Beruflich Dokumente

Kultur Dokumente

We Provide Position Feedback and Sensors For Hazardous Areas!

Hochgeladen von

Wen-Sheng JangOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

We Provide Position Feedback and Sensors For Hazardous Areas!

Hochgeladen von

Wen-Sheng JangCopyright:

Verfügbare Formate

We Provide Position Feedback and Sensors

for Hazardous Areas!

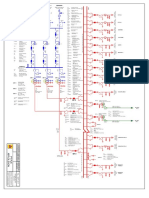

ZONE 0

ZONE 1 ZONE 2

BTL_-_ _ _-M_ _ _ _-J-DEXC-TA12 BTL_-_ _ _-M_ _ _ _-_-DEX_-_ _ _ _ BTL_-_ _ _-M_ _ _ _-_-NEX-_ _ _ _

Explanation of Markings

ATEX IECEx NEC

Marking according to EU directive 2014/34/EU (ATEX) Marking according to EN 60079 and IEC 60079 Marking according to NEC 500 (US)/CEC Annex J (CA)

Gas II 1/2G Ex d IIC T6/T5 Ga/Gb Ta +65 °C (T6) + 80 °C (T5) Class I Division 1 Groups ABCD T5/T6

1 2a 3 4 5a 6a 7 9 10 11 12 13

Dust II 1/2D Ex t IIIC T85/T100 °C Da IP68 Ta +65 °C (T85) + 80 °C (T100) Class II Division 1 Groups EFG T5/T6

1 2b 3 4 5b 6b 7 8 9 10 11 12 13

Class III Enclosure Type 4X/6P

10 14

Ambient Temperature Range: –40...+65 °C (T6) or –40...+80 °C (T5)

Zone 21 (2D) Marking according to NEC 505 (US)

Zone 2 (3G)

Zone 1 (2G) Class I Zone 1 AEx d IIC T5/T6 Ga/Gb

10 15 16 17 18 13 19 Zone 1 Zone 0 Zone 2

1 Equipment Group

Division 1 Division 1 Division 2

2a Equipment Category Gas (/= marking of a device with two categories) 10 Hazard Class

2b Equipment Category Dust 11 Permitted Division

Zone 22 (3D) 3 (Ex for Electrical Apparatus) 12 Permitted Group

Zone 0 (1G) 4 Type of Protection 13 Temperature Class Zone 0

Zone 20 (1D) 5a Explosion Group Gas 14 (U.S. Enclosure Type) Division 1

5b Explosion Group Dust 15 Permitted Zone

6a Temperature Class (Gas) 16 A = American National Standard

6b Max. Surface Temperature (Dust) Ex = Explosion Protected

7 EPL-Equipment Protection Level 17 Type of Protection

8 (IP-Code) 18 Explosion Group

9 (Max. Ambient Temperature) 19 (EPL-Equipment Protection Level)

Equipment Group I-Mines II – Other Places 2a 2b 4 Protection Type for Electrical Apparatus Area Classification

Explosive atmosphere Continuously, for a long Occasionally Rarely and for a short Type of Protection Symbol Symbol EPL 7 For Zone Standard Definition 11 Flammable Material/ Flammable Material/ Flammable Material/

period frequently period Alternative 15 Present Continously Present Intermittently Present Abnormally

Hazardous places Zone 0 Zone 20 Zone 1 Zone 21 Zone 2 Zone 22 Increased safety e eb Gb 1 EN 60079-7 Additional measures are applied to prevent the possi- NEC 505 (US) Zone 0 Zone 1 Zone 2

Equipment category M1 or M2 1G 1D 2G 2D 3G 3D bility of inadmissibly high temperatures and the occur- NEC 500 (US) Division 1 Division 2

EPL (IEC/EN 60079-0) Ma or Mb Ga Da Gb Db Gc Dc rence of sparks or electric arcs within the enclosure or CEC Section 18 (CA) Zone 0 Zone 1 Zone 2

on exposed parts of electrical equipment, where such CEC Annex J (CA) Division 1 Division 2

ignition sources would not occur in normal service. US classification per ANSI/NFPA 70 National Electrical Code (NEC) Article 500 or Article 505

1 Equipment Group Definition CA classification per CSA C22.1 Canadian Electrical Code (CEC) Section 18 or Annex J

Flameproof enclosures d db Gb 1 EN 60079-1 Parts which can ignite a potentially explosive at-

I Equipment group I applies to equipment intended for use in underground parts

mosphere are surrounded by an enclosure which

of mines, and to those parts of surface installations of such mines, liable to be Balluff DEX

withstands the pressure of an explosive mixture 16 Type of Protection Code Country Application Protection Standard

endangered by firedamp and/or combustible dust. 17 Principle

exploding inside the enclosure and prevents the

II Equipment group II applies to equipment intended for use in other places liable General requirements US Class I, Division 1 and 2 FM 3600

transmission of the explosion to the atmosphere

to be endangered by explosive atmospheres. CA Class I, Division 1 and 2 CSA C22.2 No. 0

surrounding the enclosure.

AEx US Class I, Division 1 and 2 ISA 60079-0

Ex CA Class I, Division 1 and 2 CSA C22.2

Pressurized enclosures px pxb Gb 1 EN 60079-2 The formation of a potentially explosive atmos-

Zone Definition No. 60079-0

py pyb Gb 1 phere inside an enclosure is prevented by maintaining

Zone 0 A place in which a hazardous explosive atmosphere consisting of a mixture with air of Increased safety AEx e (or AEx eb) US Class I, Zone 1 ISA 60079-7

pz pzc Gc 2 a positive internal pressure of protective gas in relation

flammable substances in the form of gas, vapor or mist is present continuously or for Ex e CA Class I, Zone 1 CSA C22.2

p pb Db 21 to the surrounding atmosphere and by supplying the

long periods or frequently. No. 60079-7

p pc Dc 22 inside of the enclosure with a constant flow of protec- No arcs,

Zone 1 A place in which an explosive atmosphere consisting of a mixture of air with Non-incendive (NI) US Class I, Division 2 FM 3611

tive gas which dilutes any combustible mixtures. sparks or

flammable substances in the form of gas, vapour or mist is likely to occur in normal (NI) CA Class I, Division 2 CSA C22.2 No. 213

Intrinsic safety ia ia Ga and 0, 20 EN 60079-11 Equipment only contains intrinsically safe electric hot surfaces

operation occasionally. Non-sparking AEx nA (or AEx nAc) US Class I, Zone 2 ISA 60079-15

ib ib Da circuits. An electric circuit is intrinsically safe if any

Zone 2 A place in which an explosive atmosphere consisting of a mixture of air with Balluff EEX Ex nA CA Class I, Zone 2 CSA C22.2

ic ic Gb and 1, 21 spark or thermal effect produced under normal

flammable substances in the form of gas, vapour or mist is not likely to occur in No.60079-15

Db operation is not capable of causing ignition of a

normal operation but, if it does occur, will persist for a short period only. Explosionproof (XP) US Class I, Division 1 FM 3615

Gc 2 given explosive atmosphere.

Zone 20 A place in which an explosive atmosphere in the form of a cloud of combustable dust (XP) CA Class I, Division 1 CSA C22.2 No. 30

in air is present continously, or for long periods or frequently. Flameproof AEx d (or AEx db) US Class I, Zone 1 ISA 60079-1

Oil immersion o ob Gb 1 EN 60079-6 Equipment are immersed in a protective fluid Ex d CA Class I, Zone 1 CSA C22.2

Zone 21 A place in which an explosive atmosphere in the form of a cloud of combustible dust

(e. g. oil) in such a way that a potentially explosive Contain

in air is likely to occur in normal operation occasionally. No. 60079-1

atmosphere existing above the surface or outside the explosion

Zone 22 A place in which an explosive atmosphere in the form of a cloud of combustible dust Powder-filled AEx q (or AEx qb) US Class I, Zone 1 ISA 60079-5

of the encapsulation cannot be ignited. and extinguish

in air is not likely to occur in normal operation but, if it does occur, will persist for a Ex q CA Class I, Zone 1 CSA C22.2

the flame

short period only. No.60079-5

Powder filling q qb Gb 1 EN 60079-5 Filling the enclosure with a fine grained packing Enclosed break AEx nC (or AEx nCc) US Class I, Zone 2 ISA 60079-15

material has the effect of making it impossible Ex nC CA Class I, Zone 2 CSA C22.2

for an electric arc created in the enclosure under No.60079-15

normal operating conditions to ignite a potentially Intrinsic safety (I.S.) US Class I, Division 1 FM 3610

Applications explosive atmosphere surrounding the enclosure. (I.S.) CA Class I, Division 1 CSA C22.2 No. 157

Ignition must neither be caused by flames nor by AEx ia US Class I, Zone 0 FM 3610

elevated temperatures on the enclosure surface. Ex ia CA Class I, Zone 0 CSA C22.2

No. 60079-11

Encapsulation ma Ga and Da 0, 20 EN 60079-18 Parts that are capable of igniting an explosive AEx ib US Class I, Zone 1 FM 3610

Zone 1 mb Gb and Db 1, 21 atmosphere are enclosed in a compound in such Ex ib CA Class I, Zone 1 Limit energy CSA C22.2

mc Gc and Dc 2, 22 a way that ignition of an explosive atmosphere is of sparks and No. 60079-11

prevented. AEx ic US Class I, Zone 2 surface temperature FM 3610

Ex ic CA Class I, Zone 2 CSA C22.2

Type of protection „n“ EN 60079-15 Additional measures are applied to prevent the No. 60079-11

Non-sparking nA nAc Gc 2 occurrence of sparks or electric arcs within the Limited energy AEx nC (or AEx nCc) US Class I, Zone 2 ISA 60079-15

enclosure, where such ignition sources would not

Balluff NEX

occur in normal service. Ex nL CA Class I, Zone 2 CSA C22.2

No. 60079-15

Pressurized Type X US Class I, Division 1 FM 3620 (NFPA 496)

Spark-proof nC nCc Gc 2 Type X CA Class I, Division 1 NFPA 496

Restricted breathing nR nRc Gc 2 Type Y US Class I, Division 1 FM 3620 (NFPA 496)

Zone 0 Type Y CA Class I, Division 1 NFPA 496

Protection by enclosures ta Da 20 EN 60079-31 Tightness of the enclosure prevents ingress of Type Z US Class I, Division 2 FM 3620 (NFPA 496)

tb Db 21 dust or limits it to a nonhazardous amount. Type Z CA Class I, Division 2 NFPA 496

tc Dc 22 The surface temperature of the enclosure must AEx px (or AEx pxb) US Class I, Zone 1 ISA 60079-2

IPXX not ignite the surrounding atmosphere. Ex px CA Class I, Zone 1 CSA C22.2

No. 60079-2

AEx py (or AEx pyb) US Class I, Zone 1 ISA 60079-2

5a Explosion Groups Ex py CA Class I, Zone 1 CSA C22.2

Gas No. 60079-2

Position feedback Level monitoring

IIA IIB IIC Ignition Temperature Temperature Class AEx pz (or AEx pzc) US Class I, Zone 2 ISA 60079-2

Ammonia, methane, Town gas, acrylonitrile Hydrogen > 450 °C T1...T6 Ex pz CA Class I, Zone 2 CSA C22.2

ethane, propane Keep No. 60079-2

Ethanol, cyclohexane, Ethylene, ethylene oxide Acetylene > 300...450 °C T2...T6 Restricted breathing AEx nR (or AEx nRc) US Class I, Zone 2 flammable ISA 60079-15

n-butane Ex nR CA Class I, Zone 2 gas out CSA C22.2

Gasoline, kerosene, Ethylene glycol, > 200...300 °C T3...T6 No. 60079-15

n-hexane hydrogen sulfide Encapsulation AEx ma US Class I, Zone 0 ISA 60079-18

Acetic aldehyde Ethyl ether > 135...200 °C T4...T6 Ex ma CA Class I, Zone 1 CSA C22.2

> 100...135 °C T5...T6 No. 60079-18

Carbon disulfide > 85...135 °C T6...T6 AEx m US Class I, Zone 1 ISA 60079-18

AEx mb US Class I, Zone 1 ISA 60079-18

6a Ignition Temperature of Max. Surface Temperature Class Ex mb CA Class I, Zone 1 CSA C22.2

Gases and Vapors Temperature on the No. 60079-18

Equipment AEx mc US Class I, Zone 2 ISA 60079-18

500 bar

Information and illustrations are non-binding. We reserve the right to changes in technology, form and features. No claims shall be recognized from specifications or illustrations.

> 450 °C 450 °C T1 Ex mc CA Class I, Zone 2 CSA C22.2

> 300...450 °C 300 °C T2 No. 60079-18

> 200...300 °C 200 °C T3 Oil immersion AEx o (or AEx ob) US Class I, Zone 1 ISA 60079-6

> 135...200 °C 135 °C T4 Ex o CA Class I, Zone 1 CSA C22.2

> 100...135 °C 100 °C T5 No. 60079-6

> 85...135 °C 85 °C T6

Group

5b Explosion Groups Substance Hazard Class 1010 NEC 500 12 NEC 505 18

Detect end-of-travel positions Dust Acetylene Group A IIC

IIIA IIIB IIIC Ignition Temperature Temperature Class Hydrogen Group B IIC

Combustible flyings Non-conductive dust Conductive dust Surface temperature is Non Ethylene Class I Group C IIB

specified directly Propane Group D IIA

For further information about products with Ex certificates please refer to Methane (mining) Group D

www.balluff.com/sensors-with-ex-certificates Metal (conductive) dust Group E

Coal (carbonaceous) dust Class II Group F

Grain dust Group G

Combustible fibers and flyings Class III, fibers and flyings

13 Temperature Classes

NEC 505 (US) NEC 500 (US) Max. Surface Temperature 6b

T1 T1 450 °C

T2 T2 300 °C

T2A 280 °C

T2B 260 °C

T2C 230 °C

T2D 215 °C

T3 T3 200 °C

T3A 180 °C

T3B 165 °C

T3C 160 °C

T4 T4 135 °C

T4A 120 °C

T5 T5 100 °C

T6 T6 85 °C

Balluff GmbH, Schurwaldstrasse 9, 73765 Neuhausen a.d.F., Germany,

Phone +49 7158 173-0, Fax +49 7158 5010, balluff@balluff.de, www.balluff.com

Doc. No. 922419/Mat. No. 246745 EN, E16; Subject to modification. Replaces G15.

Das könnte Ihnen auch gefallen

- Subaru Legacy MY05-09 Service Manual CompleteDokument4.537 SeitenSubaru Legacy MY05-09 Service Manual Completemvillalonm88% (16)

- 2011 STI Full Service ManualDokument3.350 Seiten2011 STI Full Service Manualsean m100% (2)

- Subaru Forester Service Manual PDFDokument3.548 SeitenSubaru Forester Service Manual PDFNick Nickart100% (7)

- Subaru Legacy Outback 2009 Service ManualDokument20 SeitenSubaru Legacy Outback 2009 Service Manualtanna100% (22)

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Hazardous Area ClassificationsDokument1 SeiteHazardous Area ClassificationsAndrew Bull100% (2)

- PotentiometryDokument27 SeitenPotentiometryShafique Ahmed100% (2)

- RPM PBD T4 MateDokument6 SeitenRPM PBD T4 MateAen Muhammed NorNoch keine Bewertungen

- Table of Specification: Republic of The PhilippinesDokument1 SeiteTable of Specification: Republic of The PhilippinesRosel DumlaoNoch keine Bewertungen

- Blan FlowMeterB3000 UmDokument60 SeitenBlan FlowMeterB3000 UmJavier LopezNoch keine Bewertungen

- Access Elevator SupplyDokument260 SeitenAccess Elevator SupplyRath Asypaden100% (1)

- ThamesSideIndia T34Dokument4 SeitenThamesSideIndia T34Bulk WeighingNoch keine Bewertungen

- PRD Doc Buw 669835-00001 Sall Ain V10Dokument60 SeitenPRD Doc Buw 669835-00001 Sall Ain V10Amer CajdricNoch keine Bewertungen

- HRMD91Dokument3 SeitenHRMD91Alex ValdezNoch keine Bewertungen

- Norgren-42xx Ex Me CoilsDokument3 SeitenNorgren-42xx Ex Me CoilsGHDEngNoch keine Bewertungen

- EFSC Rotary and selector switches installation and technical featuresDokument2 SeitenEFSC Rotary and selector switches installation and technical featuresYasminNoch keine Bewertungen

- EX AT: Equipment CategoriesDokument2 SeitenEX AT: Equipment CategoriesAminNoch keine Bewertungen

- FT GB Teboply Okoume ExterieurDokument2 SeitenFT GB Teboply Okoume ExterieurDumitrache IulianNoch keine Bewertungen

- 8146 Terminal Boxes PDFDokument13 Seiten8146 Terminal Boxes PDFhandyalhabsyiNoch keine Bewertungen

- Subaru Legacy Outback 2008 Service ManualDokument20 SeitenSubaru Legacy Outback 2008 Service Manualbrandon100% (46)

- Alkai Aggregate Reation of Concrete StructuresDokument60 SeitenAlkai Aggregate Reation of Concrete StructuresAndrea PerezNoch keine Bewertungen

- HazLoc Guide To Zoned EquipmentDokument8 SeitenHazLoc Guide To Zoned EquipmentDzeminSinNoch keine Bewertungen

- Laboratorium Jasa Konstruksi PT WIJAYA KARYA (Persero) TBK: SymbolDokument1 SeiteLaboratorium Jasa Konstruksi PT WIJAYA KARYA (Persero) TBK: Symbolreza ahmad ramdhaniNoch keine Bewertungen

- Manual de Utilizare Detector de Miscare Dual PIR Hikvision DS-PDP18-EG2 PDokument4 SeitenManual de Utilizare Detector de Miscare Dual PIR Hikvision DS-PDP18-EG2 PValiHusacNoch keine Bewertungen

- FB5204B3Dokument4 SeitenFB5204B3Renato RodriguesNoch keine Bewertungen

- Course: Boeing 777-200/200er/300/300er B1 - Phase 10 - Av ExtDokument26 SeitenCourse: Boeing 777-200/200er/300/300er B1 - Phase 10 - Av ExtMuhammed YaseenNoch keine Bewertungen

- Atexor ATEX GUIDELINESDokument1 SeiteAtexor ATEX GUIDELINESDhiven VesNoch keine Bewertungen

- Hazardous Areas - How to Identify Explosionproof SolenoidsDokument5 SeitenHazardous Areas - How to Identify Explosionproof SolenoidsShahram GhassemiNoch keine Bewertungen

- Etn4044 - Pentaksiran Praktikal 1Dokument5 SeitenEtn4044 - Pentaksiran Praktikal 1Sarul AfidaNoch keine Bewertungen

- AIRCAT2222 Dissection Lyst7706Dokument1 SeiteAIRCAT2222 Dissection Lyst7706HARSHIT BHATIANoch keine Bewertungen

- Surface Thermocouple Temperature MonitoringDokument12 SeitenSurface Thermocouple Temperature MonitoringMaryoly BlancoNoch keine Bewertungen

- Baghouse Compressed AirDokument17 SeitenBaghouse Compressed Airmanh hung leNoch keine Bewertungen

- 4th Gen 2004-2009 Subaru Legacy Repair ManualDokument4.983 Seiten4th Gen 2004-2009 Subaru Legacy Repair Manualgreg monroeNoch keine Bewertungen

- Subaru Outback 2003 - 2009 PDFDokument5.980 SeitenSubaru Outback 2003 - 2009 PDFDddNoch keine Bewertungen

- 1 Atex Iecex Equipment Certification Guide Atexdelvalle 18Dokument5 Seiten1 Atex Iecex Equipment Certification Guide Atexdelvalle 18Nirmalan GanapathyNoch keine Bewertungen

- Binzel Cable Cat 2Dokument4 SeitenBinzel Cable Cat 2alessia olgiatiNoch keine Bewertungen

- Road Alignment SheetDokument4 SeitenRoad Alignment SheetsushilNoch keine Bewertungen

- A319 PerformanceDokument15 SeitenA319 PerformanceM A INoch keine Bewertungen

- FT TECBOR BOARDS ENv02Dokument3 SeitenFT TECBOR BOARDS ENv02Karim MakkiNoch keine Bewertungen

- HU How To Use Subaru WRX 2006Dokument5 SeitenHU How To Use Subaru WRX 2006Felipe Akamine YamauchiNoch keine Bewertungen

- Alimentatore PS440/xxx Per Terminali Di Pesatura Istruzioni Di SicurezzaDokument13 SeitenAlimentatore PS440/xxx Per Terminali Di Pesatura Istruzioni Di SicurezzaaswinraveendranNoch keine Bewertungen

- How To Use This Manual PDFDokument3 SeitenHow To Use This Manual PDFoscar lopezNoch keine Bewertungen

- 2014 ForesterDokument7.222 Seiten2014 ForesterMykhail KubasovNoch keine Bewertungen

- Subaru-Impreza 2003 en UNK Manual de Taller D12ab41c6bDokument3.604 SeitenSubaru-Impreza 2003 en UNK Manual de Taller D12ab41c6bMatias GallardoNoch keine Bewertungen

- Thebault Dop01 Teboply Ext GBDokument2 SeitenThebault Dop01 Teboply Ext GBDumitrache IulianNoch keine Bewertungen

- Geovision PMP5597D DuoDokument16 SeitenGeovision PMP5597D DuoOldman TestNoch keine Bewertungen

- How To Use This ManualsDokument8 SeitenHow To Use This ManualsЕвгений МихайловNoch keine Bewertungen

- 2009 Service ManualDokument3.619 Seiten2009 Service ManualJimmy BarNoch keine Bewertungen

- Wika TC10-HDokument12 SeitenWika TC10-HMS COPNoch keine Bewertungen

- Sinle Line CLGRU Nov 2017Dokument1 SeiteSinle Line CLGRU Nov 2017Sandi Junior SihotangNoch keine Bewertungen

- For3 GenerDokument96 SeitenFor3 GenerTheVojislavbbNoch keine Bewertungen

- Installation GuideDokument61 SeitenInstallation GuideVõ Quang HuyNoch keine Bewertungen

- Dali XC Control Module With 4 Freely Programmable Inputs: Data Sheet 09/18-CO070-9Dokument3 SeitenDali XC Control Module With 4 Freely Programmable Inputs: Data Sheet 09/18-CO070-9Sunil Dinanath JoshiNoch keine Bewertungen

- AS610/AS630 Outdoor Siren Installation SheetDokument6 SeitenAS610/AS630 Outdoor Siren Installation Sheetمحمد عبد الفتاح محمدNoch keine Bewertungen

- PPM 2017 3.0 Luminaires Etc (Daily)Dokument1 SeitePPM 2017 3.0 Luminaires Etc (Daily)Nazlie NasirNoch keine Bewertungen

- A0020281 - OP - Bartec DXN Plug and Socket SeriesDokument5 SeitenA0020281 - OP - Bartec DXN Plug and Socket SeriesKien NguyenNoch keine Bewertungen

- Anais Do Workshop De Micro-ondasVon EverandAnais Do Workshop De Micro-ondasNoch keine Bewertungen

- StarLAN Technology ReportVon EverandStarLAN Technology ReportBewertung: 3 von 5 Sternen3/5 (1)

- Profile of the International Pump Industry: Market Prospects to 2010Von EverandProfile of the International Pump Industry: Market Prospects to 2010Bewertung: 1 von 5 Sternen1/5 (1)

- Functional and Physical Properties of Polymer NanocompositesVon EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNoch keine Bewertungen

- The Revised en 13463-1 Standard For Non-Electrical Equipment For Use in Potentially Explosive AtmospheresDokument11 SeitenThe Revised en 13463-1 Standard For Non-Electrical Equipment For Use in Potentially Explosive Atmospheresibson045001256Noch keine Bewertungen

- En 13463-5-2003 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Constructional Safety CDokument32 SeitenEn 13463-5-2003 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Constructional Safety Cshreyshah2488Noch keine Bewertungen

- Clearance Reinvestigation Instructions CiDokument6 SeitenClearance Reinvestigation Instructions CiWen-Sheng JangNoch keine Bewertungen

- Signal CatalogueDokument246 SeitenSignal CatalogueWen-Sheng JangNoch keine Bewertungen

- 446 C 946 F 8 A 6 CC 35Dokument23 Seiten446 C 946 F 8 A 6 CC 35Wen-Sheng JangNoch keine Bewertungen

- Exercise 8-Life ScienceDokument2 SeitenExercise 8-Life ScienceKarinaNoch keine Bewertungen

- Bel Ray BrochureDokument20 SeitenBel Ray BrochureaditNoch keine Bewertungen

- MERCEDES MEDIC ACROYNMS GUIDEDokument6 SeitenMERCEDES MEDIC ACROYNMS GUIDEDProkhorov100% (1)

- 3TNV70 ASA BroDokument1 Seite3TNV70 ASA BroSaMos AdRiianNoch keine Bewertungen

- Parker Substrate 4250-InTRAFLOW Dec 2003Dokument12 SeitenParker Substrate 4250-InTRAFLOW Dec 2003Laurence MalanumNoch keine Bewertungen

- Cornell Notes 3Dokument3 SeitenCornell Notes 3api-302904199Noch keine Bewertungen

- Engineering Laboratory (En19003) Experiment No. 4 (Ee2) : Open Circuit and Short Circuit Test of Single Phase TransformerDokument4 SeitenEngineering Laboratory (En19003) Experiment No. 4 (Ee2) : Open Circuit and Short Circuit Test of Single Phase TransformerEvan JoshyNoch keine Bewertungen

- Ogjournal20150706 DLDokument136 SeitenOgjournal20150706 DLrasyid93Noch keine Bewertungen

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDokument6 SeitenAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsAvs ElectronNoch keine Bewertungen

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDokument2 SeitenPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNoch keine Bewertungen

- ασκήσεις υδραυλικων λαδιουDokument160 Seitenασκήσεις υδραυλικων λαδιουchristodoulos charalambousNoch keine Bewertungen

- Unit 9 - Optical AmplifierDokument55 SeitenUnit 9 - Optical Amplifiervidyasawant2012Noch keine Bewertungen

- Busway SpecificationDokument6 SeitenBusway SpecificationNATHANNoch keine Bewertungen

- Holec ERM TDRM Restart ModulesDokument6 SeitenHolec ERM TDRM Restart Modules0b0biyd,u,uNoch keine Bewertungen

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Dokument18 SeitenPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanNoch keine Bewertungen

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDokument2 SeitenMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongNoch keine Bewertungen

- ASTM D 1298-12b APIDokument8 SeitenASTM D 1298-12b APIMAJONoch keine Bewertungen

- GM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesDokument55 SeitenGM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesBrian NormanNoch keine Bewertungen

- Innovation SiemensDokument11 SeitenInnovation SiemensOviri Charles Umude-IgbruNoch keine Bewertungen

- TD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelDokument2 SeitenTD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelFelipe SilvaNoch keine Bewertungen

- An Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementDokument15 SeitenAn Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementMamta AgarwalNoch keine Bewertungen

- Dennis Miru Graphic Design PortfolioDokument9 SeitenDennis Miru Graphic Design PortfoliodenosciNoch keine Bewertungen

- The Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysDokument10 SeitenThe Kinetics of Hydrogen Absorption in Palladium (A - and P-Phase) and Palladium-Silver-AlloysJose Fernandez AdellNoch keine Bewertungen

- MMTDokument36 SeitenMMTAvoyNoch keine Bewertungen

- Rope CouplingDokument4 SeitenRope CouplingKamal KapaNoch keine Bewertungen

- Sebp4195 76 01 Allcd - 003 PDFDokument965 SeitenSebp4195 76 01 Allcd - 003 PDFFacturas hidrodieselNoch keine Bewertungen

- Chemistry Practice Paper SA1 Class 9 CBSEDokument2 SeitenChemistry Practice Paper SA1 Class 9 CBSEgurdeepsarora8738Noch keine Bewertungen

- Lzdzmobmvrtpctpfnstcm 0616 eDokument2 SeitenLzdzmobmvrtpctpfnstcm 0616 eMomo1010Noch keine Bewertungen