 + 0.00105)

1 − 0.32

𝝈𝟐 = 𝟐𝟎𝟖. 𝟒𝟏𝑴𝑷𝒂

200 ∗ 109

𝜎3 = (0.00105 + 0.3(0.001004 + 0.0003)

1 − 0.32

𝝈𝟑 = 𝟑𝟐𝟕. 𝟖𝟑𝑴𝑷𝒂

Calculate the maximum inplane shear stress:

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

VISVESVARAYA TECHNOLOGICAL UNIVERSITY, BELAGAVI

(𝜖3 − 𝜖1 )1 (𝜖3 − 𝜖2 )1 (𝜖1 − 𝜖2 )1

𝛾𝑖𝑛𝑝𝑙𝑎𝑛𝑒 = 𝑙𝑎𝑟𝑔𝑒𝑟 𝑜𝑓 𝑎𝑛𝑑 𝑎𝑛𝑑

2 2 2

(𝝐𝟑 − 𝝐𝟏 )𝟏

𝜸𝒊𝒏𝒑𝒍𝒂𝒏𝒆 =

𝟐

And substitute the values in above equation

(327.83 − 208.41)1

𝛾𝑖𝑛𝑝𝑙𝑎𝑛𝑒 =

2

𝜸𝒊𝒏𝒑𝒍𝒂𝒏𝒆 = 𝟓𝟗. 𝟕𝑴𝑷𝒂

Calculate the maximum shear stress

(𝝐𝟑 − 𝝐𝟏 )𝟏

𝜏𝑎𝑏𝑠𝑜𝑙𝑢𝑡𝑒 =

𝟐

𝝉𝒂𝒃𝒔𝒐𝒍𝒖𝒕𝒆 = 𝟓𝟗. 𝟕𝑴𝑷𝒂

References / Bibliography:

[1]APPLICATION OF STRAIN GAUGES IN MEASUREMENTS OF STRAIN DISTRIBUTION IN COMPLEX

OBJECTS. Piotr Tutak IT Institute, University of Social Sciences, Łódź, Poland piotrtutak@wp.pl

[2]www.sensorland.com/Howpage002.html. how sensors work - strain gauge

[3]STRESS ANALYSIS BY USING STRAIN GAGESuploaded by basit_ehsan. Strain Rosettes

[4]Applied Elasticity for Engineers.T.G.Sitharam&L.GovindaRaju

[5]Mechanics of Materials by B.C. Punmia

[6]Strength of Materials by R.K. Bansal

[7]Vishay micro-measurements. www.vishaymg.com

[8]EMBEDDED OPTICAL FIBRE STRAIN GAGES FOR CIVIL ENGINEERING: APPLICATION TO CONCRETE

MONITORING

STRAIN GAGES AND STRAIN ROSETTES ARJUN RATHOD

2VX18CSE02

Das könnte Ihnen auch gefallen

- Module 1 Mechanics of Deformable BodiesDokument3 SeitenModule 1 Mechanics of Deformable BodiesWency LagumbayNoch keine Bewertungen

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDokument5 SeitenTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNoch keine Bewertungen

- Structural TheoryDokument2 SeitenStructural TheoryMelvin EsguerraNoch keine Bewertungen

- Syllabus Dynamics of Rigid Bodies PDFDokument19 SeitenSyllabus Dynamics of Rigid Bodies PDFJackNoch keine Bewertungen

- Mechanics of Deformable BodiesDokument2 SeitenMechanics of Deformable BodiesJeff LaycoNoch keine Bewertungen

- Principles of Reinforced ConcreteDokument18 SeitenPrinciples of Reinforced Concreteiking_balonNoch keine Bewertungen

- Integral Calculus: Engr. Anacleto M. Cortez JRDokument10 SeitenIntegral Calculus: Engr. Anacleto M. Cortez JRPanfilo Diaz LacsonNoch keine Bewertungen

- 1 Functions, Limits and ContinuityDokument6 Seiten1 Functions, Limits and ContinuityReign dropping100% (1)

- Module 1 Measurement VectorDokument25 SeitenModule 1 Measurement VectorGreen BrainNoch keine Bewertungen

- HIGHWAY AND RAILROAD ENG'G (Lesson 1-4)Dokument15 SeitenHIGHWAY AND RAILROAD ENG'G (Lesson 1-4)Xienlyn BaybayNoch keine Bewertungen

- Mechanics of Rigid BodiesDokument15 SeitenMechanics of Rigid BodiessoulcivicNoch keine Bewertungen

- Engineering DrawingDokument116 SeitenEngineering DrawingIonel RaveicaNoch keine Bewertungen

- Microsoft Word Mecvina PDFDokument37 SeitenMicrosoft Word Mecvina PDFErvin GohNoch keine Bewertungen

- Mechanics of Deformable Bodies Quiz 2Dokument4 SeitenMechanics of Deformable Bodies Quiz 2FerrolinoLouieNoch keine Bewertungen

- Physics For Engineers IM3Dokument17 SeitenPhysics For Engineers IM3Rexie Magastino100% (1)

- Engineering Data Analysis M9 FinalsDokument39 SeitenEngineering Data Analysis M9 FinalsJohn Arvin EscoteNoch keine Bewertungen

- 00.syllabus in Construction Materials and TestingDokument10 Seiten00.syllabus in Construction Materials and TestingCarjez LoveNoch keine Bewertungen

- Ohms Law VD CD KVL and KCLDokument50 SeitenOhms Law VD CD KVL and KCLParinay SethNoch keine Bewertungen

- Engineering Data AnalysisDokument16 SeitenEngineering Data AnalysisNeil NiervaNoch keine Bewertungen

- STATICS OF RIGID BODIES Chapter IDokument23 SeitenSTATICS OF RIGID BODIES Chapter IViron LucerianoNoch keine Bewertungen

- Statics of Rigid Bodies - Fundamental ConceptsDokument4 SeitenStatics of Rigid Bodies - Fundamental ConceptsJan Alexis MonsaludNoch keine Bewertungen

- 85-218 - Overview Mechanics of Deformable BodiesDokument8 Seiten85-218 - Overview Mechanics of Deformable BodiesOnailatiNoch keine Bewertungen

- Computer Aided DraftingDokument21 SeitenComputer Aided DraftingWan Norehan Abd AzizNoch keine Bewertungen

- Principles of Steel Design SetaDokument5 SeitenPrinciples of Steel Design Setajek vinNoch keine Bewertungen

- CE 111 Class IntroductionDokument41 SeitenCE 111 Class IntroductionWild RiftNoch keine Bewertungen

- Course Syllabus in EARTHQUAKE ENGINEERINGDokument9 SeitenCourse Syllabus in EARTHQUAKE ENGINEERINGRamil S. ArtatesNoch keine Bewertungen

- Section 1.5 General Second Degree Equations PDFDokument3 SeitenSection 1.5 General Second Degree Equations PDFRaymart Leyson100% (1)

- Differential EquationsDokument1 SeiteDifferential EquationsConan EdogawaNoch keine Bewertungen

- Double Integration MethodDokument10 SeitenDouble Integration Methodmau_boi16100% (1)

- Summative 1 ReviewerDokument11 SeitenSummative 1 ReviewerJuli BakerNoch keine Bewertungen

- QUIZ 1 - Engineering Utilities 1Dokument1 SeiteQUIZ 1 - Engineering Utilities 1Gemaris Laurenaria MercadoNoch keine Bewertungen

- WEEK 2 (Feb 8 - 13) :: REAL-TIME LIVE SESSION - Video Recording Must Be Uploaded/posted To Google ClassroomDokument12 SeitenWEEK 2 (Feb 8 - 13) :: REAL-TIME LIVE SESSION - Video Recording Must Be Uploaded/posted To Google ClassroomJoshua John JulioNoch keine Bewertungen

- Learning Module: College of Engineering and Information TechnologyDokument11 SeitenLearning Module: College of Engineering and Information TechnologyMatet MaglipacNoch keine Bewertungen

- Statics of Rigid Bodies: BS Mechanical Engineering - 2ADokument28 SeitenStatics of Rigid Bodies: BS Mechanical Engineering - 2AJeam Russell AlfaroNoch keine Bewertungen

- Engineering Geology 1st UnitDokument9 SeitenEngineering Geology 1st UnitSaikrupaVempatiNoch keine Bewertungen

- Engineering Drawing 1 and Plans: ENSC 20112Dokument55 SeitenEngineering Drawing 1 and Plans: ENSC 20112Christel GonzalesNoch keine Bewertungen

- Rectilinear Motion: Engr. John Dharyl R. de Leon, ReeDokument22 SeitenRectilinear Motion: Engr. John Dharyl R. de Leon, ReeJamie MedallaNoch keine Bewertungen

- MATH 160A - Calculus 2 Lecture 3: Integration of Trigonometric FunctionDokument2 SeitenMATH 160A - Calculus 2 Lecture 3: Integration of Trigonometric FunctionVape DrugNoch keine Bewertungen

- Engineering Data AnalysisDokument64 SeitenEngineering Data AnalysisVincent IluisNoch keine Bewertungen

- Dimensioning Objectives: A. Technique of DimensioningDokument22 SeitenDimensioning Objectives: A. Technique of DimensioningAldrin VillanuevaNoch keine Bewertungen

- Problem Set 1 CE Part 2Dokument3 SeitenProblem Set 1 CE Part 2Deus PhilipNoch keine Bewertungen

- Chapter 1 - Vector AnalysisDokument54 SeitenChapter 1 - Vector AnalysisandersonNoch keine Bewertungen

- Module 1-Thermal-ExpansionDokument14 SeitenModule 1-Thermal-ExpansionHazel A. BelloNoch keine Bewertungen

- MECHANICS OF DEFORMABLE BODIES Summary oDokument60 SeitenMECHANICS OF DEFORMABLE BODIES Summary ostraw hatNoch keine Bewertungen

- 1 Simple StressDokument5 Seiten1 Simple StressKeane CortesNoch keine Bewertungen

- Module 1 - Fundamental Concepts in Mechanics PDFDokument9 SeitenModule 1 - Fundamental Concepts in Mechanics PDFRome Erwin Manalo FestinNoch keine Bewertungen

- Engineering Mechanics DistributedForcesDokument47 SeitenEngineering Mechanics DistributedForcesChamith KarunadharaNoch keine Bewertungen

- Module #1 - Simple Stress: Engr. Lito I. MauroDokument38 SeitenModule #1 - Simple Stress: Engr. Lito I. MauroJeffrey ManansalaNoch keine Bewertungen

- Elementary Theory of StructuresDokument112 SeitenElementary Theory of StructuresGodwin AcquahNoch keine Bewertungen

- Chapter 1 Tension, Compression, and ShearDokument27 SeitenChapter 1 Tension, Compression, and ShearManolo L LandigNoch keine Bewertungen

- Dynamics of Rigid Bodies: (Problem Set)Dokument2 SeitenDynamics of Rigid Bodies: (Problem Set)lucasNoch keine Bewertungen

- Enggphys Modules - Student Copy - ST 2022Dokument177 SeitenEnggphys Modules - Student Copy - ST 2022Kyla Jynell SaquitonNoch keine Bewertungen

- EMath 214 - Engineering Data AnalysisDokument17 SeitenEMath 214 - Engineering Data AnalysisAiza AlbuferaNoch keine Bewertungen

- Statics of Rigid Bodies - Engineering MechanicsDokument9 SeitenStatics of Rigid Bodies - Engineering MechanicsJasNoch keine Bewertungen

- Vector AnalysisDokument10 SeitenVector AnalysisFlordeliza Santos MagalonaNoch keine Bewertungen

- Introduction To Simple StressDokument13 SeitenIntroduction To Simple StressRie LiNoch keine Bewertungen

- Technical Lettering in Draw10WDokument3 SeitenTechnical Lettering in Draw10WEarl FozNoch keine Bewertungen

- Module 1.0-SIMPLE STRESS - Axial-NormalDokument20 SeitenModule 1.0-SIMPLE STRESS - Axial-NormalJoseph Berlin JuanzonNoch keine Bewertungen

- Strain Measurement and Analysis On The Load in Universal Testing MachineDokument7 SeitenStrain Measurement and Analysis On The Load in Universal Testing MachineInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Course Code: CEC315A Course Title: Transportation Design and Drawing Course Leader: Chethan Gowda R KDokument50 SeitenCourse Code: CEC315A Course Title: Transportation Design and Drawing Course Leader: Chethan Gowda R KarjunNoch keine Bewertungen

- I J Times V 05 I 06150614191713Dokument4 SeitenI J Times V 05 I 06150614191713arjunNoch keine Bewertungen

- Design of Masonry StructuresDokument1 SeiteDesign of Masonry StructuresarjunNoch keine Bewertungen

- M.Tech. (Civil-Structural Engineering)Dokument31 SeitenM.Tech. (Civil-Structural Engineering)arjunNoch keine Bewertungen

- Analysis and Design of Multi Storyed Building by Using Staad ProDokument6 SeitenAnalysis and Design of Multi Storyed Building by Using Staad ProarjunNoch keine Bewertungen

- Comparative Performance of Masonry Bond Patterns: October 2008Dokument9 SeitenComparative Performance of Masonry Bond Patterns: October 2008arjunNoch keine Bewertungen

- WWW - Manaresults.Co - In: Sub-Structure DesignDokument2 SeitenWWW - Manaresults.Co - In: Sub-Structure DesignarjunNoch keine Bewertungen

- Summer Training ReportDokument56 SeitenSummer Training ReportarjunNoch keine Bewertungen

- A Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructureDokument12 SeitenA Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructurearjunNoch keine Bewertungen

- A21VGDokument32 SeitenA21VGcunvip163.comNoch keine Bewertungen

- Power Law Revs CDokument4 SeitenPower Law Revs Cdavid perezNoch keine Bewertungen

- Ebook Vector Mechanics For Engineers Dynamics PDF Full Chapter PDFDokument67 SeitenEbook Vector Mechanics For Engineers Dynamics PDF Full Chapter PDFelsie.mcintyre883100% (29)

- F19 MOM II Principal Stresses Solved Prob SolutionDokument29 SeitenF19 MOM II Principal Stresses Solved Prob Solutionsulaiman mehmoodNoch keine Bewertungen

- Edexcel GCE Mathematics Mechanics 1 M1 (6677) : Mark Scheme (Final)Dokument8 SeitenEdexcel GCE Mathematics Mechanics 1 M1 (6677) : Mark Scheme (Final)Kimmy LiewNoch keine Bewertungen

- @StudyTime - Channel 12 - Sound (Ex) PDFDokument10 Seiten@StudyTime - Channel 12 - Sound (Ex) PDFSipra PaulNoch keine Bewertungen

- Name: Reinvince Zadkiel D. Villaruel Score: Grade and Section: 9-Pascal Parent's SignatureDokument5 SeitenName: Reinvince Zadkiel D. Villaruel Score: Grade and Section: 9-Pascal Parent's SignatureJK De GuzmanNoch keine Bewertungen

- Inorganic WorksheetDokument15 SeitenInorganic WorksheetJhon LabuNoch keine Bewertungen

- A New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoDokument7 SeitenA New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoRico PadillaNoch keine Bewertungen

- Gujarat Technological UniversityDokument4 SeitenGujarat Technological UniversitySandeep SinghNoch keine Bewertungen

- Mechanical VibrationsDokument435 SeitenMechanical VibrationsUtkarsh Mishra100% (2)

- Elongational Flow in Multiple Screw ExtrudersDokument5 SeitenElongational Flow in Multiple Screw ExtrudersAmr KamelNoch keine Bewertungen

- Acceleration Due To Gravity Ishan Sharma 2148139Dokument12 SeitenAcceleration Due To Gravity Ishan Sharma 2148139Ishan SapkotaNoch keine Bewertungen

- Lesson 2. Statically Determinate Structures - Part 1 Beam ReactionsDokument23 SeitenLesson 2. Statically Determinate Structures - Part 1 Beam ReactionsCharizza Montarin CENoch keine Bewertungen

- Moments Notes Week 6Dokument4 SeitenMoments Notes Week 6drishtiNoch keine Bewertungen

- Aieee 2005Dokument41 SeitenAieee 2005Vicky JeetNoch keine Bewertungen

- Daily Practice Problems 2 PDFDokument2 SeitenDaily Practice Problems 2 PDFFUN 360Noch keine Bewertungen

- CE371 - HW6 Solutions PDFDokument9 SeitenCE371 - HW6 Solutions PDFamalnambiar9812174Noch keine Bewertungen

- Analysis of Heat and Mass Transfer On Cooling Tower FillDokument8 SeitenAnalysis of Heat and Mass Transfer On Cooling Tower FillabdulazizrohmanhakimNoch keine Bewertungen

- OpenfoamDokument31 SeitenOpenfoamStalyn SimbañaNoch keine Bewertungen

- Dynamics of The Centrifugal Governor - Lagrange Method With Vex Simulation Example - Vamfun's BlogDokument2 SeitenDynamics of The Centrifugal Governor - Lagrange Method With Vex Simulation Example - Vamfun's BlogAyorinde T TundeNoch keine Bewertungen

- Agenda: - Coriolis Flow Meter Theory of Operation - Bunkering - Marine Fuel Management - Viscosity - QuestionsDokument17 SeitenAgenda: - Coriolis Flow Meter Theory of Operation - Bunkering - Marine Fuel Management - Viscosity - QuestionsMahaManthraNoch keine Bewertungen

- SCIENCE 10 2nd QUARTER MODULE 1Dokument27 SeitenSCIENCE 10 2nd QUARTER MODULE 1Jinky Aydalla100% (2)

- Classical MechanicsDokument364 SeitenClassical MechanicsalmarpaNoch keine Bewertungen

- Soil Bearing Capacity and Modulus of Subgrade ReactionDokument16 SeitenSoil Bearing Capacity and Modulus of Subgrade Reactioninsane88Noch keine Bewertungen

- Recently Developed Quantum Kinetic Models and Their Applications To Some Linear Electrostatic and Electromagnetic Plasma ModesDokument92 SeitenRecently Developed Quantum Kinetic Models and Their Applications To Some Linear Electrostatic and Electromagnetic Plasma ModesPhysics LabNoch keine Bewertungen

- Space Force SystemDokument6 SeitenSpace Force SystemskyhellNoch keine Bewertungen

- Tugas Fisika RekayasaDokument100 SeitenTugas Fisika Rekayasa1931 Angeli Samantha100% (2)

- SOUNDDokument4 SeitenSOUNDG̷U̷N̷M̷A̷N̷ ꓕIHNoch keine Bewertungen

- Young's Modulus, Tangent Modulus, and Chord Modulus1Dokument7 SeitenYoung's Modulus, Tangent Modulus, and Chord Modulus1Josue Poot100% (1)