Beruflich Dokumente

Kultur Dokumente

75

Hochgeladen von

sebaversaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

75

Hochgeladen von

sebaversaCopyright:

Verfügbare Formate

Model CBR 125-800 HP Boilers

ILLUSTRATIONS

Figure A10-1. Model CBR Steam Boiler Dimensions and Weights - Sheet 1 of 2 ............................................. A10-5

Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2 ............................................................ A10-7

Figure A10-3. Space Required to Open Rear Head on Model CBR Boilers Equipped with Davits ................. A10-10

Figure A10-4. Model CBR Boiler Mounting Piers ............................................................................................. A10-11

Figure A10-5. Lifting Lug Locations, Model CBR Boilers ................................................................................. A10-12

Figure A10-6. Predicted Stack Temperature Increase for Pressure Greater Than 125 psig ........................... A10-14

Figure A10-7. Typical Fuel Storage Tank Arrangement ................................................................................... A10-19

Figure A10-8. Typical Cross Section of Bundled Lines .................................................................................... A10-19

Figure A10-9. Schematic of Standard Alstrom Hot Water Safety-Type Preheating System............................ A10-20

Figure A10-10. Typical Gas Piping Layout ....................................................................................................... A10-22

Figure A10-11. No. 2 Oil Piping, Single Boiler Installation, Remote Oil Pumps ............................................... A10-23

Figure A10-12. No. 2 Oil Piping, Multiple Boiler Installation, Remote Oil Pumps ............................................ A10-23

Figure A10-13. No. 2 Oil Piping, Multiple Boiler Installation ............................................................................. A10-24

Figure A10-14. No. 2 Oil Transfer Tank Detail ................................................................................................. A10-25

Figure A10-15. Boiler Room Length (Typical Layout) ...................................................................................... A10-27

Figure A10-16. Boiler Room Width (Typical Layout) ........................................................................................ A10-27

Figure A10-17. Breeching Arrangement ........................................................................................................... A10-28

TABLES

Table A10-1. Model CBR Steam Boiler Ratings................................................................................................. A10-4

Table A10-2. Model CBR Hot Water Boiler Ratings ........................................................................................... A10-4

Table A10-3. Steam Boiler Safety Valve Openings............................................................................................ A10-9

Table A10-4. Hot Water Boiler Relief Valve Openings ....................................................................................... A10-9

Table A10-5. Predicted Fuel-to-Steam Efficiencies (%), Model CBR Boilers, Natural Gas ............................. A10-13

Table A10-6. Predicted Fuel-to-Steam Efficiencies (%), Model CBR Boilers - No. 6 Oil ................................. A10-14

Table A10-7. Predicted Fuel-to-Steam Efficiencies (%), Model CBR Boilers - No. 2 Oil ................................. A10-14

Table A10-8. Model CBR Boiler Emission Data ............................................................................................... A10-15

Table A10-9. Steam Volume and Disengaging Area........................................................................................ A10-16

Table A10-10. Recommended Steam Nozzle Size (To Maintain 4000 to 5000 fpm Nozzle Velocity) ............. A10-16

Table A10-11. Recommended Non-Return Valve Size .................................................................................... A10-17

Table A10-12. Model CBR Blowdown Tank Sizing Information ....................................................................... A10-17

Table A10-13. Predicted Sound Levels (30 ppm NOx Systems) at High Fire.................................................. A10-17

Table A10-14. CBR Gas Pressure Requirements ............................................................................................ A10-21

Table A10-15. Minimum Required Gas Pressure Altitude Conversion ............................................................ A10-21

Section A10-2 Rev. 05-09

Model CBR 125-800 HP Boilers

FEATURES AND BENEFITS

• 125-800hp.

• Steam and hot water.

• Same available pressures as equivalent Model CB/CBLE/CBW/4WI.

• Capable of firing natural gas, #2-#6 oil, bio-gas, digester gas or town gas.

• Low NOx capabilities—natural gas only.

• Containerization from 125-800 hp will reduce delivered to job site price for large

boilers that would otherwise be shipped on flatracks.

• Enhanced heat transfer technology enables Cleaver-Brooks to reduce the number of

tubes, thus reducing the overall weight and shell diameters while maintaining high

fuel-to steam efficiency.

• Integral burner design.

• Allows interchangeability of burner spare parts for Models CB/CBLE/CBR.

• Enables us to offer 50/60Hz with no price surcharge.

• Corrugated furnace will be standard equipment.

• .095" tubes will be standard. (.105" tubes can be supplied at an additional cost.)

• Level master will be standard equipment.

• The CBR can be ordered with Hawk ICS as well as all other boiler extras which are

available for Model CB/CBLE/4WI boilers.

• Same factory warranty as is applied to all other Cleaver-Brooks products.

• The CBR will be manufactured in the U.S. at our facility in Thomasville, Georgia.

• Locally available spare parts and after sales services through exclusive Cleaver-

Brooks representatives around the world.

DIMENSIONS AND RATINGS

• Dimensions and ratings for the Model CBR boilers are shown in the following tables

and illustrations:

• Table A10-1. Model CBR Steam Boiler Ratings

• Table A10-2. Model CBR Hot Water Boiler Ratings

• Table A10-3. Safety Valve Openings

• Table A10-4. Relief Valve Openings

• Figure A10-1. Model CBR Steam Boiler Dimensions

• Figure A10-2 Model CBR Hot Water Boiler Dimensions

• Figure A10-3. Space Required to Open Rear Head on Model CBR Boilers Equipped

with Davits

• Figure A10-4. Model CBR Boiler Mounting Piers

• Figure A10-5. Lifting Lug Locations, Model CBR Boilers

Section A10-3 Rev. 05-09

Model CBR 125-800 HP Boilers

Table A10-1. Model CBR Steam Boiler Ratings

BOILER H.P. 125 150 200 250 300 350 400 500 600 700 800

RATINGS - SEA LEVEL TO 700 FT.

Rated Capacity (lbs-steam/hr

4313 5175 6900 8625 10350 12075 13800 17250 20700 24150 27600

from and at 212 °F)

Btu Output (1000 Btu/hr) 4184 5021 6694 8368 10042 11715 13389 16736 20083 23430 26778

APPROXIMATE FUEL CONSUMPTION AT RATED CAPACITY BASED ON NOMINAL 80% EFFICIENCY

Light Oil gph (140,000 Btu/gal) 37.4 44.8 59.8 74.7 89.7 104.6 119.5 149.4 179.3 209.2 239.1

Heavy Oil gph (150,000 Btu/gal) 34.9 41.8 55.8 69.7 83.7 97.6 111.6 139.5 167.4 195.3 223.1

Gas CFH (1000 Btu) 5230 6276 8368 10460 12552 14644 16736 20920 25104 29288 33472

Gas (Therm/hr) 52.3 62.8 83.7 104.6 125.5 146.4 167.4 209.2 251.0 292.9 334.7

POWER REQUIREMENTS - SEA LEVEL TO 700 FT. (60 HZ)

Blower Motor hp (60 ppm)A 7 1/2 10 15 7 1/2 15 20 10 15 30 40 50

Blower Motor hp (30 ppm)A 10 15 20 15 20 30 15 25 40 60 75

Oil Pump Motor, hp, No. 2 Oil 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4 1 1

Oil Pump Motor, hp, No. 6 Oil 1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4 3/4

Air Compressor Motor hp 3 3 3 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2

Heavy Oil Heater kW B 5 5 5 7 1/2 7 1/2 7 1/2 7 1/2 7 1/2C 7 1/2C 7 1/2C 7 1/2C

BOILER DATA

Heating Surface sq-ft. (Fireside) 459 459 641 764 966 1238 1226 1374 1794 2535 2535

Notes:

A. Blower motor size for boiler operating pressures 125 psig and less, contact your local Cleaver-Brooks authorized

representative for higher pressures and altitude.

B. Oil heater sized as a combination steam-electric heater. For straight electric heaters, contact your local Cleaver-Brooks

authorized representative.

C. 10 KW Oil heater for low pressure.

Table A10-2. Model CBR Hot Water Boiler Ratings

BOILER H.P. 125 150 200 250 300 350 400 500 600 700 800

RATINGS - SEA LEVEL TO 700 FT.

Btu Output (1000 Btu/hr) 4184 5021 6694 8368 10042 11715 13389 16736 20083 23430 26778

APPROXIMATE FUEL CONSUMPTION AT RATED CAPACITY BASED ON NOMINAL 80% EFFICIENCY

Light Oil gph (140,000 Btu/gal) 37.4 44.8 59.8 74.7 89.7 104.6 119.5 149.4 179.3 209.2 239.1

Heavy Oil gph (150,000 Btu/gal) 34.9 41.8 55.8 69.7 83.7 97.6 111.6 139.5 167.4 195.3 223.1

Gas CFH (1000 Btu) 5230 6276 8368 10460 12552 14644 16736 20920 25104 29288 33472

Gas (Therm/hr) 52.3 62.8 83.7 104.6 125.5 146.4 167.4 209.2 251.0 292.9 334.7

POWER REQUIREMENTS - SEA LEVEL TO 700 FT. (60 HZ)

Blower Motor hp (60 ppm) 7 1/2 10 15 7 1/2 15 20 10 15 30 40 50

Blower Motor hp (30 ppm) 10 15 20 15 20 30 15 25 40 60 75

Oil Pump Motor, hp, No. 2 Oil 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4 1 1

Oil Pump Motor, hp, No. 6 Oil 1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4 3/4

Air Compressor Motor hp 3 3 3 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2

Heavy Oil Heater kW A 5 5 5 7 1/2 7 1/2 7 1/2 10 10 10 10 10

BOILER DATA

Heating Surface sq-ft. (Fireside) 459 459 644 764 966 1238 1226 1374 1794 2535 2535

Notes:

A. Oil heater sized as a straight electric heater.

Section A10-4 Rev. 05-09

Model CBR 125-800 HP Boilers

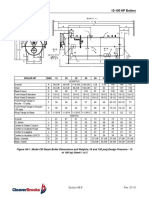

Figure A10-1. Model CBR Steam Boiler Dimensions and Weights - Sheet 1 of 2

Section A10-5 Rev. 05-09

Model CBR 125-800 HP Boilers

BOILER H.P. DIM 125 150 200 250 300 350 400 500 600 700 800

LENGTHS

Overall Length (60 PPM system) A 196.5 199.5 231.5 207 226 258 224 230 266 300 301

Overall Length (30 PPM system) A 199.5 200.5 233.5 211 228 260 225 234 267 302 303

Shell B 149 149 180 156 171 201 163 168 200 233 233

Base Frame C 136 136 167 143 158 188 150 155 187 220 220

Front Head Extension (60 PPM system) D 28 31 32 28 32 34 29 30 34 35 36

Front Head Extension (30 PPM system) D 31 32 34 32 34 36 30 34 35 37 38

Rear Head Extension E 19.5 19.5 19.5 23 23 23 32 32 32 32 32

Shell Ring Flange to Base F 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Rear Ring Flange to Base G 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5

Shell Flange to Steam Nozzle 15 psi H 90 90 96 96 98 112 101 101 96 112 112

Shell Flange to Steam Nozzle 150 psi H 84 84 96 96 98 112 100 100 96.25 112.75 112.75

Front Shell Extension P 12 12 12 15 15 15 17 17 17 17 17

Over Tubesheets V 137 137 168 141 156 186 146 151 183 216 216

WIDTHS

Overall Width I 85 85 85 92 92 92 109 109 109 109 109

I.D. Boiler J 60 60 60 67 67 67 83 83 83 83 83

Center to Water Column K 45 45 45 48.5 48.5 48.5 56.5 56.5 56.5 56.5 56.5

Center to Outside Davit/Hinge KK 35 35 35 45.5 45.5 45.5 45.5 45.5 45.5 45.5 45.5

Center to Lagging L 33 33 33 36.5 36.5 36.5 44.5 44.5 44.5 44.5 44.5

Center to Auxiliary LWCO LL 40 40 40 43.5 43.5 43.5 52.5 52.5 52.5 52.5 52.5

Base Outside M 52.5 52.5 52.5 51 51 51 60 60 60 60 60

Base Inside N 44.5 44.5 44.5 43 43 43 47 47 47 47 47

HEIGHTS

Overall Height OO 86 86 86 102.5 102.5 102.5 120.5 120.5 120.5 120.5 120.5

Base to Vent Outlet O 85 85 85 94.5 94.5 94.5 112 112 112 112 112

Height of Base Frame Q 12 12 12 12 12 12 12 12 12 12 12

Base to Bottom of Boiler R 16 16 16 14 14 14 16 16 16 16 16

Base to Steam Outlet X 82.375 82.375 82.375 90.25 90.25 90.25 108 108 108 108 108

BOILER CONNECTIONS

Feedwater Inlet (Both Sides) S 1.5 1.5 2 2 2 2.5 2.5 2.5 2.5 2.5 2.5

Surface Blowoff (150 lb only) T 1 1 1 1111 1 1 1 1

Steam Nozzle 15 lb (See Note "A") U 8 8 10 10 12 12 12 12 12 12 12

Steam Nozzle 150 lb (See Note "B") U 4 4 4 6 6 6 6 8 8 8 8

Blowdown-Front & Rear (15 lb) W 1.5 1.5 2 2222 2 2 2 2

Blowdown-Front & Rear (150 lb) W 1.5 1.5 1.5 1.5 1.5 1.5 2 2 2 2 2

Chemical Feed Z 1 1 1 1111 1 1 1 1

VENT STACK

Vent Stack Diameter (Flanged) BB 16 16 16 20 20 20 24 24 24 24 24

MINIMUM CLEARANCES

Rear Door Swing DD 32 32 32 36 36 36 45 45 45 45 45

Front Door Swing EE 67 67 67 75 75 75 80 80 80 80 80

Tube Removal - Rear FF 139 139 170 143 157 187 147 152 184 217 217

Tube Removal - Front GG 127 127 158 128 142 172 130 135 167 200 200

MINIMUM BOILER ROOM LENGTH ALLOWING FOR DOOR SWING AND TUBE REMOVAL FROM:

Thru Window or Door RD 248 248 279 267 282 312 288 293 325 358 358

Front of Boiler RF 308 308 370 320 349 409 338 348 412 478 478

Rear of Boiler RR 355 355 417 374 403 463 390 400 464 530 530

WEIGHTS IN LBS

Normal Water Weight 6,950 6,950 8,350 8,400 9,050 10,550 11,650 11,900 14,150 15,700 15,700

Approx. Shipping Weight - (15 psig) 11,850 11,850 13,550 15,400 17,550 19,750 26,450 27,100 30,700 35,700 35,700

Approx. Shipping Weight - (150 psig) 13,000 13,000 14,850 18,100 19,300 20,750 29,050 29,750 32,400 37,600 37,600

Approx. Shipping Weight - (200 psig) 13,200 13,200 15,100 19,250 20,300 23,300 29,800 30,150 34,850 38,800 38,800

NOTES:

Accompanying dimensions, while sufficiently accurate for layout purposes, must be confirmed for construction by certified dimension

All Connections are Threaded Unless Otherwise Indicated:

Note "A": ANSI 150 psig Flange

Note "B": ANSI 300 psig Flange

Figure A10-1. Model CBR Steam Boiler Dimensions and Weights - Sheet 2 of 2

Section A10-6 Rev. 05-09

Das könnte Ihnen auch gefallen

- Efficient 15-100 HP Boilers for BuildingsDokument5 SeitenEfficient 15-100 HP Boilers for BuildingssebaversaNoch keine Bewertungen

- Model CB 15-100 HP BoilersDokument5 SeitenModel CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CB 15-100 HP BoilersDokument5 SeitenModel CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Sound LevelDokument5 SeitenModel CB 15-100 HP Boilers: Sound LevelsebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDokument5 SeitenModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDokument5 SeitenModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDokument5 SeitenModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDokument5 SeitenModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDokument5 SeitenModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNoch keine Bewertungen

- 900-1800 HP Boiler SpecsDokument5 Seiten900-1800 HP Boiler SpecssebaversaNoch keine Bewertungen

- 15-100 HP Boilers Dimensions SpecsDokument5 Seiten15-100 HP Boilers Dimensions SpecssebaversaNoch keine Bewertungen

- Section A5: Model CBL 900-1800 HP BoilersDokument5 SeitenSection A5: Model CBL 900-1800 HP BoilerssebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP Boilers: Engineering DataDokument5 SeitenModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDokument5 SeitenModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNoch keine Bewertungen

- Features and Benefits: Model CB 15-100 HP BoilersDokument5 SeitenFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP BoilersDokument5 SeitenModel CBL 900-1800 HP BoilerssebaversaNoch keine Bewertungen

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDokument5 Seiten125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Dokument6 SeitenModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNoch keine Bewertungen

- Model CBR 125-800 HP BoilersDokument5 SeitenModel CBR 125-800 HP BoilerssebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDokument5 SeitenModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNoch keine Bewertungen

- General: Model ICB 100-800 HP BoilersDokument4 SeitenGeneral: Model ICB 100-800 HP BoilerssebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Front Feedwater TankDokument5 SeitenModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDokument5 SeitenModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNoch keine Bewertungen

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDokument5 Seiten900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNoch keine Bewertungen

- 81Dokument5 Seiten81sebaversaNoch keine Bewertungen

- 78Dokument5 Seiten78sebaversaNoch keine Bewertungen

- High-efficiency boiler specifications for 100-800 HP modelsDokument4 SeitenHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNoch keine Bewertungen

- Model ICB 100-800 HP BoilersDokument4 SeitenModel ICB 100-800 HP BoilerssebaversaNoch keine Bewertungen

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDokument5 Seiten125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Prueba de Alternador CaterpillarDokument2 SeitenPrueba de Alternador CaterpillarRamón José Aponte FrancoNoch keine Bewertungen

- Corrosion Prevention and ProtectionDokument9 SeitenCorrosion Prevention and ProtectionKyaw Kyaw AungNoch keine Bewertungen

- AC - MonthlyDokument1 SeiteAC - MonthlyManibalanNoch keine Bewertungen

- Automated Guided Vehicle Systems: Style and FunctionDokument16 SeitenAutomated Guided Vehicle Systems: Style and FunctionJayant DeshmukhNoch keine Bewertungen

- A Review of Hydrogen UsageDokument12 SeitenA Review of Hydrogen UsageRonnie GenezNoch keine Bewertungen

- Burn-In, Reliability Testing, and Manufacturing ofDokument19 SeitenBurn-In, Reliability Testing, and Manufacturing ofAbhinav SrivastavNoch keine Bewertungen

- 13M244 Instructions PDFDokument430 Seiten13M244 Instructions PDFDark ShadowNoch keine Bewertungen

- Components: Hitec® 536Dokument2 SeitenComponents: Hitec® 536Liliana RodriguezNoch keine Bewertungen

- PRESSURE DROP CALCULATION FOR DRILL WATER PIPEDokument9 SeitenPRESSURE DROP CALCULATION FOR DRILL WATER PIPEdasubhaiNoch keine Bewertungen

- Catalogo de Filtros Separador de Aire (Parker)Dokument112 SeitenCatalogo de Filtros Separador de Aire (Parker)Mikel1020Noch keine Bewertungen

- Scope of Work (Plumbing)Dokument1 SeiteScope of Work (Plumbing)Mochammad Waris S100% (1)

- BTS Ac SystemDokument40 SeitenBTS Ac Systemmohsinaliqureshi02Noch keine Bewertungen

- Awz 410Dokument2 SeitenAwz 410vukelic79Noch keine Bewertungen

- Processing of Grease With PDFDokument92 SeitenProcessing of Grease With PDFahmetNoch keine Bewertungen

- Thermal properties of polycarbonateDokument20 SeitenThermal properties of polycarbonateThụy Thảo LinhNoch keine Bewertungen

- Reinforced and Prestressed ConcreteDokument11 SeitenReinforced and Prestressed ConcreteFiel Ericson SolaresNoch keine Bewertungen

- APCYDokument64 SeitenAPCYChachou MohamedNoch keine Bewertungen

- Bus Duct-DesignDokument4 SeitenBus Duct-DesignjaktomsNoch keine Bewertungen

- Rotary Seal V-Ring GuideDokument25 SeitenRotary Seal V-Ring GuideAnonymous D5QForitcNoch keine Bewertungen

- Avenegr 220 150 CruizeDokument44 SeitenAvenegr 220 150 CruizeSiva GuruNoch keine Bewertungen

- 15CV71 Dec18-Jan19 PDFDokument2 Seiten15CV71 Dec18-Jan19 PDFKavyaNoch keine Bewertungen

- Paper On Plastic To RoadDokument6 SeitenPaper On Plastic To RoadSumskrutha Kosgi ShroffNoch keine Bewertungen

- Q Max Cumene ProductionDokument4 SeitenQ Max Cumene ProductionTey Kaijing100% (1)

- PRODUCTION OF INTERLOCKING ThisisDokument43 SeitenPRODUCTION OF INTERLOCKING Thisisjohn mark pampo100% (1)

- Diesel Engineering Handbook Cooling SystemsDokument14 SeitenDiesel Engineering Handbook Cooling Systemsmartin.ruben100% (1)

- Slow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingDokument7 SeitenSlow Strain Rate Testing To Evaluate The Susceptibility of Metallic Materials To Environmentally Assisted CrackingSandeep BhatiaNoch keine Bewertungen

- Modeling Transient Liquid Phase Bonding Process in The Ni (Final)Dokument20 SeitenModeling Transient Liquid Phase Bonding Process in The Ni (Final)Debopriyo RoyNoch keine Bewertungen

- Low Voltage Temperature Sensors / /: TMP35 TMP36 TMP37Dokument19 SeitenLow Voltage Temperature Sensors / /: TMP35 TMP36 TMP37lord mace tyrellNoch keine Bewertungen

- PAES 317-Metal Sheets - PlatesDokument12 SeitenPAES 317-Metal Sheets - Platesandrew cabilesNoch keine Bewertungen

- Subject: "Hwaco" Brand Stainless Steel Sectional Water Tank (SST) PROJECT: Substation at Jurong IslandDokument1 SeiteSubject: "Hwaco" Brand Stainless Steel Sectional Water Tank (SST) PROJECT: Substation at Jurong IslandThanThansccNoch keine Bewertungen