Beruflich Dokumente

Kultur Dokumente

Activities of SiO2 and Al2O3 and Activity Coefficients of FetO and MnO in CaO-SiO2-Al2O3-MgO Slags

Hochgeladen von

Rasul BzOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Activities of SiO2 and Al2O3 and Activity Coefficients of FetO and MnO in CaO-SiO2-Al2O3-MgO Slags

Hochgeladen von

Rasul BzCopyright:

Verfügbare Formate

Activities of SiO2 and Al2O3 and Activity Coefficients of FetO

and MnO in CaO-SiO2-Al2O3-MgO Slags

HIROKI OHTA and HIDEAKI SUITO

The activities of SiO2 and Al2O3 in CaO-SiO2-Al2O3-MgO slags were determined at 1873 K along

the liquidus lines saturated with 2CaO z SiO2, 2(Mg,Ca)O z SiO2, MgO, and MgO z Al2O3 phases

using a slag-metal equilibration technique. Based on these and previous results obtained in ternary

and quaternary slags, the isoactivity lines of SiO2 and Al2O3 over the liquid region on the 0, 10, 20,

30, and 40 mass pct Al2O3 planes and those on the 10 and 20 mass pct MgO planes were determined.

The activity coefficients of FetO and MnO, the phase boundary, and the solubility of MgO were also

determined.

I. INTRODUCTION activity coefficients of FetO and MnO and the solubility of

MgO were also obtained.

THE activities of components in ladle slags, which con-

sist of a CaO-SiO2-Al2O3-MgO system with a high

CaO/SiO2 ratio, are the most indispensable for the ther- II. EXPERIMENTAL

modynamic analysis of ladle refining processes such as de-

sulfurization, deoxidation, and other aspects. Rein and Eight grams of CaO-SiO2-MgO-FetO (0.07 to 1.2 pct)-

Chipman[1] determined the activities of SiO2 on the 10, 20, MnO (0.2 to 1.9 pct) or CaO-SiO2-Al2O3-MgO-FetO (0.04

and 30 mass pct MgO planes of this system at 1873 K from to 0.9 pct)-MnO (0.03 to 2.2 pct) slag and 30 g of Fe

the measurements of silicon distribution between slags and containing 0.0006 to 1.9 pct Si, 0 to 0.03 pct Al, and 0.04

Fe-Si-C alloys saturated with either graphite or silicon car- to 1.3 pct Mn were melted at 1873 K for 1 to 3 hours in

bide under PCO 5 1 atm. However, their slag compositions CaO and MgO crucibles and then quenched by water. In

are less basic than those used in ladle refining processes. previous slag-metal equilibrium experiments using CaO-

The activity coefficients of FetO and MnO in CaO-SiO2- Al2O3,[4] CaO-Al2O3-MgO,[6] and CaO-Al2O3-SiO2[5] slags,

Al2O3-MgO slags with compositions of low SiO2 and high the time for attainment of equilibrium was confirmed to be

CaO contents are also a basic prerequisite for the thermo- within 1 hour. All compositions in this article are given in

dynamic understanding of the reduction of FetO and MnO mass pct. The contents of the elements in metal and slag

in a ladle slag by the addition of Al, reoxidation of Al, and phases were determined by chemical analyses. Details of

desulfurization. Tsao and Katayama[2] measured the activity the experimental method and chemical analyses are given

coefficients of FetO in CaO (34 to 47 mass pct)—SiO2 (8 in the previous article.[7]

to 18 mass pct)—Al2O3 (22 to 41 mass pct)—MgO (10 to

15 mass pct) slags at 1873 K using a slag-metal equilibrium

technique in an MgO crucible. The activity coefficients of III. RESULTS AND DISCUSSION

FetO in the range of 2 to 3 mass pct FetO were determined In this paper, CaO-SiO2-MgO slags are denoted as CSM-

as 3.2 to 4.5 from the contents of analyzed oxygen. The 1 and CSM-2; CaO-SiO2-Al2O3-MgO slags saturated with

present authors previously measured the activity coeffi- the 2CaO z SiO2 or 3CaO z SiO2 phase are denoted as SC-

cients of FetO[3,4] and MnO[4] in a CaO-SiO2-Al2O3-FetO 1 to SC-5; and those saturated with MgO, 2(Mg,Ca)O z

(,5 mass pct)-MnO (,10 mass pct) system at 1873 K

SiO2, and MgO z Al2O3 are denoted as M-1 to M-4, MS-1,

using an Al2O3 or CaO crucible. As a result, it was found and MA-1 to MA-3, respectively. It is noted that a molten

that the activity coefficients of FetO increased with an in-

slag is not necessarily saturated with a crucible material

crease in SiO2 content, while those of MnO decreased with

such as MgO. It may be saturated with another phase such

a decrease in CaO content.

as MgO z Al2O3, depending on the initial slag composition.

The activities of components in CaO-SiO2-Al2O3[5] and The CSM-2, SC-1 to SC-5, MS-1, and MA-1 to MA-3 slags

CaO-Al2O3-MgO[6] systems were assessed at 1873 K in pre-

and metal compositions are given in Table I. The chemical

vious articles. This work is a continuation of previous

compositions of the CSM-1 and M-1 to M-4 slags and

investigations. The activities of SiO2 and Al2O3 in CaO-

metal phases were given in the previous article.[7]

SiO2-MgO and CaO-SiO2-Al2O3-MgO slags at the compo-

sitions saturated with the 2CaO z SiO2, 2(Mg, Ca)O z SiO2,

MgO, and MgO z Al2O3 phases were determined at 1873 K A. Activity of SiO2

using a slag-metal equilibration technique. Furthermore, the Silicon deoxidation can be given as

Si 1 2O 5 SiO2 (s) [1]

HIROKI OHTA, Research Associate, and HIDEAKI SUITO, Professor

are with Institute for Advanced Materials Processing, Tohoku University, DG71 5 2581,900 1 221.8 T J/mol[9,10]

Sendai 980, Japan.

Manuscript submitted January 3, 1997. The activities of SiO2 were calculated from Eq. [1] using

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—119

Table I. Chemical Compositions of Metal and Slag Phases at 1873 K

[Al] Metal Slag

Soluble Insoluble [TzSi] [Mn] [Ca] [Mg] [TzO] (CaO) (SiO2) (Al2O3) (MgO) (MnO) (FetO)

(Mass Ppm) (Mass Pct) (Mass Ppm) (Mass Pct)

SC-1

2.9 1.2 0.0563 0.0461 ,0.05 0.35 31.5 49.2 35.4 8.6 5.9 0.129 0.367

1.7 1.6 0.0189 0.183 ,0.05 0.25 47.9 48.7 33.4 9.8 5.7 0.861 0.593

21.8 1.6 1.04 0.520 10.4 5.2 25.4 49.0 34.6 9.2 5.7 0.306 0.157

23.6 0.8 1.37 0.396 0.55 2.4 10.3 48.7 34.8 9.5 5.7 0.307 0.168

SC-2

1.4 0.6 0.0100 0.0421 ,0.05 0.17 30.1 47.9 26.3 19.7 4.9 0.0527 0.307

,0.1 1.4 0.0016 0.196 ,0.05 ,0.05 72.4 50.4 24.2 18.7 5.1 0.562 0.597

66.8 1.5 1.03 0.886 1.3 2.6 10.4 53.2 22.5 18.3 4.9 0.108 0.0940

66.4 0.7 1.24 1.14 6.3 2.3 15.2 49.7 24.9 19.6 5.1 0.149 0.154

SC-3

2.7 0.8 0.0124 0.0788 ,0.05 0.49 24.2 54.6 22.5 13.6 8.8 0.105 0.140

1.0 0.7 0.0008 0.211 ,0.05 ,0.05 87.8 56.2 19.2 13.8 8.3 0.755 0.772

83.4 1.3 1.12 0.852 3.2 4.2 14.6 53.1 21.0 16.8 8.8 0.0910 0.0887

87.5 0.7 1.16 1.21 1.2 10.8 16.0 53.6 21.2 15.5 8.5 0.141 0.398

SC-4

0.9 ,0.1 0.0008 0.186 ,0.05 0.65 45.9 56.5 14.6 19.3 7.9 0.219 0.415

1.2 0.8 0.0006 0.283 ,0.05 0.58 62.8 57.4 13.8 18.7 7.8 0.403 0.932

139 ,0.1 0.922 1.02 0.53 7.7 12.2 56.1 15.5 20.4 7.7 0.0301 0.0587

214 0.3 1.17 1.30 1.9 12.2 13.4 58.3 13.6 20.2 6.9 0.0321 0.0363

SC-5

2.0 0.8 0.0187 0.0506 ,0.05 1.9 27.7 47.5 29.8 9.5 11.9 0.0451 0.200

,0.1 0.7 0.0040 0.312 ,0.05 0.41 54.4 47.1 31.0 8.2 11.6 0.759 0.452

61.0 2.2 1.04 0.859 1.6 3.3 33.5 48.3 29.2 8.9 12.4 0.148 0.173

88.5 1.4 1.21 0.974 1.3 3.5 15.0 47.0 30.2 9.5 12.0 0.103 0.326

MS-1

2.6 0.2 0.220 0.425 ,0.05 0.87 29.9 13.2 40.9 9.8 32.5 2.15 0.606

3.5 0.2 0.590 0.572 0.28 0.76 19.8 13.4 42.5 9.3 31.7 1.91 0.326

8.2 0.1 1.54 0.466 0.29 1.2 12.6 13.3 41.8 11.3 32.2 0.746 0.193

MA-1

1.3 0.3 0.0836 0.188 ,0.05 0.20 25.6 21.8 30.6 17.2 28.3 0.766 0.501

14.0 0.1 0.438 0.779 ,0.05 ,0.05 13.9 21.6 32.3 16.4 28.0 1.02 0.329

29.0 4.4 1.07 1.02 0.22 ,0.05 9.3 19.7 31.2 20.1 28.4 0.782 0.263

MA-2

3.7 0.3 0.0848 0.277 ,0.05 ,0.05 26.1 21.1 27.5 27.2 22.0 0.866 0.486

24.6 ,0.1 0.508 0.291 ,0.05 0.25 15.1 20.1 26.2 29.5 23.0 0.300 0.254

63.8 ,0.1 1.27 0.851 ,0.05 0.66 9.6 18.1 25.0 32.3 23.4 0.695 0.200

MA-3

12.6 0.6 0.101 0.189 0.14 0.67 16.6 23.7 27.5 37.4 9.9 0.432 0.477

69.1 0.2 1.01 0.220 ,0.05 ,0.05 8.7 25.7 23.4 40.3 10.6 0.224 0.272

109 1.1 1.60 0.217 1.1 0.19 13.2 25.1 22.0 40.8 10.8 0.101 0.218

CSM-2

— — 0.509 0.0437 ,0.05 0.98 33.2 13.1 52.1 — 32.6 0.615 1.01

— — 0.547 0.0776 ,0.05 0.71 28.2 12.2 50.6 — 34.0 0.950 1.16

— — 1.10 0.368 ,0.05 0.41 19.3 12.6 50.0 — 34.8 1.90 0.399

the DG71 value, the contents of O and Si, and the respective tent instead of acid-soluble Si content will be described

interaction coefficients[9] for fO and fSi, where fi is the activ- later. It can be seen that the aSiO2 values at the compositions

ity coefficient of element i in Henry’s state, referred to as of [pct T z Si] .1 are considerably high for some of the

1 mass pct. The interaction coefficients of Ca and Mg for slags, despite the fact that Mn was added to approach the

fO, obtained from a previous report,[7] are used. The results equilibrium from supersaturation.

for the SC-1 to SC-5 and M-1 to M-4 slags and those for By using the aSiO2 values in the CaO-SiO2-MgO (CSM-

the MS-1, MA-1 to MA-3, and CSM-1 and CSM-2 slags 1 and CSM-2) and CaO-SiO2-Al2O3-MgO (SC-1 to SC-5,

are plotted against total Si contents in logarithmic form in M-1 to M-4, MS-1, and MA-1 to MA-3) slags given in

Figures 1 and 2, and are given in Table II along with the Table II and those in the CaO-SiO2 (CS),[11] CaO-SiO2-

standard deviation. The reason for the use of total Si con- Al2O3 (CSA),[3–5,12,13] and CaO-SiO2-Al2O3-MgO (CASM)[14]

120—VOLUME 29B, FEBRUARY 1998 METALLURGICAL AND MATERIALS TRANSACTIONS B

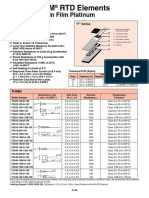

Table II. Activities of SiO2 and Al2O3 and Activity

Coefficients of MnO and FetO

Slag Log aSiO2 Log aAl2O3 LoggMnO LoggFetO

SC-1 21.6850.08 21.5750.09 0.3850.10 0.6950.02

SC-2 22.4350.04 21.7650.09 0.7350.07 0.7950.08

SC-3 22.5350.04 21.7050.01 0.7150.07 0.9250.11

SC-4 23.0650.11 21.8250.14 1.0350.03 0.6950.21

SC-5 22.2550.06 21.4050.16 0.8050.09 0.8950.01

M-1 22.1150.09 21.4750.10 0.6250.03 0.7450.02

M-2 21.7750.10 21.4350.14 0.6450.08 0.6650.09

M-3 22.4450.11 21.3050.12 0.8350.06 0.7250.12

M-4 22.4450.13 20.9450.08 0.8250.10 0.4850.13

MS-1 21.1450.07 21.7650.22 0.1650.04 0.4750.02

MA-1 21.6150.05 21.1750.11 0.3150.07 0.4150.14

MA-2 21.5350.12 20.6350.14 0.3550.07 0.4650.09

MA-3 21.8150.18 20.6750.04 0.2150.12 0.31

CSM-1 22.0250.11 — 0.4850.19 0.8750.24

CSM-2 20.8150.12 — 20.1950.13 0.1850.05

Fig. 1—Activity of SiO2 plotted against total Si content in mass pct in

logarithmic scale.

Fig. 3—Comparison of observed activities of SiO2 and Al2O3 with

calculated ones from Eqs. [2] and [5], respectively.

Fig. 2—Activity of SiO2 plotted against total Si content in mass pct in

logarithmic scale.

tion of the slag component, but it was found that this func-

slags calculated from Eq. [1], the aSiO2 values were ex- tion could not reasonably well explain the experimental

pressed as a function of slag composition using a multiple data. Accordingly, the fourth term in the right-hand side

regression analysis as follows: of Eq. [2] was added. It is noted that Eq. [2], which is

utterly an empirical formula, can be applied only to 10 to

log aSiO25 0.036 (pct MgO) 1 0.061 (pct Al2O3) 60 pct CaO-10 to 50 pct SiO2-O to 50 pct Al2O3-0 to 30

1 0.123 (pct SiO2) 2 0.595 (pct SiO2)/ [2] pct MgO slags. The relationship between the calculated

(pct CaO) 2 6.456 (R 5 0.85) aSiO2 value from Eq. [2] and the observed value in loga-

rithmic form is shown in the upper diagram of Figure 3,

where R is the correlation coefficient. where the correspondence between the two is within the

Activities of SiO2 were first expressed as a linear func- experimental scatter.

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—121

Fig. 4—(a) and (b) Activities of SiO2 on 0 and 10 mass pct Al2O3 planes.

Fig. 6—(a) and (b) Activities of SiO2 on 30 and 40 mass pct Al2O3 planes.

are also indicated. The data given by brackets correspond

to those estimated by extrapolation.

The isoactivity lines by Rein and Chipman[1] indicate that

the aSiO2 values decrease slightly by the replacement of CaO

by MgO for a given SiO2 content. This trend is different

from the present ones derived by Eq. [2]. Such inconsis-

tency is observed particularly at the slag compositions with

0, 10, and 20 pct Al2O3, as shown in Figures 4 and 5. At

a constant content of SiO2 for a given Al2O3 content, the

aSiO2 value is expected to increase with the replacement of

CaO by MgO due to the fact that MgO is less basic than

CaO. The isoactivity lines of SiO2 on 10 and 20 pct MgO

Fig. 5—Activities of SiO2 on 20 mass pct Al2O3 plane. planes reported by Rein and Chipman[1] and those derived

from Eq. [2] are shown in the upper diagrams of Figures 7

The aSiO2 values obtained from the present and previ- and 8, along with the present and previous[14] results.

ous[14] results along the liquidus lines are shown on the 0,

10, 20, 30, and 40 pct Al2O3 planes of the CaO-SiO2-Al2O3- B. Activity of Al2O3

MgO phase diagram[15,16] in Figures 4 through 6. The isoac-

tivity lines for SiO2 calculated from Eq. [2] are indicated The exchange reaction with respect to Al and Si between

by solid lines over the liquid region along with those ob- slag and metal is expressed as follows:

tained based on the results by Rein and Chipman,[1] which

are represented by dashed-dotted lines. The aSiO2 values in Al 1 3/4 SiO2 (s) 5 3/4 Si 1 1/2 Al2O3 (s) [3]

previous studies for the CaO-SiO2[11] binary slag and the

CaO-SiO2-Al2O3[1,3,4,12] and MgO-SiO2-Al2O3[1] ternary slags DG73 5 2164,600 1 26.8 T J/mol[9,10]

122—VOLUME 29B, FEBRUARY 1998 METALLURGICAL AND MATERIALS TRANSACTIONS B

Fig. 7—(a) and (b) Activities of SiO2 and Al2O3 on 10 mass pct MgO

Fig. 8—(a) and (b) Activities of SiO2 and Al2O3 on 20 mass pct MgO

plane.

plane.

The following relation is obtained using the equilibrium respective interaction coefficients[9] for fSi and fAl. The re-

constant of Eq. [3], K3: sults are plotted against total Al contents in Figure 10. It

log [pct Al] 5 (3/4) log [pct Si] 1 log (fSi3/4 / fAl) can be seen that the aAl2O3 values in the very low concen-

[4] tration range of [ppm T z Al] ,10 deviate considerably due

1 log {aAl2O31/2 / (K3 z aSiO23/4)} to the uncertainty of the analyzed Al contents, which mark-

edly influence the calculation of the aAl2O3 values. Therefore,

Total Al contents are plotted against total Si contents in the experimental data with [ppm T z Al] .10, except for

logarithmic form in Figure 9. Instead of acid-soluble Al (Si) those of the MS-1 slag, were used for the evaluation of

content, total Al (Si) content is used in this work because aAl2O3. These results are summarized in Table II along with

acid-insoluble Al (Si) is considered to be the secondary the standard deviation.

inclusion precipitated during solidification. Further details By using the aAl2O3 values in the present CaO-SiO2-Al2O3-

of this have been given elsewhere.[17,18] It can be seen from MgO (SC-1 to SC-5, M-1 to M-4, MS-1, and MA-1 to MA-

Figure 9 that the data points follow approximately the lines 3) slags and those in previous CaO-SiO2-Al2O3 (CSA)[3–

having a slope of 3/4, as predicted from Eq. [4], even for 5,12,13]

and CaO-SiO2-Al2O3-MgO (CASM)[14] slags calcu-

the data points at the compositions of [pct T z Si] . 1. lated from Eq. [4], the aAl2O3 values were expressed as a

Although these data points deviate considerably from the function of slag composition using a multiple regression

lines in the plot of log aSiO2 vs [pct T z Si], as shown in analysis as follows:

Figures 1 and 2, this finding is consistent with the previous

observations[3,12,13] in which the aAl vs aSi relation in loga- log aAl2O3 5 {20.275 (pct CaO) 1 0.167 (pct MgO)}/(pct SiO2) [5]

rithmic form shows the linearity without respect to the pres- 1 0.033 (pct Al2O3) 2 1.560 (R 5 0.89)

ence of supersaturated oxygen. The data points obtained in

the range of low Si levels deviate from the line. This is due Activities of Al2O3 were first expressed as a linear function

to the scattering of the values of analyzed Al for such a of slag component, but it could not well explain the exper-

low Si level. imental data. It was found that the aAl2O3 values expressed

The activities of Al2O3 were calculated from Eq. [4] us- by Eq. [5] fit the data with the correlation coefficient R 5

ing the average values of aSiO2 given in Table II and the 0.89. The relations between the calculated aAl2O3 from Eq.

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—123

Fig. 9—Relation between total Al content in mass ppm and total Si content

in mass pct in logarithmic scale.

Fig. 11—(a) and (b) Activities of Al2O3 on 10 and 20 mass pct Al2O3

planes.

Eq. [5] over the liquid region and the aAl2O3 values in the

respective ternary systems[1,3–5,12,13] are given. The data sat-

urated with the MS-1 slag shown in the upper diagram of

Figure 11 is significantly different from the calculated

value. This is due to the scatter of Al content, which is

below 10 ppm. The data given by brackets correspond to

those estimated by extrapolation. The isoactivity lines for

Al2O3 from Eq. [5] are shown on the 10 and 20 pct MgO

planes of the CaO-SiO2-Al2O3-MgO phase diagram[15,16] in

the lower diagrams of Figures 7 and 8, along with the pres-

ent and previous[1,6,14] results. Activity of Al2O3 can be also

estimated from the SiO2 isoactivity curves using the Gibbs–

Duhem relation. The present authors[6] determined the ac-

tivities of Al2O3 in a CaO-Al2O3-SiO2 system using this

method. In the present CaO-Al2O3-SiO2-MgO system, how-

ever, the values for the integration limit on the Gibbs–Du-

hem relation are not accurately determined. For this reason,

this method was not used in this work.

It should be pointed out that the activities of MgO in the

slags saturated with the MgO z Al2O3 phase can be esti-

Fig. 10—Activity of Al2O3 plotted against total Al content in mass ppm mated from the reaction MgO (s) 1 Al2O3 (s) 5 MgO z

in logarithmic scale.

Al2O3 (s), DG7Spinel 5 218,800 2 6.3 T J/mol[1] using the

aAl2O3 values. The aAl2O3 value at the MgO and MgO z Al2O3

double-saturated composition using the free energy change

[5] and the observed value in logarithmic form are plotted for MgO z Al2O3 was calculated as 0.14, which agreed with

in the lower diagram of Figure 3. the present value. Similarly, the activities of CaO at the

The present and previous[14] results along the liquidus slag compositions saturated with the 2CaO z SiO2 phase can

lines are shown on the 10, 20, 30, and 40 pct Al2O3 planes be obtained from the reaction 2CaO (s) 1 SiO2 (s) 5 2CaO

of the CaO-SiO2-Al2O3-MgO phase diagram[15,16] in Figures z SiO2 (s), DG7C2S 5 2118,800 2 11.3 T J/mol[19] using the

11 and 12. The isoactivity lines for Al2O3 calculated from aSiO2 values.

124—VOLUME 29B, FEBRUARY 1998 METALLURGICAL AND MATERIALS TRANSACTIONS B

Fig. 13—Activity coefficient of MnO plotted against MnO content in mass

pct in logarithmic scale.

Fig. 12—(a) and (b) Activities of Al2O3 on 30 and 40 mass pct Al2O3

planes.

C. Activity Coefficient of MnO

Slag-metal reaction with respect to Mn and Si can be

expressed as follows:

Mn 1 1/2 SiO2 (s) 5 MnO (s) 1 1/2 Si [6]

DG76 5 2800 1 17.4 T J/mol[9,10,20]

The activity coefficients of MnO relative to the solid

standard state, gMnO, were calculated from Eq. [7] using the

equilibrium constant of Eq. [6], K6, the average values of Fig. 14—Activity coefficient of MnO plotted against MnO content in mass

aSiO2 given in Table II, and the respective interaction coef- pct in logarithmic scale.

ficients[9] for fMn and fSi.

log gMnO 5 log {[pct Mn]/[pct Si]1/2} 1 log (fMn/fSi1/2) [7] II along with the standard deviation. The gMnO values cal-

1 log {azK6zaSiO21/2/(pct MnO)} culated from the reaction Mn 1 O 5 MnO (s), DG7 5

2288,100 1 128.3 T J/mol,[20] using the contents of Mn

where a is the constant related to the conversion from mol and O and the respective interaction coefficients,[9] agreed

fraction of MnO to mass pct. Although a is a function of with those calculated from Eq. [7] for the data except the

slag composition, it is regarded to be approximately con- value for supersaturated oxygen.

stant under the present experimental condition. The gMnO By using the gMnO values in the present CaO-SiO2-Al2O3-

values are plotted against the MnO contents in logarithmic MgO (SC-1 to SC-5, M-1 to M-4, MS-1, and MA-1 to MA-

form in Figures 13 and 14 for SC-1 to SC-5 and M-1 to 3) slag and the previous CaO-SiO2-Al2O3 (CSA)[4] and

M-4 slags and MS-1, MA-1 to MA-3, CSM-1, and CSM- CaO-SiO2-Al2O3-MgO (CASM)[14] slags containing less

2 slags, respectively. These values are also given in Table than 10 pct MnO, the gMnO values were expressed as a func-

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—125

Fig. 15—Comparison of observed activity coefficients of MnO and FetO

with calculated ones from Eqs. [8] and [10], respectively.

Fig. 16—(a) and (b) Activity coefficients of MnO on 0 and 10 mass pct

Al2O3 planes.

tion of slag composition using a multiple regression anal-

ysis as follows:

log gMnO 5 0.019 (pct CaO) 1 0.023 (pct MgO) Figure 18 that the gMnO values increase with an increase in

[8]

the (pct CaO)/(pct SiO2) ratio, except for the compositions

2 0.023 (pct SiO2) 1 0.129 (R 5 0.88)

with low SiO2 and high Al2O3 contents.

The relations between the calculated value from Eq. [8]

and the observed value in logarithmic form are shown in D. Activity Coefficient of FetO

the upper diagram of Figure 15, in which the present results

for the CaO-SiO2-MgO (CSM-1 and CSM-2) slag, the pre- The reaction of Si with FetO in slag can be expressed by

vious results[4] for the CaO-Al2O3 (AC, CA) and CaO-SiO2

(CS) slags with (pct MnO) ≤7, and those for the CaO-SiO2- 2 FetO (1) 1 Si 5 SiO2 (s) 1 2 Fe (1) [9]

Al2O3 (CSA) slag, obtained at 1923 K by Abraham et al.[21] DG79 5 2349,700 1 124.2 T J/mol[9,10,23]

and Mehta and Richardson,[22] are also included. It can be

seen that the data points agree well with the gMnO values The activity coefficients of FetO, gFetO , relative to the liq-

calculated from Eq. [8]. uid standard state, were calculated from the DG79 value, the

The present and previous[14] experimental data along the average values of aSiO2 given in Table II, and the respective

liquidus lines are shown on the 0, 10, 20, 30, and 40 pct interaction coefficients[9] for fSi, using Eq. [7] with respect

Al2O3 planes of the CaO-SiO2-Al2O3-MgO phase dia- to gFetO. The results are plotted against total Si contents in

gram[15,16] in Figures 16 and 17. The iso-gMnO lines calcu- Figure 20 and are summarized in Table II. The gFetO values

lated from Eq. [8] are plotted over the liquid region, along can also be estimated from the contents of analyzed O from

with previous results[4] in the CaO-SiO2-Al2O3 system. The the reaction Fe (l) 1 O 5 FetO (l), DG7 5 2116,100 1

data given by brackets correspond to those estimated by 48.79 T J/mol.[23] These results, except for the data at su-

extrapolation. It can be seen that the gMnO values decrease persaturation, are in agreement with those from Eq. [9].

with an increase in SiO2 content for a given Al2O3 content. By using the gFetO values in the present CaO-SiO2-

The isoactivity coefficient lines for MnO from Eq. [8] are Al2O3-MgO (SC-1 to SC-5, M-1 to M-4, MS-1, and MA-

shown on the 10 and 20 pct MgO planes of the CaO- 1 to MA-3) slag and previous CaO-SiO2-Al2O3 (CSA)[3,4]

SiO2-Al2O3-MgO phase diagram[15,16] in the upper diagrams and CaO-SiO2-Al2O3-MgO (CASM)[14] slags, the gFetO val-

of Figures 18 and 19, along with the present and previ- ues were expressed as a function of slag composition using

ous[6,14] results. It can be seen from the upper diagram of a multiple regression analysis as follows:

126—VOLUME 29B, FEBRUARY 1998 METALLURGICAL AND MATERIALS TRANSACTIONS B

Fig. 18—(a) and (b) Activity coefficients of MnO and FetO on 10 mass

Fig. 17—(a) through (c) Activity coefficients of MnO on 20, 30, and 40 pct MgO planes.

mass pct Al2O3 planes.

SiO2) ,20. More detailed study is necessary in this com-

position range.

log gFetO 5 {0.676 (pct MgO) 1 0.267 (pct Al2O3) 2 19.07}/ [10] E. Phase Boundary and Solubility of MgO

(pct SiO2) 1 0.0214 (pct CaO) 2 0.047 (R 5 0.59)

The liquidus lines on the 0, 10, 20, and 30 pct Al2O3

The relations between the calculated value from Eq. [10] planes shown in Figures 4 through 6 are those by Osborn

and the observed value are shown in the lower diagram of et al.[15] Those on the 40 pct Al2O3 plane shown in the lower

Figure 15, in which the results for the present CaO-SiO2- diagram of Figure 6 were obtained by extrapolation based

MgO (CSM-1 and CSM-2) and the previous CaO-SiO2 on the results obtained by Cavalier and Sandreo–Dendon.[16]

(CS)[4] slags are also included. The present and previous[14] slag compositions fall approx-

The gFetO values along the liquidus lines and the iso- imately on the liquidus lines except for the line saturated

gFetO lines over the liquid region on the 0, 10, 20, 30, and with the MgO z Al2O3 phase.

40 pct Al2O3 planes of CaO-SiO2-Al2O3-MgO phase dia- The liquidus lines on the 10 pct MgO plane shown in

gram[15,16] are shown in Figures 21 and 22. The gFetO values Figure 7 are those by Cavalier and Sandreo–Dendon,[16] but

decrease with an increase in SiO2 content at compositions those on the 20 pct MgO plane shown in Figure 8 were

for a given low Al2O3 level, but they increase with increas- obtained by extrapolation based on the results obtained by

ing MgO content for a given high Al2O3 level. The isoac- Osborn et al.[15] The present and previous[14] slag compo-

tivity coefficient lines for FetO from Eq. [10] are shown on sitions saturated with 2CaO z SiO2, MgO, and MgO z Al2O3

the 10 and 20 pct MgO planes of the CaO-SiO2-Al2O3-MgO phases on the 10 pct MgO plane are significantly different

phase diagram[15,16] in the lower diagrams of Figures 18 and from the results reported by Cavalier and Sandreo–Den-

19, along with the present and previous[6,14,24] results. It can don,[16] as shown in Figure 7, but those on the 20 pct MgO

be seen from the lower diagram of Figure 18 that the plane agree with those reported by Osborn et al.,[15] as

gFetO values increase with an increase in CaO content at the shown in Figure 8. The disagreement observed in Figure 7

compositions of (pct SiO2) .20, but they tend to decrease may be partly due to the fact that liquidus lines change

with an increase in CaO content at the compositions of (pct drastically with an increase in MgO content, as shown in

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—127

Fig. 20—Relation between FetO and total Si content in mass pct in

logarithmic scale.

Fig. 19—(a) and (b) Activity coefficients of MnO and FetO on 20 mass

pct MgO planes.

Figures 7 and 8, and the results by Osborn et al.[15] are

different from those by Cavalier and Sandreo–Dendon.[16]

In the parallel projection method in which the composi-

tions in a quaternary system can be represented by a two-

dimensional representation, a given point on a saturated

plane is projected onto the basal plane of the CaO-Al2O3-

SiO2 system parallel to the edge CaO-MgO. As a result,

the point in the tetrahedron can be plotted in a (CaO 1

MgO) 2 Al2O3-SiO2) quasiternary diagram.

The present and previous[2,14] results are shown in Figure

23, in which the heavy and light lines represent the phase

boundaries and the iso-MgO solubility lines, respectively.

The lines for 5, 10, and 15 pct MgO were determined

mainly from the data by Cavalier and Sandreo–Dendon,[16]

but that for 20 pct was determined from the data of Osborn

et al.[15] The present and previous[14] results in the MgO or

MgO z Al2O3-saturated phase are in agreement with these

lines. The phase boundaries were estimated mostly from the

results by Osborn et al.[15] It can be seen from the iso-MgO

solubility lines that, with an increase in Al2O3 content for

a given SiO2 content, the solubility of MgO in the MgO-

saturated phase increases to the MgO-MgO z Al2O3 double-

saturated phase boundary and, thereafter, decreases in the Fig. 21—(a) and (b) Activity coefficients of FetO on 0 and 10 mass pct

MgO z Al2O3-saturated phase. Al2O3 planes.

128—VOLUME 29B, FEBRUARY 1998 METALLURGICAL AND MATERIALS TRANSACTIONS B

IV. CONCLUSIONS

By using a slag-metal equilibration technique, the activ-

ities of SiO2 and Al2O3, the activity coefficients of FetO and

MnO, and the phase boundaries in a CaO-SiO2-Al2O3-MgO

slag were determined at 1873 K. The aSiO2 values were

found to agree with those by Rein and Chipman and the

phase boundaries are also in reasonable agreement with pre-

vious results. Comparison could not be made with respect

to the aAl2O3, because no data are available for the activities

of Al2O3 in the present slag. It can be said, however, from

the results for the aAl2O3 values in the respective ternary

slags, that the aAl2O2 values are satisfactory. In the present

work, the activities of MgO and CaO could not be deter-

mined. If accurate thermochemical data on the respective

interoxide compounds are available, these activities can be

estimated based on the activities of SiO2 and Al2O3.

REFERENCES

1. R.H. Rein and J. Chipman: Trans. TMS-AIME, 1965, vol. 233, pp.

415-25.

2. T. Tsao and H.G. Katayama: Trans. Iron Steel Inst. Jpn., 1986, vol.

26, pp. 717-23.

3. K.R. Lee and H. Suito: Metall. Mater. Trans. B, 1994, vol. 25B, pp.

893-902.

4. H. Ohta and H. Suito: Metall. Mater. Trans. B, 1995, vol. 26B, pp.

295-304.

5. H. Ohta and H. Suito: Metall. Mater. Trans. B, 1996, vol. 27B, pp.

943-53.

6. H. Ohta and H. Suito: Iron Steel Inst. Jpn. Int., 1996, vol. 36, pp.

983-90.

7. H. Ohta and H. Suito: Metall. Mater. Trans. B, 1997, vol. 28B, pp.

97-6B-G.

8. K.R. Lee and H. Suito: Metall. Mater. Trans. B, 1996, vol. 27B, pp.

423-31.

9. G.K. Sigworth and J.F. Elliott: Met. Sci., 1974, vol. 8, pp. 298-310.

Fig. 22—(a) through (c) Activity coefficients of FetO on 20, 30, and 40 10. J.F. Elliott, M. Gleiser, and V. Ramakrishna: Thermochemistry for

mass pct Al2O3 planes. Steelmaking, Addison-Wesley, London, 1963, vol. 2, pp. 620-21.

11. R. Inoue and H. Suito: Metall. Trans. B, 1992, vol. 23B, pp. 613-21.

12. F. Tamura and H. Suito: Metall. Trans. B, 1993, vol. 24B, pp. 121-

30.

13. S.W. Cho and H. Suito: Iron Steel Inst. Jpn. Int., 1994, vol. 34, pp.

177-85.

14. J.D. Seo and H. Suito: Bulletin of the Institute for Advanced Materials

Processing, Tohoku University (SOZAIKEN IHO), Sendai, Japan,

1996, vol. 52, pp. 23-32.

15. E.F. Osborn, R.C. Devries, K.H. Gee, and H.M. Kraner: J. Met., 1954,

vol. 6, pp. 33-45.

16. G. Cavalier and M. Sandreo-Dendon: Rev. Metall., 1960, vol. 57, pp.

1143-57.

17. H. Suito, H. Inoue, and R. Inoue: Iron Steel Inst. Jpn. Int., 1991, vol.

31, pp. 1381-88.

18. H. Suito: Proc. Ethem T. Turkdogan Symp., Fundamentals and

Analysis of New and Emerging Steelmaking Technologies, Iron and

Steel Society, TMS-AIME, and U.S. Steel Group of USX

Corporation, Pittsburgh, PA, 1994, pp. 141-52.

19. E.T. Turkdogan: Physical Chemistry of High Temperature

Technology, Academic Press, New York, NY, 1980, p. 8.

20. H. Gaye, C. Gatellier, M. Nadif, P.V. Riboud, J. Saleil, and M. Faral:

Rev. Metall.-CIT, 1987, Nov., pp. 759-71.

21. K.P. Abraham, M.W. Davies, and F.D. Richardson: J. Iron Steel Inst.,

1960, vol. 196, pp. 82-89.

22. S.R. Mehta and F.D. Richardson: J. Iron Steel Inst., 1965, vol. 203,

pp. 524-28.

23. H. Suito and R. Inoue: Trans. Iron Steel Inst. Jpn., 1984, vol. 24, pp.

Fig. 23—Iso-solubility lines of MgO plotted in the (CaO 1 MgO)-SiO2- 301-07.

Al2O3 quasiternary diagram. 24. R. Inoue and H. Suito: Metall. Trans. B, 1994, vol. 25B, pp. 235-44.

METALLURGICAL AND MATERIALS TRANSACTIONS B VOLUME 29B, FEBRUARY 1998—129

Das könnte Ihnen auch gefallen

- Crystallization Behavior of CaO-SiO2-MgO-Al2O3-Based Slags and Its Potential Application in P-Bearing Steelmaking SlagsDokument6 SeitenCrystallization Behavior of CaO-SiO2-MgO-Al2O3-Based Slags and Its Potential Application in P-Bearing Steelmaking SlagsJJNoch keine Bewertungen

- Quality of The Seam in Welding Under Flux by Means of Barium-Strontium CarbonatiteDokument5 SeitenQuality of The Seam in Welding Under Flux by Means of Barium-Strontium CarbonatiteBurag HamparyanNoch keine Bewertungen

- Variation DiagramsDokument6 SeitenVariation Diagramsmariam saniNoch keine Bewertungen

- S.G IronDokument6 SeitenS.G IronQasim BarkatNoch keine Bewertungen

- FTIR Spectroscopy MontmorilloniteDokument6 SeitenFTIR Spectroscopy MontmorilloniteAdrian VolceanovNoch keine Bewertungen

- Industrial & Engineering Chemistry Research Volume 38 Issue 11 1999 (Doi 10.1021/ie990156b) Vegliò, F. Passariello, B. Abbruzzese, C. - Iron Removal Process For High-Purity Silica Sands ProductioDokument6 SeitenIndustrial & Engineering Chemistry Research Volume 38 Issue 11 1999 (Doi 10.1021/ie990156b) Vegliò, F. Passariello, B. Abbruzzese, C. - Iron Removal Process For High-Purity Silica Sands ProductioTaufik RaharjoNoch keine Bewertungen

- Chemical and Physical Properties of Fluxes For SAW of Low-Carbon SteelsDokument20 SeitenChemical and Physical Properties of Fluxes For SAW of Low-Carbon SteelsAdam Al AufaNoch keine Bewertungen

- 2003 Net Chemical Characteristics of Iron and Steel SlagDokument2 Seiten2003 Net Chemical Characteristics of Iron and Steel SlagmazaherramazaniNoch keine Bewertungen

- A New Pyrometallurgical Recycling Technique For Lead Battery Paste Without SO Generation - A Thermodynamic and Experimental InvestigationDokument12 SeitenA New Pyrometallurgical Recycling Technique For Lead Battery Paste Without SO Generation - A Thermodynamic and Experimental InvestigationwanNoch keine Bewertungen

- Consumo de Caucho en EafDokument9 SeitenConsumo de Caucho en EafKatherine TamayoNoch keine Bewertungen

- Cement BookDokument21 SeitenCement BookKeshav NandaNoch keine Bewertungen

- Thermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFDokument4 SeitenThermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFRasul BzNoch keine Bewertungen

- Evaluation of MnOx, Mn2O3, and Mn3O4 (Sup)Dokument13 SeitenEvaluation of MnOx, Mn2O3, and Mn3O4 (Sup)AhmedNoch keine Bewertungen

- Precipitation of Metallic Chromium During Rapid Cooling of CR O SlagsDokument4 SeitenPrecipitation of Metallic Chromium During Rapid Cooling of CR O SlagsChayon MondalNoch keine Bewertungen

- BIOTITE - SalinDokument1 SeiteBIOTITE - Salinaradhea karnaNoch keine Bewertungen

- Uts PetrogenesisDokument8 SeitenUts PetrogenesisSayyid AbdullahNoch keine Bewertungen

- Mass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesDokument15 SeitenMass and Heat Balance of Steelmaking in Bof As Compared To Eaf ProcessesAgil Setyawan100% (1)

- 1448 PDFDokument9 Seiten1448 PDFjoyNoch keine Bewertungen

- Yazawa 1969Dokument5 SeitenYazawa 1969marcelo_ivnNoch keine Bewertungen

- Fe MgTourmalineDokument22 SeitenFe MgTourmalineRene Y Cobas TorresNoch keine Bewertungen

- Effect of Portland Cement On Magnesium Oxysulfate Cement Using Lightburned Dolomite2018IOP Conference Series Earth and Environmental ScienceDokument8 SeitenEffect of Portland Cement On Magnesium Oxysulfate Cement Using Lightburned Dolomite2018IOP Conference Series Earth and Environmental ScienceCamilo lopezNoch keine Bewertungen

- RMW3 08 Morita HDokument50 SeitenRMW3 08 Morita Hnovas88Noch keine Bewertungen

- MgO Based Inclusions in Aluminum Killed SteelsDokument19 SeitenMgO Based Inclusions in Aluminum Killed SteelsEstéfano Aparecido VieiraNoch keine Bewertungen

- SJC 20180606 12Dokument7 SeitenSJC 20180606 12elkey987654321Noch keine Bewertungen

- MODELLING CR CONTAINING 0391-ZhangDokument12 SeitenMODELLING CR CONTAINING 0391-ZhangRunkitoNoch keine Bewertungen

- Journal Pre-Proof: Journal of Solid State ChemistryDokument22 SeitenJournal Pre-Proof: Journal of Solid State ChemistryDinana Anissatul FuadiyahNoch keine Bewertungen

- Effect of Sic Particles On Mechanical Properties of Aluminium Adc12 Composite Through Stir Casting ProcessDokument6 SeitenEffect of Sic Particles On Mechanical Properties of Aluminium Adc12 Composite Through Stir Casting ProcessJosiah PasaribuNoch keine Bewertungen

- Muh 1009 6Dokument8 SeitenMuh 1009 6Chris BothaNoch keine Bewertungen

- The Effect of Elevated Curing Temperatures On High Ye'elimite Calcium Sulfoaluminate Cement MortarsDokument17 SeitenThe Effect of Elevated Curing Temperatures On High Ye'elimite Calcium Sulfoaluminate Cement MortarsLuís Urbano Durlo TambaraNoch keine Bewertungen

- Supporting Information: A A, B A A A A, BDokument13 SeitenSupporting Information: A A, B A A A A, BPavan SharmaNoch keine Bewertungen

- 2002 Kinetochemical and Morphological Differentiation of Ettringites by The Le Chatelier-Anstett TestDokument11 Seiten2002 Kinetochemical and Morphological Differentiation of Ettringites by The Le Chatelier-Anstett TestRodrigo Henryque Reginato Quevedo MeloNoch keine Bewertungen

- CSA Raw Mix Design: Effect On Clinker Formation and ReactivityDokument18 SeitenCSA Raw Mix Design: Effect On Clinker Formation and ReactivityDawit MogesNoch keine Bewertungen

- Austenitic Stainless SteelsDokument23 SeitenAustenitic Stainless Steelslorena14Noch keine Bewertungen

- Sulfide Capacity of The Cao-Sio2-Mno Slag at 1 873 K: Isij International September 2011Dokument33 SeitenSulfide Capacity of The Cao-Sio2-Mno Slag at 1 873 K: Isij International September 2011joyNoch keine Bewertungen

- The in Uence of SO3: August 2009Dokument4 SeitenThe in Uence of SO3: August 2009halkawtNoch keine Bewertungen

- ppmp44 257-272Dokument16 Seitenppmp44 257-272Chemical Ferdi IzzecsonNoch keine Bewertungen

- Assignment 1 SteelmakingDokument2 SeitenAssignment 1 SteelmakingVishal KumarNoch keine Bewertungen

- Modeling of Nature and Strength of Acid Centres in U - 1999 - Studies in SurfaceDokument4 SeitenModeling of Nature and Strength of Acid Centres in U - 1999 - Studies in SurfaceLindsey BondNoch keine Bewertungen

- Rilem SMSS 2019Dokument6 SeitenRilem SMSS 2019Iva DespotovicNoch keine Bewertungen

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDokument12 SeitenStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationNoch keine Bewertungen

- Slag Fundamentals & Phase DiagramsDokument38 SeitenSlag Fundamentals & Phase DiagramsNicole Altamirano Catalán100% (1)

- Slag/metal Reactions During Ladle Treatment With Focus On DesulphurisationDokument23 SeitenSlag/metal Reactions During Ladle Treatment With Focus On DesulphurisationwefewfwefNoch keine Bewertungen

- Formation of Cerium-Based Bulk Metallic GlassesDokument8 SeitenFormation of Cerium-Based Bulk Metallic Glassescat nightNoch keine Bewertungen

- Copper Matte - Slag Reaction Sequences and SeparatDokument12 SeitenCopper Matte - Slag Reaction Sequences and SeparatLLoydDomingoMandocdocNoch keine Bewertungen

- Effect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessDokument7 SeitenEffect of Slag Basicity Adjusting On Inclusions in Tire Cord Steels During Ladle Furnace Re Fining ProcessBoujemaa DrifNoch keine Bewertungen

- Thermodynamics and Agglomeration Behavior On SpineDokument16 SeitenThermodynamics and Agglomeration Behavior On SpinePranjal SinghNoch keine Bewertungen

- Fly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67Dokument9 SeitenFly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67NikhilNoch keine Bewertungen

- Utilization Os Nickel Slag PDFDokument7 SeitenUtilization Os Nickel Slag PDFGaetanoD'AloiaNoch keine Bewertungen

- Influence of MgO On The Formation of Ca3SiO5 and 3CaO 3Al2O3 CaSO4 Minerals in Alite-Sulphoaluminate CementDokument5 SeitenInfluence of MgO On The Formation of Ca3SiO5 and 3CaO 3Al2O3 CaSO4 Minerals in Alite-Sulphoaluminate CementMarcelo GauNoch keine Bewertungen

- Effect of WT.% Sicp and Tib On The Mechanical Properties in Sicp/Az81A Magnesium Matrix Composite by The Method Semi Solid Stir CastingDokument9 SeitenEffect of WT.% Sicp and Tib On The Mechanical Properties in Sicp/Az81A Magnesium Matrix Composite by The Method Semi Solid Stir CastingNatalino FonsecaNoch keine Bewertungen

- Sorbent Cost and Performance in CO2 Capture SystemsDokument5 SeitenSorbent Cost and Performance in CO2 Capture SystemsserchNoch keine Bewertungen

- Slag Valorisation of Reductive Smelting Process by Shaft Furnace in The Lead Metallurgy of "Trepça" Complex With Economical and Environmental EffectsDokument10 SeitenSlag Valorisation of Reductive Smelting Process by Shaft Furnace in The Lead Metallurgy of "Trepça" Complex With Economical and Environmental EffectsNurten DevaNoch keine Bewertungen

- 2013-Liu - Transition Between Different Oxidation Modes of Binary Fe-Si Alloys at 600-800C in Pure O2Dokument24 Seiten2013-Liu - Transition Between Different Oxidation Modes of Binary Fe-Si Alloys at 600-800C in Pure O2David Hernández EscobarNoch keine Bewertungen

- Zhang, R.E. Ernst, T.J. Munson Et Al. Research 2 (2022) 84-100Dokument3 SeitenZhang, R.E. Ernst, T.J. Munson Et Al. Research 2 (2022) 84-100Moezselmi.12 SelmiNoch keine Bewertungen

- Synthesis and Characterization of Ceramic Materials Based On The System Mgo-Cao-Tio From DolomiteDokument10 SeitenSynthesis and Characterization of Ceramic Materials Based On The System Mgo-Cao-Tio From DolomiteGunawan DarmaNoch keine Bewertungen

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDokument1 SeiteSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNoch keine Bewertungen

- Exp - 6 - Carbothermal Reductive MeltingDokument7 SeitenExp - 6 - Carbothermal Reductive MeltingIbrahim MücahitNoch keine Bewertungen

- Selective Recovery of Phosphorus and Manganese From Steelmaking Slag by Carbothermic ReductionDokument4 SeitenSelective Recovery of Phosphorus and Manganese From Steelmaking Slag by Carbothermic ReductionBinh NghiemNoch keine Bewertungen

- Project Koripampa MiningDokument35 SeitenProject Koripampa MiningLeslie IvettNoch keine Bewertungen

- Simulation and Application of Tapping Online Refining in EAF Steelmaking ProcessDokument10 SeitenSimulation and Application of Tapping Online Refining in EAF Steelmaking ProcessRasul BzNoch keine Bewertungen

- Modelling of Electric Arc Furnace Off-Gas Removal System: N. Timoshenko, A. Semko and S. TimoshenkoDokument5 SeitenModelling of Electric Arc Furnace Off-Gas Removal System: N. Timoshenko, A. Semko and S. TimoshenkoRasul BzNoch keine Bewertungen

- DownloadDokument8 SeitenDownloadRasul BzNoch keine Bewertungen

- Theoretical Aspects of Scrap Dissolution in Oxygen Steelmaking ConvertersDokument12 SeitenTheoretical Aspects of Scrap Dissolution in Oxygen Steelmaking ConvertersRasul BzNoch keine Bewertungen

- Development of The Process of Electric Steel Production and Methods For Improving The Technicalandeconomic Indices of Electric Arc FurnacesDokument5 SeitenDevelopment of The Process of Electric Steel Production and Methods For Improving The Technicalandeconomic Indices of Electric Arc FurnacesRasul BzNoch keine Bewertungen

- Aspect of Design and Developments in EAF: December 2014Dokument6 SeitenAspect of Design and Developments in EAF: December 2014Rasul BzNoch keine Bewertungen

- Foaming Characteristics of BOF SlagsDokument8 SeitenFoaming Characteristics of BOF SlagsRasul BzNoch keine Bewertungen

- A Mathematical Model For The Reduction Stage of The CAS-OB ProcessDokument13 SeitenA Mathematical Model For The Reduction Stage of The CAS-OB ProcessRasul BzNoch keine Bewertungen

- Hydrogen Pick-Up After Vacuum Degassing: J. B. Hurtig and D. SichenDokument6 SeitenHydrogen Pick-Up After Vacuum Degassing: J. B. Hurtig and D. SichenRasul BzNoch keine Bewertungen

- Removal of Hydrogen, Nitrogen and Sulphur From Tool Steel During Vacuum DegassingDokument7 SeitenRemoval of Hydrogen, Nitrogen and Sulphur From Tool Steel During Vacuum DegassingRasul BzNoch keine Bewertungen

- The Effect of Fe O Content On Mgo Solubilities in Lime-Based SlagsDokument5 SeitenThe Effect of Fe O Content On Mgo Solubilities in Lime-Based SlagsRasul BzNoch keine Bewertungen

- Desulfurization of Liquid Steel Containing Aluminum or Silicon With Lime PDFDokument6 SeitenDesulfurization of Liquid Steel Containing Aluminum or Silicon With Lime PDFRasul BzNoch keine Bewertungen

- Thermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFDokument4 SeitenThermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFRasul BzNoch keine Bewertungen

- The Physical and Mathematical Modelling of Gas Stirred Ladle Systems PDFDokument20 SeitenThe Physical and Mathematical Modelling of Gas Stirred Ladle Systems PDFRasul BzNoch keine Bewertungen

- Selection of Stirring and Shrouding Gases For Steelmaking Applications PDFDokument20 SeitenSelection of Stirring and Shrouding Gases For Steelmaking Applications PDFRasul BzNoch keine Bewertungen

- 037 39 Science Making Glaze ClayCraft Issue 4Dokument3 Seiten037 39 Science Making Glaze ClayCraft Issue 4sedenmodikiNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 3Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 3estudiemosNoch keine Bewertungen

- Pliogrip 7770Dokument5 SeitenPliogrip 7770Francesco VignaliNoch keine Bewertungen

- Water Related ProblemsDokument4 SeitenWater Related ProblemsAdibNoch keine Bewertungen

- LOTO-101 SegurançaDokument4 SeitenLOTO-101 SegurançaRyan KaneNoch keine Bewertungen

- BPVC Code Cases 5Dokument54 SeitenBPVC Code Cases 5Burak KececiNoch keine Bewertungen

- RAB Retaining Wall - REVDokument167 SeitenRAB Retaining Wall - REVOkti AfriadelaNoch keine Bewertungen

- Flat Profile Thin Film Platinum: "F" SeriesDokument1 SeiteFlat Profile Thin Film Platinum: "F" SeriesJairo FernandezNoch keine Bewertungen

- Unclassified Ad Number Limitation Changes TODokument36 SeitenUnclassified Ad Number Limitation Changes TORuben's OscarNoch keine Bewertungen

- Aluminium Metal Casting PracticeDokument24 SeitenAluminium Metal Casting PracticeMuhammad AbrarNoch keine Bewertungen

- 1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%Dokument1 Seite1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%amir kamaliNoch keine Bewertungen

- 2 Galv Mall Iron Pipe FittingsDokument17 Seiten2 Galv Mall Iron Pipe FittingsGerryNoch keine Bewertungen

- Catalogue PPR - Ekoplastik - GreyDokument52 SeitenCatalogue PPR - Ekoplastik - GreyHeri SetiyantoNoch keine Bewertungen

- De HSG Ta10.ngt.l1Dokument5 SeitenDe HSG Ta10.ngt.l1dinh linhNoch keine Bewertungen

- PQ - Woqod - AALCO GroupDokument104 SeitenPQ - Woqod - AALCO GroupJason RazatlabNoch keine Bewertungen

- Department of Labor: Pe Bondsfiled08Dokument49 SeitenDepartment of Labor: Pe Bondsfiled08USA_DepartmentOfLaborNoch keine Bewertungen

- 01 - Fire Concept & Fire ScenarioDokument30 Seiten01 - Fire Concept & Fire ScenarioAnnisaNoch keine Bewertungen

- Gantrail Crane Rail WeldingDokument2 SeitenGantrail Crane Rail WeldingJorge Cruz RodriguezNoch keine Bewertungen

- New Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6Dokument1 SeiteNew Lahore Science Academy: Q1. Choose The Correct Answer. 1X6 6AmaezaNoch keine Bewertungen

- Sika - AG GroutDokument4 SeitenSika - AG GroutBill MurrayNoch keine Bewertungen

- Supplement Catalogue 2013Dokument135 SeitenSupplement Catalogue 2013Faiz El MakkyNoch keine Bewertungen

- ChemistryDokument17 SeitenChemistryRohit SahuNoch keine Bewertungen

- Class 8 Chap 4 Metals and Non MetalsDokument34 SeitenClass 8 Chap 4 Metals and Non MetalsAncy davidNoch keine Bewertungen

- Thermoset Vs Thermoplastic CompositesDokument4 SeitenThermoset Vs Thermoplastic Compositesairbuk doeingNoch keine Bewertungen

- Composite Steel-Concrete Construction: Economy of Cfts in A MRFDokument47 SeitenComposite Steel-Concrete Construction: Economy of Cfts in A MRFRaja GopalNoch keine Bewertungen

- Manufacturing of Tablets by Direct Compression Method - Reader ViewDokument1 SeiteManufacturing of Tablets by Direct Compression Method - Reader ViewMarta HalimNoch keine Bewertungen

- DR Fixit Pidipoxy MI EP Jan 2020Dokument3 SeitenDR Fixit Pidipoxy MI EP Jan 2020rakeshNoch keine Bewertungen

- 8x12 Shed PlansDokument15 Seiten8x12 Shed PlansRocio Cajo0% (1)

- 1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringDokument8 Seiten1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringChan Dara KoemNoch keine Bewertungen

- SikaplastDokument2 SeitenSikaplastPrakashkothandanNoch keine Bewertungen