Beruflich Dokumente

Kultur Dokumente

Valbia Actuator Setup

Hochgeladen von

kikinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valbia Actuator Setup

Hochgeladen von

kikinCopyright:

Verfügbare Formate

5.0 Specifications and technical information (Tab.

1-2)

5.2 Power requirements and current draw information (Tab.3)

ELECTRIC ACTUATORS SERIES 85 (VB030 - VB350) TECHNICAL INFORMATION DATA

INSTALLATION AND MAINTENACE INSTRUCTIONS MANUAL Object of device Electric actuator MODELS VB030 VB060 VB110 VB190 VB270 VB350 6.1 Electrical connection

Enclosure material Self-estinguish technopolymer (V0)

Nominal torque [Nm] 30 60 110 190 270 350 The wiring diagram, which should be followed for proper wiring of the actuators, is shown in Paragraph 10.0 and it can be found also on the label inside

Enclosure rating IP67

TABLE OF CONTENTS the upper cover. Please follow the maximum allowed electrical rating values. The terminal block “F” in the 100-240Vac is shown in Fig. 3, 12Vac/dc and

Duty Cycle 75% Nominal torque 24Vac/dc in Fig. 2. The cables through the connector must be of the proper size.

266 530 975 1680 2390 3100

Duty Cycle 12V version 50% [LbIn]

1.0 WARNING • the signal cable of “closing (clockwise rotation)” (positive supply +12Vdc / +24Vdc or phase 12Vac / 24Vac / 100-240Vac) must be connected to the

Nominal voltage terminal “1” of the terminal-block “F”;

2.0 TRANSPORTATION AND STORAGE Ambient temperature range -20 °C ÷ +55 °C -4 °F ÷ +131 °F (H Version) 100 – 240 Vac

3.0 APPLICATIONS Auxiliary limit switches 2A @ 250Vac - 2A @ 30 Vdc (resistive load) • the signal cable of “opening (counter-clockwise rotation)” (positive supply +12Vdc / +24Vdc or phase 12Vac / 24Vac / 100-240Vac) must be connected

Absorbed current to the terminal “3” of the terminal-block “F”;

4.0 VALVES AUTOMATION Fault auxiliary contact 1A @ 120Vac- 2A @24Vdc (resistive load) (H Version) [A] 0.4 - 0.2 0.6 - 0.3 0.4 - 0.2 0.6 - 0.3 0.6 - 0.3 0.75 - 0.4

5.0 SPECIFICATIONS AND TECHNICAL INFORMATION • the signal cable “common” (0V / neutral) must be connected to the terminal “2” of the terminal-block “F”;

Terminal block type Plug in connector Absorbed power

5.1 TECHNICAL FEATURES (H Version) [VA] 40 - 48 60 - 72 40 - 48 60 - 72 60 - 72 75 - 96 • the grounding cable must be connected to the properly signaled terminal.

5.2 POWER REQUIREMENTS AND CURRENT DRAW INFORMATION Section of terminal block 14 ÷ 22 AWG 2.08 ÷ 0.32 mm2 In addition to the 3-points control mode, the 2-points control mode is also available.

Nominal voltage

6.0 INSTALLATION INSTRUCTION Minimum conductors temperature 85 °C 185 °F (L Version) 12Vac/dc 24Vac/dc 12Vac/dc 24Vac/dc 12Vac/dc 24Vac/dc 12Vac/dc 24Vac/dc 12Vac/dc 24Vac/dc 12Vac/dc 24Vac/dc WARNING: the ground wiring system is mandatory.

6.1 ELECTRICAL CONNECTION Protection class against electric shock Class I

6.2 AUXILIARY SWITCHES WIRINGS Absorbed current 2.2 - 1.8 1 - 0.7 3.8 -2.85 1.8 - 1.2 2.2 - 1.8 1 - 0.7 3.8 - 2.85 1.8 - 1.2 3.8 - 2.85 1.8 - 1.2 4.75 - 3.65 1.95 - 1.65

Restriction of continue operation time (time out) Standard (L Version) [A]

6.3 POTENTIOMETER WIRINGS (OPTIONAL)

6.4 HEATING RESISTORS Power supply voltage tolerance ±10% Absorbed power 26.5 - 22 24 - 17 46 - 34 43 - 29 26.5 - 22 24 - 17 46 - 34 43 - 29 46 - 34 43 - 29 57 - 44 47 - 40

Multiple parallel actuators wiring Standard (*) (L Version) [VA]

6.5 SIGNAL LAMP UNIT TERMINAL BLOCK “F”

6.6 SETTING ACTUATOR STOP POSITIONS Cable entries PG11 electric connections (cable diam. 6-9 mm/0.24”-0.35”) Frequency [Hz] 50/60

6.7 ACTUATOR COVER ASSEMBLY Standard stroke 90° Rotation time 8 9 27 27 50 50

7.0 MANUAL OVERRIDE 0° - 90° [sec]

Position indicator Standard

8.0 FAIL-SAFE OPERATION WITH BATTERY BACKUP (OPTIONAL)

9.0 MAINTENANCE Manual override Standard

6.0 Installation instruction

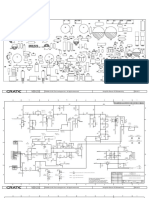

10.0 WIRING DIAGRAMS

1.0 Warning (*) It is important to verify that the application and its components are properly sized with the actuator characteristics and requirements

REQUESTED FEATURES FOR UL508 STANDARD

B C

• Please read the following instructions before making any installation of the actuator. The damages caused from the non-observance of these instructions

are not covered in the warranty. UL listed file number NMTR.E303174 - remove position indicator “B” by loosening the screws “C”;

• This documentation must be kept in dry place and available for use. Enclosure Type Type 4x Indoor Use Only - screw the fasteners “D” to remove the upper cover “A”;

• The actuator is an electronic device and during its working operations some parts are live components. The installation and maintenance of electric - raise up the cover “A” carefully to avoid to damage the internal electric parts;

actuator must be made only by qualified personnel, in accordance with current electrical engineering and safety standards and all other applicable directives. Connection conductor/wires Listed flexible cord (ZJCZ) minimum S or SJ A H - turn in the electric supply cable (diameter 6 ÷ 9 mm / 0.24” ÷ 0.35”) by the properly

• Valbia s.r.l. reserves the right to change the data and the characteristics of this manual at any time and with no notice in the scope of a constant updating Terminal block screws maximum tightening capacity of model bolds “E” (PG11);

0.50 Nm 4.50 LbIn - proceed to connect the cable in its proper terminal block “F” by looking at the

and technological improvement. 100-240 Vac Fig.2 Board for the low voltage supply and particular of terminal block “F”

Terminal block screws maximum tightening capacity of model wiring diagram (Fig.8) according to the different voltage (please also review the tag

0.40 Nm 3.50 LbIn you find inside the cover).

WARNING: the mechanical and electronic parts, according to which the device is designed, are not eligible for modifications. 12-24 Vac/dc D

Enclosure screws maximum tightening capacity 2.5 Nm 22.15Lbln

2.0 Transportation and storage E TERMINAL BLOCK “F”

Pollution degree III

Valbia electric actuators are supplied in paperboard boxes which are of solid construction for a normal transport. Handle with care and keep the cover until Overvoltage category II

the moment of the installation of the actuator. The storage of the actuators requires a covered, dry and ventilated environment, protected from temperature

changes. The device must be stored with the cover mounted. Prior to installation, visual inspection is recommended to detect any anomalies caused by

transport or storage. Fig.1 External view of the actuator

Product in conformity with the European Community norms

WARNING: do not lift or move the actuator by the manual hand-wheel.

LOW VOLTAGE 2014/35/UE (LVD)

3.0 Field application ELECTROMAGNETIC COMPATIBILITY 2014/30/UE (EMC)

MACHINERY 2006/42/CE

WARNING: the actuators should be properly grounded and wired in accordance with local electrical code.

VALBIA electric actuators have been designed and tested to ball and butterfly valves and dampers for the industrial sector. Actuators are available in standard ROHS 2011/65/UE

WARNING: before performing any maintenance on the actuator, always make sure to shut off the power supply first.

version with rotation 0°-90°. On request we can supply actuators with rotation 0°-180° or 0°-270°. For applications other than that above are needed please REGULATION No 1907/2006 (REACH)

WARNING: make sure that the power supply is set between the values indicated as indicated on the label on the side of the actuator.

contact VALBIA sales department. Use copper (CU) conductor

WARNING: Valbia electric actuators may be mounted in many positions, however, we do not suggest using it with the cable glands positioned upright,

since it cannot guarantee a perfect wiring tightness. We also recommend to avoid using it with the indicator facing down. If the actuator assembly and

4.0 Valve automation 5.1 Technical features

the respective electrical connection are provided in different moments, make sure that the cable entries are hermetically sealed.

WARNING: please ensure suitably rated cable glands and protection plug are used, according to IP protection rating. Fig.3 Board for the high voltage supply and particular of terminal block “F”

The mechanical assembling between the electric actuator and the item to be automated (for example: the valve) can be done by direct mounting or by a Technical characteristics of Valbia electric actuators as below:

Properly seal the electrical connectors to prevent any liquid and dust infiltration. Warranty is voided if this warning is not respected.

mounting kit. Both the cases you can verify the right alignment and the correct dimensions of the part to transmit the power in order to avoid axial stress which • they are standard equipped with heating resistors to avoid condensate into the actuator (Paragraph 6.4);

The cables must be of the appropriate size to the type of electrical connector selected. Verify the correct tightening of the electrical connectors.

can damage valve and actuator. • a safety system detects when the actuator supplies a torque higher than expected (torque limiter): the device makes three triggering attempts. In case of negative results, it

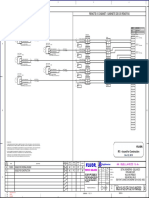

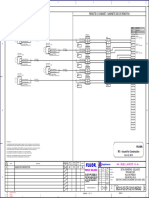

WARNING: if the device is used not respecting the manufacturer specifications, the provided protection may be impaired. 6.2 Auxiliary switches wirings (Fig.4)

All Valbia electric actuators are in conformity of norm EN ISO 5211 (DIN 3337). makes a short rotation in the opposite direction to relieve the mechanical tension to the gears. The torque limiter intervention is indicated by a red color LED (Paragraph 6.5)

For the wiring, it is necessary to open the upper cover “A” in order to locate the terminal block on the power supply board.

and by the closure of the remote signal an auxiliary contact (Paragraph 6.2).

In order to have a right automation of the valve, is necessary to use a Valbia electric actuators whose range has a torque of at least 25% over the valve WARNING: before opening the upper cover shut down the power supply voltage. The “G” terminal block is connected to two auxiliary and independent limit switches (SPDT free contacts), FCU1 and FCU2, which indicate the position

• a safety system intervenes to shut off the actuator in case the motor works past over the allowable operation time value (the time value depends on the actuator models).

maximum torque. To remove the upper cover “A” untighten the screws “D” and make sure to avoid collisions with the internal electrical parts. Insert the power supply cables of the actuator to the final user. The terminal block “G” is composed by two parts, one of which removable for easier wiring. To simplify the procedure, it

The maximum working time fault is indicated by a red color LED (Paragraph 6.5) and by the closure of the auxiliary contact of the remote signal (Paragraph 6.2).

Verify the actuator duty rating suitability with the application. inside the lower enclosure entries “E”, tighten by the user. The terminal block “F” is composed by two parts, one of which removable. To simplify the is possible to remove the removable part, wiring it and insert it once the wiring is done.

• duty rating: the electric actuator was designed to work with a nominal duty rating of 75% (or 50% in the 12V ac/dc models), referred to the working time, the maximum

procedure, it is possible to remove the removable part, wiring it and insert it once the wiring is done. Proceed to the cable connections in the appropriate Connect to the terminal block “G” between the following terminals:

temperature and to the nominal load. This parameter defines the rest time after an operation. The use of the actuator with an higher duty rating or with a temperature above

WARNING: do not raise up or moved the motorized valve by using the electric actuator as point of grip or hold. terminal block “F” following the wiring diagram (Paragraph 6.1). • “B” and “C” to obtain the signal of closing position.

55°C (131°F) can cause the improper torque limiter intervention or the failure of electronic components.

WARNING: please pay attention during the wiring and setting phases of the electromechanical limit switches, in order to avoid fluids or other substance • “E” and “H” to obtain the signal of opening position.

from getting on or around any electronic components. Moreover, before assembling the upper cover please make sure that the o-ring is seated in the The opening or closing signal comes when the blue cams push the auxiliary electromechanical limit switch on the logic board. The cams adjustment

proper groove and there are no impediments that could compromised the enclosure sealing. procedure is described on Paragraph 6.6.

WARNING: during the installation it is recommended to verify the alignment of the auxiliary limit switches by using a multimeter/tester.

The terminal block “R” is connected to a free contact NO which provides the anomaly signal to the end user. The terminal block “R” is composed by

two parts, one of which removable for easier wiring. To simplify the procedure, it is possible to remove the removable part, wiring it and insert it once

the wiring is done.

2 3 4

1

• on the control board a warning red light (LED) and a free contact signal, eventual, anomalies, such as:

TERMINAL BLOCK "G" TERMINAL BLOCK “R” • torque limiter intervention;

6.7 Closure of electric actuator enclosure (Fig.1) 10.0 Wiring diagrams

• power supply voltage below the minimum required limit; The wiring diagram to be followed for the proper cabling to the actuators is showed in Fig.8 and also it is, as tag, inside the cover. In addition

• After making the proper connection, please proceed to the assembling of cover “A”, by paying close attention not to hit any electronic parts.

• exceeded maximum working time per single operation (time out); to the 3-points control mode it is possible the cabling of the actuator for the 2-points control mode.

• re-assemble the position indicator “B” on “OPEN ” blocking it by screw “C”;

• loss of limit switch position not electronically managed;

• make sure that the tightening of cables is secure, by screwing the gland “E”;

• finish the closing of cover “A” by screwing in the fasteners “D”.

When, one of the above anomalies is detected, in order to recover the correct operation of the actuator, it is necessary to turn off the actuator, find the

source of the anomaly and remove it, turn the power back on. 7.0 Emergency operation

WARNING: It is necessary to shut off the power supply for more than 10 sec to ensure the full capacitors discharge. All the VALBIA electric actuators have an external handwheel “H” (Fig.1), which can manually operate the closing and opening positions.

The manual operation operates by put in a pressure on the top of handwheel and by making a small rotation in order to engage the stem to the

6.6 Setting actuator stop positions (Fig.7) handwheel.

After engaging the manual operation you can make desired the position you wish by keeping pressure on, and turning the handwheel.

Fig.4 Control/logic board and particular of terminal blocks “G” and “R” The opening or closing operation of the electric actuator is reached when the black cams push the electromechanical limit switches on the logic board WARNING: the handwheel for the manual override can be used with actuator NOT power supplied.

(POS1 for closing position and POS2 for opening position). The signal of opening and closing operation is obtained when the blue cams push the electro- Do not use tools to action the handwheel. Ground (PE)

6.3 Potentiometer wirings (optional) (Fig.5) WARNING: do not operate the manual override when the actuator is turning.

mechanical limit switches on the logic board. L (+)

N (-)

The actuator with potentiometer includes an extra terminal block “POT” (Fig.5) which grants the possibility to use the resistive information concerning 8.0 Fail-Safe Operation with battery backup (optional)

the actuator position. Wiring instruction presented at Paragraph 10.0. The procedure necessary to adjust the actuator stroke is the following: Fuse

1. make sure that the power supply is off;

For the actuators with battery back-up, VALBIA can set up the actuator to automatically carry out one of the following actions in the event of power

2. remove the upper cover of the actuator (Paragraph 6.0); outage:

Opening

3 points control mode 2 points control mode

Closing

3. to simplify the operation it is recommended to remove the removable parts of the terminal block “G” and “R”;

COM

Ground

• Opening: the in-progress/current operation is interrupted.

TERMINAL BLOCK “POT” 4. make sure that the automated device (for instance the valve) is in the “OPEN” position. For a more accurate and precise adjustment, use the manual Optional with L(+) N(-)

• Closing: the in-progress/current operation is interrupted. L(+) N(-)

potentiometer

override “H” (Paragraph 7.0); • Completes the in-progress operation: the motor continues the in progress action until it touches the travel stops/limit switches. 1 2 3 A B C D E H J K

"G"

Opening

Terminal block " R "

5kΩ 1W

5. loosen the set screw in the cam 1 (black color), and rotate the cam until it pushes the limit switch POS2 and until the “click” of the electromechanical The operation with the battery is immediately activated if the actuator is rotating during loss of power, and the operation is delayed when the actuator MORSETTIERA 4 5 6 Ground (PE)

micro switch. Then tighten the set cam screws; is in the full ”open” or “closed” position. Terminal block

opening

Ground (PE)

Closing

Terminal block

Closed

FCU2

FCU1

Open

6. loosen the set screw in the cam 3 (blue color), and rotate the cam until it pushes the limit switch FCU2 and until the “click” of the electromechanical micro "F"

switch). Then tighten the set cam screws; A red light (LED) mounted on the power supply board signals the charging level of the battery:

• fast flashing, the battery is not connected to the power supply board or the battery is charging;

Optional

1 2 3 1 2 3

7. power on the actuator and carry out the closing operation; 24V dc battery

• light on, the battery is not enough charged to guarantee a complete back-up operation; (not available

NO

NO

FREE CONTACTS Term

NC

NC

8. wait for the completion of the operation, then shut off the power supply; for 12V versions)

MAX 1A 120Vac / 2A 24Vdc Term

“F” “F”

• light off, the battery is charged at the nominal value; Free contacts

9. make sure that the automated device (for instance the valve) is in the “CLOSED” position. For a more accurate and precise adjustment, use the manual

The LED signal is reliable if the battery back-up has not been damaged. Power supply MAX 2A 250Vac / 30Vdc

override “H” (Paragraph 7.0); voltage board Electric actuator

Control/logic board Electric actuator

12/24V DC Motor

10. loosen the set screw in the cam 2 (black color) and rotate the cam until it pushes the limit switch POS1 and until the “click” of the electromechanical 9.0 Maintenance

micro switch. Then tighten the set cam screws; ON/OFF electric actuator

11. loosen the set screw in the cam 4 (blue color) and rotate the cam until it pushes the limit switch FCU1 and until the “click” of the electromechanical The electric actuator does not need any kind of maintenance. The internal lubrication of the gears is sufficient for the device life. For enclosure

Fig.5 Electric actuator particular of the terminal block “POT” micro switch. Then tighten the set cam screws. cleaning, use a light non-aggressive detergent. In case of damages or operation issues, we suggest sending the actuators back to Valbia for inspection.

Valbia s.r.l. declines responsibility and warranty on our actuators repaired from any third party.

6.4 Heaters (Fig.6)

All the actuators are equipped with “RIS” heating resistors which work only if the actuator is connected to the power supply, when the motor is not rotating

and the temperature inside the actuator goes down to 25°C / 77°F. They protect the actuator from the formation of condensation due to temperature

Fig.8

changes. The resistors are part of the electronics, they do not require additional wiring and are disabled when the internal temperature exceed 25°C / 77° F.

WARNING: to guarantee the normal operation of the resistors, it is necessary to keep the actuator connected to the power supply even in the open/close

positions.

RESISTORS “RIS”

CAM 4

CAM 3

CAM 2

CAM 1

Fig.6 Electric actuator particular of the heating resistors “RIS”

6.5 Signal lamp unit

Fig.7 Particular of the cams of limit switches

• On the power supply board, a green light (LED)indicates that the actuator is powered on;

• on the control board, a yellow light (LED) indicates the actuator working mode:

- slow flashing: the power supply is provided on the terminal block “F”;

- fast flashing: the power supply is provided by the battery backup;

5 6 7 8

VALBIA S.r.l. - Via Industriale, 30 - 25065 Lumezzane S.S. (BS) Italia - Tel. +39 030 8969411 - Fax +39 030 8610014 - www.valbia.it - E-mail valbia@bonomi.it Instructions sheet 90004000059 Rev. D

Das könnte Ihnen auch gefallen

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Wcenim2064 en AqDokument4 SeitenWcenim2064 en AqaleNoch keine Bewertungen

- An I0QVGhXXZVE6CctefD2tbkXiL9xW0XtbDJhPPNITLJlgwg1JxFvCglq 4o6mXL8dyqUPvsZKxO8zISFfPBys5AnCtrnJ bTecanUwMcOTq6k3StpvsTi 0nSrgDokument2 SeitenAn I0QVGhXXZVE6CctefD2tbkXiL9xW0XtbDJhPPNITLJlgwg1JxFvCglq 4o6mXL8dyqUPvsZKxO8zISFfPBys5AnCtrnJ bTecanUwMcOTq6k3StpvsTi 0nSrgAmit JainNoch keine Bewertungen

- Wireless Po en 0758-1029-82 v2001Dokument1 SeiteWireless Po en 0758-1029-82 v2001Jose Cano SaezNoch keine Bewertungen

- NN BlokDokument3 SeitenNN BlokMarko ŽivkovićNoch keine Bewertungen

- Innovance H2U Data SheetDokument2 SeitenInnovance H2U Data SheetAmr samir ShahinNoch keine Bewertungen

- Electrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ADokument3 SeitenElectrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ARodrigo Pedraza GalazNoch keine Bewertungen

- KV-5500/5000/3000 KV-DR1: Programmable ControllerDokument2 SeitenKV-5500/5000/3000 KV-DR1: Programmable ControllerCatngoNoch keine Bewertungen

- Crate V33-212Dokument7 SeitenCrate V33-212Danielo ErréNoch keine Bewertungen

- Schematics and SchedulesDokument24 SeitenSchematics and SchedulesWassim DaherNoch keine Bewertungen

- KT-502H en Tcd210202ab 20211221 Inst WDokument1 SeiteKT-502H en Tcd210202ab 20211221 Inst WGopal HegdeNoch keine Bewertungen

- Schedule of Loads: Notes and SpecificationsDokument1 SeiteSchedule of Loads: Notes and SpecificationsAngelice Alliah De la CruzNoch keine Bewertungen

- 777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsDokument2 Seiten777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsNorman CoetzeeNoch keine Bewertungen

- Elan - 72 5BB P-Type PERC Bifacial PV ModuleDokument2 SeitenElan - 72 5BB P-Type PERC Bifacial PV Modulenitin9860Noch keine Bewertungen

- SP0793-E951.00-G30-1252 - Rev A - VSD - Block Diagram - ABB - 2021-01-20Dokument2 SeitenSP0793-E951.00-G30-1252 - Rev A - VSD - Block Diagram - ABB - 2021-01-2018-01-0096Noch keine Bewertungen

- 65 93 PR Pid 01090 - 0001 - BDokument1 Seite65 93 PR Pid 01090 - 0001 - BgeocaustasNoch keine Bewertungen

- Datasheet PDFDokument1 SeiteDatasheet PDFRycky de la CruzNoch keine Bewertungen

- ST MicroInverter SchemeticDokument12 SeitenST MicroInverter Schemeticpuspendu janaNoch keine Bewertungen

- 2 SC 5287Dokument1 Seite2 SC 5287Angelos AnagnostouNoch keine Bewertungen

- QB400Dokument2 SeitenQB400Éverton KafskiNoch keine Bewertungen

- WeldForceKWF200S Om enDokument22 SeitenWeldForceKWF200S Om enValiBardaNoch keine Bewertungen

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0Dokument2 SeitenField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5022 0hugoNoch keine Bewertungen

- ABB - AF - Contactor - 4poleDokument6 SeitenABB - AF - Contactor - 4poleAhmad HamdanNoch keine Bewertungen

- Panel Drawing PDFDokument40 SeitenPanel Drawing PDFashutosh200967% (3)

- 11-12-Bruner - FINAL27 12 23Dokument756 Seiten11-12-Bruner - FINAL27 12 23Adolfo Augusto Salazar HernandezNoch keine Bewertungen

- Plts Chemco Karawang 3.2 MWP: LegendDokument3 SeitenPlts Chemco Karawang 3.2 MWP: LegendmuliamakmurNoch keine Bewertungen

- Tecnical DataDokument1 SeiteTecnical DataNADERNoch keine Bewertungen

- 3 Mps Building Dingras ElectricalDokument7 Seiten3 Mps Building Dingras ElectricalJuan MarcosNoch keine Bewertungen

- Acs 6t UsermanualDokument4 SeitenAcs 6t UsermanualMuhammad rizkiNoch keine Bewertungen

- Silicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)Dokument1 SeiteSilicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)miloud1911Noch keine Bewertungen

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Dokument1 SeiteSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Angel Simo MoralesNoch keine Bewertungen

- Cat Dcs Sis Controller (1) 938gllDokument4 SeitenCat Dcs Sis Controller (1) 938gllhernanNoch keine Bewertungen

- User Guide: IT6000-IOT Series HMIDokument2 SeitenUser Guide: IT6000-IOT Series HMINgọc NhấtNoch keine Bewertungen

- Celpac: Solid State Relays & ContactorsDokument5 SeitenCelpac: Solid State Relays & ContactorsOmarAlirioSuarezCañareteNoch keine Bewertungen

- Renewable Energy: Solar Central Systems & AccessoriesDokument23 SeitenRenewable Energy: Solar Central Systems & AccessoriesAchira DasanayakeNoch keine Bewertungen

- User Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetDokument2 SeitenUser Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetyanlayNoch keine Bewertungen

- Operation Manual: Fieldbus DeviceDokument1 SeiteOperation Manual: Fieldbus DeviceRodrigo CostaNoch keine Bewertungen

- (For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedDokument1 Seite(For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedAbid AyubNoch keine Bewertungen

- UntitledjsjjsDokument1 SeiteUntitledjsjjsPaulo GallardoNoch keine Bewertungen

- Plano de Blindaje 24MDokument2 SeitenPlano de Blindaje 24MAndree Ayma NuñezNoch keine Bewertungen

- 2SC3263 en 10044835Dokument2 Seiten2SC3263 en 10044835Janos NagyNoch keine Bewertungen

- wm-558 2d Drawing PDFDokument5 Seitenwm-558 2d Drawing PDFEgidijus DaukšysNoch keine Bewertungen

- WLAN InstallationDokument29 SeitenWLAN Installation4cvnwvf26pNoch keine Bewertungen

- RM-74 RM-75 Schematics V2 0Dokument8 SeitenRM-74 RM-75 Schematics V2 0Владимир КлюевNoch keine Bewertungen

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDokument6 Seiten993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeNoch keine Bewertungen

- Plano Eléctrico Camión 793DDokument4 SeitenPlano Eléctrico Camión 793DCarlos Florencio UrbanoNoch keine Bewertungen

- Cat 312c Diagr Elec PDFDokument4 SeitenCat 312c Diagr Elec PDFDaniel GalvisNoch keine Bewertungen

- Cat 312c Diagr ElecDokument4 SeitenCat 312c Diagr ElecDaniel Galvis75% (12)

- Field / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0Dokument2 SeitenField / Campo Remote I/O Cabinet / Gabinete de E/S Remotas: MQ13-02-DR-3210-IN5042 0hugoNoch keine Bewertungen

- Lc1d18e7 Datasheet Us En-UsDokument7 SeitenLc1d18e7 Datasheet Us En-UsnusaNoch keine Bewertungen

- EGX100 - Installation Guide PDFDokument2 SeitenEGX100 - Installation Guide PDFRodolfoAntonioLeónCárdenasNoch keine Bewertungen

- Electrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsDokument4 SeitenElectrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsJose luis ConsuegraNoch keine Bewertungen

- Winone Elevator Connection DiagramDokument40 SeitenWinone Elevator Connection DiagramMuhammad Rashid75% (4)

- Accessories: 120 - Professional Blue Power Tools For Trade & IndustryDokument28 SeitenAccessories: 120 - Professional Blue Power Tools For Trade & IndustryD Manmath RaoNoch keine Bewertungen

- 15 000-Bcl2000414-El-Dr-1 - AfcDokument1 Seite15 000-Bcl2000414-El-Dr-1 - AfcYousab JacobNoch keine Bewertungen

- Plano ElectricoDokument2 SeitenPlano Electricomauricio suarezNoch keine Bewertungen

- Equipment Grounding ConductorDokument1 SeiteEquipment Grounding Conductoramelna enterpriNoch keine Bewertungen

- 300 WATTS: 12 V Prim 190 To 440 V + Active PFCDokument1 Seite300 WATTS: 12 V Prim 190 To 440 V + Active PFCGuillaume FoubertNoch keine Bewertungen

- Bid Plan - AveryDokument8 SeitenBid Plan - AveryMarc LxmnNoch keine Bewertungen

- Mpfiltri Icm 201.017Dokument4 SeitenMpfiltri Icm 201.017kikinNoch keine Bewertungen

- Visual Index: Catalog 4400 USDokument30 SeitenVisual Index: Catalog 4400 USRodrigo González SilvaNoch keine Bewertungen

- Lovejoy CouplingsDokument28 SeitenLovejoy CouplingsCarlos Alberto Bardales GarciaNoch keine Bewertungen

- Dahua XVR ManualDokument7 SeitenDahua XVR ManualkikinNoch keine Bewertungen

- Wolflube Catalog 2016Dokument161 SeitenWolflube Catalog 2016kikinNoch keine Bewertungen

- Icount LCM20Dokument5 SeitenIcount LCM20Subash SenwarNoch keine Bewertungen

- Settima - ParkerDokument40 SeitenSettima - ParkerkikinNoch keine Bewertungen

- Settima Screw Pumps - SMT SeriesDokument28 SeitenSettima Screw Pumps - SMT SerieskikinNoch keine Bewertungen

- Logo! V8 230v DatasheetDokument2 SeitenLogo! V8 230v DatasheetkikinNoch keine Bewertungen

- Dehydration of Emulsified Lubricating OilDokument7 SeitenDehydration of Emulsified Lubricating OilkikinNoch keine Bewertungen

- BS08B and ASA-40 Sprocket DimensionsDokument1 SeiteBS08B and ASA-40 Sprocket DimensionskikinNoch keine Bewertungen

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalDokument11 SeitenStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalBryan Pérez PérezNoch keine Bewertungen

- Advanced Power Electronics Corp.: AP70T03GH/JDokument4 SeitenAdvanced Power Electronics Corp.: AP70T03GH/JkikinNoch keine Bewertungen

- BFT P Series - Instruction ManualDokument12 SeitenBFT P Series - Instruction ManualkikinNoch keine Bewertungen

- Engineering DataDokument26 SeitenEngineering DataadcaNoch keine Bewertungen

- Pid Legend PDFDokument1 SeitePid Legend PDFSocMed Dtk UI0% (1)

- Fabia 2 Fitting LocationsDokument128 SeitenFabia 2 Fitting Locationskikin100% (1)

- Fabia II SM - 25 PDFDokument1.744 SeitenFabia II SM - 25 PDFFarid MchNoch keine Bewertungen

- 2018 Alemite Product CatalogDokument220 Seiten2018 Alemite Product CatalogAnonymous H3I29yjNoch keine Bewertungen

- 1 Safety: VLT Micro Drive FC 51 Operating InstructionsDokument70 Seiten1 Safety: VLT Micro Drive FC 51 Operating InstructionsTaufiqurrahman100% (1)

- Swagelok Ball ValveDokument4 SeitenSwagelok Ball ValvePhornlert WanaNoch keine Bewertungen

- Mechatronics. Electronic Control Systems in Mechanical and Electrical EngineeringDokument649 SeitenMechatronics. Electronic Control Systems in Mechanical and Electrical EngineeringDaniaNoch keine Bewertungen

- Sigma - 2 - Operating Instructions S2BADokument52 SeitenSigma - 2 - Operating Instructions S2BApatipanpanitanNoch keine Bewertungen

- ABV ActuatorsDokument32 SeitenABV Actuatorsadil_farooq_6Noch keine Bewertungen

- SMC The PneubookDokument79 SeitenSMC The PneubookTisha LaneNoch keine Bewertungen

- Mechatronics AssignmentDokument60 SeitenMechatronics Assignmentkavindya GeemaduNoch keine Bewertungen

- Airframe Stock ListDokument546 SeitenAirframe Stock List2yp4sj97vcNoch keine Bewertungen

- 01 AircSystDokument4 Seiten01 AircSystrecastorNoch keine Bewertungen

- Electronic Control SystemDokument14 SeitenElectronic Control Systemgsantosh06Noch keine Bewertungen

- Automatic Pneumatic Bumper and Break Actuation BeforeDokument11 SeitenAutomatic Pneumatic Bumper and Break Actuation BeforePraveen KumarNoch keine Bewertungen

- KSB Valves 2023Dokument68 SeitenKSB Valves 2023leonardseniorNoch keine Bewertungen

- Control ValveDokument98 SeitenControl ValveawanishupNoch keine Bewertungen

- Actuation Sizing ChartDokument12 SeitenActuation Sizing ChartBùi Cảnh TrungNoch keine Bewertungen

- Pneumatic Positioner Electropneumatic Positioner Type 3760: Mounting and Operating InstructionsDokument36 SeitenPneumatic Positioner Electropneumatic Positioner Type 3760: Mounting and Operating InstructionsRoger Molina GomezNoch keine Bewertungen

- Slides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H RashidDokument43 SeitenSlides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H Rashidjohnyrock07100% (2)

- ShowjytjtDokument91 SeitenShowjytjteducator56Noch keine Bewertungen

- Product Manual 26518V3 (Revision C) : Micronet TMR 5009Ft Fault-Tolerant Steam Turbine ControlDokument240 SeitenProduct Manual 26518V3 (Revision C) : Micronet TMR 5009Ft Fault-Tolerant Steam Turbine Controlkazmi81Noch keine Bewertungen

- Catálogo Del Actuador LHSDokument8 SeitenCatálogo Del Actuador LHSJohn CruzNoch keine Bewertungen

- Bettis TS GseriesDokument5 SeitenBettis TS GseriesLimin ZhangNoch keine Bewertungen

- Variable Flow PICV - Case StudyDokument19 SeitenVariable Flow PICV - Case StudySikander AahilNoch keine Bewertungen

- Spray Rinse & Steam HandlingDokument8 SeitenSpray Rinse & Steam Handlingkresimir.mikoc9765Noch keine Bewertungen

- Mod 1BDokument13 SeitenMod 1BfernandoNoch keine Bewertungen

- Information Product-Markets - 59-2021 - Pneumatic Actuator Type PPA+ - Pneumatic Ball Valve Type 546 Pro PDokument7 SeitenInformation Product-Markets - 59-2021 - Pneumatic Actuator Type PPA+ - Pneumatic Ball Valve Type 546 Pro POmar GuillenNoch keine Bewertungen

- Advanced BFV BrochureDokument4 SeitenAdvanced BFV Brochureenlightened1718Noch keine Bewertungen

- ElectricActuatorBasics CEPMagazine JustinLedger PDFDokument6 SeitenElectricActuatorBasics CEPMagazine JustinLedger PDFElvis Alberto Rodriguez BravoNoch keine Bewertungen

- HT-TM2200-75-E4: Rotary ActuatorDokument3 SeitenHT-TM2200-75-E4: Rotary ActuatorJan Antonius DjunaediNoch keine Bewertungen

- Beco Catalog PDFDokument87 SeitenBeco Catalog PDFMd. Mominul IslamNoch keine Bewertungen

- (G) 72K Series Installation and Operation Instruction: Electrohydraulic ServovalveDokument4 Seiten(G) 72K Series Installation and Operation Instruction: Electrohydraulic Servovalvephankhoa83-1Noch keine Bewertungen

- 667 Actuator PDFDokument8 Seiten667 Actuator PDFAlejandro Ruiz de la CruzNoch keine Bewertungen

- Bray Actuators Series 9293Dokument12 SeitenBray Actuators Series 9293Rafael CardosoNoch keine Bewertungen