Beruflich Dokumente

Kultur Dokumente

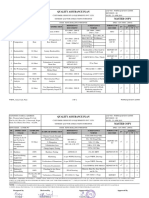

PDS NA Type S

Hochgeladen von

abcOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PDS NA Type S

Hochgeladen von

abcCopyright:

Verfügbare Formate

Liquid Epoxy Type S

Wet epoxy for superior 3-layer

corrosion protection

Canusa Liquid Epoxy Type S is a wet applied, two part epoxy,

used as the primary layer with Canusa 3-layer systems, such as

GTS-PE, GTS-65 and GTS-80. It is composed of a specially

formulated 100% solids epoxy system, which does not use any

volatile solvents. This keeps the thickness of the epoxy layer as

it cures, ensuring superior corrosion protection of field welded

joints on steel pipes. Liquid Epoxy Type S has extended pot life at

high temperatures which allows for longer working time.

Applications

Coating Continuity

• The Liquid Epoxy Type S layer offers similar corrosion protection to

Oil & Gas

the FBE primary layer in 3 layer polyethylene and 3 layer

polypropylene mainline coated pipelines.

Improved Cathodic Disbondment Resistance Offshore Pipelines

• Liquid Epoxy Type S will improve the Cathodic Disbondment

resistance results for hotmelt type adhesives when compared against

bare steel substrate. Repair & Rehab

Extended Pot Life

• Liquid Epoxy Type S has an extended pot life to allow ample time

to complete the application of Canusa 3-layer systems to maximize High Temperature

quality assurance and ensure correct product installation.

Girth-Weld Joints

PRODUCT DATA SHEET canusacps.com

The product information

Liquid Epoxy Type S shown here is intended as a

guide for standard products.

Consult your Canusa

Wet epoxy for superior 3-layer corrosion protection representative for specific

projects or unique applications.

Properties Typical Values

Mixing Ratio 3:1 (by volume)

Percent Solids 100%

1.58 ± 0.03 (Base)

Specific Gravity

1.02 ± 0.02 (Cure)

14,000 ± 14% cps (Base) @ 60 C, #7 spindle at 10 rpm

Viscosity

250 ± 20% cps (Cure) @ 25°C, #3 spindle at 20 rpm

Typical Thickness 6 ± 2 mils

Number of Coats One

Pot Life 140 minutes @ 23°C, 30 minutes @ 40°C

3 years @ 23°C, out of direct sunlight. Shelf life will be lesser

Shelf Life

at higher temperatures.

Thinner Do not dilute.

Minimum Curing Canusa-CPS

10°C

Temperature A division of Shawcor Ltd.

5.3 sq.m/litre (57 sq.ft/litre). This coverage is based on 6 mils Head Office

Typical Coverage

of thickness & assuming 20% waste factor 25 Bethridge Road

Toronto, ON, Canada M9W 1M7

Calculation of Liquid Epoxy Type S Quantity Required

Tel: +1 416 743 7111

Bare Steel Surface Area Fax: +1 416 743 5927

Circumference (m) * Cutback length (mm) / 1000

(square meter) Canada

Required Volume of Bare Steel Surface Area * Thickness (microns) / 1000000 * Dome Tower St. 2200, 333-7th Avenue SW

Liquid Epoxy Type E (Liter) [(1+Wastage Factor¹/100) * 1000] Calgary, AB, Canada T2P 2Z1

Tel: +1 403 218 8207

Total Required Number of Kits Required Volume of Liquid Epoxy Type S / 0.170 Fax: +1 403 264 3649

Typical Quantity of 170 ml Liquid Epoxy Type S kits required by Pipe Size² Americas

5875 N. Sam Houston Pkwy W., Suite 200

4.5” to 22” One Houston, TX, USA 77086

Tel: +1 281 886 2350

24” to 42” Two Fax: +1 281 886 2353

44” to 60” Three Middle East

ADPC - Mussafah Port, P.O. Box 2621

¹ Typical Wastage Factor: 25-50% Abu Dhabi, UAE

² Based on a 300 mm wide cut back with 6 mils average thickness and typical wastage Tel: +971 2 496 3500

Fax: +971 2 496 3501

Epoxy Consumption is based on the following variables and will differ Europe, Africa & Russia

between applications: Dellaertweg 9-E, Gebouw “Le Carrefour”

2316 WZ Leiden, The Netherlands (NL)

• Applicator Type (roller or sponge) • Surface Profile Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

• Applicator Skill • Pipeline Layout Asia-Pacific

101 Thomson Road, #11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Safety Fax: +65 6749 8919

Handle with care. Before and during use, observe all safety labels on packaging containers, consult with Canusa-CPS is registered

Canusa-CPS Safety Data Sheets and abide by all local or national safety regulations. to ISO 9001:2008

Canusa warrants that the product conforms to its

chemical and physical description and is appropriate

for the use stated on the product data sheet when used

in compliance with Canusa’s written instructions. Since

many installation factors are beyond our control, the

user shall determine the suitability of the products for

the intended use and assume all risks and liabilities in

connection therewith. Canusa’s liability is stated in the

standard terms and conditions of sale. Canusa makes

no other warranty either expressed or implied. All

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings information contained in this data sheet is to be used

as a guide and is subject to change without notice. This

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high data sheet supersedes all previous data sheets on this

product. E&OE

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications.

PDS_Epoxy(S)_rev014

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Welding Consumable Control ProcedureDokument15 SeitenWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Sample Internship ReportDokument34 SeitenSample Internship ReportIsaac Okorie zaku89% (9)

- Bill No. 10 - Construction of Office and StoreDokument25 SeitenBill No. 10 - Construction of Office and StorePn EkanayakaNoch keine Bewertungen

- TB HBEExpeditedCureDokument2 SeitenTB HBEExpeditedCureabcNoch keine Bewertungen

- HPPC corrosion protection powder coatingDokument2 SeitenHPPC corrosion protection powder coatingabcNoch keine Bewertungen

- Field Joint Developments and Compatibility ConsiderationsDokument13 SeitenField Joint Developments and Compatibility ConsiderationsabcNoch keine Bewertungen

- BrederoShaw PDS A4 3LPPDokument2 SeitenBrederoShaw PDS A4 3LPPabcNoch keine Bewertungen

- HPPC corrosion protection powder coatingDokument2 SeitenHPPC corrosion protection powder coatingabcNoch keine Bewertungen

- 19water SeparatorDokument2 Seiten19water SeparatorabcNoch keine Bewertungen

- Diaphragm Pump Manual (B25 X25 Metallic Manual)Dokument12 SeitenDiaphragm Pump Manual (B25 X25 Metallic Manual)abcNoch keine Bewertungen

- ECMAServoDokument10 SeitenECMAServoJohn Henry ContrerasNoch keine Bewertungen

- Feed Pump 1095927 - 02Dokument8 SeitenFeed Pump 1095927 - 02abcNoch keine Bewertungen

- BrederoShaw PDS A4 3LPPDokument2 SeitenBrederoShaw PDS A4 3LPPabcNoch keine Bewertungen

- PWL5102Dokument2 SeitenPWL5102abcNoch keine Bewertungen

- AC Servo Motor World K Asia SeriesDokument28 SeitenAC Servo Motor World K Asia SeriesabcNoch keine Bewertungen

- Polypropylene Anti-Corrosion Coatings Protect Subsea StructuresDokument2 SeitenPolypropylene Anti-Corrosion Coatings Protect Subsea StructuresabcNoch keine Bewertungen

- 44compressed Air Dryers - HDDDokument2 Seiten44compressed Air Dryers - HDDLê Anh Chiến100% (1)

- WK Series-Single Phase-Reversible MotorDokument8 SeitenWK Series-Single Phase-Reversible MotorabcNoch keine Bewertungen

- Datasheet ZBE101Dokument3 SeitenDatasheet ZBE101Jet TorresNoch keine Bewertungen

- Holiday Detector PoroTest 7 enDokument4 SeitenHoliday Detector PoroTest 7 enabcNoch keine Bewertungen

- Research DefenseDokument16 SeitenResearch DefenseJeanetteEoniceRodriguezNoch keine Bewertungen

- PolyethyleneDokument31 SeitenPolyethyleneHesham chemecology100% (1)

- Modeling Slump Flow of Concrete Using Second-Order Regressions and Artificial Neural NetworksDokument7 SeitenModeling Slump Flow of Concrete Using Second-Order Regressions and Artificial Neural NetworksLiliana ForzaniNoch keine Bewertungen

- Proposed Bungalow Residential Building ProjectDokument6 SeitenProposed Bungalow Residential Building Projectjek vinNoch keine Bewertungen

- Effect of Post Weld Heat Treatment On The Oxide Scaling of Cr-Mo Steel WeldmentsDokument7 SeitenEffect of Post Weld Heat Treatment On The Oxide Scaling of Cr-Mo Steel WeldmentsFebriant SchweinsteigerNoch keine Bewertungen

- Glossary Steel Reinforcement For ConcreteDokument16 SeitenGlossary Steel Reinforcement For ConcreteJaneshaNoch keine Bewertungen

- Chemical Composition AluminiumDokument3 SeitenChemical Composition AluminiumEmreNoch keine Bewertungen

- Transparent (Light Transmitting) ConcreteDokument3 SeitenTransparent (Light Transmitting) Concretevenkateswara rao PothinaNoch keine Bewertungen

- Drainage, Water Supply & InsulationDokument56 SeitenDrainage, Water Supply & InsulationRiddhi PatelNoch keine Bewertungen

- Bosta Catalogue Export (ENG)Dokument362 SeitenBosta Catalogue Export (ENG)Rene van ErkelensNoch keine Bewertungen

- Fire Cabinets: and AccessoriesDokument4 SeitenFire Cabinets: and AccessoriesSaiko AlyNoch keine Bewertungen

- NH-Armaflex SpecificationDokument2 SeitenNH-Armaflex SpecificationPanya PurahongNoch keine Bewertungen

- Mechanical Properties of Sustainable Ado PDFDokument10 SeitenMechanical Properties of Sustainable Ado PDFAneesha MuthurajNoch keine Bewertungen

- High-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsDokument3 SeitenHigh-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsakhileshNoch keine Bewertungen

- CANTEX Fitting Brochure 200809Dokument48 SeitenCANTEX Fitting Brochure 200809Kim Ill JeongNoch keine Bewertungen

- Piping Erection MethodDokument10 SeitenPiping Erection Methodari zeinNoch keine Bewertungen

- Splicing Bar Resources: Additional Information On Lap Splices Can Be Found HereDokument5 SeitenSplicing Bar Resources: Additional Information On Lap Splices Can Be Found HereLiyakhat aliNoch keine Bewertungen

- Gliss Master Product SheetDokument58 SeitenGliss Master Product SheetDiana JitariuNoch keine Bewertungen

- Astm A572 Steel, Grade 50 DurezaDokument1 SeiteAstm A572 Steel, Grade 50 DurezaMaikol Chino100% (1)

- Cec 313 Lect NoteDokument10 SeitenCec 313 Lect NoteSamson Mide FolorunshoNoch keine Bewertungen

- Padrão JúpiterDokument2 SeitenPadrão JúpiterZito CarlosNoch keine Bewertungen

- Mechanics of Composite Materials - 2017 PDFDokument2 SeitenMechanics of Composite Materials - 2017 PDFJAGANNATH PRASADNoch keine Bewertungen

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDokument2 SeitenWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNoch keine Bewertungen

- Thermal & Moisture ProtectionDokument14 SeitenThermal & Moisture Protectionmarc naganoNoch keine Bewertungen

- BTM Catalog Tog L Loc Tooling (Non 940)Dokument36 SeitenBTM Catalog Tog L Loc Tooling (Non 940)Abrão GarciaNoch keine Bewertungen

- YG1 INDEXABLE INSERTS YE IT DrillingDokument8 SeitenYG1 INDEXABLE INSERTS YE IT DrillingMariano MoralesNoch keine Bewertungen

- MTC Catalog 2009 ENGLISCHDokument196 SeitenMTC Catalog 2009 ENGLISCHAsif JalgaonkarNoch keine Bewertungen