Beruflich Dokumente

Kultur Dokumente

Selecting Wire (Module)

Hochgeladen von

Charity PanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Selecting Wire (Module)

Hochgeladen von

Charity PanCopyright:

Verfügbare Formate

CodeCorner

Module

Your area experiences 40°C (104°F) temperatures

every summer. The modules are rack mounted, but

frequently experience no cooling breezes. The normal

winter low temperatures are about 0°C (32°F), and

Wiring moderate winds are experienced in the winter. You

choose to run direct burial conductors in the ground (24

inches (60 cm) deep), and choose USE-2 cable

Example because a high-temperature, sunlight-resistant, wet-

rated cable is required.

John Wiles The required ampacity for the conductors is 9 amps

Sponsored by the Photovoltaic Systems Assistance Center,

(1.56 x 5.8 A = 9 A). The 1.56 safety factor is explained

Sandia National Laboratories in HP79’s Code Corner, on page 112. The high ambient

temperatures in the summer cause the module junction

electing the proper cables and

S connecting them to a PV module

seem like relatively simple tasks.

However, as we have seen in the last

boxes and areas adjacent to the modules to operate at

about 65°C (149°F). With USE-2 conductors rated at

90°C (194°F), the temperature correction factor is 0.58.

At this point, you could select (guess) a cable size,

correct its ampacity with this correction factor, and see

three Code Corner columns, there are if the corrected ampacity was greater than the required

several steps involved. In this column 9 A. Or you could calculate the 30°C (86°C) required

and the next we will look at some typical ampacity by taking the 9 A and dividing by the

temperature correction factor. In this case, the

PV systems. We’ll examine how the calculation yields 15.5 A (9 ÷ 0.58 = 15.5).

module cables should be selected, From NEC Table 310-16, we see that #14 (2 mm2)

sized, and connected to meet the USE-2 cable has a 30°C (86°F) ampacity of 25 amps,

meeting the requirement. Since #14 is the smallest

requirements of the National Electrical cable allowed for use with this module, it is our first

Code (NEC), and to achieve a durable choice. Incidentally, #14 USE-2 is not a commonly

system that performs well. available cable type and size, and would have to be

special ordered in large quantities (500 foot (152 m)

Simple Example minimum) from a major wire distributor. Section 240-3

Let’s imagine that someone has given you a DC water of the code restricts #14 conductors to a 15 A

pumping system consisting of a 24 volt submersible overcurrent device, so we are permitted to use it.

pump and two 75 watt, 12 volt PV modules. You have

Voltage drop can now be calculated. From Table 8 in

90 foot (27 m) trees on your property, so you have to

Chapter 9 of the NEC (or Code Corner, HP80), we find

mount the two PV modules on the hill behind the house.

that a #14 (2 mm2) conductor has a resistance of 3.14

The total distance from the PV array to the wellhead,

ohms per 1,000 feet (305 m). For our 400 foot (122 m)

and down the well to the pump, is 200 feet (61 m).

circuit length (round trip), the resistance will be 1.26

The PV modules have the following information printed ohms (3.14 x 400 ÷ 1,000 = 1.26). At a maximum power

on the back: current of 4.33 amps, the voltage drop in the circuit

from the conductors alone is 5.5 volts, which is 23

At STC:

percent of the nominal 24 volts in the system—way too

Voc = 21.7 V, Isc = 5.8 A, Vmp = 17.3 V, I = 4.33 A

much for a renewable energy system.

Maximum systems voltage = 600 V

The module maximum power point current was

Maximum series fuse = 15 A selected as a compromise between the short-circuit

current of the module and other unknown operating

#14-8 AWG conductors rated at 90°C required

points that require less current than Isc. Pumps and PV

Voc is the open-circuit voltage, Isc is the short-circuit modules operate all over the current range of the

current, mp refers to maximum power point, and STC module, depending on temperature conditions, system

refers to Standard Test Conditions of 25°C (77°F) and design, time of day and other factors.

1,000 W/m2 irradiance.

When we add a few milliohms (estimated at 0.005

ohms) for connections and a disconnect switch, we get

100 Home Power #81 • February / March 2001

Code Corner

even more drop. So we need to select a larger Typical Copper Conductor Prices

conductor size. Since #10 (5 mm2) is more commonly

Range in US$ per foot

available and is stocked by PV distributors, let’s check

Size (AWG) Low High

it. The resistance for the 400 foot (122 m) run will be

10 0.22 0.35

0.496 ohms (1.24 x 4 ÷ 1,000 = 0.496), which yields a

voltage drop of 2.14 volts or 8.9 percent. This is still too 8 0.26 0.42

high. 6 0.30 0.55

4 0.32 0.80

Electrical supply houses and building supply stores

normally stock #8 (8 mm 2) USE-2. The use of this 2 0.45 1.25

conductor size would cut the voltage drop to 1.3 volts

(0.778 x 400 ÷ 1,000 x 4.33 = 1.34), which is 5.6 Chapter 9 of the NEC, or Code Corner in HP80, we see

percent of the nominal system voltage—still a little high. that #3 (27 mm2) copper wire has a resistance of 0.245

ohms per 1,000 feet (305 m), so it will meet our

The module terminals can accept a maximum

requirements.

conductor size of #8, so we must start getting creative.

There are wire reducers made for just such Does it cost more than #10? Yes. Is it necessary? Yes,

applications. They are copper sleeves that fit over large if you want to pump water. Will a smaller size work?

cable sizes and reduce them to a smaller size that will Yes, but pumping performance will suffer.

fit into smaller terminals. We could also splice a larger

The table shows some typical prices for copper

conductor (used for the long run) to a #8 (8 mm 2)

conductors in these sizes. Prices vary significantly

conductor that would fit the module terminals. The

depending on where and when you buy. No one source

splicing devices would probably be split bolts, which

(PV equipment distributor, electrical supply, home

need to be properly insulated with tape and installed in

building store, or hardware store) consistently has the

a protected (junction box) environment. There is usually

lower prices, so it pays to shop around.

not sufficient room in the module junction boxes to do

these splices. Want to use aluminum conductors with the hope of

saving some money over copper? No problem. Since

While we could continue to guess at larger conductor

aluminum has a higher resistance than copper, a #1 (42

sizes, let’s instead work the problem backwards.

mm2) conductor will be needed (resistance is 0.253

Assume that we want a voltage drop of no more than 2

ohms per 1,000 feet or 305 m). Special splicing devices

percent, including wire drop and connection drop. We

rated to connect copper to aluminum will be needed at

can solve for the necessary wire resistance per 1,000

each end to convert the aluminum conductors back to

feet as follows.

the copper conductors. Copper is required by the PV

Maximum allowable voltage drop is 0.48 volts (0.02 x modules, many pumps, and some switchgear.

24 = 0.48). This voltage consists of a drop from the

Grounding and Balance of Systems

connection resistance (0.005 ohms) and a drop from

Although this Code Corner primarily deals with module

the wire resistance that is unknown.

conductors, a few comments on the rest of the system

At the operating current of 4.33 amps, the connection are in order. The module location will require a ground

voltage drop is 0.022 volts (4.33 x 0.005 = 0.022). If we rod to which module frames must be attached. The

subtract this drop from the maximum allowable drop, negative circuit conductor may also be attached to this

we get 0.458 volts (0.48 - 0.022 = 0.458) that can result ground rod, and if this is done, an equipment-grounding

from just the conductor resistance. conductor must not be used between the modules and

the pump. This grounding and bonding system is

We have an equation for voltage drop (Vd) and total

described in HP74, Code Corner, Grounding the South

resistance (Rt) that is Vd = Rt x 4.33 amps. We can

Forty. The Southwest Technology Development Institute

solve for Rt (Rt = Vd ÷ 4.33). The result is 0.106 ohms

(SWTDI) Web site has all of the past Code Corner

(Rt equals 0.458 ÷ 4.33 = 0.106) for the 400 foot (122

columns in PDF format.

m) run.

The negative conductor and the equipment-grounding

We need to find the resistance in ohms per 1,000 feet

conductors from the pump motor housing and the

of cable (R1000) so that we can look up the conductor

disconnect switch enclosure will be connected to a

size in a table. To solve for ohms per 1,000 feet

second ground rod at the pump.

(R1000), we use the following equation. Rt = R1000 x

400 ÷ 1,000. R1000 = Rt x 2.5. In this case, R1000 Since there is no energy storage in the system, and

equals 0.265 ohms (0.106 x 2.5 = 0.265). From Table 8, there is only one string of two modules, there is no

Home Power #81 • February / March 2001 101

Code Corner

requirement for overcurrent protection in the circuit (see Access

NEC Section 690-9(a) Exception). Only a disconnect John C. Wiles • Southwest Technology Development

switch (listed for DC and rated for load-break operation) Institute (SWTDI), New Mexico State University,

will be required at the pump location. Box 30,001/ MSC 3 SOLAR, Las Cruces, NM 88003

505-646-6105 • Fax: 505-646-3841 • jwiles@nmsu.edu

Summary

www.nmsu.edu/~tdi

It takes longer to describe these calculations than to do

them. SWTDI is working on an interactive CD-ROM to Sponsor: Sandia National Laboratories, Ward Bower,

do some of these calculations for PV systems, and an Department 6218, PO Box 5800 MS 0753,

initial version may be available late in 2001. However, Albuquerque, NM 87185-0753 • 505-844-5206

the calculations are relatively straightforward. All that is Fax: 505-844-6541 • wibower@sandia.gov

really required is a copy of the NEC, a calculator, and a www.sandia.gov/pv

little time to size conductors properly. In the next Code

National Electrical Code® and NEC® are registered

Corner, we will take on a more complicated system.

trademarks of the National Fire Protection Association.

If you have questions about the NEC or the The 1999 NEC and the NEC Handbook are available

implementation of PV systems following the from the NFPA, 11 Tracy Dr., Avon, MA 02322

requirements of the NEC, feel free to call, fax, email, or 800-344-3555 or 508-895-8300 • Fax: 800-593-6372 or

write me. Sandia National Laboratories sponsors my 508-895-8301 • custserv@nfpa.org • www.nfpa.org

activities in this area as a support function to the PV

National Renewable Energy Laboratory solar radiation

Industry. This work was supported by the United States

and weather data base:

Department of Energy under Contract DE-FC04-

http://rredc.nrel.gov/solar/old_data/nsrdb/redbook/sum2

00AL66794. Sandia is a multi-program laboratory

operated by Sandia Corporation, a Lockheed Martin

Company, for the United States Department of Energy.

102 Home Power #81 • February / March 2001

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- JBL Class D Training WorkbookDokument24 SeitenJBL Class D Training WorkbookGerardo Mendez CamarilloNoch keine Bewertungen

- Battery Electric Vehicle 17387Dokument29 SeitenBattery Electric Vehicle 17387Aditya thakurNoch keine Bewertungen

- Earthing SystemDokument22 SeitenEarthing Systemashokparikh100% (2)

- 9086 Cuadro AnacondaDokument19 Seiten9086 Cuadro Anacondaestefany camargoNoch keine Bewertungen

- Physics 10th A Chap 10.11.12.13,14 (First Half) (A)Dokument4 SeitenPhysics 10th A Chap 10.11.12.13,14 (First Half) (A)Vɩʀtʋʌɭ BʀʌɩŋsNoch keine Bewertungen

- Research Article: Damage Boundary Study of Crystal Oscillators Under Shock EnvironmentDokument14 SeitenResearch Article: Damage Boundary Study of Crystal Oscillators Under Shock Environmentjohnjs8766Noch keine Bewertungen

- Bta 40600 BDokument6 SeitenBta 40600 BesamNoch keine Bewertungen

- NordDokument40 SeitenNordMohan MohaNoch keine Bewertungen

- User Manual: Batch ControllerDokument52 SeitenUser Manual: Batch ControllerCAP UTN RosarioNoch keine Bewertungen

- Whirlpool Art 481 R Sm2Dokument5 SeitenWhirlpool Art 481 R Sm2sasa68Noch keine Bewertungen

- Eeng 590j Ch01 - SzeDokument16 SeitenEeng 590j Ch01 - SzeAswad ShakurNoch keine Bewertungen

- JM Electro - Persamaan TransistorDokument4 SeitenJM Electro - Persamaan TransistorAndi KaNoch keine Bewertungen

- Prisma Plus PH System CatalogueDokument33 SeitenPrisma Plus PH System CataloguedavidninrioNoch keine Bewertungen

- KP-F D XXGV OperationManual EDokument7 SeitenKP-F D XXGV OperationManual EabathunNoch keine Bewertungen

- Mediciones y PruebasDokument59 SeitenMediciones y PruebasAnonymous zTUWsMNoch keine Bewertungen

- LDK DS 185P-24(s) Value EN V3 120817Dokument2 SeitenLDK DS 185P-24(s) Value EN V3 120817doly damanikNoch keine Bewertungen

- US Product King Cobra 500 PSIDokument48 SeitenUS Product King Cobra 500 PSINestor Marquez-DiazNoch keine Bewertungen

- Capacitor Test Neet 30 Ques FinalDokument6 SeitenCapacitor Test Neet 30 Ques Finaldeejam123Noch keine Bewertungen

- OP27Dokument20 SeitenOP27Asif HameedNoch keine Bewertungen

- Fdocuments - in - Ca650059en 600 A 25 KV Class T Op II Deadbreak Apparatus With Its Cooper PowerDokument8 SeitenFdocuments - in - Ca650059en 600 A 25 KV Class T Op II Deadbreak Apparatus With Its Cooper PowerJalal AlbadriNoch keine Bewertungen

- Use of SCADA Systems in Power System AutomationDokument10 SeitenUse of SCADA Systems in Power System AutomationKamlesh KumarNoch keine Bewertungen

- GU3310 & GU3311 Controller Brief Operation Manual: 1. Main Buttons' InstructionDokument6 SeitenGU3310 & GU3311 Controller Brief Operation Manual: 1. Main Buttons' InstructiongutierkNoch keine Bewertungen

- Plasma Display TV: Chassis: D53A (P) - 42" TTX Model: Ps42P2Stx/AagDokument136 SeitenPlasma Display TV: Chassis: D53A (P) - 42" TTX Model: Ps42P2Stx/Aagsm14jNoch keine Bewertungen

- ProblemDokument89 SeitenProblemPanneer SelvamNoch keine Bewertungen

- Ultra Isolation TransformerDokument2 SeitenUltra Isolation TransformerKhashane Willy MohaleNoch keine Bewertungen

- Carvalho 2020Dokument10 SeitenCarvalho 2020JHONNY FRANK CARLOS LEON MEZANoch keine Bewertungen

- Operating Manual Transmission Test Set 806A / 806ARDokument56 SeitenOperating Manual Transmission Test Set 806A / 806ARKeith FoorNoch keine Bewertungen

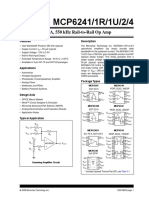

- MCP6241 PDFDokument38 SeitenMCP6241 PDFNiyaz Ahmad100% (1)

- Westinghouse Lighting MFB-1000 General Purpose Mercury Floodlight Spec Sheet 3-72Dokument2 SeitenWestinghouse Lighting MFB-1000 General Purpose Mercury Floodlight Spec Sheet 3-72Alan MastersNoch keine Bewertungen

- Temperature Control Solution With PLC: October 2016Dokument5 SeitenTemperature Control Solution With PLC: October 2016Lu Pham KhacNoch keine Bewertungen