Beruflich Dokumente

Kultur Dokumente

T 1966

Hochgeladen von

hasan099Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T 1966

Hochgeladen von

hasan099Copyright:

Verfügbare Formate

PGS ENGINEERING TIL 1966

PRODUCT SERVICE 19 OCTOBER 2015

Compliance Category – C

Timing Code - 6

TECHNICAL INFORMATION LETTER

324 LEADS UP 50HZ END WINDING MODIFICATIONS

APPLICATION

Specific 324 leads up 50 Hz machines that were manufactured between 2001 through 2014 with wet tie connection

ring blocking and backset blocking.

PURPOSE

This TIL provides recommendations to the specific 324 LU 50Hz units for blocking modifications on the end winding to

prevent copper failure in the end windings.

Compliance Category

M - Maintenance Identifies maintenance guidelines or best practices for reliable equipment

operation.

C - Compliance Required Identifies the need for action to correct a condition that, if left uncorrected,

may result in reduced equipment reliability or efficiency. Compliance may be

required within a specific operating time.

A - Alert Failure to comply with the TIL could result in equipment damage or facility

damage. Compliance is mandated within a specific operating time.

S – Safety Failure to comply with this TIL could result in personal injury. Compliance is

mandated within a specific operating time.

Timing Code

1 Prior to Unit Startup / Prior to Continued Operation (forced outage condition)

2 At First Opportunity (next shutdown)

3 Prior to Operation of Affected System

4 At First Exposure of Component

5 At Scheduled Component Part Repair or Replacement

6 Next Scheduled Outage

© 2015 General Electric Company

The proprietary information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service

relationship with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since operation

of the plant is in your control and ultimate responsibility for its continuing successful operation rests with you, GE specifically disclaims any

responsibility for liability based on claims for damage of any type, i.e. direct, consequential or special that may be alleged to have been incurred as

result of applying this information regardless of whether it is claimed that GE is strictly liable, in breach of contract, in breach of warranty, negligent, or

is in other respects responsible for any alleged injury or damage sustained by your organization as a result of applying this information.

This Technical Information Letter contains proprietary information of General Electric Company and is furnished to its customer solely to assist that

customer in the installation, testing, operation and/or maintenance of the equipment described. This document shall not be reproduced or distributed

in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Power & Water PGS Engineering. All rights

reserved.

TIL 1966

BACKGROUND DISCUSSION

Connection rings are part of generator end winding assembly (Figure 1) and are used to connect circuits in the

generator to transfer electrical power from the generator core to the grid. For a 324 generator, the connection rings can

consists of either 21 or 27 individual segments that are blocked and tied to resist not only the fault forces, but also the

running resonant vibrations at 1x or 2x the line frequencies.

Figure 1: Overview of Partial 324 End Winding Assembly

GE has utilized different types of blocking methods (e.g. dry ties, consolidated dry ties and wet ties) and blocking

schemes to support the connection ring structure for long term operation with reduced preventive maintenance. The

most recent blocking method currently in use by GE on conformable end windings is the wet tie method which has

proven to date to be the most robust method of blocking the connection rings.

Due to recent events within the 324 fleet, GE has determined that some units with wet ties, backset blocks and specific

end winding configurations are thermally constrained within the connection ring structure. This lack of thermal

compliance in the end windings can either lead to repeated dusting of the backset block or in limited cases can lead to

copper failure at either the phase strap bends or backset bends.

Analysis has shown that the presence of the backset blocks in the generator end winding has the potential to add strain

at the backset bends which can fatigue the copper and cause pre-mature failure of the backset. Removing the backset

blocks relieves this strain at the backset bends and increases the thermal compliance of the end winding. GE has also

developed an optional comprehensive blocking upgrade and modification package that can also be implemented on

the end windings on pro-active basis to further increase the thermal compliance of the end winding and reduce dusting

in the end winding.

RECOMMENDATIONS

Maintain inspection outage interval per GEK 103566 and follow the recommended actions during the next MAJOR

inspection:

1. Test and record the winding resistance of each phase of the generator stator. All resistance values should

agree within 1% of each other.

2. The backset blocks (see Fig. 2) should be removed (not replaced or repaired) if found loose or dusted.

© 2015 General Electric Company

This Technical Information Letter contains proprietary information of General Electric Company and is furnished to its customer solely to assist that

customer in the installation, testing, operation and/or maintenance of the equipment described. This document shall not be reproduced or distributed

in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Power & Water PGS Engineering. All rights

reserved.

Page 2 of 4

TIL 1966

Figure 2: Illustration of a Dusted Backset Block

3. Perform an inertance/bump test in accordance with GE procedures following backset block removal. If

resonance frequencies are found outside of GE specifications, GE Generator Product Services should be

contacted for recommendations.

This TIL will be considered complete after completing the recommended actions 1 through 3 noted above.

PLANNING INFORMATION

Compliance

Compliance Category: C

Timing Code: 6

Manpower Skills

This repair can be completed by a winder under the direction of a generator specialist.

Parts

Contact your GE Customer Service Manager for assistance in ordering defined parts kits.

Special Tooling

Standard inspection tools for the outage

Reference Documents

Any questions regarding this TIL should be directed to GE Generator Product Service through local GE Customer Service

Manager.

Previous Modifications

None

Scope of Work

The repairs take approximately 4 days.

Contact your local GE Service Representative for assistance or for additional information.

Contact your local GE Customer Service Manager in order to update GE unit record sheets or to submit as-built

drawings for changes incurred by this TIL.

© 2015 General Electric Company

This Technical Information Letter contains proprietary information of General Electric Company and is furnished to its customer solely to assist that

customer in the installation, testing, operation and/or maintenance of the equipment described. This document shall not be reproduced or distributed

in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Power & Water PGS Engineering. All rights

reserved.

Page 3 of 4

TIL 1966

TIL COMPLIANCE RECORD

Compliance with this TIL must be entered in local records. GE requests that the customer notify GE upon compliance of

this TIL.

Complete the following TIL Compliance Record and FAX or Email it to:

TIL Compliance

FAX: (678) 844-3451

Email: til.compreq@ge.com

TIL COMPLIANCE RECORD For Internal Records Only #

Site Name: Customer Name:

Customer Contact Information GE Contact Information

Contact Name: Contact Name:

Address: Address:

Email: Email:

Phone: Phone:

FAX: FAX:

Turbine Serial Number(s):

INSTALLED EQUIPMENT TIL Completed Date:

100% TIL Completed:

Description:

Unit Numbers: Part Description: Part Number MLI Number

Comments:

NOTE: If there are any redlined drawings that pertain to this TIL implementation, please FAX or Email the drawings

along with this TIL Compliance Record.

FAX this form to: TIL Compliance

FAX: (678) 844-3451

Email: til.compreq@ge.com

© 2015 General Electric Company

This Technical Information Letter contains proprietary information of General Electric Company and is furnished to its customer solely to assist that

customer in the installation, testing, operation and/or maintenance of the equipment described. This document shall not be reproduced or distributed

in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Power & Water PGS Engineering. All rights

reserved.

Page 4 of 4

Das könnte Ihnen auch gefallen

- Hogan'S Heroes March: Arranged by JOHNNIE VINSONDokument11 SeitenHogan'S Heroes March: Arranged by JOHNNIE VINSONRuby Waltz100% (1)

- Psib 20130813a - R1Dokument4 SeitenPsib 20130813a - R1Léandre Ettekri NdriNoch keine Bewertungen

- Training - Flowserve Apm Pump CW PumpDokument19 SeitenTraining - Flowserve Apm Pump CW Pumphasan099100% (1)

- UtopiaDokument5 SeitenUtopiaOana SpănţulescuNoch keine Bewertungen

- Til 1755-R3 Lci Water - Cooled Bus LeaksDokument8 SeitenTil 1755-R3 Lci Water - Cooled Bus LeaksMichael SanchezNoch keine Bewertungen

- Flowserve PumpsDokument44 SeitenFlowserve Pumpshasan099Noch keine Bewertungen

- TIL 1547 2 - Gas Turbine Flex Hose RecommendationDokument4 SeitenTIL 1547 2 - Gas Turbine Flex Hose RecommendationHernan GirautNoch keine Bewertungen

- Uprate OptionsDokument18 SeitenUprate Optionstryitnow123100% (1)

- SB LM2500 Ind 312 R1Dokument7 SeitenSB LM2500 Ind 312 R1Daniil SerovNoch keine Bewertungen

- Technical Information Letter: Thermal Engineering Product Service TIL 1108-R1Dokument7 SeitenTechnical Information Letter: Thermal Engineering Product Service TIL 1108-R1Heryanto SyamNoch keine Bewertungen

- TIL 1420-2r1 Lube Oil Logic EnhancementDokument4 SeitenTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoNoch keine Bewertungen

- Mx0301-E (Pump) FlowserveDokument34 SeitenMx0301-E (Pump) Flowservehasan099Noch keine Bewertungen

- Parts 328 - WWW - Powerplant.partsDokument31 SeitenParts 328 - WWW - Powerplant.partsQuinhan LtdNoch keine Bewertungen

- Til 1323-3R1Dokument2 SeitenTil 1323-3R1Hernan GirautNoch keine Bewertungen

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDokument47 SeitenNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNoch keine Bewertungen

- Technical Information Letter: GE PowerDokument10 SeitenTechnical Information Letter: GE PowerRichard Puicon PuyenNoch keine Bewertungen

- Technical Information Letter: Energy Services Engineering Product Service TIL 1713Dokument5 SeitenTechnical Information Letter: Energy Services Engineering Product Service TIL 1713ankarao69Noch keine Bewertungen

- Til 1236-R2Dokument5 SeitenTil 1236-R2makarov.olegNoch keine Bewertungen

- Electrical Design - Dax Generators: © BRUSH GroupDokument66 SeitenElectrical Design - Dax Generators: © BRUSH GroupKyleNoch keine Bewertungen

- T 1566Dokument5 SeitenT 1566Erwin Mauricio Alarcon PradenasNoch keine Bewertungen

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDokument5 Seiten26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69Noch keine Bewertungen

- Gek111330 HDokument47 SeitenGek111330 Hdede azandriNoch keine Bewertungen

- T 1918Dokument4 SeitenT 1918esutjiadiNoch keine Bewertungen

- TIL 1819 ImplementationDokument4 SeitenTIL 1819 ImplementationManuel L LombarderoNoch keine Bewertungen

- Cable Trays RequirementDokument1 SeiteCable Trays RequirementSulaiman JafferyNoch keine Bewertungen

- 1420-2R1 Lube Oil Logic Enhancement PDFDokument4 Seiten1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoNoch keine Bewertungen

- Psib 20160603aDokument3 SeitenPsib 20160603aLéandre Ettekri Ndri100% (1)

- Farolan v. CTADokument2 SeitenFarolan v. CTAKenneth Jamaica FloraNoch keine Bewertungen

- GT13E2 Infographic - Final - PDFDokument1 SeiteGT13E2 Infographic - Final - PDFGregory StockNoch keine Bewertungen

- H GP SpecificationsDokument5 SeitenH GP Specificationszss84Noch keine Bewertungen

- Ex2100 PDFDokument118 SeitenEx2100 PDFMohammed FaresNoch keine Bewertungen

- GE Energy - MS7001EA Gas TurbineDokument2 SeitenGE Energy - MS7001EA Gas TurbineJiho AhnNoch keine Bewertungen

- Operating Instructions (December, 2006 Rev 4) PDFDokument292 SeitenOperating Instructions (December, 2006 Rev 4) PDFMiguel CarpioNoch keine Bewertungen

- EngDokument44 SeitenEngzomglolzscribdNoch keine Bewertungen

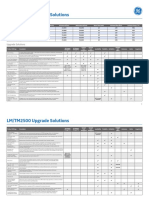

- LM TM2500 Upgrade Solutions PDFDokument2 SeitenLM TM2500 Upgrade Solutions PDFLibyanManNoch keine Bewertungen

- Til 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFDokument6 SeitenTil 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum Boilers PDFManuel L LombarderoNoch keine Bewertungen

- 2015 Certification Handbook - Final - Rev 5 2015-1-13Dokument28 Seiten2015 Certification Handbook - Final - Rev 5 2015-1-13hasan099Noch keine Bewertungen

- Training - Flowserve Apm Pump CW Pump Part 2Dokument12 SeitenTraining - Flowserve Apm Pump CW Pump Part 2hasan099Noch keine Bewertungen

- Til 2086Dokument4 SeitenTil 2086makarov.olegNoch keine Bewertungen

- Technical Information Letter: GE PowerDokument6 SeitenTechnical Information Letter: GE PowerHashim BukhariNoch keine Bewertungen

- Til 1213 R1Dokument6 SeitenTil 1213 R1Hernan GirautNoch keine Bewertungen

- 2 1 01 Auxiliary Gear BoxDokument30 Seiten2 1 01 Auxiliary Gear BoxHeryanto SyamNoch keine Bewertungen

- SBLM2500 IND 174rev1Dokument7 SeitenSBLM2500 IND 174rev1Daniil SerovNoch keine Bewertungen

- Technical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)Dokument28 SeitenTechnical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)exergicNoch keine Bewertungen

- T 2119Dokument3 SeitenT 2119bruno devinck100% (1)

- TIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinDokument6 SeitenTIL 1237-1: Potential Flexible Hose Installation Errors: Technical BulletinAkramNoch keine Bewertungen

- SBLM2500 Ind 217Dokument5 SeitenSBLM2500 Ind 217Daniil SerovNoch keine Bewertungen

- Nic 13.05Dokument14 SeitenNic 13.05BouazzaNoch keine Bewertungen

- T 2055 R 1Dokument6 SeitenT 2055 R 1srinivasNoch keine Bewertungen

- Training - Flowserve Apm Pump CW Pump Part3Dokument4 SeitenTraining - Flowserve Apm Pump CW Pump Part3hasan099Noch keine Bewertungen

- Til 1566-R2 Hazardous Gas Detection System RecommendationsDokument4 SeitenTil 1566-R2 Hazardous Gas Detection System RecommendationsMichael Sanchez100% (2)

- Technical Information Letter: Thermal Engineering Product Service TIL 1881Dokument11 SeitenTechnical Information Letter: Thermal Engineering Product Service TIL 1881Ignacio Moratinos Castañeda100% (1)

- Brush Dax Generadores Dax - 2 - PoleDokument4 SeitenBrush Dax Generadores Dax - 2 - PoleHernan GirautNoch keine Bewertungen

- Til 1576-R1Dokument4 SeitenTil 1576-R1Bouazza100% (1)

- Training - Flowserve Apm Pump CW Pump Part4Dokument11 SeitenTraining - Flowserve Apm Pump CW Pump Part4hasan099Noch keine Bewertungen

- Optional: Service BulletinDokument5 SeitenOptional: Service BulletinDaniil SerovNoch keine Bewertungen

- Training - Flowserve Apm Pump CW Pump Part3-2Dokument4 SeitenTraining - Flowserve Apm Pump CW Pump Part3-2hasan099Noch keine Bewertungen

- Technical Specifications, Fuel Nozzle GR 127 PDFDokument8 SeitenTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarNoch keine Bewertungen

- DLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemDokument8 SeitenDLN-1 Heavy Duty Gas Turbines: Improved Secondary Flame Detector SystemManuel L LombarderoNoch keine Bewertungen

- Vibration PenDokument4 SeitenVibration PenIohan Marius100% (1)

- Vibration PenDokument4 SeitenVibration PenIohan Marius100% (1)

- 7FA Atomizing Air SystemDokument12 Seiten7FA Atomizing Air SystemHeryanto Syam100% (1)

- Psib 20130524aDokument1 SeitePsib 20130524aLéandre Ettekri NdriNoch keine Bewertungen

- IEC Motor HyundaiDokument19 SeitenIEC Motor HyundaiDendi DenisNoch keine Bewertungen

- SFC Operation 029.950819Dokument8 SeitenSFC Operation 029.950819Osama Kamel ElghitanyNoch keine Bewertungen

- Computers: Acer - N20H2 : SF114-33Dokument2 SeitenComputers: Acer - N20H2 : SF114-33Alhams TorrentNoch keine Bewertungen

- GT Bearings Six SigmaDokument12 SeitenGT Bearings Six SigmaJJNoch keine Bewertungen

- NIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDokument29 SeitenNIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDjaber ElhaicharNoch keine Bewertungen

- PDF 83885 Mark IV Operator Manual DLDokument46 SeitenPDF 83885 Mark IV Operator Manual DLkareema92Noch keine Bewertungen

- Generator VOL 8ADokument18 SeitenGenerator VOL 8AEmadAlhosien AlhosienNoch keine Bewertungen

- TIL 1352 R3 - MS6001B Stator 17 and Exit Guide Vane DistressDokument6 SeitenTIL 1352 R3 - MS6001B Stator 17 and Exit Guide Vane DistressBouazzaNoch keine Bewertungen

- TIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeDokument15 SeitenTIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNoch keine Bewertungen

- February March January: Our Services Are Easier & Faster On Our WebsiteDokument2 SeitenFebruary March January: Our Services Are Easier & Faster On Our Websitehasan099Noch keine Bewertungen

- Pages From Gek89628Dokument1 SeitePages From Gek89628hasan099Noch keine Bewertungen

- Tender Notice: Monday 09:00 AM To 03:00 PM Friday 09:00 AM To 02:00 PMDokument1 SeiteTender Notice: Monday 09:00 AM To 03:00 PM Friday 09:00 AM To 02:00 PMhasan099Noch keine Bewertungen

- Inancial Ertification Tatement: Section I: General InformationDokument4 SeitenInancial Ertification Tatement: Section I: General Informationhasan099Noch keine Bewertungen

- PP ControlDokument32 SeitenPP Controlhasan099Noch keine Bewertungen

- MTC PaperDokument25 SeitenMTC Paperhasan099Noch keine Bewertungen

- Hazard SubtanceDokument6 SeitenHazard Subtancehasan099Noch keine Bewertungen

- Iso 7919-2Dokument9 SeitenIso 7919-2liepan_baraNoch keine Bewertungen

- SnapLogic - Market Leader 3 Industry Reports Jan 2019Dokument5 SeitenSnapLogic - Market Leader 3 Industry Reports Jan 2019dharmsmart19Noch keine Bewertungen

- Education in Colonial EraDokument17 SeitenEducation in Colonial EraAnanda PadhanNoch keine Bewertungen

- Iecq 03-2-2013Dokument14 SeitenIecq 03-2-2013RamzanNoch keine Bewertungen

- Case 20Dokument6 SeitenCase 20Chelle Rico Fernandez BONoch keine Bewertungen

- Please Return This Form To:: Brill - Nl/rightsDokument1 SeitePlease Return This Form To:: Brill - Nl/rightslimetta09Noch keine Bewertungen

- Persons Reporting Q&ADokument3 SeitenPersons Reporting Q&ARachel LeachonNoch keine Bewertungen

- September PDFDokument402 SeitenSeptember PDFNihal JamadarNoch keine Bewertungen

- 04 Dam Safety FofDokument67 Seiten04 Dam Safety FofBoldie LutwigNoch keine Bewertungen

- Accounting For Insurance Contracts Deferred Tax and Earnings Per ShareDokument2 SeitenAccounting For Insurance Contracts Deferred Tax and Earnings Per ShareJanine CamachoNoch keine Bewertungen

- In Exceedance To AWWA Standards Before It IsDokument2 SeitenIn Exceedance To AWWA Standards Before It IsNBC 10 WJARNoch keine Bewertungen

- PACQUIAOebookDokument150 SeitenPACQUIAOebookpugnar100% (1)

- God Sees The Truth But Waits Leo Tolstoy AnalysisDokument3 SeitenGod Sees The Truth But Waits Leo Tolstoy AnalysisKeithNoch keine Bewertungen

- FINAL-Telephone Directory-2019Dokument107 SeitenFINAL-Telephone Directory-2019Rizwan TahirNoch keine Bewertungen

- ## JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDokument2 Seiten## JSA - 008 - Hydraulic Rig and Mobile Crane MarchingAbhijit JanaNoch keine Bewertungen

- Seminar On Business Valuation (Property Related) IsmDokument166 SeitenSeminar On Business Valuation (Property Related) IsmrokiahhassanNoch keine Bewertungen

- Ebecryl-4175 en A4Dokument1 SeiteEbecryl-4175 en A4I Love MusicNoch keine Bewertungen

- Icici Declaration - Itm (Online Training)Dokument2 SeitenIcici Declaration - Itm (Online Training)Vivek HubanurNoch keine Bewertungen

- Industries-Heritage Hotel Manila Supervisors Chapter (Nuwhrain-HHMSC) G.R. No. 178296, January 12, 2011Dokument2 SeitenIndustries-Heritage Hotel Manila Supervisors Chapter (Nuwhrain-HHMSC) G.R. No. 178296, January 12, 2011Pilyang SweetNoch keine Bewertungen

- In Modern BondageDokument221 SeitenIn Modern BondageetishomeNoch keine Bewertungen

- PVL2602 Assignment 1Dokument3 SeitenPVL2602 Assignment 1milandaNoch keine Bewertungen

- Deed of Absolute Sale of Real Property in A More Elaborate Form PDFDokument2 SeitenDeed of Absolute Sale of Real Property in A More Elaborate Form PDFAnonymous FExJPnC100% (2)

- Robhy Dupree ArmstrongDokument2 SeitenRobhy Dupree ArmstrongRobhy ArmstrongNoch keine Bewertungen

- Supreme Court: Republic of The PhilippinesDokument13 SeitenSupreme Court: Republic of The PhilippinesellaNoch keine Bewertungen

- Farooq e Azam Ka Khuaf e KhudaDokument42 SeitenFarooq e Azam Ka Khuaf e KhudaAneeka SyedNoch keine Bewertungen

- Sulfuric Acid CatalystDokument4 SeitenSulfuric Acid CatalystRajeshNoch keine Bewertungen

- Revocation of Patent in IndiaDokument8 SeitenRevocation of Patent in IndiaAartika SainiNoch keine Bewertungen

- Cpi Sells Computer Peripherals at December 31 2011 Cpi S InventoryDokument1 SeiteCpi Sells Computer Peripherals at December 31 2011 Cpi S Inventorytrilocksp SinghNoch keine Bewertungen