Beruflich Dokumente

Kultur Dokumente

894 52413 1913

Hochgeladen von

Anonymous CZbChofeAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

894 52413 1913

Hochgeladen von

Anonymous CZbChofeACopyright:

Verfügbare Formate

Service Information

Rinsing and ventilating the steering

system

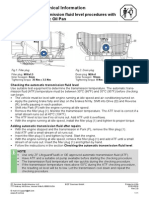

Fig. 1: Rack-and-pinion steering system Fig. 2: Ball-and-nut steering system

1 Fluid reservoir with fine filter 5 Steering rack

2 Supply pipe 6 Hub

3 Steering pump 7 Return pipe

4 Pressure line (expandable hose)

Faulty work can cause serious accidents!

During all work on the hydraulic steering system, extremely close attention must be paid to cleanliness

– even the smallest contamination can cause the steering system to fail!

Self-locking nuts, self-locking screws, sealing parts and safety elements must be replaced.

If a steering part is replaced due to an accident, the other parts of the steering system and the mechani-

cal connecting parts must be closely checked for damage.

If there is any sign of damage, the following parts must be replaced:

Axle and axle suspension

Tyres, Wheels

Mechanical connecting parts

Use type-specific, fresh hydraulic oil only. Follow the instructions issued by the vehicle manufacturer.

Dispose of used hydraulic oil in an appropriate manner.

ZF Friedrichshafen AG ▪ ZF Services © ZF Friedrichshafen AG Printed in Germany

Obere Weiden 12, 97424 Schweinfurt, Germany 60000 EN

Technical Support Phone: +49 9721 4755555 04.2014

Fax: +49 9721 4755556

techsupport.zf-services@zf.com

www.zf.com 1/2

Service Information

Rinsing and ventilating the steering

system

Rinsing the steering system Ventilating steering system

Switch off engine Fill fluid reservoir (1) to its top mark with fresh

Switch off ignition hydraulic oil

Secure radio code Raise vehicle until steering axles are relieved of

Disconnect negative pole of battery pressure

Ventilate steering pump (3) before installation If the engine is at a standstill, rotate the steer-

Fill up steering pump (3) at the supply pipe ing wheel slowly twice from lock to lock

connection (2) Fill with fresh hydraulic oil up to top mark

Rotate hub (6) manually until hydraulic oil Start the engine and ensure the oil reservoir is

escapes on the pressure side of the hydrau- always filled with oil to prevent suction of air

lic pump (expanding hose connection) (4) Rotate steering wheel 10 to 15 times slowly

Disconnect return pipe (7) from fluid reservoir from lock to lock

(1) Do not hold the steering wheel at the end

Collect hydraulic oil and feed it into the stop for more than 5 seconds

used oil recycling Do not apply great force at the limit stop.

Connect the fluid reservoir (1) to the return Otherwise the hydraulic oil may foam up

borehole Repeat procedure until no more bubbles

Lay the open end of the return pipe (7) in a escape from the fluid reservoir (1)

collecting tray Fill fluid reservoir (1) to its top mark with fresh

Remove the fine filter from the fluid reservoir hydraulic oil and close

(1) (not possible with all vehicles) Check the entire steering system for leaks

Clean fluid reservoir (1) Switch off engine

Install new fine filter The level of the hydraulic oil must go up af-

Fill steering system with fresh hydraulic oil via ter the engine is switched off (observe

the fluid reservoir (1) manufacturer specifications)

Connect negative pole of battery Check how far over the top marking the oil

Carry out measures to prevent engine from level has risen

starting (observe manufacturer's instructions!) Repeat ventilation procedure if the oil level

Rotate engine with starter speed and fill up has risen up to reference value 5 mm (ob-

with fresh hydraulic oil – at least 1 litre serve manufacturer specifications) over the

Remove return borehole seal on the fluid reser- top mark

voir (1) Check the hydraulic oil level during and after

Connect return hose (7) the test drive

Ventilate steering system While the engine is running, fill the fluid reser-

voir up to the top marking (1) with fresh hy-

draulic oil

For the return of the old steering system, observe the package leaflet!

Properly recycle old hydraulic oil.

www.zf.com/serviceinformation

ZF Friedrichshafen AG ▪ ZF Services © ZF Friedrichshafen AG Printed in Germany

Obere Weiden 12, 97424 Schweinfurt, Germany 60000 EN

Technical Support Phone: +49 9721 4755555 04.2014

Fax: +49 9721 4755556

techsupport.zf-services@zf.com

www.zf.com 2/2

Das könnte Ihnen auch gefallen

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsVon Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsBewertung: 1 von 5 Sternen1/5 (1)

- Cheuqeo Cilindros Hidraulicos Del Cargador 988KDokument5 SeitenCheuqeo Cilindros Hidraulicos Del Cargador 988KRAMON CALDERONNoch keine Bewertungen

- Vac Pump Manual Jewelry CastingDokument12 SeitenVac Pump Manual Jewelry CastingjfuentesemploymentNoch keine Bewertungen

- 2 - Canrig Top Drive Rig Crew TrainingDokument104 Seiten2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- FLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eDokument2 SeitenFLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eLIVIANoch keine Bewertungen

- Bomba Hidraulica SKFDokument84 SeitenBomba Hidraulica SKFJůan LópežNoch keine Bewertungen

- Forklift MaintenanceDokument11 SeitenForklift MaintenanceTrường NguyenNoch keine Bewertungen

- Automatic Transmission NAG1 - Fluid and FilterDokument4 SeitenAutomatic Transmission NAG1 - Fluid and FilterKrivega88Noch keine Bewertungen

- BMW ZF Transmission Level ProceduresDokument1 SeiteBMW ZF Transmission Level ProceduresDarius BogoslovNoch keine Bewertungen

- Capitol 5HD200-service-manual PDFDokument46 SeitenCapitol 5HD200-service-manual PDFlabatea100% (1)

- Prueva y Ajuste Sist Hid. 950EDokument32 SeitenPrueva y Ajuste Sist Hid. 950ESantiago FacundaNoch keine Bewertungen

- Testing and Adjunting Steering 950FDokument10 SeitenTesting and Adjunting Steering 950FEsteban MunaresNoch keine Bewertungen

- PVS 600 460 DS P 2qe 36 Ac 5DW PDLDokument83 SeitenPVS 600 460 DS P 2qe 36 Ac 5DW PDLHenry CorreaNoch keine Bewertungen

- Fitting Steering Pump SpidDokument15 SeitenFitting Steering Pump SpidJuan GarcNoch keine Bewertungen

- Dhpp10 Powerpack GuideDokument6 SeitenDhpp10 Powerpack Guideapi-3803863100% (1)

- Daewoo Engine D1146-T-TI Shop ManualDokument108 SeitenDaewoo Engine D1146-T-TI Shop ManualSilas F Pimenta100% (10)

- 121 - PDFsam22 - QH441 Operations Manual 14 04 15 EnglishDokument30 Seiten121 - PDFsam22 - QH441 Operations Manual 14 04 15 Englishisahin0508Noch keine Bewertungen

- Car Dumper-Operating Instruction ManualDokument40 SeitenCar Dumper-Operating Instruction ManualParthiban KarunaNoch keine Bewertungen

- M2.0 1460 200Dokument5 SeitenM2.0 1460 200Coque de LunaNoch keine Bewertungen

- Engine Oil Pressure - Test: NoticeDokument8 SeitenEngine Oil Pressure - Test: NoticebejoythomasNoch keine Bewertungen

- Pilot Pressure To The Main Control Valve - Check - 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDokument6 SeitenPilot Pressure To The Main Control Valve - Check - 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNoch keine Bewertungen

- Jin Bei ManualDokument300 SeitenJin Bei Manualrjan7pe100% (6)

- Rack and Pinion Installation Instructions: Technical ServiceDokument2 SeitenRack and Pinion Installation Instructions: Technical ServiceneozerokNoch keine Bewertungen

- Training Handout D25K D45 HydraulicDokument97 SeitenTraining Handout D25K D45 HydraulicAslam Kamal AfdhalNoch keine Bewertungen

- Pilot Pressure - Test and AdjustDokument4 SeitenPilot Pressure - Test and AdjustAnthony Inca MaytaNoch keine Bewertungen

- Engine Oil Pressure - Test: Cerrar SISDokument6 SeitenEngine Oil Pressure - Test: Cerrar SISIvan PalominoNoch keine Bewertungen

- Cat 325F L Operators ManualDokument4 SeitenCat 325F L Operators ManualСергій БоженкоNoch keine Bewertungen

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-11Dokument5 SeitenPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-11Tolias EgwNoch keine Bewertungen

- Service Manual SM1-10-6.0: Steering Pump, R & IDokument2 SeitenService Manual SM1-10-6.0: Steering Pump, R & IMohamed RashedNoch keine Bewertungen

- PSITier 2 1.6L Engine SM (1654)Dokument371 SeitenPSITier 2 1.6L Engine SM (1654)Codeiro SilvaNoch keine Bewertungen

- 722.9 Tranny Oil Line FlushDokument3 Seiten722.9 Tranny Oil Line FlushAntonio da LuzNoch keine Bewertungen

- NEHS07740001Dokument4 SeitenNEHS07740001mahmodNoch keine Bewertungen

- FDM TDokument13 SeitenFDM TMTK2016Noch keine Bewertungen

- Hydraulic System Tr. ShootingDokument11 SeitenHydraulic System Tr. Shootinghassan hamdyNoch keine Bewertungen

- Duetz 1011 & 2011 CE246Dokument8 SeitenDuetz 1011 & 2011 CE246PaulFoote100% (1)

- 952 12Dokument7 Seiten952 12RuthAnayaNoch keine Bewertungen

- D5M Track-Type Tractor Maintenance ManualDokument50 SeitenD5M Track-Type Tractor Maintenance ManualLubetech1993Noch keine Bewertungen

- 1 - Titan Owners Manual For End UsersDokument24 Seiten1 - Titan Owners Manual For End Userschristian vergaray gonzalesNoch keine Bewertungen

- Oil ServiceDokument11 SeitenOil Servicefrankie leungNoch keine Bewertungen

- Instruction Manual: Dosing Pump MaxroyDokument26 SeitenInstruction Manual: Dosing Pump Maxroyenedanielcristian100% (1)

- 1A Metallic ManualDokument10 Seiten1A Metallic ManualMayur PatilNoch keine Bewertungen

- Lubrication System: Systems OperationDokument5 SeitenLubrication System: Systems OperationbejoythomasNoch keine Bewertungen

- Piston Pump (Steering) PressureDokument8 SeitenPiston Pump (Steering) Pressureal muhajirinNoch keine Bewertungen

- Basic MaintenanceDokument23 SeitenBasic MaintenancePedro Lucas Rodrigues QueirozNoch keine Bewertungen

- R129 Hydraulic System - Draining and Refilling - RaDokument10 SeitenR129 Hydraulic System - Draining and Refilling - RaEvaristoEulalioNoch keine Bewertungen

- 93FWD 5SDokument46 Seiten93FWD 5SLuis Oswaldo Roa PerezNoch keine Bewertungen

- 24 Automatic TransmissionDokument102 Seiten24 Automatic TransmissionWilly AlvarezNoch keine Bewertungen

- 3412C Fuel System Pruebas y AjustesDokument13 Seiten3412C Fuel System Pruebas y AjustesJuan Carlos Inga VasquezNoch keine Bewertungen

- Fuel System Pressure TestDokument6 SeitenFuel System Pressure TestADIMITRA100% (2)

- The Ideal Power Steering InstallationDokument4 SeitenThe Ideal Power Steering InstallationFordiNoch keine Bewertungen

- Hydraulic Press Machine ManualDokument8 SeitenHydraulic Press Machine ManualAbdulaziz Alrawi100% (1)

- Operating Manual Parker Filtration UnitDokument27 SeitenOperating Manual Parker Filtration Unitjjlameda9112100% (2)

- Test de Presion de Aceite 3126Dokument8 SeitenTest de Presion de Aceite 3126WilsonAntonioGualdrónPachecoNoch keine Bewertungen

- Hydraulic PumpsDokument2 SeitenHydraulic PumpsCoque de LunaNoch keine Bewertungen

- Alfie 200 - Cleaning Unit For Coolant - Instruction Manual - 2009Dokument38 SeitenAlfie 200 - Cleaning Unit For Coolant - Instruction Manual - 2009Centrifugal Separator100% (1)

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDokument7 SeitenGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNoch keine Bewertungen

- XRV 163 and 204 Service Manual - Aug 2016Dokument55 SeitenXRV 163 and 204 Service Manual - Aug 2016Juwoon LeeNoch keine Bewertungen

- HPFi Hydraulic Support System 0700Dokument35 SeitenHPFi Hydraulic Support System 0700g665013Noch keine Bewertungen

- SX SI Austauschkupp As Tronic enDokument1 SeiteSX SI Austauschkupp As Tronic enAnonymous CZbChofeANoch keine Bewertungen

- Teava CSC Diametre Diferite SX SI CSC Korrekte Zuordnung enDokument1 SeiteTeava CSC Diametre Diferite SX SI CSC Korrekte Zuordnung enAnonymous CZbChofeANoch keine Bewertungen

- Prin Tragere Pull Type SI SX Ausruecker Mit Schnappverbindung enDokument1 SeitePrin Tragere Pull Type SI SX Ausruecker Mit Schnappverbindung enAnonymous CZbChofeANoch keine Bewertungen

- Injection Completo 960 V22 Ingles PDFDokument29 SeitenInjection Completo 960 V22 Ingles PDFAnonymous CZbChofeA0% (1)

- Dramix Setting The Standard SDokument8 SeitenDramix Setting The Standard SwilmanesNoch keine Bewertungen

- Cambridge International AS & A Level: Mathematics 9709/42Dokument16 SeitenCambridge International AS & A Level: Mathematics 9709/42Huzaim SulaimanNoch keine Bewertungen

- Ndtl:Bhel: Tiruchirappalli-620 014: P91 PipingDokument25 SeitenNdtl:Bhel: Tiruchirappalli-620 014: P91 PipingRupam BaruahNoch keine Bewertungen

- Lateral, Pipe Lateral, Steel Pipe Lateral, 45 Degree LateralDokument2 SeitenLateral, Pipe Lateral, Steel Pipe Lateral, 45 Degree Lateralณัฐพล ศักดิ์นภาพรเลิศNoch keine Bewertungen

- Assessment of Liquefaction Triggering: The UBC3D-PLM Constitutive Model Versus Semi-Empirical Methods Based On SPT-N ValuesDokument11 SeitenAssessment of Liquefaction Triggering: The UBC3D-PLM Constitutive Model Versus Semi-Empirical Methods Based On SPT-N ValuesSamiul IslamNoch keine Bewertungen

- Fluid Phase EquilibriaDokument19 SeitenFluid Phase EquilibriaYli S'cNoch keine Bewertungen

- P&S Tightening Instructions 07 GBDokument12 SeitenP&S Tightening Instructions 07 GBaputraNoch keine Bewertungen

- Globe Valves Stop Valves JISDokument7 SeitenGlobe Valves Stop Valves JISShivakumar KNoch keine Bewertungen

- Chapter IV - Driveline DynamicsDokument22 SeitenChapter IV - Driveline DynamicsHUQUYENNoch keine Bewertungen

- Gas MedisDokument12 SeitenGas MedistrisaktiyNoch keine Bewertungen

- Diesel Engine StartingDokument28 SeitenDiesel Engine Startingpatrick banisaNoch keine Bewertungen

- Introduce NDTDokument12 SeitenIntroduce NDTGandika PutraNoch keine Bewertungen

- Incompressible Flow Solution Using SIMPLE AlgorithmDokument26 SeitenIncompressible Flow Solution Using SIMPLE AlgorithmxavierNoch keine Bewertungen

- Directional Valves: Characteristic Value / Characteristic / InformationDokument1 SeiteDirectional Valves: Characteristic Value / Characteristic / InformationcontrolorNoch keine Bewertungen

- SVC/SHC Series: Sanitary Check ValvesDokument5 SeitenSVC/SHC Series: Sanitary Check ValvesChemikal EngineerNoch keine Bewertungen

- FadeccccDokument69 SeitenFadeccccsugihnuNoch keine Bewertungen

- FTS 2Dokument9 SeitenFTS 23PD20EE002 ABID SHAFINoch keine Bewertungen

- Spherical Roller Thrust Bearings - 29412 EDokument1 SeiteSpherical Roller Thrust Bearings - 29412 EManuel MartinezNoch keine Bewertungen

- Valvulas PSV FarrisDokument94 SeitenValvulas PSV FarrisdieferjimenezNoch keine Bewertungen

- Serv Manual CARDIFF T1 R22 Big Duct TypeDokument86 SeitenServ Manual CARDIFF T1 R22 Big Duct Typerobmeier100% (1)

- Procedure For Pump Line Stress AnalysisDokument9 SeitenProcedure For Pump Line Stress AnalysisNilesh Gohel100% (1)

- Valves 65Dokument37 SeitenValves 65Mohamed SabryNoch keine Bewertungen

- MAN B&W V48-60B Spare Parts CatalogueDokument346 SeitenMAN B&W V48-60B Spare Parts CatalogueLasse Hansen100% (1)

- NaphthaleneDokument3 SeitenNaphthaleneNur Hafeza75% (4)

- 9976 Weichai WP7 Spec Sheet RevmDokument3 Seiten9976 Weichai WP7 Spec Sheet Revmmurjani macindoNoch keine Bewertungen

- Vetus Thruster SelectionDokument1 SeiteVetus Thruster SelectionKiky IchanafiNoch keine Bewertungen

- Electrical SubstationDokument19 SeitenElectrical SubstationMigueldelaTorreNoch keine Bewertungen

- Mechanical Properties of Solids - NotesDokument15 SeitenMechanical Properties of Solids - NotesNyra HillsNoch keine Bewertungen

- Why The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncDokument11 SeitenWhy The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncAnoj pahathkumburaNoch keine Bewertungen

- 747 400 Boeing: ATA 36 PneumaticDokument138 Seiten747 400 Boeing: ATA 36 Pneumaticazadair100% (1)