Beruflich Dokumente

Kultur Dokumente

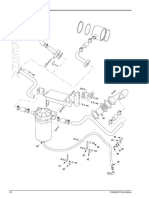

14 - 200 DPG Catalogue New

Hochgeladen von

MOHANOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

14 - 200 DPG Catalogue New

Hochgeladen von

MOHANCopyright:

Verfügbare Formate

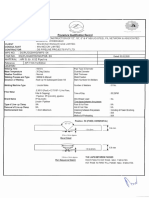

Abhishek Kumar Singh

Instrumentation Engineer

Mail: akditm@gmail.com, aksingh62@outlook.com

Mob: +91-8447253990, 8368410978

Objective:

In quest of a role in the organization that offers me generous opportunities to explore &

outshine in Oil & Gas/Petrochemicals/Fertilizers & Power industry while accomplishing

personal, professional as well as organizational goals.

Synopsis:

Currently I am working on Project (Gas compressor) with Cairn india ltd, Having 4 years

experience in process control instrumentation field. I have principally been involved in

Instrumentation construction projects and maintenance fields of continuous process

plants in onshore. I have actively participated as key member in projects and I am well

conversant with project life cycle from concept to commissioning.

Having knowledge of Natural Gas Sweetening & Dehydration Unit and Field

Instrumentation, Process safety systems. Familiar with Work permit systems, Job Saftey

Analysis, Fatal risks, Fire & gas safety systems.

Process and Operation knowledge of Gas Processing Plant, equipment Installation and

calibration.

Knowledge of Smart plant instrumentation (INTOOLS) and AutoCAD 3D

PROFESSIONAL EXPERIENCE:

Working with Deep Energy Ltd as Project engineer (Instrumentation)

Duration: Feb 2017 to till date

Current Project : Gas compressor (AGI-12)

Client: Cairn india ltd

Location: Radhanpur, Patan

Duration: 30 june 2017 to till date

Project : Gas compressor-3 (Viramgam terminal)

Client: Cairn india ltd

Location: Viramgam, Ahemdabad

Duration: 16 Apr 2017 to 9 june 2017

Job Responsibilities:

1) ITR activities

a) Cable tray installation under access floor

b) MCT frame installation

c) Laying of internal earthing, power, signal and field cables as per schedule

d) Installation of Cabinets and consoles

e) Testing& Termination of all cables

f) instrument pre-installation and calibration

g) Control valve pre-installation

h) Trip and Alarm checks

i) junction Boxes Etc.

2) Preparing materials according to drawing

3) Installation of cable tray supports and tray routing as per given and typical drawing

4) Stub up installation as per given and typical drawing

5) Jb’s installation as per given and typical drawing

6) Installation of field instruments as per P&I drawings

7) Involved in preparing for cable cross section

Duration: Aug 2013 to Feb 2017

Working with Focus Energy Ltd as Instrumentation Engineer

Industry: Oil & Gas Exploration & Production, Energy

Location: block-RJ-ON/06, Jaisalmer (Thar Desert), Rajasthan

Core Competencies:

Installation, commissioning and construction

Field Instrumentation/Maintenance

Planning & Supervising

Analytical Instruments & Gas Chromatograph

Troubleshooting

Calibration of Instruments

Job Responsibilities:

Scheduled maintenance, calibration of transmitters, overhauling of transmitters, final

control elements, pressure switches, solenoid valves, level trolls, and remote operated

valves.

Ultrasonic level sensor, Proximity sensor

Well aware about configuration / calibration of SMART family transmitters using HART

field calibrator.

Loop wiring/Control valve/transmitters trouble shooting.

Compilation of documentation, handover reports, making fixtures for routine

maintenance and joint calibration with the vendor.

Operation and maintenance of Moisture analyzer, H2S analyzer and Hydrocarbon dew

point analyzer.

Gas chromatograph (Daniel model-500), ultrasonic flow meter(Daniel measurement

solution)

Preparation of loop wiring and Hook-up drawing on AutoCAD & INTOOLS

Preparation of cable/JB schedule, instrument index,I/O list, loop wiring, Data/ Spec.

Sheet, Sizing calculation of control valve and orifice plate on SPI INTOOL

Interfacing the field instruments with DCS, Loop checking of analog signals.

Routine calibration and maintenance of instruments & repair of pressure gauge.

Operation and monitoring of Thermic fluid heater (Isotex) Process: Therminol55 oil

heating from gas fuel burner

Erection & commissioning

Commissioning of instrumentation and control system for natural gas gathering &

processing station capacity- 65MMSCFD.

Installation and commissioning of instruments for TEG unit (GAS DEHYDRATION UNIT)

Mounting & commissioning of field Instruments as-

- Control valve (Dynaflow, Schubert & salzer, Norriseal and Mallard)

- Positioner (Siemens, ABB, Norriseal) and Air filter regulator(Bell gas, Placka,

Norriseal)

- Pressure, Temperature, Level and flow transmitter (ABB, Rosemount, Yokogawa)

- RTD(PT100), PT1000, Pressure gauge, Temperature gauge

Testing and continuity checking and integration with automation.

Instruments cabling with junction boxes, processor panel and metering panel, from

Panel end to junction boxes and junction boxes to field instruments.

Natural Gas booster compressor having capacity 7MMSCFD.

Duration: From june 2012 to Aug 2013

Working with KEE PHARMA Ltd as Maintenance Engineer

Industry: Bio-medical instrumentation

Location: Naraina industrial area, New Delhi

Job Responsibilities:

Experience in maintenance of bio-chemistry analyzer(fully-automatic) specially in “

Logotech“, Italy

Skilled in understanding the working of machine and good observation skill for problem

identification

Good knowledge of semi-auto analyzer and it’s application apart

One year experience in maintenance of hematology analyzer(Blood cell counter) ( 3-

part )

Industrial Training:

Bharat electronic Limited, Ghaziabad, Uttar Pradesh

P.G diploma in industrial automation

EDUCATION:

Bachelor of Technology in Electronic and communication Engineering from M.D.

University

12th from Govt. Sarvodaya bal vidyalay ,Delhi

10th from St. Thomas school, Ghaziabad, Uttar pradesh

PERSONAL DETAILS:

Father’s Name : Virendra singh

Date of Birth: 06 Feb 1990

Language Know : English, Hindi

Nationality: Indian

Passport no. : P0355337 (Valid up to 2026)

Permanent Address: Vill- Dubhar ,P.O- Dubhar, Dist- Ballia, U.P

Notice period: 21 Days

I solemnly declare that the all statements made by me in this application are true, complete and

correct to the best of my knowledge and belief.

(Abhishek Kumar Singh) Sign ……………..

Das könnte Ihnen auch gefallen

- A.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveDokument5 SeitenA.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveAkoKhalediNoch keine Bewertungen

- Instrumentation Engineer Resume.Dokument4 SeitenInstrumentation Engineer Resume.Arun Kumar100% (1)

- Control & InstrumentationDokument3 SeitenControl & InstrumentationmkoelrealNoch keine Bewertungen

- Mir Saidul Islam: Career ProfileDokument3 SeitenMir Saidul Islam: Career ProfileVivek PandeyNoch keine Bewertungen

- Lead Mechanical EngineerDokument5 SeitenLead Mechanical EngineervcharlesNoch keine Bewertungen

- Rim and Face Shaft AlignmentDokument38 SeitenRim and Face Shaft AlignmentJaime Berry100% (2)

- M.S.Kirubhananth: Senior Instrument TechnicianDokument4 SeitenM.S.Kirubhananth: Senior Instrument TechnicianDonNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Design Calculations MalidduwaDokument72 SeitenDesign Calculations MalidduwaUmesg100% (1)

- Heat Rate EpriDokument48 SeitenHeat Rate EpritbfakhrimNoch keine Bewertungen

- CVDokument5 SeitenCVFenil ShingalaNoch keine Bewertungen

- SDE Instrumentation 2012Dokument5 SeitenSDE Instrumentation 2012Mohammed Makeen0% (1)

- Cross Head Removal For Man B WDokument13 SeitenCross Head Removal For Man B WMOHAN100% (1)

- Force Feed Lubricator SystemDokument34 SeitenForce Feed Lubricator SystemMOHANNoch keine Bewertungen

- Mis in WalmartDokument36 SeitenMis in WalmartNupur Vashishta93% (14)

- Resume Ravi Chandra ProjectDokument2 SeitenResume Ravi Chandra ProjectKrantikumar KolliNoch keine Bewertungen

- Curriculam VitaeDokument5 SeitenCurriculam VitaeGuru MaheshNoch keine Bewertungen

- Town of Riverhead Update On COVID-19 PDFDokument16 SeitenTown of Riverhead Update On COVID-19 PDFRiverheadLOCALNoch keine Bewertungen

- D893Dokument5 SeitenD893rpajaro75Noch keine Bewertungen

- Faizal AhmedDokument5 SeitenFaizal AhmedEngineer - E&INoch keine Bewertungen

- Finite Difference Method of Modelling Groundwater FlowDokument7 SeitenFinite Difference Method of Modelling Groundwater FlowVenegasNoch keine Bewertungen

- Anandababu Curriculam VitaeDokument6 SeitenAnandababu Curriculam VitaeANANDABABUNoch keine Bewertungen

- 15-23 MEP GuidelinesDokument9 Seiten15-23 MEP GuidelinesChandrakant Tiwari100% (1)

- 911 (996), 1998 - 2005 PDFDokument777 Seiten911 (996), 1998 - 2005 PDFRadovan NikolcicNoch keine Bewertungen

- 5 Years 3 Months: Working Experience: Career ObjectiveDokument4 Seiten5 Years 3 Months: Working Experience: Career ObjectiveKrantikumar KolliNoch keine Bewertungen

- Design EngineerDokument5 SeitenDesign EngineerFenil Shingala100% (2)

- Trim Heater PDFDokument2 SeitenTrim Heater PDFsaadashfaq100% (1)

- SOP-017-Testing of Specific Gravity of CondensateDokument9 SeitenSOP-017-Testing of Specific Gravity of CondensateAmnaKamranNoch keine Bewertungen

- CURRICULUM VITAE (5 Years in O&G) : Email ID Contact: AddressDokument4 SeitenCURRICULUM VITAE (5 Years in O&G) : Email ID Contact: AddressBibhu Ranjan MohantyNoch keine Bewertungen

- Junaid CV 16-04-2022Dokument6 SeitenJunaid CV 16-04-2022prabhat2000.kNoch keine Bewertungen

- Sharad Mohan CV InstDokument5 SeitenSharad Mohan CV InstmasilamaniNoch keine Bewertungen

- Mohammad Gufran Inst. Tech - MaintenanceDokument3 SeitenMohammad Gufran Inst. Tech - Maintenancerazaullahkhan37Noch keine Bewertungen

- Instrument TechnicianDokument4 SeitenInstrument Technicianrazaullahkhan37Noch keine Bewertungen

- Offline SPI TrainingDokument2 SeitenOffline SPI Trainingsmartravi222Noch keine Bewertungen

- Jpce Company Profile DecDokument16 SeitenJpce Company Profile DecJPCE1288Noch keine Bewertungen

- Preveen Vishwakarma: Mobile: +91-9988740560 9870109462 EmailDokument2 SeitenPreveen Vishwakarma: Mobile: +91-9988740560 9870109462 EmailPraveen VishwakarmaNoch keine Bewertungen

- Aamir Alam E&I QC INSPECTORDokument6 SeitenAamir Alam E&I QC INSPECTORTouhid AhmadNoch keine Bewertungen

- Divyesh DDokument3 SeitenDivyesh DVIMALNoch keine Bewertungen

- Merman ResumeDokument2 SeitenMerman Resumesyinst92Noch keine Bewertungen

- Imran K Very New Updated Cv.Dokument5 SeitenImran K Very New Updated Cv.imran kauchaliNoch keine Bewertungen

- Abarajithan R: An Instrumentation and Control EngineerDokument5 SeitenAbarajithan R: An Instrumentation and Control EngineerAbarajithan RajendranNoch keine Bewertungen

- CV - Mohd Nadim - 01-06-2017Dokument6 SeitenCV - Mohd Nadim - 01-06-2017Mohammad NadimNoch keine Bewertungen

- Kashif Riaz E&I Supervisor-1-Merged - OrganizedDokument5 SeitenKashif Riaz E&I Supervisor-1-Merged - Organizedkashif2080Noch keine Bewertungen

- MydocDokument3 SeitenMydocghatevinod9360Noch keine Bewertungen

- Surendra Yadav - Updated CVDokument5 SeitenSurendra Yadav - Updated CVsiva prasadNoch keine Bewertungen

- Arun WoodDokument5 SeitenArun WoodArun KumarNoch keine Bewertungen

- Ranjan Kumar Sahoo - GailDokument3 SeitenRanjan Kumar Sahoo - GailRanjanKumarNoch keine Bewertungen

- Application: Instrument Commissioning Technician: Jignesh I PatelDokument7 SeitenApplication: Instrument Commissioning Technician: Jignesh I PatellongnguyenNoch keine Bewertungen

- Sarat UpdatedresumeDokument3 SeitenSarat UpdatedresumeKaushik Kumar AushNoch keine Bewertungen

- ResumeDokument4 SeitenResumeBibhu RanjanNoch keine Bewertungen

- Instrument Technician Faisal FarooqueDokument3 SeitenInstrument Technician Faisal FarooqueDIJUNoch keine Bewertungen

- Shoban Aftab Sindhu - I&C Technician (2) - 1Dokument4 SeitenShoban Aftab Sindhu - I&C Technician (2) - 1muhammad.wajahat194Noch keine Bewertungen

- Engineer InstrumentationDokument4 SeitenEngineer InstrumentationmangeshjoNoch keine Bewertungen

- Experience in Instrumentation Field: Total - 14 Years: Sudhansu BeheraDokument3 SeitenExperience in Instrumentation Field: Total - 14 Years: Sudhansu BeheraSudhansu BeheraNoch keine Bewertungen

- Himanshu Manori-E&IDokument3 SeitenHimanshu Manori-E&Ihimanshu manoriNoch keine Bewertungen

- Curriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Dokument8 SeitenCurriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Danish HNoch keine Bewertungen

- Instrumentation PankajDokument3 SeitenInstrumentation Pankajpankaj sharma100% (1)

- Vikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Dokument2 SeitenVikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Kushal ChatterjeeNoch keine Bewertungen

- Chandrashekhar Mondal: 170, Rabindra Nath Tagore RoadDokument4 SeitenChandrashekhar Mondal: 170, Rabindra Nath Tagore RoadChandrashekhar MondalNoch keine Bewertungen

- Curriculam Vitae: Vemula Govinda Raju Personal DataDokument3 SeitenCurriculam Vitae: Vemula Govinda Raju Personal DataAJAYNoch keine Bewertungen

- Bismillah Inst-SupvrDokument5 SeitenBismillah Inst-SupvrHaris KhanNoch keine Bewertungen

- Sudhansu Behera - ResumeDokument4 SeitenSudhansu Behera - Resumesudhansu8beheraNoch keine Bewertungen

- Ali Huzafa Sayyar - OriginalDokument3 SeitenAli Huzafa Sayyar - OriginalMuhammad ShehzadNoch keine Bewertungen

- Tahir AliDokument4 SeitenTahir Aliaslam mohdNoch keine Bewertungen

- Amit Pandey Dehradun 4.00 YrsDokument3 SeitenAmit Pandey Dehradun 4.00 YrsmeenuNoch keine Bewertungen

- CVAsikin (Project Engineer)Dokument13 SeitenCVAsikin (Project Engineer)Anonymous j6AXjDKNoch keine Bewertungen

- Subramanian Karunanithi,: Curriculum VitaeDokument5 SeitenSubramanian Karunanithi,: Curriculum VitaePazhamalairajan KaliyaperumalNoch keine Bewertungen

- Mohammad Shahbaz Alam (E&I QAQC Engineer)Dokument5 SeitenMohammad Shahbaz Alam (E&I QAQC Engineer)Touhid AhmadNoch keine Bewertungen

- Shah Behram: Career ObjectiveDokument4 SeitenShah Behram: Career Objectivefaraz24Noch keine Bewertungen

- C& I - Resume - ThakurDokument4 SeitenC& I - Resume - ThakurKhushboo Pandey100% (1)

- Gas Turbine Controls EngineerDokument3 SeitenGas Turbine Controls EngineerHBNBILNoch keine Bewertungen

- Resume SenaDokument4 SeitenResume SenasenathibathiNoch keine Bewertungen

- XSV 3001b2 CloseDokument1 SeiteXSV 3001b2 CloseMOHANNoch keine Bewertungen

- XSV 3001a2 OpenDokument1 SeiteXSV 3001a2 OpenMOHANNoch keine Bewertungen

- MCP ADokument1 SeiteMCP AMOHANNoch keine Bewertungen

- PayslipDokument1 SeitePayslipMOHAN0% (1)

- XSV 3002b CloseDokument1 SeiteXSV 3002b CloseMOHANNoch keine Bewertungen

- Deep ResumeDokument4 SeitenDeep ResumeMOHANNoch keine Bewertungen

- Delivery Challan: Deep Industries LimitedDokument1 SeiteDelivery Challan: Deep Industries LimitedMOHANNoch keine Bewertungen

- 6315 Alternator PDFDokument2 Seiten6315 Alternator PDFMOHANNoch keine Bewertungen

- Rotex Rotary Actuator PDFDokument20 SeitenRotex Rotary Actuator PDFMOHANNoch keine Bewertungen

- Series Four 12 Cylinder With ESM & Extender Series Parts CatalogDokument1 SeiteSeries Four 12 Cylinder With ESM & Extender Series Parts CatalogMOHANNoch keine Bewertungen

- Oil PumpDokument2 SeitenOil PumpMOHANNoch keine Bewertungen

- W A U K E S H A: 112 FORM 6315 First EditionDokument2 SeitenW A U K E S H A: 112 FORM 6315 First EditionMOHANNoch keine Bewertungen

- W A U K E S H A: 136 FORM 6315 First EditionDokument2 SeitenW A U K E S H A: 136 FORM 6315 First EditionMOHANNoch keine Bewertungen

- W A U K E S H A: 102 FORM 6315 First EditionDokument2 SeitenW A U K E S H A: 102 FORM 6315 First EditionMOHANNoch keine Bewertungen

- 6315 Cylinder Head, ValvesDokument2 Seiten6315 Cylinder Head, ValvesMOHANNoch keine Bewertungen

- 6315 Water Manifold PDFDokument2 Seiten6315 Water Manifold PDFMOHANNoch keine Bewertungen

- 6315 Wastegate Backpressure Regulator LT PDFDokument2 Seiten6315 Wastegate Backpressure Regulator LT PDFMOHANNoch keine Bewertungen

- W A U K E S H A: 102 FORM 6315 First EditionDokument2 SeitenW A U K E S H A: 102 FORM 6315 First EditionMOHANNoch keine Bewertungen

- 6315 Crankshaft, Pulley, Flywheel, Vibration DamperDokument2 Seiten6315 Crankshaft, Pulley, Flywheel, Vibration DamperMOHANNoch keine Bewertungen

- 6315 Cylinder Head Valve Bridges, Spark Plug SleeveDokument2 Seiten6315 Cylinder Head Valve Bridges, Spark Plug SleeveMOHANNoch keine Bewertungen

- New Doc 2018-08-11 PDFDokument2 SeitenNew Doc 2018-08-11 PDFMOHANNoch keine Bewertungen

- 6315 Intercooler ConnectionsDokument2 Seiten6315 Intercooler ConnectionsMOHANNoch keine Bewertungen

- W A U K E S H A: 110 FORM 6315 First EditionDokument2 SeitenW A U K E S H A: 110 FORM 6315 First EditionMOHANNoch keine Bewertungen

- DBP vs. Guarina Agricultural and Realty Development CorporationDokument18 SeitenDBP vs. Guarina Agricultural and Realty Development CorporationAsh Manguera0% (1)

- Alaska Air CasestudyDokument6 SeitenAlaska Air CasestudyDumbrava Caius FlorinNoch keine Bewertungen

- Summary Writing: Grade VIIDokument11 SeitenSummary Writing: Grade VIIMs Abeer UsmaniNoch keine Bewertungen

- BMA5318 YWY 1213 Sem2 (A)Dokument3 SeitenBMA5318 YWY 1213 Sem2 (A)Sumedha Shocisuto Das JpsNoch keine Bewertungen

- Et Iso 12543 2 2011Dokument11 SeitenEt Iso 12543 2 2011freddyguzman3471Noch keine Bewertungen

- Rainfall-Induced Slope Instability PRESENTATIONDokument15 SeitenRainfall-Induced Slope Instability PRESENTATIONasamselaseNoch keine Bewertungen

- VSphere Troubleshooting and TricksDokument46 SeitenVSphere Troubleshooting and TricksManoj KumarNoch keine Bewertungen

- TURCK - Edb - 4635801 - GBR - enDokument3 SeitenTURCK - Edb - 4635801 - GBR - enminhpham.sunautomationNoch keine Bewertungen

- PQR 3Dokument2 SeitenPQR 3Mecon HyderabadNoch keine Bewertungen

- B2 Progress TestDokument3 SeitenB2 Progress TestDenisa NeagoeNoch keine Bewertungen

- Lab Report 1 BioinformaticsDokument13 SeitenLab Report 1 BioinformaticsRabiatul Adawiyah HasbullahNoch keine Bewertungen

- Retail Excel - POS Software PresentationDokument64 SeitenRetail Excel - POS Software PresentationRavi shankar chavali100% (7)

- TCP - IP Stack TutorialDokument3 SeitenTCP - IP Stack Tutorialkaty peña corroNoch keine Bewertungen

- Thesis Statement Worksheet 5th GradeDokument4 SeitenThesis Statement Worksheet 5th GradeMary Montoya100% (2)

- Applied Business Tools and Technologies: A. Activation of Prior KnowledgeDokument12 SeitenApplied Business Tools and Technologies: A. Activation of Prior KnowledgeClaire CarpioNoch keine Bewertungen

- Ielts Writing Task 2 Essay (100 Plus Essay)Dokument151 SeitenIelts Writing Task 2 Essay (100 Plus Essay)Sopha Sd50% (2)

- Marketing Research ProposalDokument42 SeitenMarketing Research ProposalFahmida HaqueNoch keine Bewertungen

- Environmental Clearance For Construction Projects - OptimaDokument11 SeitenEnvironmental Clearance For Construction Projects - OptimaSiddharth ChoksiNoch keine Bewertungen

- Csec Poa June 2015 p2Dokument33 SeitenCsec Poa June 2015 p2goseinvarunNoch keine Bewertungen

- 4th Term PLC Lab ManualDokument8 Seiten4th Term PLC Lab ManualOPIYO ONYANGONoch keine Bewertungen