Beruflich Dokumente

Kultur Dokumente

Main Bearing Torque K50

Hochgeladen von

jengandxb100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

565 Ansichten1 SeiteThis document provides instructions for servicing main bearing caps on diesel engines. It describes loosening the caps one at a time to locate any misaligned caps and check for end clearance on the crankshaft. Three different designs of capscrews are noted, along with their appropriate tightening procedures. The final summary provides a torque sequence for tightening main bearing caps using the torque plus angle method for K38 and QSK38 engines.

Originalbeschreibung:

mb

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides instructions for servicing main bearing caps on diesel engines. It describes loosening the caps one at a time to locate any misaligned caps and check for end clearance on the crankshaft. Three different designs of capscrews are noted, along with their appropriate tightening procedures. The final summary provides a torque sequence for tightening main bearing caps using the torque plus angle method for K38 and QSK38 engines.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

565 Ansichten1 SeiteMain Bearing Torque K50

Hochgeladen von

jengandxbThis document provides instructions for servicing main bearing caps on diesel engines. It describes loosening the caps one at a time to locate any misaligned caps and check for end clearance on the crankshaft. Three different designs of capscrews are noted, along with their appropriate tightening procedures. The final summary provides a torque sequence for tightening main bearing caps using the torque plus angle method for K38 and QSK38 engines.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

1/27/2019 QuickServe Online | (4021528) GTA38, K38, K50, QSK38, and QSK50 Service Manual

7. 610 n•m [ 450 ft-lb ]

Turn the crankshaft with your hands. If it will not turn, loosen

the main bearing caps one at a time until the crankshaft turns

freely. This helps to locate the cap that is not in alignment.

Check to make sure there is end clearance.

Three different designs of capscrew have been used.

1. 12-point capscrews that are black

2. 6-point capscrews that are light gray

3. 6-point capscrews with angle marking (Part Number

3628452).

Note : Capscrews (1 and 2) use the torque procedure

for tightening. They can be intermixed and installed in

the same cap. Capscrew (3) uses the torque turn

procedure for tightening.

Note : All engines built using the torque turn procedure

are to have the torque turn procedure applied when

rebuilt or repaired in the field. These engines can be

identified by the capscrew markings. Older engines,

unless block line bored, retain the old torque values. In

cases where the torque turn procedure is not possible,

due to limited access, a torque value of 814 N•m [600

ft-lb] can be used in place of the torque turn procedure.

Note : As the torque required for the torque turn

procedure is significantly higher than the torque only

procedure, Cummins Inc. recommends that a torque

multiplier and breaker bar be used when advancing the

capscrew the final 90 degrees. A standard torque

wrench with 407 N•m [300 ft-lb] minimum capability, is

to be used (without the torque multiplier) to obtain the

initial 339 N•m [250 ft-lb] torque value.

Note : The below torque sequence is for the torque plus

angle method.

For K38 and QSK38 engines, tighten the main bearing cap

mounting capscrews alternately and evenly, use the torque

sequence shown.

Torque Value:

https://quickserve.cummins.com/qs3/portal/service/manual/en/4021528/ 11/15

Das könnte Ihnen auch gefallen

- K19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullDokument13 SeitenK19 Industrial and Marine Operation and Maintenance Manual - Maintenance Schedule FullLeandro Mauricio100% (3)

- Kta38 PDFDokument19 SeitenKta38 PDFMohamed A. Naguib73% (11)

- Cummins KTA19 Engine Specs, Bolt Torques and ManualsDokument12 SeitenCummins KTA19 Engine Specs, Bolt Torques and Manualsfaizal78% (9)

- Nta855 g2 Service ManualDokument2 SeitenNta855 g2 Service ManualKanjeng Raden Aryo Saifu67% (27)

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDokument2 SeitenQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbNoch keine Bewertungen

- QSK78 Owners Manual PDFDokument17 SeitenQSK78 Owners Manual PDFjengandxb100% (2)

- Kta 38 g12 Parts CatlogDokument198 SeitenKta 38 g12 Parts CatlogVinesh Vineshb100% (3)

- Cummins K-Series Engine Schedule MaintenanceDokument31 SeitenCummins K-Series Engine Schedule Maintenancenagari Power100% (5)

- QuickServe Online - (5411406) Fluids For Cummins® Products Service ManualDokument7 SeitenQuickServe Online - (5411406) Fluids For Cummins® Products Service Manualjengandxb100% (1)

- QuickServe Online - (4021539) QST30 Service ManualDokument7 SeitenQuickServe Online - (4021539) QST30 Service Manualjengandxb33% (3)

- QSK50 e KTA50Tabela de Ajuste de VálvulaDokument28 SeitenQSK50 e KTA50Tabela de Ajuste de VálvulaEvander Sarraff75% (4)

- WWW - Incar.tw-Cummins Vta28 Service ManualDokument5 SeitenWWW - Incar.tw-Cummins Vta28 Service ManualJhon Connor80% (5)

- 904-0211 Onan VT28 VTA28 PMG Genset Parts Manual PDFDokument48 Seiten904-0211 Onan VT28 VTA28 PMG Genset Parts Manual PDFGIGI100% (1)

- Kta19 G2Dokument4 SeitenKta19 G2Sauro Gordini75% (4)

- Part Catelogue 750 Kva - KTA 38 G2 I - 5276656Dokument133 SeitenPart Catelogue 750 Kva - KTA 38 G2 I - 5276656sblnt2008100% (4)

- CentinalDokument2 SeitenCentinaljengandxb0% (1)

- K38, K50, Owners ManualDokument3 SeitenK38, K50, Owners ManualjengandxbNoch keine Bewertungen

- QSK78 Troubleshooting and Repair Manual PDFDokument4 SeitenQSK78 Troubleshooting and Repair Manual PDFjengandxbNoch keine Bewertungen

- QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualDokument9 SeitenQuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service Manualjengandxb100% (2)

- V28 Rebuild GuidelinesDokument26 SeitenV28 Rebuild Guidelinesacere18100% (1)

- Cummins K38, KT38, KTA38 Inframe-Overhaul Engine Rebuild KitDokument2 SeitenCummins K38, KT38, KTA38 Inframe-Overhaul Engine Rebuild Kitfelix amador100% (2)

- Specification D683 234.5KW 2300rpm Marine Engine PDFDokument31 SeitenSpecification D683 234.5KW 2300rpm Marine Engine PDFKIJETYNoch keine Bewertungen

- QSK60 Over Head Valve Setting PerformaDokument2 SeitenQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- Systems Operation Testing and Adjusting: 4012-46A Industrial EngineDokument12 SeitenSystems Operation Testing and Adjusting: 4012-46A Industrial Enginenam voNoch keine Bewertungen

- Valve Lash For Cummins Engine K38Dokument9 SeitenValve Lash For Cummins Engine K38Youssef Ali100% (1)

- Overhaul Considerations: Operation and Maintenance ManualDokument6 SeitenOverhaul Considerations: Operation and Maintenance ManualCamilo Andres Cardozo FajardoNoch keine Bewertungen

- Kta19 Spare Parts BookDokument152 SeitenKta19 Spare Parts BookGeorgios Logakis91% (11)

- QuickServe Online - (3666422) ICON™ Idle Control SystemDokument18 SeitenQuickServe Online - (3666422) ICON™ Idle Control Systemjengandxb100% (1)

- 002-004 Cylinder Head Cummins 6BTA5.9 G2Dokument10 Seiten002-004 Cylinder Head Cummins 6BTA5.9 G2AleksaNoch keine Bewertungen

- Cummin KTA50-G3 Main Bearing Installation ManualDokument15 SeitenCummin KTA50-G3 Main Bearing Installation ManualRey Anthony Pole100% (2)

- Cummins Serie K Calibracion de ValvulasDokument63 SeitenCummins Serie K Calibracion de Valvulasfrank_16100% (1)

- MEK Marine Yanmar Engine Spare PartsDokument6 SeitenMEK Marine Yanmar Engine Spare PartsMEK Marine100% (1)

- Overhead Set (Travel Method)Dokument8 SeitenOverhead Set (Travel Method)jengandxb100% (8)

- Engine Valve LashDokument3 SeitenEngine Valve LashImron Alif100% (3)

- K38 Rocker HousingDokument13 SeitenK38 Rocker HousinghindraNoch keine Bewertungen

- Crankshaft Position For Fuel Injector AdjustmentDokument2 SeitenCrankshaft Position For Fuel Injector AdjustmentSteven Y.M100% (1)

- fr4212 KTA19-G4Dokument4 Seitenfr4212 KTA19-G4acere18Noch keine Bewertungen

- Kta19 G3 EngineDokument3 SeitenKta19 G3 EngineMuhammad rizkiNoch keine Bewertungen

- Cummins Inc.: Engine Data SheetDokument4 SeitenCummins Inc.: Engine Data SheetAnh Nguyen100% (1)

- K50 Cylinder Head TorqueDokument1 SeiteK50 Cylinder Head Torquejengandxb100% (1)

- Injection Timing ChartDokument17 SeitenInjection Timing ChartAli ArdinNoch keine Bewertungen

- SG Governor: This Manual Replaces Manual 04022Dokument56 SeitenSG Governor: This Manual Replaces Manual 04022pcatruongNoch keine Bewertungen

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-54Dokument1 SeiteParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-54Hardiansyah SimarmataNoch keine Bewertungen

- Cat 3406Dokument8 SeitenCat 3406Dir Sales100% (1)

- Mitsubishi HeavyDokument17 SeitenMitsubishi HeavyNguyễn Văn CảnhNoch keine Bewertungen

- PDF Kta19m PDFDokument2 SeitenPDF Kta19m PDFFelipe Antonio Aurolo Moraga100% (2)

- C32 Gear Group (Front) - Install PDFDokument4 SeitenC32 Gear Group (Front) - Install PDFmanu luvungaNoch keine Bewertungen

- Cummins Engine Service Manual Cum S C Series PDFDokument8 SeitenCummins Engine Service Manual Cum S C Series PDFAhmed Elsayed50% (2)

- S6a3-Pt, S6a3-Pta, S6a3-Mpta, S6a3-MptkDokument1 SeiteS6a3-Pt, S6a3-Pta, S6a3-Mpta, S6a3-Mptkaram hayarpetyan100% (1)

- 6ha2m WHTWDTDokument2 Seiten6ha2m WHTWDTdha100% (1)

- Cummins NT Maintenance ManualDokument52 SeitenCummins NT Maintenance ManualChristian Kunze100% (2)

- KTA 19 Parts Catalogue PDFDokument58 SeitenKTA 19 Parts Catalogue PDFArgee PadauanNoch keine Bewertungen

- TC Kta-50Dokument69 SeitenTC Kta-50jengandxb100% (1)

- 6bt Valve Lash PDFDokument7 Seiten6bt Valve Lash PDFmilNoch keine Bewertungen

- Cylinder Head: SpecificationsDokument5 SeitenCylinder Head: SpecificationsFares100% (1)

- 15 18 047 1M - Notice - 12M26.2 - ENDokument128 Seiten15 18 047 1M - Notice - 12M26.2 - ENsxturboNoch keine Bewertungen

- Part Catalog 4TNV106T-GGEDokument29 SeitenPart Catalog 4TNV106T-GGESemproel BekenNoch keine Bewertungen

- Dvigatel Mitsubishi s16r Pta PDFDokument49 SeitenDvigatel Mitsubishi s16r Pta PDFSid Ali RABEHINoch keine Bewertungen

- 6W126S SheetDokument2 Seiten6W126S SheetirdawanNoch keine Bewertungen

- Operating Manual W5200Dokument42 SeitenOperating Manual W5200anto starlin100% (1)

- Vdocuments - MX - Cummins k38 Manual k50 qsk38 qsk50 Workshop Service Cummins KDokument2 SeitenVdocuments - MX - Cummins k38 Manual k50 qsk38 qsk50 Workshop Service Cummins KRauf Khan lakhweraNoch keine Bewertungen

- 08-Fuel SytmDokument7 Seiten08-Fuel SytmDevid Waladan SholehanNoch keine Bewertungen

- Cap KSM72Dokument6 SeitenCap KSM72Jaffer HussainNoch keine Bewertungen

- 3500 Tool List SimpleDokument7 Seiten3500 Tool List Simplemohamed hamedNoch keine Bewertungen

- General Information: Note: If A Connecting Rod Does Not Meet The ReuseDokument10 SeitenGeneral Information: Note: If A Connecting Rod Does Not Meet The Reuseshamim imthiyasNoch keine Bewertungen

- Torque SpecificationsDokument50 SeitenTorque SpecificationsNilton sergio gomes lins100% (1)

- Sebf 8054 Обмеры и Правка КвDokument33 SeitenSebf 8054 Обмеры и Правка КванджелаNoch keine Bewertungen

- Manual For N14Dokument16 SeitenManual For N14Jechkong78% (9)

- QuickServe Online - (4915540) QSX15 Owners ManualDokument4 SeitenQuickServe Online - (4915540) QSX15 Owners ManualjengandxbNoch keine Bewertungen

- K38 - Cylinder Head InstallationDokument3 SeitenK38 - Cylinder Head InstallationjengandxbNoch keine Bewertungen

- Remove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)Dokument2 SeitenRemove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)jengandxbNoch keine Bewertungen

- ECM TroubleshootingDokument27 SeitenECM Troubleshootingjengandxb100% (4)

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Dokument7 SeitenPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbNoch keine Bewertungen

- Main Bearing Torque K50Dokument1 SeiteMain Bearing Torque K50jengandxb100% (1)

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Dokument7 SeitenPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbNoch keine Bewertungen

- Fault Code 113: Electronic Step Timing Control (STC) CircuitDokument2 SeitenFault Code 113: Electronic Step Timing Control (STC) CircuitjengandxbNoch keine Bewertungen

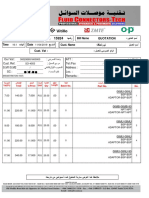

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDokument3 SeitenPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNoch keine Bewertungen

- General Information: Industrial EnginesDokument17 SeitenGeneral Information: Industrial EnginesjengandxbNoch keine Bewertungen

- Cummins K-50 Performance PartsDokument10 SeitenCummins K-50 Performance Partsjengandxb100% (1)

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDokument3 SeitenPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNoch keine Bewertungen

- Pay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationDokument3 SeitenPay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationjengandxbNoch keine Bewertungen

- QSK78 Troubleshooting and Repair ManualDokument4 SeitenQSK78 Troubleshooting and Repair Manualjengandxb0% (1)

- Single Phase AlternatorsDokument3 SeitenSingle Phase AlternatorsjengandxbNoch keine Bewertungen

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDokument6 SeitenPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNoch keine Bewertungen

- Electronic Parts Catalog - Option DetailDokument2 SeitenElectronic Parts Catalog - Option DetailjengandxbNoch keine Bewertungen

- Make Your Own Miniature Electric Hub Motor - 6Dokument12 SeitenMake Your Own Miniature Electric Hub Motor - 6jengandxbNoch keine Bewertungen

- K50 Cylinder Head TorqueDokument1 SeiteK50 Cylinder Head Torquejengandxb100% (1)

- LinersDokument4 SeitenLinersjengandxbNoch keine Bewertungen

- Print ﻲﺑرﻋ No new messages Help: Pay another billDokument1 SeitePrint ﻲﺑرﻋ No new messages Help: Pay another billjengandxbNoch keine Bewertungen