Beruflich Dokumente

Kultur Dokumente

Investigation On Strength and Workability at Low Temperature by Using Locally Available Materials 2472 0437 1000131

Hochgeladen von

Narasimha ReddyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Investigation On Strength and Workability at Low Temperature by Using Locally Available Materials 2472 0437 1000131

Hochgeladen von

Narasimha ReddyCopyright:

Verfügbare Formate

ctu

el

Stru re & Manzoor, J Steel Struct Constr 2017, 3:1

DOI: 10.4172/2472-0437.1000131

Co

e

urnal of St

Journal of Steel Structures & Construction

nstr tion

uc

Jo

ISSN: 2472-0437

Research

Perspective Article Open

OMICS Access

International

Investigation on Strength and Workability at Low Temperature by Using

Locally Available Materials

Shaief Manzoor*

Baba Ghulam Shah Badshah University, Rajouri, Jammu and Kashmir, India

Abstract

Kashmir lies in region where temperature in winter is very low. The temperature in Kashmir is often below

0°C during couple of months winter. Concrete mixed, transported and placed under low temperatures requires an

understanding for the adverse effects of such environmental factors on the durability of concrete. The damage caused

by extreme weather conditions can never be fully eliminated but efforts can be made to minimize these adverse

effects. This research was undertaken to investigate the effects of Extreme weather on different properties of concrete

and influence of early temperature on the strength of concrete.

Three temperatures, two 5°C and one 25°C were selected and maintained for the first three days for freshly

prepared concrete and during the early hardening state of concrete. After three days all the samples were cured at

room temperature. The most common traditional mix of 1:2:4 was selected for the research work because it is used

for maximum construction projects. Admixtures Sodium Nitrite was used to see useful effects of these during extreme

weather conditions.

After the conduct of research, it has been concluded that cold wheather concreting has serious effect on different

properties of concrete, like strength, workability and rate of hardening, during the early hardening state.To eliminate

the ill effects, it is the duty of the designer/engineer to plan in advance the selection of materials, types quality and

quantity of admixtures and coordination of all phases of work so that conreting can be done safely without damage

from freezing throughout the winter months in cold climates.

Keywords: Investigation; Concrete; Climates 4. Loss of compressive strength even upto 50% incase, if concrete

freezes when it is in plastic state.

Introduction

5. Durability of the concrete is impaired due to freezing and

The normal procedure adopted for concreting in fair weather will thawing of fresh or hardened concrete.

not be valid for concreting when the temperature is low or below the

freezing point. The production of concrete in cold weather introduces

6. Large temperature differentials within the concrete member

may promote cracking while removal of formwork in cold weather

special and peculiar problems, such as delay in setting and hardening,

(Figures 1-3).

damage to concrete in plastic condition when exposed to below

freezing point owing to the formation of ice lenses Therefore, it is Purpose and Scope of Present Research

essential to maintain the temperature of the concrete positively above

0°C , possibly at much higher temperature. Any concreting operation The main aim of the research was to study

done at a temperature below 5°C is termed as cold weather concreting • The cold weather effects on concreting during the early time of

There are two main problems with concrete in cold weather: setting and gaining strength.

i. Concrete can freeze before it gains strength which breaks up • Influence of first three days temperature on 28-days compressive

the matrix strength of concrete was studied and analyzed.

ii. Concrete sets more slowly when it is cold very slow below • Also effect of low temperature on the workability of concrete

50°F; below 40°F the hydration reaction basically stops and the was investigated.

concrete doesn’t gain strength. • Low temperature effects on Tensile strength and modulus of

iii. Hardened concrete subjected to alternate Freezing and rupture were also considered.

Thawing.

Effects of cold weather on concrete *Corresponding author: Shaief Manzoor, Baba Ghulam Shah Badshah

University, Rajouri, Jammu and Kashmir, 185131, India, Tel: +919419023302,

Cold weather affects the concrete in following manner: +91700634373; E-mail: shaief38@gmail.com

1. Delay in setting and hardening period because rate of Received June 12, 2017; Accepted June 30, 2017; Published July 06, 2017

hydration. Citation: Manzoor S (2017) Investigation on Strength and Workability at Low

Temperature by Using Locally Available Materials. J Steel Struct Constr 3: 131.

2. Delay in setting time makes concrete vulnerable to frost attack doi: 10.4172/2472-0437.1000131

and other disturbances.

Copyright: © 2017 Manzoor S. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

3. Progress of work is slowed down and removal of formwork is use, distribution, and reproduction in any medium, provided the original author and

delayed thus affecting economically. source are credited.

J Steel Struct Constr, an open access journal Volume 3 • Issue 1 • 1000131

ISSN: 2472-0437

Citation: Manzoor S (2017) Investigation on Strength and Workability at Low Temperature by Using Locally Available Materials. J Steel Struct Constr

3: 131. doi: 10.4172/2472-0437.1000131

Page 2 of 4

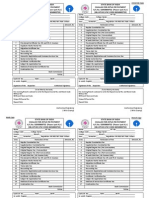

3500 3310 3500 3200

3000 3000

Compressive Strength in Psi

2500 2540

Compressive Strength in Psi

2500 2500

1920

2000 2000

1620

1500 1500

1050 1000

1000

1000

500

500

0

0 0 5 10 15 20 25 30

0 5 10 15 20 25 30

Days Days

Compressive Strength

Figure 3: Graph Showing Compressive with variation in temperature (5°C)

Figure 1: Graph Showing Compressive with variation in room temperature. with admixture.

extreme weather temperature, which a concrete mix can come across

4000 during first three days. Temperatures selected were 5°C, and 25°C. 1, 3,

7 and 28-day tests were carried on samples prepared.

3500

A manually operated drum mixer, having a maximum of 2.5 cft

Compr essive Str enth in Psi

3000 capacity was used for mixing concrete

2500 Results and Conclusions

2000 Effect on compressive strength

1500 The specimens manufactured at low temperature (5°C) showed

slow gain of one-day compressive strengths as compared to those made

1000 at room temperatures. Those samples put on low temperature started

500 recovering by the seventh day and there strength was almost equal to

room temperature samples. At 28th day compressive strength of the

0 cylinders placed at low temperature gained slow early days strength

0 5 10 15 20 25 30 but later recovered and seem to have more strength than normal room

Days temperature made cylinders. Use of admixtures low temperatures

Compressive Strength seem to be beneficial to some extent. The admixture Sodium Nitrite has

Figure 2: Graph Showing Compressive with variation in temperature (5°C). shown some early gain of strength but 28 days strength was reduced

(Tables 1 and 2; Figures 4 and 5).

• An admixture Sodium Nitrite was added to study the effects an Effect on workability

admixture on strength of concrete during a cold weather.

With constant w/c ratio and variable temperature it was found

Methodology and Materials Used that workability of concrete mix decreases as the temperature of

the concrete increases i.e., slump and the compacting factor values

Locally available materials were used in this research work. Details

are as following: decreases as the temperature increases. But when the surrounding and

concrete temperature is low there is no such effect on the workability.

Cement: Ambuja Cement The use of Sodium Nitrite has no notable effect on the workability of

Aggregates: Sand (Obtained from River Jehlum near Anantnag) concrete at low temperature.

Coarse Aggregates: Locally available crush Effect on modulus of rupture

Admixtures: Sodium Nitrite It is seen by test results that prisms/beams made at room

temperature showed less tensile strength at 28th days as compared to

Testing of constituent materials was carried out as per ASTM samples made are 5°C. While the samples in which admixture was used

specified procedures. showed higher modulus of rupture as compared to the samples, which

Although one concrete mix was taken i.e., 1: 2:4 with w/c ratio 0.65 were without admixture. Thus values of modulus of rupture of concrete

but the temperature was varied. It was varied according to possible are greatly affected by the variation in temperature.

J Steel Struct Constr, an open access journal Volume 3 • Issue 1 • 1000131

ISSN: 2472-0437

Citation: Manzoor S (2017) Investigation on Strength and Workability at Low Temperature by Using Locally Available Materials. J Steel Struct Constr

3: 131. doi: 10.4172/2472-0437.1000131

Page 3 of 4

S. No. Condition Temperature °C Compressive Strength (Psi)

(First 3 days)

1-Day 3-Day 7-Day 28-Day Remarks

1 Room Temperature 25°C 1050 1920 2500 3310

2 Low Temperature 5°C 830 1550 2490 3250 2% decrease in 28 days strength

3 Low Temperature with admixture 5°C 1000 1620 2540 3200 3.3% decrease in 28 days strength

Strength of cylinders at various ages

Mix ratio: 1: 2:4, w/c ratio- 0.65

Table 1: Test Results for Compressive.

S. No. Condition Temperature °C Slump (MM) Compact Factor

1 Room Temperature 25°C 58 0.87

2 Low Temperature 5°C 56 .086

3 Low Temperature with admixture 5°C 51 0.91

Measurement of slump and Compaction factor

Mix ratio: 1: 2:4, w/c ratio- 0.65

Table 2: Test results for workability.

Temprature Effect on Compaction factor

0.92

0.91

0.9

Compaction factor

0.89

0.88

0.87 0.91

0.86

0.85 0.87

0.86

0.84

0.83

Compact factor at room Compact at low temprature(5°C) Slump at low temprature(5°C)

temprature with admixture

Tempratre °C

Figure 4: Temperature Effect on compaction factor.

Temprature Effect onSlump

60

58

56

Slimp mm

54

52 58

56

50

51

48

46

Slump at room temprature Slump at low temprature(5°C) Slump at low temprature(5°C) with

Tempratre °C admixture

Figure 5: Temperature Effect on slump.

J Steel Struct Constr, an open access journal Volume 3 • Issue 1 • 1000131

ISSN: 2472-0437

Citation: Manzoor S (2017) Investigation on Strength and Workability at Low Temperature by Using Locally Available Materials. J Steel Struct Constr

3: 131. doi: 10.4172/2472-0437.1000131

Page 4 of 4

Effect on tensile strength • High temperature showed early gain of strength but later the

strength of concrete was considerably reduced.

Splitting tensile strength test was performed to evaluate the effect

of temperature on tensile strength of concrete. It was observed that as • Temperature of ingredients of concrete should be given

the temperature increases, there is quick early gain of tensile strength consideration to control the temperature of the concrete.

but later 28-day tensile strength was decreased, as in the case of

compressive strength. • Cold weather may cause delay in setting and hardening period,

thus delaying removal of formwork.

Recommendations

• Use chemical means (admixtures) to prevent damage/loss of

• If the temperature is too low it should be given importance by

strength. It is not that much expensive as compared to loss that can

site engineer while concreting.

occur to concrete without chemicals by extreme temperature.

• Plan all concreting works completed during suitable weather/

temperature so that newly placed concrete should not encounter odd • Certain precautionary measures are highly recommended for

temperature. concreting both in hot and cold weathers.

OMICS International: Open Access Publication Benefits &

Features

Unique features:

• Increased global visibility of articles through worldwide distribution and indexing

• Showcasing recent research output in a timely and updated manner

• Special issues on the current trends of scientific research

Special features:

• 700+ Open Access Journals

• 50,000+ Editorial team

• Rapid review process

• Quality and quick editorial, review and publication processing

• Indexing at major indexing services

• Sharing Option: Social Networking Enabled

Citation: Manzoor S (2017) Investigation on Strength and Workability at Low • Authors, Reviewers and Editors rewarded with online Scientific Credits

Temperature by Using Locally Available Materials. J Steel Struct Constr 3: • Better discount for your subsequent articles

131. doi: 10.4172/2472-0437.1000131 Submit your manuscript at: http://www.omicsonline.org/submission

J Steel Struct Constr, an open access journal Volume 3 • Issue 1 • 1000131

ISSN: 2472-0437

Das könnte Ihnen auch gefallen

- Review On Early Strength ConcreteDokument6 SeitenReview On Early Strength ConcreteNarasimha ReddyNoch keine Bewertungen

- Acc 0801004Dokument5 SeitenAcc 0801004Narasimha ReddyNoch keine Bewertungen

- PDFDokument10 SeitenPDFNarasimha ReddyNoch keine Bewertungen

- Review Article: Mechanical Characteristics of Hardened Concrete With Different Mineral Admixtures: A ReviewDokument16 SeitenReview Article: Mechanical Characteristics of Hardened Concrete With Different Mineral Admixtures: A ReviewNarasimha ReddyNoch keine Bewertungen

- CT Question PaperDokument1 SeiteCT Question PaperNarasimha ReddyNoch keine Bewertungen

- PDFDokument10 SeitenPDFNarasimha ReddyNoch keine Bewertungen

- Effect of Pozzolanic Additives On The Strength Development of High Performance ConcreteDokument9 SeitenEffect of Pozzolanic Additives On The Strength Development of High Performance ConcreteNarasimha ReddyNoch keine Bewertungen

- Development of High Strength Fly Ash Based Geopolymer Concrete With AlccofineDokument4 SeitenDevelopment of High Strength Fly Ash Based Geopolymer Concrete With AlccofineNarasimha ReddyNoch keine Bewertungen

- 282PDokument6 Seiten282PNarasimha ReddyNoch keine Bewertungen

- A Comparative Study of Bis and Bs (Doe) Method of Concrete Mix Design Using Alccofine As A Partial Replacement of Cement"Dokument9 SeitenA Comparative Study of Bis and Bs (Doe) Method of Concrete Mix Design Using Alccofine As A Partial Replacement of Cement"Narasimha ReddyNoch keine Bewertungen

- Chemical, Mechanical, and Durability Properties of Concrete With Local Mineral Admixtures Under Sulfate Environment in Northwest ChinaDokument14 SeitenChemical, Mechanical, and Durability Properties of Concrete With Local Mineral Admixtures Under Sulfate Environment in Northwest ChinaNarasimha ReddyNoch keine Bewertungen

- Development of High Strength Fly Ash Based Geopolymer Concrete With AlccofineDokument4 SeitenDevelopment of High Strength Fly Ash Based Geopolymer Concrete With AlccofineNarasimha ReddyNoch keine Bewertungen

- GATE Syllabus for Civil Engineering - CEDokument2 SeitenGATE Syllabus for Civil Engineering - CEArjun ReddyNoch keine Bewertungen

- Calcium Chloride Concrete Accelerator GuideDokument2 SeitenCalcium Chloride Concrete Accelerator GuideNarasimha ReddyNoch keine Bewertungen

- Kim 2008Dokument8 SeitenKim 2008Narasimha ReddyNoch keine Bewertungen

- Chapter - 10: Logic-Based TestingDokument43 SeitenChapter - 10: Logic-Based TestingNarasimha ReddyNoch keine Bewertungen

- Astm C 642 90 Calidad Del ConcretoDokument3 SeitenAstm C 642 90 Calidad Del ConcretoBayron Medina Ospina0% (1)

- Alkali FreeDokument9 SeitenAlkali FreeNarasimha ReddyNoch keine Bewertungen

- 9D57101 VLSI TechnologyDokument1 Seite9D57101 VLSI TechnologyNarasimha ReddyNoch keine Bewertungen

- Challan For JNTUA Fee Payment-JNTUWORLDDokument2 SeitenChallan For JNTUA Fee Payment-JNTUWORLDNarasimha ReddyNoch keine Bewertungen

- Elongation Test Determines Aggregate ShapeDokument2 SeitenElongation Test Determines Aggregate ShapeNarasimha ReddyNoch keine Bewertungen

- Study of Strength Characteristics of Crushed Glass Used As Fine Aggregate in ConcreteDokument4 SeitenStudy of Strength Characteristics of Crushed Glass Used As Fine Aggregate in ConcreteNarasimha ReddyNoch keine Bewertungen

- Kalani BookDokument149 SeitenKalani Bookniranjan_nitjNoch keine Bewertungen

- Pipelining ToanDokument21 SeitenPipelining ToandubstepoNoch keine Bewertungen

- Water Resources Engineering Course SyllabusDokument2 SeitenWater Resources Engineering Course SyllabusNarasimha ReddyNoch keine Bewertungen

- 9D04102 Finite Element Methods PDFDokument2 Seiten9D04102 Finite Element Methods PDFVijay Kshatriya HRNoch keine Bewertungen

- Question PaperDokument1 SeiteQuestion PapercomputerstudentNoch keine Bewertungen

- 9D04102 Finite Element Methods PDFDokument2 Seiten9D04102 Finite Element Methods PDFVijay Kshatriya HRNoch keine Bewertungen

- Front MaterialDokument18 SeitenFront MaterialNarasimha ReddyNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PGCB ReportDokument36 SeitenPGCB ReportNayemul Hasan NayemNoch keine Bewertungen

- 3D PrintingDokument32 Seiten3D Printing9700216256Noch keine Bewertungen

- LRP I Approved ProjectsDokument1 SeiteLRP I Approved ProjectsTheReviewNoch keine Bewertungen

- Section 3.3.4 Neutral Earthing Resistors R1Dokument7 SeitenSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaNoch keine Bewertungen

- X-Arcade Tankstick Manual USADokument13 SeitenX-Arcade Tankstick Manual USAmight69Noch keine Bewertungen

- Types of Wind Turbines - Horizontal Axis and Vertical Axis ComparedDokument1 SeiteTypes of Wind Turbines - Horizontal Axis and Vertical Axis Comparedmendhi123Noch keine Bewertungen

- Chapter 4 Wastewater Collection and TransportationDokument8 SeitenChapter 4 Wastewater Collection and Transportationmulabbi brian100% (1)

- Serrano y Olalla - Linearization of The Hoek y BrownDokument11 SeitenSerrano y Olalla - Linearization of The Hoek y BrownEsteban JamettNoch keine Bewertungen

- Jobs For Software Testers in Siemens Teamcenter Software Through Industry Experience ProgramDokument4 SeitenJobs For Software Testers in Siemens Teamcenter Software Through Industry Experience ProgramKumar SNoch keine Bewertungen

- A Detailed Report ON Incense Stick ProductionDokument6 SeitenA Detailed Report ON Incense Stick Productionanand agarwalNoch keine Bewertungen

- The Future of HovercraftDokument3 SeitenThe Future of Hovercrafthovpod6214100% (4)

- Cie - Publist - 2008 Penerangan PDFDokument11 SeitenCie - Publist - 2008 Penerangan PDFAli RosidiNoch keine Bewertungen

- AC - ADENIYI MARUF OPEYEMI - FEBRUARY, 2023 - 2148745001 - FullStmtDokument6 SeitenAC - ADENIYI MARUF OPEYEMI - FEBRUARY, 2023 - 2148745001 - FullStmtmophadmophadNoch keine Bewertungen

- Wa0040Dokument3 SeitenWa0040cia sin kwangNoch keine Bewertungen

- Cable Diagram: Technical Data SheetDokument1 SeiteCable Diagram: Technical Data SheetCharlie MendozaNoch keine Bewertungen

- Loyalty Program Description PDFDokument7 SeitenLoyalty Program Description PDFJayjay latiNoch keine Bewertungen

- Electronically Controlled On-Demand 4WDDokument32 SeitenElectronically Controlled On-Demand 4WDjulio797Noch keine Bewertungen

- Research and Practice in HRM - Sept 8Dokument9 SeitenResearch and Practice in HRM - Sept 8drankitamayekarNoch keine Bewertungen

- Participatory Technology DevelopmentDokument20 SeitenParticipatory Technology DevelopmentSri HimajaNoch keine Bewertungen

- Digital Vision Installation PDFDokument2 SeitenDigital Vision Installation PDFnikola5nikolicNoch keine Bewertungen

- Enterprise, Innovation Creativity 2018-19 S3 CourseworkDokument7 SeitenEnterprise, Innovation Creativity 2018-19 S3 CourseworkSajidNoch keine Bewertungen

- DesuperheatersDokument8 SeitenDesuperheatersmuhdrijasmNoch keine Bewertungen

- PQA824 ManualDokument100 SeitenPQA824 ManualElkin AguasNoch keine Bewertungen

- Social Skills LessonDokument5 SeitenSocial Skills LessonAshley DavidsonNoch keine Bewertungen

- CV for Mechanical Inspector and Welding InspectorDokument28 SeitenCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMNoch keine Bewertungen

- 1st Term Exam Part 2 - QSDokument10 Seiten1st Term Exam Part 2 - QSMark Anthony TajonNoch keine Bewertungen

- Food Safety ChecklistDokument5 SeitenFood Safety ChecklistDenver Palingit Rimas100% (3)

- Medonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsDokument6 SeitenMedonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsSubhanullah JalalNoch keine Bewertungen

- Explosion Proof Control Device SpecificationsDokument12 SeitenExplosion Proof Control Device SpecificationsAnonymous IErc0FJNoch keine Bewertungen

- UDRPDokument10 SeitenUDRPDomainNameWire100% (1)