Beruflich Dokumente

Kultur Dokumente

Momentive

Hochgeladen von

frox123Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Momentive

Hochgeladen von

frox123Copyright:

Verfügbare Formate

Starting Formulation 1010

Re-Issued June 2007

Gloss White Enamel

EPON™ Resin 1001-Y-75 / EPIKURE™ Curing Agent 3115-E-73

Formula Material Supplier Pounds Gallons

Part A

TI-PURE® R960 HG Du Pont Company 250.0 7.55

Bentone 38 Thixotrop Elementis Specialties Inc. 14.0 0.91

Imperial Anti-Flooding (IAF) RLM Industries, Inc. 4.0 0.18

Compound X-2280

EPON Resin 1001-Y-75 Momentive Specialty 305.0 33.00

Chemicals

Beetle U-216-8 Urea Cytec Industries 17.0 2.00

Formaldehyde Resin

2-Propoxyethanol 23.3 3.00

High Speed Disperse to Grind Hegman 7-8

Cyclohexanone 63.0 8.00

Diacetone Alcohol Shell Chemical Company 35.2 4.50

n-Butyl Alcohol 5

Shell Chemical Company 50.8 7.53

Total Part A 762.3 66.67

Part B

EPIKURE Curing Agent 3115- Momentive Specialty 168.0 21.90

E-73 Chemicals

Xylene 14.4 2.00

Ethyl Benzene 25.4 3.50

Isopropyl Alcohol Shell Chemical Company 39.0 5.93

Total Part B 246.8 33.33

Total Part A & B 1,009.1 100.00

HCD-1188 (Rev. 1/9/2014 8:31:07 AM) Page 1 of 4

SF 1010 Gloss White Enamel 1001 3115

Mixing

Instructions Pounds Gallons

Part A 762.3 66.67

Part B 246.8 33.33

Part A + B 1,009.1 100.00

Resin Composition

Units Value

Part A % Solids 65

Part B % Solids 35

Part A + B % Solids 100

Disperse the pigments in a suitable portion of the vehicle using high speed

dispersing equipment or a sand mill. Let down the pigment dispersion with the

remaining vehicle. Charge the two ingredients of the curing agent component to a

separate suitable container and mix thoroughly. Package the base component and

the curing agent component separately to be combined just prior to use.

Typical Handling Slowly combine three parts by volume of base component with one part by volume

Properties of curing agent component and mix thoroughly. Allow the mixed formulation to

“sweat in” for one hour. The system is then ready for spray application. Because of

the limited pot life of the mixed formulation, do not mix more material than can be

used in a working day. For application of this system in confined or poorly ventilated

areas, we recommend the use of a fresh air-supplied hood and other protective

clothing sufficient to cover the applicator’s entire body.

Typical Table 1 / Formulation Properties

Formulation

Properties

Units Value

Mix ratio Part A : Part B By volume 2:1

By weight 3.09:1.0

Nonvolatile content by weight % 47.6

Weight per gallon lb./gal. 10.09

Total weight solids % 61.5

Pigment volume concentration (PVC) % 17.9

Volatile Organic Compound (VOC) lb/gal 3.88

g/L 466

Viscosity @ 25°C

Part A KU 74

Part B KU 60

HCD-1188 (Rev. 1/9/2014 8:31:07 AM) Page 2 of 4

SF 1010 Gloss White Enamel 1001 3115

Part A & B KU 71

Storage Recommendations regarding storage conditions can be obtained by visiting our

web site at www.momentive.com

General Information

These are starting formulations and are not proven in the user’s particular application but are simply meant

to demonstrate the efficacy of the products and to assist in the development of the user’s own formulation. It

is the user’s responsibility to fully-test and qualify the formulation, along with the ingredients, methods,

applications or equipment identified herein (“Information”), by the user’s knowledgeable formulator or

scientist, and to determine the appropriate use conditions and legal restrictions, prior to use of any

Information.

Safety, Storage & Handling

Please refer to the MSDS for the most current Safety and Handling information.

Exposure to these materials should be minimized and avoided, if feasible, through the observance of proper

precautions, use of appropriate engineering controls and proper personal protective clothing and

equipment, and adherence to proper handling procedures. None of these materials should be used,

stored, or transported until the handling precautions and recommendations as stated in the

Material Safety Data Sheet (MSDS) for these and all other products being used are understood by

all persons who will work with them. Questions and requests for information on Momentive Specialty

Chemicals, Inc. ("Momentive") products should be directed to your Momentive sales representative, or the

nearest Momentive sales office. Information and MSDSs on non-Momentive products should be obtained

from the respective manufacturer.

Contact Information

For product prices, availability, or order placement, call our toll-free customer service number at:

1-877-859-2800

For literature and technical assistance, visit our website at: www.momentive.com

HCD-1188 (Rev. 1/9/2014 8:31:07 AM) Page 3 of 4

® and ™ Licensed trademarks of Momentive Specialty Chemicals

Inc.::LicensedTrademarkDisclaimer::

DISCLAIMER

The information provided herein was believed by Momentive Specialty Chemicals Inc. (“Momentive”) to be

accurate at the time of preparation or prepared from sources believed to be reliable, but it is the

responsibility of the user to investigate and understand other pertinent sources of information, to comply with

all laws and procedures applicable to the safe handling and use of the product and to determine the

suitability of the product for its intended use. All products supplied by Momentive are subject to Momentive’s

terms and conditions of sale. MOMENTIVE MAKES NO WARRANTY, EXPRESS OR IMPLIED,

CONCERNING THE PRODUCT OR THE MERCHANTABILITY OR FITNESS THEREOF FOR ANY

PURPOSE OR CONCERNING THE ACCURACY OF ANY INFORMATION PROVIDED BY

MOMENTIVE, except that the product shall conform to Momentive’s specifications. Nothing contained

herein constitutes an offer for the sale of any product.

HSF-1188- (Rev.1/9/2014 8:31:07 AM)

Das könnte Ihnen auch gefallen

- ETERSOL 6512AF-1 styrene-acrylic emulsion polymer for interior exterior paintsDokument3 SeitenETERSOL 6512AF-1 styrene-acrylic emulsion polymer for interior exterior paintsHelmi Rizki Hayati100% (1)

- 2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Dokument2 Seiten2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Oswaldo Manuel Ramirez MarinNoch keine Bewertungen

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDokument24 SeitenUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunNoch keine Bewertungen

- NipsilR Precipitated Silica Grades for Paints, Papers and MoreDokument16 SeitenNipsilR Precipitated Silica Grades for Paints, Papers and MoreDewiNoch keine Bewertungen

- Can Coating Formulations (Sheet 1 To 4)Dokument3 SeitenCan Coating Formulations (Sheet 1 To 4)No NameNoch keine Bewertungen

- Coating Resins Technical Data SheetDokument2 SeitenCoating Resins Technical Data SheetWALTER KLISSMANNoch keine Bewertungen

- Fdocuments - in - Edaplan Metolat Guide Formulatio PDFDokument6 SeitenFdocuments - in - Edaplan Metolat Guide Formulatio PDFNoor HafidlullahNoch keine Bewertungen

- Tds Eterac 73626-S-70 (En)Dokument1 SeiteTds Eterac 73626-S-70 (En)Liliana Higuera NítolaNoch keine Bewertungen

- Ucar Latex 379G: The Best Just Got BetterDokument12 SeitenUcar Latex 379G: The Best Just Got BetterQuimicosgenericosgaffaro GaffaroNoch keine Bewertungen

- 24 391 01 Coatings and Inks Additive Selection GuideDokument16 Seiten24 391 01 Coatings and Inks Additive Selection GuideLong An DoNoch keine Bewertungen

- Jo GradeDokument40 SeitenJo GradeEvonne TanNoch keine Bewertungen

- Evonik-Ancamide 221-X70 - EUDokument5 SeitenEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- Dow-Espesantes ACRYSOLES PDFDokument12 SeitenDow-Espesantes ACRYSOLES PDFAntonio Benitez MendozaNoch keine Bewertungen

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDokument45 SeitenHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006Noch keine Bewertungen

- Painting GuideDokument29 SeitenPainting GuidekenNoch keine Bewertungen

- Starting Formulation: Kronos 2360 Novoperm Yellow 5 GD 71 Novoperm Yellow F2GDokument3 SeitenStarting Formulation: Kronos 2360 Novoperm Yellow 5 GD 71 Novoperm Yellow F2Gهیمن مNoch keine Bewertungen

- Cement, Concrete & Mortar: Product Characteristics Brand NameDokument2 SeitenCement, Concrete & Mortar: Product Characteristics Brand NameAliaksandr PrybauNoch keine Bewertungen

- Thermal Insulating Coating Composition and MethodDokument24 SeitenThermal Insulating Coating Composition and MethodDvs RamaraoNoch keine Bewertungen

- Varnishes and Surface CoatingsDokument11 SeitenVarnishes and Surface CoatingsLong An ĐỗNoch keine Bewertungen

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDokument62 Seiten07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverNoch keine Bewertungen

- Henghe Materials (Catalogue)Dokument45 SeitenHenghe Materials (Catalogue)juanrosonNoch keine Bewertungen

- ETERKYD 50713-S-60 TDS (Non Stick Coating) PDFDokument2 SeitenETERKYD 50713-S-60 TDS (Non Stick Coating) PDFImran AhmadNoch keine Bewertungen

- Solvent Evap RateDokument2 SeitenSolvent Evap RateBoro TerakolNoch keine Bewertungen

- Croda How To LoVOCoatDokument6 SeitenCroda How To LoVOCoatkarla100% (1)

- Nuosperse FA 196Dokument2 SeitenNuosperse FA 196Sandra Rojas100% (1)

- FoamStar ST 2412 August 2018 R3 ED2Dokument2 SeitenFoamStar ST 2412 August 2018 R3 ED2APEX SONNoch keine Bewertungen

- Eastman Coatings: Formulating Solutions: Meeting VOC Regulations With CoalescentsDokument4 SeitenEastman Coatings: Formulating Solutions: Meeting VOC Regulations With Coalescentsvijay662Noch keine Bewertungen

- MAINCOTE™ AEH-20 Acrylic-EpoxyDokument5 SeitenMAINCOTE™ AEH-20 Acrylic-EpoxyAPEX SONNoch keine Bewertungen

- TDS 7212 XB 60Dokument3 SeitenTDS 7212 XB 60Shafiq LatifNoch keine Bewertungen

- Angus Amp 95 Latexpaint TdsDokument5 SeitenAngus Amp 95 Latexpaint TdsOng Kok TongNoch keine Bewertungen

- Acronal MB 6476Dokument3 SeitenAcronal MB 6476jose mondacaNoch keine Bewertungen

- Problems of Moisture Contamination in Polyurethane CoatingsDokument2 SeitenProblems of Moisture Contamination in Polyurethane CoatingsJeffrey Bempong100% (1)

- Adekanol Uh-420: Thickener Rheology ModifiersDokument6 SeitenAdekanol Uh-420: Thickener Rheology ModifierszxcvxcvxzcvNoch keine Bewertungen

- Acronal S 400 Ap PDFDokument3 SeitenAcronal S 400 Ap PDFRajuNSanaboinaNoch keine Bewertungen

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDokument5 SeitenSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNoch keine Bewertungen

- Acronal NX 3587: ConstructionDokument3 SeitenAcronal NX 3587: ConstructionRajuNSanaboinaNoch keine Bewertungen

- TDS Celvolit 1326 (SG)Dokument2 SeitenTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Arcosolv TPNBDokument4 SeitenArcosolv TPNBamiller1987Noch keine Bewertungen

- NeoResin DTM Presentation 9-01Dokument22 SeitenNeoResin DTM Presentation 9-01idreesgisNoch keine Bewertungen

- AkzoNobel Paint Eng Tcm54-18194Dokument20 SeitenAkzoNobel Paint Eng Tcm54-18194a2009sNoch keine Bewertungen

- Cong Thuc SonDokument23 SeitenCong Thuc Sonvanhung68Noch keine Bewertungen

- Opaque Polymer HIQUE - as white as the driven snowDokument12 SeitenOpaque Polymer HIQUE - as white as the driven snowLong An ĐỗNoch keine Bewertungen

- Dirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.DDokument31 SeitenDirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.Dichsan hakimNoch keine Bewertungen

- Eterac 7226-1-B-60Dokument2 SeitenEterac 7226-1-B-60Imran Ahmad100% (1)

- Economic Paint RedaDokument1 SeiteEconomic Paint RedaForeverNoch keine Bewertungen

- Soyol Polyol FormulationsDokument3 SeitenSoyol Polyol FormulationsurethanNoch keine Bewertungen

- Technical Data Sheet: Rexin DP 127Dokument1 SeiteTechnical Data Sheet: Rexin DP 127sriatul2006Noch keine Bewertungen

- Acronal Ps 713 APDokument2 SeitenAcronal Ps 713 APCarlos100% (1)

- Falamine Plus Pages LQDokument1 SeiteFalamine Plus Pages LQSatish ChipkarNoch keine Bewertungen

- Cryol 912 60 - TDSDokument2 SeitenCryol 912 60 - TDSShafiq LatifNoch keine Bewertungen

- AdmixtureDokument7 SeitenAdmixturevinay rodeNoch keine Bewertungen

- RosinDokument42 SeitenRosinVingiu Katre100% (1)

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDokument4 SeitenLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaNoch keine Bewertungen

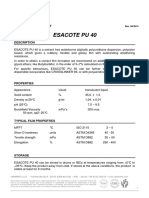

- Esacote Pu 40: Technical Data SheetDokument2 SeitenEsacote Pu 40: Technical Data SheetShambhatiaNoch keine Bewertungen

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachVon EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudBewertung: 5 von 5 Sternen5/5 (1)

- Handbook of Vinyl FormulatingVon EverandHandbook of Vinyl FormulatingRichard F GrossmanBewertung: 3 von 5 Sternen3/5 (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Von EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Noch keine Bewertungen

- Hexion SF 1010Dokument3 SeitenHexion SF 1010JOSEPH ABRAHAM CARDOSO ANGARITANoch keine Bewertungen

- Starting Formulation: SF 1002 Clear Coating EPON™ Resin 8521-MX-60 / EPIKURE™ Curing Agent 3125Dokument2 SeitenStarting Formulation: SF 1002 Clear Coating EPON™ Resin 8521-MX-60 / EPIKURE™ Curing Agent 3125Swapnil AlandNoch keine Bewertungen

- Starting Formulation: SF 2000 Two-Package Low Bake Clear Coating EPON™ Resin 1007F / Beckamine 21-511Dokument2 SeitenStarting Formulation: SF 2000 Two-Package Low Bake Clear Coating EPON™ Resin 1007F / Beckamine 21-511rajesh kothariNoch keine Bewertungen

- DSP-W215 A1 Manual v1.00 (DI)Dokument31 SeitenDSP-W215 A1 Manual v1.00 (DI)frox123Noch keine Bewertungen

- Sonoff 4CH PRO Manual GuideDokument19 SeitenSonoff 4CH PRO Manual GuidebetobertatoNoch keine Bewertungen

- Vogel - Boric AcidDokument5 SeitenVogel - Boric Acidfrox123Noch keine Bewertungen

- OrganoCatalisys Angew 2004 PDFDokument38 SeitenOrganoCatalisys Angew 2004 PDFfrox123Noch keine Bewertungen

- Francis Francis x1 Espresso Machine Circuit Board Schematic and Wiring Diagram v2Dokument2 SeitenFrancis Francis x1 Espresso Machine Circuit Board Schematic and Wiring Diagram v2frox123100% (2)

- Installation and User ManualDokument19 SeitenInstallation and User Manualfrox123Noch keine Bewertungen

- Installation and User ManualDokument19 SeitenInstallation and User Manualfrox123Noch keine Bewertungen

- EUBP Guidelines Seedling LogoDokument2 SeitenEUBP Guidelines Seedling Logofrox123Noch keine Bewertungen

- Atac Nuline Cone Plate Viscometer Data Sheet Rev 02Dokument2 SeitenAtac Nuline Cone Plate Viscometer Data Sheet Rev 02frox123Noch keine Bewertungen

- Programmateur Nez de Robinet E-Drip2: 3/4'' 1'' 0,5 - 8 BarsDokument6 SeitenProgrammateur Nez de Robinet E-Drip2: 3/4'' 1'' 0,5 - 8 Barsfrox123Noch keine Bewertungen

- Hammett PersDokument11 SeitenHammett PersdyaharifNoch keine Bewertungen

- Do Moti CZ ManualDokument36 SeitenDo Moti CZ ManualtonitonitoneNoch keine Bewertungen

- Products - Cone and Plate ViscometerDokument1 SeiteProducts - Cone and Plate Viscometerfrox123Noch keine Bewertungen

- Reg en BrakingDokument4 SeitenReg en BrakingSaurabh MishraNoch keine Bewertungen

- 730AL 221 Allnex Crosslinkers Amino Web 0Dokument23 Seiten730AL 221 Allnex Crosslinkers Amino Web 0frox123Noch keine Bewertungen

- Sink and Float Separation ProcessDokument16 SeitenSink and Float Separation Processfrox123Noch keine Bewertungen

- Installation Instructions DLAN 200 AVpro DINrail ComDokument2 SeitenInstallation Instructions DLAN 200 AVpro DINrail Comfrox123Noch keine Bewertungen

- IP Camera CGI - English VersionDokument28 SeitenIP Camera CGI - English Versionfrox123Noch keine Bewertungen

- Petersen Coils Limit Fault Currents in Ungrounded SystemsDokument3 SeitenPetersen Coils Limit Fault Currents in Ungrounded SystemsasotozuazuaNoch keine Bewertungen

- The Williamson AmplifierDokument44 SeitenThe Williamson Amplifierfrox123Noch keine Bewertungen

- Corporate Brochure 2008Dokument33 SeitenCorporate Brochure 2008frox123Noch keine Bewertungen

- Installation Instructions DLAN 200 AVpro DINrail ComDokument2 SeitenInstallation Instructions DLAN 200 AVpro DINrail Comfrox123Noch keine Bewertungen

- Brand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-EnglishDokument6 SeitenBrand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-Englishfrox123Noch keine Bewertungen

- FloorPolisher NLDokument4 SeitenFloorPolisher NLfrox123Noch keine Bewertungen

- IP Camera CGI - English VersionDokument28 SeitenIP Camera CGI - English Versionfrox123Noch keine Bewertungen

- Torlon Processing and PostprocessingDokument26 SeitenTorlon Processing and Postprocessingfrox123Noch keine Bewertungen

- Topcom Outdoor 2010 Manuel MultiDokument152 SeitenTopcom Outdoor 2010 Manuel Multifrox123Noch keine Bewertungen

- Do Moti CZ ManualDokument36 SeitenDo Moti CZ ManualtonitonitoneNoch keine Bewertungen

- Explorations in PersonalityDokument802 SeitenExplorations in Personalitypolz2007100% (8)

- Viscometer Toki Sangyo - TV25 - 35Dokument12 SeitenViscometer Toki Sangyo - TV25 - 35Eddy CurrentNoch keine Bewertungen

- Inu 2216 Idt - Question PaperDokument5 SeitenInu 2216 Idt - Question PaperVinil JainNoch keine Bewertungen

- RRL CapstoneDokument3 SeitenRRL CapstoneMatthew Dane SitoNoch keine Bewertungen

- PERDEV Module 3 (Week 5 and 6)Dokument8 SeitenPERDEV Module 3 (Week 5 and 6)Christy ParinasanNoch keine Bewertungen

- Ten Laws of BoundariesDokument17 SeitenTen Laws of Boundariesstjohn30067% (3)

- DLL - Science 6 - Q2 - W1Dokument6 SeitenDLL - Science 6 - Q2 - W1AnatasukiNoch keine Bewertungen

- Chemical Equation CalculationsDokument6 SeitenChemical Equation CalculationsHera RiegoNoch keine Bewertungen

- (UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Dokument33 Seiten(UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Mohd Ashraf Mohd IsmailNoch keine Bewertungen

- Pdev 111 Week 1 20 1st SemesterDokument123 SeitenPdev 111 Week 1 20 1st SemesterReyn TabelismaNoch keine Bewertungen

- KGMC DirectoryDokument6 SeitenKGMC DirectoryFaisal KhanNoch keine Bewertungen

- HPC ReportDokument316 SeitenHPC ReportmamansgNoch keine Bewertungen

- ClindamycinDokument1 SeiteClindamycinTanalie Dulawan100% (3)

- Cap Dev Dimalinao 2023-2027Dokument4 SeitenCap Dev Dimalinao 2023-2027CA T HeNoch keine Bewertungen

- Traceability Summary - Supplies July 2015 - June 2016: PT Multimas Nabati Asahan, Kuala TanjungDokument4 SeitenTraceability Summary - Supplies July 2015 - June 2016: PT Multimas Nabati Asahan, Kuala TanjungAbu KhalidNoch keine Bewertungen

- Air Regulations CPL Level QuestionsDokument56 SeitenAir Regulations CPL Level QuestionsRahul100% (3)

- HemophiliaDokument62 SeitenHemophiliamuhirwa Samuel100% (1)

- Understand TSGLI BenefitsDokument2 SeitenUnderstand TSGLI BenefitsJoseph LawerenceNoch keine Bewertungen

- Job's Method of Continuous VariationDokument11 SeitenJob's Method of Continuous Variationalex3bkNoch keine Bewertungen

- Filipino Nurses' Deep Faith and Cultural Attitudes in HealthcareDokument41 SeitenFilipino Nurses' Deep Faith and Cultural Attitudes in HealthcareKeziah Marie Chua Santa-AnaNoch keine Bewertungen

- HawkeyeDokument12 SeitenHawkeyeJanardhanam VaratharajanNoch keine Bewertungen

- Original Instruction Manual: Hypro Series 9303Dokument24 SeitenOriginal Instruction Manual: Hypro Series 9303vandoNoch keine Bewertungen

- Commercial Inverter AC Service ManualDokument116 SeitenCommercial Inverter AC Service ManualEdwin JaramilloNoch keine Bewertungen

- New Haven Harbor Connecticut Navigation Improvement Project Integrated Feasibility Report and Environmental Impact StatementDokument23 SeitenNew Haven Harbor Connecticut Navigation Improvement Project Integrated Feasibility Report and Environmental Impact StatementHelen BennettNoch keine Bewertungen

- Compact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetDokument4 SeitenCompact Dehumidifier Fluted Flat Bed - FFB Series: Technical Data SheetLê ĐạtNoch keine Bewertungen

- O-Rings & SealsDokument10 SeitenO-Rings & SealsPartsGopher.comNoch keine Bewertungen

- Butonal NS 175 TDSDokument2 SeitenButonal NS 175 TDSPT. PITAGORAS KONSULTANNoch keine Bewertungen

- Tan Trok Tam Devi Suk TamDokument4 SeitenTan Trok Tam Devi Suk Tamtejasg82Noch keine Bewertungen

- WasdabDokument13 SeitenWasdabfakhri84Noch keine Bewertungen