Beruflich Dokumente

Kultur Dokumente

Sampling and Testing Frequency Chart Quality Control/Quality Assurance Specifications

Hochgeladen von

Mohamed ElfawalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sampling and Testing Frequency Chart Quality Control/Quality Assurance Specifications

Hochgeladen von

Mohamed ElfawalCopyright:

Verfügbare Formate

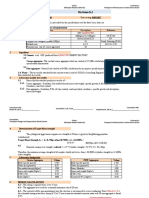

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 300

CALCIUM CHLORIDE b Sample first container

Sec. 301, 305 & 1702 received on project.

LIME TREATED SUBGRADE Moisture Tests KT-11 k

Sec. 302, 2000 & 2400 (0.1 g or 0.01% of mass)

Sieve Analysis for Acceptance of KT-42 k

Lime or Cement Treated Subgrade

(1% of mass)

Percent Solids of Lime Slurry KT-62 1 per day or batch, whichever

(WPG 0.01 g, Slurry Solids 0.1%) is greater.

AGGREGATE BASE COURSE

Sec. 305 and 1104

Individual Aggregates Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Binder Material Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Combined Material Sieve Analysis of Aggregate KT-2 c 1000 ft (300 m) each lift. If 1 per 6000 ft (2000 m). If

(1%, 0.1% for No. 200 [75 µm] total aggregate (no binder) total aggregate (no binder)

sieve, of mass) then each 500 TONS (500 then each 3500 TONS

Mg). (3500 mg).

Plasticity Tests KT-10 c 1000 ft (300 m) each lift. If 1 per 6000 ft (2000 m). If

(0.01 g or 0.1% of mass) total aggregate (no binder) total aggregate (no binder)

then each 500 TONS (500 then each 3500 TONS

Mg). (3500 mg).

Moisture Tests KT-11 1000 ft (300 m) each lift. If 1 per 6000 ft (2000 m). If

(0.1 g or 0.01% of mass) total aggregate (no binder) total aggregate (no binder)

then each 500 TONS (500 then each 3500 TONS

Mg). (3500 mg).

Page 1/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 300 (continued)

AGGREGATE BASE COURSE (continued)

Sec. 305 and 1104

Completed Base Field Density Tests KT-13 or 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 lb/ft3 [1 kg/m3] or 0.1% of KT-41

optimum density)

Moisture Tests KT-11 or 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 g or 0.01% of mass) KT-41

AGGREGATE SHOULDERS (Non-Bituminous)

Sec. 305 and 1113

Individual Aggregates Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Binder Material Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Combined Material Sieve Analysis of Aggregate KT-2 c

(1%, 0.1% for No. 200 [75 µm] 1000 ft (300 m) each lift. If 1 per 6000 ft (2000 m). If

sieve, of mass) total aggregate (no binder) total aggregate (no binder)

Plasticity Tests KT-10 c

then each 500 TONS (500 then each 3500 TONS

(0.01 g or 0.1% of mass)

Mg). (3500 mg).

Moisture Tests KT-11

(0.1 g or 0.01% of mass)

Completed Shoulder Field Density Tests KT-13 or 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 lb/ft3 [1 kg/m3] or 0.1% of KT-41

optimum density)

Moisture Tests KT-11 or 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 g or 0.01% of mass) KT-41

Page 2/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 300 (continued)

CEMENT TREATED BASE Sieve Analysis of Aggregate KT-2 c 1 per day. 1 per week.

(CTB) (1%, 0.1% for No. 200 [75 µm] h

Sec. 306 & 1105 sieve, of mass)

Plasticity Tests KT-10 4 per day per design. 1 per week.

(0.01 g or 0.1% of mass)

Moisture Tests KT-11 or 4 per day per design. 1 per week.

(0.1 g or 0.01% of mass) KT-41

Density KT-37 or 1 per day per design 1 per project per design.

(0.1 lb/ft3 [1 kg/m3] or 0.1% of KT-20* (* KT-20 option is only

optimum density) permitted in conjunction with

a fluid mix.)

Compressive Strength KT-37 4 test specimens for each 1 specimen for each day’s

(1 psi [0.01 MPa]) normal day's production. production.

Completed Shoulder Field Density Tests KT-13 or 4 per day per design. 1 per week per design.

(0.1 lb/ft3 [1 kg/m3] or 0.1% of KT-41

optimum density)

Moisture Tests KT-11 or 4 per day per design. 1 per week per design.

(0.1 g or 0.01% of mass) KT-41

GRANULAR BASE

Sec. 307 and 1106

Individual Aggregates Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Binder Material Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Plasticity Tests KT-10 c Minimum 1 per project. Minimum 1 per project.

(0.01 g or 0.1% of mass) k

Page 3/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 300 (continued)

GRANULAR BASE (continued)

Sec. 307 and 1106

Pulverization Sieve Analysis of Aggregate KT-2 c Minimum 1 per project. Minimum 1 per project.

(1%, 0.1% for No. 200 [75 µm] k

sieve, of mass)

Combined Material Sieve Analysis of Aggregate KT-2 c

(1%, 0.1% for No. 200 [75 µm] 1000 ft (300 m) each lift. If 1 per 6000 ft (2000 m). If

sieve, of mass) total aggregate (no binder) total aggregate (no binder)

Plasticity Tests KT-10 c

then each 500 TONS (500 then each 3500 TONS

(0.01 g or 0.1% of mass)

Mg). (3500 mg).

Moisture Tests KT-11

(0.1 g or 0.01% of mass)

Completed Work Field Density Tests KT-13 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 lb/ft3 [1 kg/m3] or 0.1% of or KT-41

optimum density)

Moisture Tests KT-11 1 per 1000 ft (300 m). 1 per 1000 ft (300 m).

(0.1 g or 0.01% of mass) or KT-41

HYDRATED LIME AND KT-29 b 1 sample for every 10

PEBBLE QUICKLIME loads.

Sec. 302, 1103, 2002, & 2003

FLY ASH FOR KT-29 b 2 samples per month per

STABILIZATION AND COLD source per district.

RECYCLE

DIVISION 500

PORTLAND CEMENT CONCRETE PAVEMENT

Sec. 501 & 503

Individual Aggregates Material Passing the No. 200 (75 KT-3 c 1 per 250 TONS (250 Mg) for 1 per project for each

µm) Sieve by the Wash Method m each individual aggregate. individual aggregate.

(0.1% of mass)

Sieve Analysis of Aggregate KT-2 c 1 per 250 TONS (250 Mg) for 1 per project for each

(1%, 0.1% for No. 200 [75 µm] m each individual aggregate. individual aggregate.

Clay Lumps and Friable Particles in KT-7 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Page 4/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 500 (continued)

PORTLAND CEMENT CONCRETE PAVEMENT

Sec. 501 & 503 (continued

Individual Aggregates Shale or Shale-Like Materials in KT-8 c As required.

(continued) Aggregate h

(0.1 g or 0.01% of mass)

Sticks in Aggregate KT-35 c As required.

(0.01% of mass) h

Unit Weight – lightweight KT-5 c As required.

aggregates only k

(0.1 lb [50 g] or 0.1% of mass)

Combined Aggregate Moisture in Aggregate KT-24 1 per 1/2 day. 1 per week.

(0.1 g or 0.01% of mass)

Concrete Mass KT-20 a 1 per 500 yd3 (500 m3). 1 per day.

(0.1 lb [50 g])

Slump KT-21 a 1 per 500 yd3 (500 m3). 1 per day.

(0.25 in [5 mm])

Temperature KT-17 a 1 per 500 yd3 (500 m3). 1 per day.

(1 °F [0.5 °C])

Air Content KT-18 or a 1 per 500 yd3 (500 m3). 1 per day.

(0.25%) KT-19

Density of Fresh Concrete KT-38 Initially, 1 complete 1 density per week.

3 3 transverse profile, then 1

(0.1 lb/ft [1 kg/m ])

density per ½ day.

Beams KT-22 & 1 set of 3 as required for 1 set of 3 per week.

(1 psi [1 kPa]) KT-23 opening to traffic.

Cores KT-49 As required in SS 2007 Thickness measurement and

(1 lbf [1 N], 0.1 in [1 mm], 1 psi section 501.5g. compression test – 1 per

[0.01 MPa]) lot.

Air Void Analyzer KT-71 Prequalification of mix 1 test randomly during

(0.0001 in [0.001 mm]) required as per SS 2007 every 4 weeks of

section 401.10. production.

1 test at the start of paving.

Thereafter, 1 test randomly

per week of production.

Page 5/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 500 (continued)

PORTLAND CEMENT CONCRETE PAVEMENT

Sec. 501 & 503 (continued

Concrete (continued) Permeability KT-73 or 1 per mix design per

(0.01%, KT-73; 10 coulomb, AASHTO project.

AASHTO T 277) T 277

Profilograph KT-46 2 tracks per 12 ft (3.7 m) of At the Engineer’s

width for the full length of the discretion.

project.

Class I/II Aggregates See 5.6.5.3 of this manual.

DIVISION 600

HMA (Plant Mix)

Sec. 602, 603, 611 & 1103

Individual Aggregates Sieve Analysis of Aggregate KT-2 c 1 per 1000 TONS (1000 Mg) 1 during the first 5000

(1%, 0.1% for No. 200 [75 µm] for each individual aggregate. TONS (5000 Mg) of HMA

sieve, of mass) produced for each

individual aggregate.

Clay Lumps and Friable Particles in KT-7 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Shale or Shale-Like Materials in KT-8 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Sticks in Aggregate KT-35 c As required.

(0.01% of mass) h

Uncompacted Void Content of Fine KT-50 l 1 on the first lot then 1 per

Aggregate 10,000 TONS (10,000 Mg) of

(0.1%) crushed gravel. 1 during the first 5000

Uncompacted Void Content of AASHTO l 1 on the first lot then 1 per TONS (5000 Mg) of HMA

Coarse Aggregate T 326 10,000 TONS (10,000 Mg) of produced.

(0.01%) (Method crushed gravel.

A)

Mineral Filler Supplement Sieve Analysis of Aggregate KT-2 c 1 per 250 TONS (250 Mg).

(1%, 0.1% for No. 200 [75 µm] h 1 during the first 5000

sieve, of mass) TONS (5000 Mg) of HMA

Plasticity Tests KT-10 c 1 per 250 TONS (250 Mg). produced.

(0.01 g or 0.1% of mass) h

Page 6/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 600 (continued)

HMA (Plant Mix)

Sec. 602, 603, 611 & 1103

Combined Aggregate Coarse Aggregate Angularity KT-31 c 1 per lot 1 per week or 1 per 10,000

(continued) (0.1% of mass) g TONS (10,000 Mg).

Uncompacted Void Content of Fine KT-50 1 on the first lot then 1 per

Aggregate 10,000 TONS (10,000 Mg) of

(0.1%) combined aggregate.

Sand Equivalent Test KT-55 f 1 per lot. 1 during the first 5000

(1%) TONS (5000 Mg) of HMA

Flat or Elongated Particles KT-59 1 on the first lot. produced.

(1%)

Moisture Tests KT-11 1 per lot.

(0.1 g or 0.01% of mass)

Asphalt Material Sampling KT-26 b 1 sample for every 3 loads. 1 during the first 5000

e (CMS = VER) TONS (5000 Mg) of HMA

produced.

HMA Mixtures Percent Moisture in Mixture KT-11 1 per lot. 1 during the first 5000

(0.1 g or 0.01% of mass) TONS (5000 Mg) of HMA

produced.

Air Voids KT-15, 1 per sublot. j 1 per lot. [Compact split

(Va = 0.01%; Gmm & Gmb = 0.001) KT-39, (See code n for Gmm) sample on KDOT Gyratory

KT-58, & – 1 per week or every

SF Manual 15,000 TONS (15,000

Mg)]

Binder Content (by ignition) KT-57 1 per sublot. j 1 per lot.

(0.1 g or 0.01% of mass)

Mix Gradation (after ignition) KT-34 1 per sublot. 1 per lot.

(0.1 g or 0.01% of mass)

Moisture Damage to Mix (Modified KT-56 d 1 on first lot then 1 per week 1 during the first 5000

Lottman) or every 10,000 TONS TONS (5000 Mg) of HMA

(0.1%) (10,000 Mg). produced. Performed by the

District Lab.

Page 7/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 600 (continued)

HMA (Plant Mix)

Sec. 602, 603, 611 & 1103

Reclaimed Asphalt Pavement Binder Content in RAP (by ignition) KT-57 1 during the first lot then 1 j 1 during the first lot then 1

(RAP) (0.1 g or 0.01% of mass) per 1000 TONS (1000 Mg) of per 4000 TONS (4000 Mg)

RAP. of RAP.

RAP Gradation (after ignition) KT-34 1 per 1000 TONS (1000 Mg)

(0.1 g or 0.01% of mass) of RAP. 1 during the first 5000

Percent Moisture in RAP KT-11 1 per lot. TONS (5000 Mg) of HMA

(0.1 g or 0.01% of mass) produced.

Completed Road Work Field Density - Cores or Nuclear KT-15 or i 10 tests per lot. i 5 companion tests per lot.

Density Gauge KT-32

Field Density Tests (Gmb = 0.001; 0.1 lb/ft3 [1 kg/m3]

(Use Cores or Nuclear Density or 0.1% of Gmm)

Gauge on all HMA roadway or Profilograph KT-46 2 tracks per 12 ft (3.7 m) of At the Engineer’s

shoulder construction.) width for the full length of the discretion.

project.

Cold In-Place Recycle (CIR) Sampling Aggregate KT-1 2 per mile (1.5 km). k 1 per day.

Sec. 604 (Sieve according to

specification.)

Percent Retained on the #200 KT-4 2 per day.

(75 µm) Sieve by Dry Screen

Field Moisture Tests KT-32 Minimum 1 per day. Use

(0.1 g or 0.01% of mass) nuclear gauge w/o

correction. (Test before

overlay or seal.)

Field Density KT-32 3 locations per width laid

(Gmb = 0.001; 0.1 lb/ft3 [1 kg/m3] or per mile (1.5 km) per lift.

0.1% of Gmm) Minimum of 1 per day.

Asphalt Material (Emulsion) Sampling KT-26 b 1 sample for every 3 loads. b 1 per project.

e

Lime Slurry Percent Solids of Lime Slurry KT-62 1 at beginning of project then k

1 at each mix design change.

Page 8/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 600 (continued)

MICROSURFACING Sieve Analysis of Aggregate KT-2 c 1 per 250 TONS (250 Mg) for 1 per day.

Sec. 606 & 1109 (1%, 0.1% for No. 200 [75 µm] each individual aggregate.

sieve, of mass)

Moisture Tests KT-11 3 per day. 1 per day.

Emulsified Asphalt KT-26 1 per project. k

Sampling Cement KT-29 1 per project. k

Percent Crushed Particles in KT-31 1 per project. k

Crushed Gravel

(0.1%)

Uncompacted Void Content of Fine KT-50 1 per project. k

Aggregate

(0.1%)

Sand Equivalent Test KT-55 1 per project. k

(1%)

ULTRATHIN BONDED ASPHALT SURFACE (UBAS)

Sec. 613 & 1103

Individual Aggregates Sieve Analysis of Aggregate KT-2 c 1 per 1000 TONS (1000 Mg) 1 per project per individual

(1%, 0.1% for No. 200 [75 µm] for each individual aggregate. aggregate.

sieve, of mass)

Clay Lumps and Friable Particles in KT-7 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Shale or Shale-Like Materials in KT-8 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Sticks in Aggregate KT-35 c As required.

(0.01% of mass) h

Uncompacted Void Content of Fine KT-50 l 1 on the first lot then 1 per 1 per project.

Aggregate 10,000 TONS (10,000 Mg) of

(0.1%) crushed gravel.

Uncompacted Void Content of AASHTO l 1 on the first lot then 1 per 1 per project.

Coarse Aggregate T 326 10,000 TONS (10,000 Mg) of

(0.01%) (Method crushed gravel.

A)

Page 9/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 600 (continued)

ULTRATHIN BONDED ASPHALT SURFACE (UBAS) (continued)

Sec. 613 & 1103

Mineral Filler Supplement Sieve Analysis of Aggregate KT-2 c 1 per 250 TONS (250 Mg). 1 per project.

(1%, 0.1% for No. 200 [75 µm] h

sieve, of mass)

Mineral Filler Supplement Plasticity Tests KT-10 c 1 per 250 TONS (250 Mg). 1 per project.

(continued) (0.01 g or 0.1% of mass) h

Combined Aggregate Coarse Aggregate Angularity KT-31 c 1 per lot 1 per week or 1 per 10,000

(0.1% of mass) g TONS (10,000 Mg).

Uncompacted Void Content of Fine KT-50 1 on the first lot then 1 per 1 per project.

Aggregate 10,000 TONS (10,000 Mg) of

(0.1%) combined aggregate.

Sand Equivalent Test KT-55 f 1 per lot. 1 per project.

(1%)

Moisture Tests KT-11 1 per 2000 TONS (200 Mg) 1 per project.

(0.1 g or 0.01% of mass) of combined mix.

Asphalt Material Sampling KT-26 b 1 sample for every 3 loads. 1 per project.

e (CMS = VER)

HMA Mixtures Percent Moisture in Mixture KT-11 1 per 2000 TONS (200 Mg) 1 per project.

(0.1 g or 0.01% of mass) of combined mix.

Theoretical Maximum Specific KT-39 n 1 per sublot. 1 per lot.

Gravity (Rice)

(Gmm = 0.001)

Binder Content (by ignition) KT-57 1 per sublot. j 1 per lot.

(0.1 g or 0.01% of mass)

Mix Gradation (after ignition) KT-34 1 per sublot. 1 per lot.

(0.1 g or 0.01% of mass)

Page 10/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CONSTRUCTION OR TESTS REQUIRED TEST CODE QUALITY CONTROL BY CODE VERIFICATION BY

MATERIAL TYPE (RECORDED TO) METHOD CONTRACTOR KDOT

2007 Std. Spec. (SS 2007)

DIVISION 700

MULTI-LAYER POLYMER Surface Preparation and Adhesion KT-70 Test by contractor, KDOT to

CONCRETE OVERLAY (10 lbf [10 N] or 10 psi [0.1 MPa]) witness. Once every span or

Sec. 729 & 1705 every 300 yd2 [300 m2] of

prepared deck surface,

whichever is smaller.

Polymer Binder Infrared Spectroscopy Sample 1/2 pint of each

component lot and send to

MRC 1 week prior to

placement.

DIVISION 1100

SURFACE OR RESURFACING Sieve Analysis of Aggregate KT-2 c 1 per 500 TONS (500 Mg). 1 per 2500 TONS (2500

AGGREGATE (1%, 0.1% for No. 200 [75 µm] Mg).

Sec. 1111 & 1112 sieve, of mass)

Material Passing the No. 200 (75 KT-3 c 1 per 500 TONS (500 Mg). 1 per 2500 TONS (2500

µm) Sieve by the Wash Method Mg).

(0.1% of mass)

Clay Lumps and Friable Particles in KT-7 c As required.

Aggregate h

(0.1 g or 0.01% of mass)

Moisture Tests KT-11 1 per 500 TONS (500 Mg). 1 per 2500 TONS (2500

(0.1 g or 0.01% of mass) Mg).

Sticks in Aggregate KT-35 c As required.

(0.01% of mass) h

DIVISION 2000

PORTLAND CEMENT, KT-29 b Cement

BLENDED HYDRAULIC See section 5.7.9 of this

CEMENT, FLY ASH FOR USE manual, and the Standard

IN CONCRETE specifications.

Sec. 2001 & 2004

Fly Ash

Minimum 1 semi-annual

sample per source per

concrete project.

Page 11/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CODE INSTRUCTION

a The contractor may reduce the sampling and testing frequency to one test per 1,000 yd3 (1,000 m3) provided the first two tests each day show compliance

with the specification requirements.

b Sampled by the district field personnel, or contractor and tested at KDOT Central Materials Laboratory (Materials and Research Center).

c The aggregate producer’s tests may be used for quality control purposes if the tests were performed by an appropriately certified technician. In such

cases, the contractor shall perform testing as necessary to determine the degrading effects of hauling and stockpiling on the individual aggregates. For

CTB, the minimum testing frequency shall be every 4,000 Tons (4,000 Mg).

d The first Modified Lottman test will cover the first week or 10,000 Tons (10,000 Mg) of production.

e Specification compliance will be determined on a producer basis not on a project basis. Producer and product testing frequency is maintained in CMS.

Start with one in three loads, then generally, the sampling frequency will be reduced to one sample per six loads and then per twelve loads if test results

determined by the Department show satisfactory compliance of the material with the specifications.

f Determine the Sand Equivalent (SE) value on the combined virgin aggregates on the first lot of production and then frequency may be reduced to one test

per week provided the SE value exceeds the minimum specified value by five (5) percentage points. The frequency may be reduced to one test per two

weeks provided the SE value exceeds the minimum specified value by 25 percentage points. When any test (including verification and assurance) shows

the SE value to be less than five (5) percentage points above the specified minimum value then the testing frequency will revert to one per lot until two

consecutive tests exceed the minimum specified value by five (5) percentage points.

g All aggregate types except siliceous gravels and steel slag will be considered to have at least two crushed faces on 100% of the aggregate particles. For

mixes containing crushed or uncrushed siliceous gravels or steel slag, determine the Coarse Aggregate Angularity (CAA) value of the combined virgin

aggregate of the first lot of production. After three consecutive passing tests, the frequency may be reduced to one per three lots or one per week. If any

of the quality control or verification tests fail, the frequency will revert to one per lot until the above criteria for reduced frequency is met.

h If during the determination of individual aggregate gradation, clay lumps and soft or friable particles, shale or shale-like particles, or sticks are found then

perform KT-7, KT-8, and KT-35, respectively, at such frequencies as jointly deemed necessary by the Contractor and the District Materials Engineer.

i For small lots [lots with less than 1,000 tons (1,000 Mg)], the number of tests may be reduced (see special provision).

j Provide access to Contractor owned forced air ignition furnace, ovens, and Superpave Gyratory compactor for the Sate Inspector to perform verification

tests.

Page 13/13 Appendix B 04/12

SAMPLING AND TESTING FREQUENCY CHART

QUALITY CONTROL/QUALITY ASSURANCE SPECIFICATIONS

CODE INSTRUCTION

k Engineer’s discretion. Frequency of tests shall be agreed upon by the Field Engineer and the District Materials Engineer. Frequency will be governed by

field conditions. Written documentation of the agreed upon testing frequency shall be included in the project records.

l This testing of crushed gravel is only needed to confirm that 35% or less natural sand is used in the traveled way mixes. If 95% or more of crushed gravel

is retained on the #8 (2.65 mm) sieve, then the material must have a minimum Uncompacted Void Content of Coarse Aggregate (UVA) value of 45 when

tested in accordance with AASHTO T 326, Method A. Testing will be the same frequency as KT-50. Do not use material with a UVA value less than 45.

m The contractor may reduce the sampling and testing frequency to one test per 1,000 Tons (1,000 Mg) provided the first two tests each day show

compliance with the specification requirements.

n If more than one test is performed on the sample, use the average value.

GENERAL NOTES

•

All sampling and testing frequencies listed are minimums. Additional quality control, verification, and assurance tests will be performed, when necessary, to

provide effective control the work. When any quality control test result fails to comply with the specification requirements then the next sublot of production

after obtaining the failing test results will be sampled and tested, regardless of any lesser frequency specified in this appendix.

• For the Construction Management System (CMS), Acceptance Sampling and Tests have been divided into two sections. Items called “ACC” will be

Acceptance Tests and will have a quantity assigned. Items called “ACI” will be Acceptance Information Tests and they will normally have a quantity

assigned, but not for payment. “ACC” tests make the assignment of tested materials to the contract or mix plant. “Type Insp” must = “ACC” when

assignment of a pay quantity is being made. “ACI” when recording test values for additional acceptance information.

• For QUALITY CONTROL BY CONTRACTOR, CMS uses ACI or ACC unless otherwise noted. For VERIFICATION BY KDOT, CMS uses VER unless

otherwise noted. For INDEPENDENT ASSURANCE BY KDOT, CMS uses ASW (Assurance Witness), ASR (Assurance Replicate), and ASP (Assurance

Split) unless otherwise noted (see section 5.4.2 of this manual).

• For a better explanation of metric (SI) units, see section 5.9, “Sampling and Test Methods Forward”, of this manual.

• All samples will be taken from the place of incorporation into the project unless otherwise noted.

Page 13/13 Appendix B 04/12

Das könnte Ihnen auch gefallen

- GRI-GM30 Specification Coated Tape Polymeric BarriersDokument28 SeitenGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовNoch keine Bewertungen

- TDS VDSLDokument1 SeiteTDS VDSLAbdel Baziir EkongNoch keine Bewertungen

- For - Geocells Made From HDPE Strips: GTI-GS15 SpecificationDokument33 SeitenFor - Geocells Made From HDPE Strips: GTI-GS15 SpecificationГригорий ЛевашовNoch keine Bewertungen

- Technical Data Sheet Eurobent Nt-35 (Zakładka)Dokument1 SeiteTechnical Data Sheet Eurobent Nt-35 (Zakładka)Dannyamil AriasNoch keine Bewertungen

- GRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesDokument27 SeitenGRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesГригорий ЛевашовNoch keine Bewertungen

- Everything You Need to Know About Grooved Rubber Sole Plates (GRSPDokument30 SeitenEverything You Need to Know About Grooved Rubber Sole Plates (GRSPChaitanyaNoch keine Bewertungen

- Sampling and Testing Requirements: Description RemarksDokument2 SeitenSampling and Testing Requirements: Description Remarksarvin jay santarinNoch keine Bewertungen

- Qualitex Lab Tests MaterialsDokument15 SeitenQualitex Lab Tests MaterialsRajanikant SuryawanshiNoch keine Bewertungen

- Summary of Quality Control Tests Required For BridgesDokument4 SeitenSummary of Quality Control Tests Required For BridgesJakka LakshmikanthNoch keine Bewertungen

- Specifications For Geotextiles in India: by R. P. Indoria 19 November 2010Dokument42 SeitenSpecifications For Geotextiles in India: by R. P. Indoria 19 November 2010Sandeep MeruguNoch keine Bewertungen

- An Experimental Investigation On HPC Using Basalt Rock FiberDokument19 SeitenAn Experimental Investigation On HPC Using Basalt Rock FiberIJRASETPublicationsNoch keine Bewertungen

- CC - GCCM Data SheetDokument2 SeitenCC - GCCM Data SheetLarizza TesicoNoch keine Bewertungen

- SCC properties with bagasse ashDokument27 SeitenSCC properties with bagasse ashHegdeVenugopalNoch keine Bewertungen

- Hand Book On Road PDFDokument56 SeitenHand Book On Road PDFrajan sharma100% (1)

- Test Frequency: (As Per Mort&H 5Th Revision)Dokument6 SeitenTest Frequency: (As Per Mort&H 5Th Revision)jitendra dixitNoch keine Bewertungen

- HD Smooth Geomembrane Technical Data SheetDokument1 SeiteHD Smooth Geomembrane Technical Data SheetAndreas Erdian WijayaNoch keine Bewertungen

- Frequency of Tests of Various Items Up To May2018Dokument1 SeiteFrequency of Tests of Various Items Up To May2018Prasanta ParidaNoch keine Bewertungen

- Sub-Annexure B8 ASPHALT (Specification 245)Dokument1 SeiteSub-Annexure B8 ASPHALT (Specification 245)Tanmay VegadNoch keine Bewertungen

- Footing - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500Dokument3 SeitenFooting - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500parathasiNoch keine Bewertungen

- Computation of Dead Load and Live LoadDokument4 SeitenComputation of Dead Load and Live LoadPetal SarkarNoch keine Bewertungen

- ACI 211.1 Method Final 2Dokument21 SeitenACI 211.1 Method Final 2Yemane KebedeNoch keine Bewertungen

- ET-3000.00-6651-962-PGT-001: SpecificationDokument15 SeitenET-3000.00-6651-962-PGT-001: SpecificationArildo Chaves de AndradeNoch keine Bewertungen

- Form - Trial Mix Report: Technical Marketing Department CustomerDokument6 SeitenForm - Trial Mix Report: Technical Marketing Department CustomerRedi PascaNoch keine Bewertungen

- Effect of Metakaolin on Concrete Strength and Durability Using Treated Waste WaterDokument11 SeitenEffect of Metakaolin on Concrete Strength and Durability Using Treated Waste WaterIsrael VenkatNoch keine Bewertungen

- GRI-GM13 Specification High Density Polyethylene GeomembranesDokument24 SeitenGRI-GM13 Specification High Density Polyethylene GeomembranesFauzia Rizky0% (1)

- °øÀÎ ÃÇè â°üÀÎÁ (¿ ®)Dokument130 Seiten°øÀÎ ÃÇè â°üÀÎÁ (¿ ®)davidNoch keine Bewertungen

- 4-Loss Angeles Abrasion TestDokument4 Seiten4-Loss Angeles Abrasion Testisraksiam311Noch keine Bewertungen

- Astm A500 Pipe Tolerances (Round Tubing)Dokument1 SeiteAstm A500 Pipe Tolerances (Round Tubing)Anwarul AfrojNoch keine Bewertungen

- Tech Data Sheet Smooth GeomembraneDokument1 SeiteTech Data Sheet Smooth GeomembraneNasasira DerrickNoch keine Bewertungen

- Comminution Ore TestingDokument35 SeitenComminution Ore TestingHarrison Antonio Mira NiloNoch keine Bewertungen

- Qlassic Vs JKRDokument15 SeitenQlassic Vs JKRFrederick TanNoch keine Bewertungen

- HDPE Smooth Geomembrane Technical Data SheetDokument1 SeiteHDPE Smooth Geomembrane Technical Data SheetAgun GunawanNoch keine Bewertungen

- Hdpe LinerDokument15 SeitenHdpe LinerDaniel MartinezNoch keine Bewertungen

- Primacore MW 71Dokument2 SeitenPrimacore MW 71rjan7peNoch keine Bewertungen

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDokument2 SeitenSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNoch keine Bewertungen

- Strenx 700MC Plus: General Product DescriptionDokument1 SeiteStrenx 700MC Plus: General Product DescriptionMircea FloreaNoch keine Bewertungen

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDokument2 SeitenData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoNoch keine Bewertungen

- RESIDENTIAL STRUCTURE DESIGN USING STAADDokument36 SeitenRESIDENTIAL STRUCTURE DESIGN USING STAADFaye M. LarioqueNoch keine Bewertungen

- DPP AGRU Geosinteticos DataSheet-SmoothLiner-HighDensityDokument1 SeiteDPP AGRU Geosinteticos DataSheet-SmoothLiner-HighDensityArquimedes Juarez SaavedraNoch keine Bewertungen

- Cement Aggregate Test FrequencyDokument2 SeitenCement Aggregate Test FrequencyEmlin RajNoch keine Bewertungen

- 0.8mm THK Pennar Metal Deck PropertiesDokument4 Seiten0.8mm THK Pennar Metal Deck PropertiesSathwik kattaNoch keine Bewertungen

- CTSB - NH - 106 Ilfs - R1Dokument20 SeitenCTSB - NH - 106 Ilfs - R1Bidur JhaNoch keine Bewertungen

- Performace Evaluation of Slag Aggregates As Construction MaterialDokument49 SeitenPerformace Evaluation of Slag Aggregates As Construction MaterialMd Ashiqur RahmanNoch keine Bewertungen

- MINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSDokument17 SeitenMINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSAris TesoroNoch keine Bewertungen

- Achieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymerDokument2 SeitenAchieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymermosesNoch keine Bewertungen

- CEFOR™ 1221P: Linear Low Density Polyethylene ResinDokument3 SeitenCEFOR™ 1221P: Linear Low Density Polyethylene ResincuppycuppycupNoch keine Bewertungen

- SRI-TL-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22144R0Dokument8 SeitenSRI-TL-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22144R0Dito NarendraNoch keine Bewertungen

- Miratech GT500: Technical Data SheetDokument3 SeitenMiratech GT500: Technical Data SheetNicolás CanoNoch keine Bewertungen

- Metode Underpass Dan BoxCulvert R1Dokument16 SeitenMetode Underpass Dan BoxCulvert R1Muhamad HaikalNoch keine Bewertungen

- Design For Trial Mix 5000psiDokument1 SeiteDesign For Trial Mix 5000psiMarielNoch keine Bewertungen

- BLH t3p1Dokument3 SeitenBLH t3p1Omar GermanNoch keine Bewertungen

- Detailing of Steel Structure: SI CtureDokument36 SeitenDetailing of Steel Structure: SI CtureKosygin LeishangthemNoch keine Bewertungen

- Modern Ultra-Supercritical Boiler and Emission Control TechnologiesDokument18 SeitenModern Ultra-Supercritical Boiler and Emission Control TechnologiesAnonymous KzJcjGCJbNoch keine Bewertungen

- Harris2000 PDFDokument19 SeitenHarris2000 PDFDaniel EscobarNoch keine Bewertungen

- Document From Sonu MatchDokument11 SeitenDocument From Sonu MatchSahabiddin AnsariNoch keine Bewertungen

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDokument2 SeitenData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoNoch keine Bewertungen

- GM 13 PPDokument48 SeitenGM 13 PPbdoeraNoch keine Bewertungen

- A Short Course in Foundation EngineeringVon EverandA Short Course in Foundation EngineeringBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingVon EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNoch keine Bewertungen

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingVon EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNoch keine Bewertungen

- Soil Sampling Form 01Dokument1 SeiteSoil Sampling Form 01Mohamed ElfawalNoch keine Bewertungen

- Log of Boring: Project: Poject Location: Project NumberDokument3 SeitenLog of Boring: Project: Poject Location: Project NumberMohamed ElfawalNoch keine Bewertungen

- Radiographic Testing FundamentalsDokument30 SeitenRadiographic Testing FundamentalsMohamed ElfawalNoch keine Bewertungen

- Steel Design - LRFD Bolted Connections TutorialDokument4 SeitenSteel Design - LRFD Bolted Connections TutorialFernando PizarroNoch keine Bewertungen

- Graphite Slide PlateDokument1 SeiteGraphite Slide PlateSuthan SelvarajNoch keine Bewertungen

- 19-DT-4 Carbon Steel Dove Tail Bar GratingsDokument3 Seiten19-DT-4 Carbon Steel Dove Tail Bar GratingsMohamed ElfawalNoch keine Bewertungen

- Soil Sampling Form 01Dokument1 SeiteSoil Sampling Form 01Mohamed ElfawalNoch keine Bewertungen

- Western Builder Guide: Introducing The BCI 6000 1.8Dokument12 SeitenWestern Builder Guide: Introducing The BCI 6000 1.8Mohamed ElfawalNoch keine Bewertungen

- Controlling Costs in Welded FabricationDokument8 SeitenControlling Costs in Welded FabricationMohamed ElfawalNoch keine Bewertungen

- 56c17f15b290e-Space Truss DesignDokument11 Seiten56c17f15b290e-Space Truss DesignMohamed ElfawalNoch keine Bewertungen

- Revit Web PresentationDokument32 SeitenRevit Web PresentationMohamed ElfawalNoch keine Bewertungen

- Cost Effective Design of Space Structures Joints A ReviewDokument5 SeitenCost Effective Design of Space Structures Joints A ReviewMMASNoch keine Bewertungen

- Revit Structure 2011 User GuideDokument1.848 SeitenRevit Structure 2011 User Guidegerabaldismith100% (2)

- High Strength Bolts - KulakDokument21 SeitenHigh Strength Bolts - KulakalmeteckNoch keine Bewertungen

- Advanced Analysis of Steel Frames Using Parallel Processign and Vectorization PDFDokument21 SeitenAdvanced Analysis of Steel Frames Using Parallel Processign and Vectorization PDFMohamed ElfawalNoch keine Bewertungen

- An Innovative Tool For Teaching Structural - 2006Dokument153 SeitenAn Innovative Tool For Teaching Structural - 2006Rodrigo LameirasNoch keine Bewertungen

- Cambering Steel BeamsDokument2 SeitenCambering Steel BeamsFernando PizarroNoch keine Bewertungen

- Dynamic Space Frame Structures Michel BuijsenDokument96 SeitenDynamic Space Frame Structures Michel Buijsenin678100% (4)

- 340Dokument9 Seiten340Mohamed ElfawalNoch keine Bewertungen

- D 4328 97 PDFDokument6 SeitenD 4328 97 PDFMohamed ElfawalNoch keine Bewertungen

- Design of Retaining Wall and Support Systems For Deep Basement Construction - A Malaysian ExperienceDokument28 SeitenDesign of Retaining Wall and Support Systems For Deep Basement Construction - A Malaysian ExperienceChengHian YapNoch keine Bewertungen

- CIDECT Design Guide 9Dokument213 SeitenCIDECT Design Guide 9paris06250% (2)

- 03 BracingDokument72 Seiten03 BracingJune Suriyawanakul100% (1)

- Etabs AutoDrawCladdingoption 071219 0547 9202 PDFDokument4 SeitenEtabs AutoDrawCladdingoption 071219 0547 9202 PDFMohamed ElfawalNoch keine Bewertungen

- Méretezési Táblázatok Design Tables AngolDokument144 SeitenMéretezési Táblázatok Design Tables AngolMohamed ElfawalNoch keine Bewertungen

- 1999 - Anaiysis of Construction Loads On Concrete FormworkDokument210 Seiten1999 - Anaiysis of Construction Loads On Concrete FormworkbobbynguyenNoch keine Bewertungen

- Monitoring Lateral Deflections of A Berthing Structure During DreDokument6 SeitenMonitoring Lateral Deflections of A Berthing Structure During DreMohamed ElfawalNoch keine Bewertungen

- Eurocode 7 Geotechnical Design Worked ExamplesDokument172 SeitenEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- A Review of The Curing Compounds and Application Techniques Used by The Minnesota Department of Transportation For Concrete PavementsDokument35 SeitenA Review of The Curing Compounds and Application Techniques Used by The Minnesota Department of Transportation For Concrete PavementsAbhijeet Gandage100% (1)

- Tutorial ETABSDokument60 SeitenTutorial ETABSValentin VrabieNoch keine Bewertungen

- Sieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForDokument5 SeitenSieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForAkkshay ChadhaNoch keine Bewertungen

- Sieve Analysis TestDokument5 SeitenSieve Analysis TestFarihan MailNoch keine Bewertungen

- Port Sector Rehabilitation Project Sieve AnalysisDokument1 SeitePort Sector Rehabilitation Project Sieve AnalysisYasin BaturNoch keine Bewertungen

- Hindustan Construction (HCC) - Civil Engg. (CE) Summer Industrial Training Report - Free PDF DownloadDokument55 SeitenHindustan Construction (HCC) - Civil Engg. (CE) Summer Industrial Training Report - Free PDF DownloadVinnie SinghNoch keine Bewertungen

- SoilsDokument180 SeitenSoilsAyman KandeelNoch keine Bewertungen

- Test Sieves, Sieve Shakers & Particle Analysis Equipment: AddressDokument66 SeitenTest Sieves, Sieve Shakers & Particle Analysis Equipment: AddressRaúl DoroNoch keine Bewertungen

- BS StandartDokument9 SeitenBS StandartNorma Syahnasa Diah IslamyNoch keine Bewertungen

- (A) Grading: Lesson 4: Aggregates and Its PropertiesDokument3 Seiten(A) Grading: Lesson 4: Aggregates and Its PropertiesDjonraeNarioGalvezNoch keine Bewertungen

- Stabilization of Soil Using AdmixtureDokument17 SeitenStabilization of Soil Using AdmixtureVarun Singh ChandelNoch keine Bewertungen

- Screening and Size ReductionDokument9 SeitenScreening and Size ReductionhanzomoniyanNoch keine Bewertungen

- Design Mix PCC BlockDokument8 SeitenDesign Mix PCC Blockvikrant987Noch keine Bewertungen

- Aggregate For Job-Mixed Portland Cement-Based PlastersDokument3 SeitenAggregate For Job-Mixed Portland Cement-Based PlastersINARQ1979Noch keine Bewertungen

- Geotech Lab Report 1 FinalDokument11 SeitenGeotech Lab Report 1 FinalkennethcyinNoch keine Bewertungen

- C.T. Lab Manual 2019-20 New1Dokument52 SeitenC.T. Lab Manual 2019-20 New1James DNoch keine Bewertungen

- Important Notes: Vigilance & Quality Control Circle, PuneDokument9 SeitenImportant Notes: Vigilance & Quality Control Circle, PuneMGKalyanshetti50% (4)

- Asphalt Practicum ReportDokument92 SeitenAsphalt Practicum ReportSteveNoch keine Bewertungen

- New Bohol Airport PCC Pavement ProjectDokument24 SeitenNew Bohol Airport PCC Pavement ProjectJustine Ralph Zata100% (1)

- Seive Shaker ManualDokument48 SeitenSeive Shaker ManualTayyab BashirNoch keine Bewertungen

- Astm C535-16Dokument3 SeitenAstm C535-16G AzNoch keine Bewertungen

- Physical Properties of Boiler SlagDokument4 SeitenPhysical Properties of Boiler SlagAz AbqariNoch keine Bewertungen

- Bitumen Content TestingDokument9 SeitenBitumen Content TestingjaffnaNoch keine Bewertungen

- Company Profile (16.01.2016) PDFDokument168 SeitenCompany Profile (16.01.2016) PDFAnonymous G6ceYCzwtNoch keine Bewertungen

- Familiarization With The Apparatus and Equipment Used in Materials TestingDokument72 SeitenFamiliarization With The Apparatus and Equipment Used in Materials TestingCHRISTINE JOY AFRICANoch keine Bewertungen

- MSE301-1.3 - Sizing (2spp) - 362513Dokument15 SeitenMSE301-1.3 - Sizing (2spp) - 362513Moises HenriquesNoch keine Bewertungen

- Experiment No 2Dokument10 SeitenExperiment No 2Kirby CamposanoNoch keine Bewertungen

- Adobe Scan 03 Dec 2021Dokument4 SeitenAdobe Scan 03 Dec 2021RAJKUMAR CHATTERJEE. (RAJA.)Noch keine Bewertungen

- Aggregates - SlideshareDokument44 SeitenAggregates - SlideshareHugoMarinGoNoch keine Bewertungen

- Hydrometer Analysis Lab Report: Soil Particle Size DistributionDokument7 SeitenHydrometer Analysis Lab Report: Soil Particle Size DistributiondexNoch keine Bewertungen

- Company Profile Abu Dhabi 2017Dokument145 SeitenCompany Profile Abu Dhabi 2017Anonymous G6ceYCzwtNoch keine Bewertungen