Beruflich Dokumente

Kultur Dokumente

D3 G+flash+code

Hochgeladen von

X'mix ĐreamerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D3 G+flash+code

Hochgeladen von

X'mix ĐreamerCopyright:

Verfügbare Formate

D3G XL & D3G LGP Track-Type Tractors JMH00001-UP (MACHINE)

POWERED BY 3046 Engine(SEBP3825 - 51) - Documentation

Sunday, April 03, 2016

2:56 PM

Welcome: d430btm1

Product: TRACK-TYPE TRACTOR

Model: D3G TRACK-TYPE TRACTOR JMH

Configuration: D3G XL & D3G LGP Track-Type Tractors JMH00001-UP (MACHINE) POWERED BY 3046 Engine

Troubleshooting

D3G, D4G and D5G Track-Type Tractors Electrohydraulic

Media Number -RENR7313-02 Publication Date -01/03/2015 Date Updated -18/03/2015

i01951524

Using the Diagnostic Indicator to Determine Diagnostic Codes

SMCS - 7569

Use the following tools in order to determine the diagnostic codes: Diagnostic Indicator and the ET.

Determine the diagnostic codes. Perform the procedure that corresponds to the diagnostic code.

The Quick Reference Table for the Operation of the

Diagnostic Indicator

Operation Contact 1 (1) Contact Contact

3 (1) 5 (1)

The code is placed on hold. Open Open Open

Scroll through the active diagnostic codes. Ground (2) Open Open

Clear (3) the diagnostic codes Open Ground Open

Table 1

(1)

The contact is located in the connector for the harness code. Remove the harness code plug.

(2)

Remove the ground in order to stop scrolling. The diagnostic code will be placed on hold.

(3)

An active diagnostic code can not be cleared. The diagnostic code must be on hold in order to clear the

diagnostic code.

Use the following procedure when a problem is detected:

When a diagnostic code is detected, the diagnostic indicator is illuminated. Determine the diagnostic

code. Use table 2 in order to find the correct component failure. The code is flashed on the diagnostic

indicator.

Troubleshoot the diagnostic codes with the following procedures:

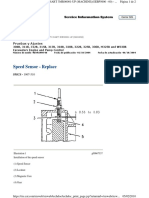

Illustration 1 g0084216

6

Harness code connector for the D3G through D5G machines

1. To enter service mode, disconnect the machine identification plug from the harness code

connector. When the control module is in the service mode the control module's diagnostics are

available in order to assist with troubleshooting.

2. A single diagnostic code is shown. The diagnostic code is on hold. Information is shown on the

diagnostic indicator by flashing the indicator ON and OFF. The flashes represent a three digit

number. A series of flashes represent the first digit. A one second pause follows the first digit.

Another series of flashes represents the second digit. A one second pause follows the second digit.

Another series of flashes represents the third digit. Count the number of flashes. The number of

flashes determine each digit. A three second pause separates each three digit number. Use table 2

in order to find the correct CID.

3. When you scroll through the diagnostic codes, the codes for all of the active diagnostic codes are

shown one at a time. Ground connector contact 1 in order to scroll through the active diagnostic

codes. Remove the ground from connector contact 1 in order to stop scrolling. The diagnostic

code that is shown is now on hold. A code of 222 indicates that diagnostic codes are NOT active or

logged.

4. Perform the procedure that corresponds to the diagnostic codes.

5. Clearing a diagnostic code removes the diagnostic code from the control module's memory. When

a problem is corrected, it is necessary to remove the diagnostic code from the memory of the

control module. The diagnostic code must be on hold in order to clear an inactive diagnostic code.

The control module does not allow active diagnostic codes to be cleared.

6. Place the diagnostic code on hold.

7. The diagnostic code is on hold. Ground connector contact 3 in order to remove the logged

diagnostic code from the control module's memory. The diagnostic indicator is extinguished after

the inactive diagnostic code has been cleared. The diagnostic indicator is extinguished until you

scroll through the diagnostic codes. The control module does not allow active diagnostic codes to

be cleared.

8. Repeat the procedure for any remaining diagnostic codes. Return to normal mode when you are

finished by replacing the machine identification plug. A diagnostic code of 222 indicates that

diagnostic codes are NOT active or logged.

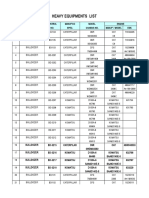

Conversion Table for the

Diagnostic Codes

Codes Component Description

Identifier

166 CID 0017 Fuel Shutoff Valve

124 CID 0041 Sensor Power Supply (8 DCV)

168 CID 0110 Engine Coolant Temp Sensor

222 None Not Active or Logged Diagnostic Codes

244 CID 0070 Rocker Switch (Parking Brake)

245 CID 0133 Solenoid Valve (Transmission Pilot

Pressure)

246 CID 0153 Speed Sensor (Right Track)

251 CID 0154 Speed Sensor (Left Track)

411 CID 0168 Electrical System

141 CID 0190 Engine Speed Sensor

144 CID 0444 Magnetic Switch (Start Relay)

252 CID 0468 Position Sensor (Service Brake Pedal)

178 CID 0617 Relay (Intake Air Heater)

426 CID 0650 Harness Code

253 CID 0681 Solenoid Valve (Parking Brake)

434 CID 0817 ECM Internal Backup Battery

422 CID 1482 Sensor Power Supply (10 DCV)

254 CID 1693 Position Sensor (Deceleration Pedal)

255 CID 1699 Position Sensor

(Forward/Neutral/Reverse)

256 CID 1700 Position Sensor (Steering)

261 CID 1701 Switch (Acceleration)

262 CID 1702 Switch (Deceleration)

263 CID 1703 Proportional Solenoid (Forward Left Drive

Pump)

264 CID 1704 Proportional Solenoid (Reverse Left Drive

Pump)

265 CID 1705 Proportional Solenoid (Forward Right Drive

Pump)

271 CID 1706 Proportional Solenoid (Reverse Right Drive

Pump)

272 CID 1707 Proportional Solenoid (Left Drive Motor)

273 CID 1708 Proportional Solenoid (Right Drive Motor)

435 CID 1960 Ignition Key Reader

Table 2

Copyright 1993 - 2016 Caterpillar Inc. Sun Apr 3 14:56:02 CDT 2016

All Rights Reserved.

d430btm1

Private Network For SIS Licensees.

Inserted from

<https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheaderinfo

frameset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp>

Das könnte Ihnen auch gefallen

- Cat00000 PSRPT 2020-05-18 15.01.25 PDFDokument16 SeitenCat00000 PSRPT 2020-05-18 15.01.25 PDFArturo A Maldonado OrtizNoch keine Bewertungen

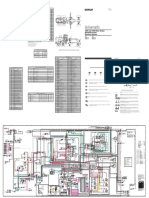

- D3G, D4G, AND D5G HYSTAT TRACK-TYPE TRACTORS ELECTRICAL SYSTEM - CAT Machines Electrical Schematic 1Dokument2 SeitenD3G, D4G, AND D5G HYSTAT TRACK-TYPE TRACTORS ELECTRICAL SYSTEM - CAT Machines Electrical Schematic 1Ariel Mercocha100% (3)

- Speed Sensor - Replace: Pruebas y AjustesDokument2 SeitenSpeed Sensor - Replace: Pruebas y AjustesyeisonNoch keine Bewertungen

- Bobcat Engine Analyzer User ManualDokument29 SeitenBobcat Engine Analyzer User ManualHarith Emaad100% (2)

- AjusteDokument3 SeitenAjusteAmy MurrayNoch keine Bewertungen

- 336DL - Torque Culata 1Dokument4 Seiten336DL - Torque Culata 1Vargas Ortiz Jean DiomenesNoch keine Bewertungen

- Cat D5K WWW DiagramaDokument75 SeitenCat D5K WWW DiagramaCarlos Pabon SalomNoch keine Bewertungen

- Instruction Manual Instruction Manual: Operating & Maintenance Operating & MaintenanceDokument176 SeitenInstruction Manual Instruction Manual: Operating & Maintenance Operating & MaintenancePatrick CunananNoch keine Bewertungen

- D6M Carta de PresionesDokument26 SeitenD6M Carta de Presionescandido vargas gutierrezNoch keine Bewertungen

- Fuse Diagram Cat 320 d2Dokument3 SeitenFuse Diagram Cat 320 d2Irsan NasriNoch keine Bewertungen

- System Operation Steering 950FDokument20 SeitenSystem Operation Steering 950FEsteban MunaresNoch keine Bewertungen

- Servicing The Outlet Check Plugs On The Fuel Injection Pump On C6.6 and C4.4 Engines (1251, 1290)Dokument5 SeitenServicing The Outlet Check Plugs On The Fuel Injection Pump On C6.6 and C4.4 Engines (1251, 1290)teobaldo criatian silva casca100% (1)

- 525 Skidder Power TrainDokument14 Seiten525 Skidder Power TrainAbelardo Pina100% (2)

- Toyota Engine W04D (130HT)Dokument216 SeitenToyota Engine W04D (130HT)Suryana Iskandar100% (1)

- Kobelco SK330 Excavator Mitsubishi Engine Workshop ManualDokument2 SeitenKobelco SK330 Excavator Mitsubishi Engine Workshop ManualErdenekhuu Unurjargal0% (2)

- Low Idle RPM AdjustDokument4 SeitenLow Idle RPM AdjustSteven ManuputtyNoch keine Bewertungen

- r210-7 Eppr ValveDokument3 Seitenr210-7 Eppr Valvearfa ujiantoNoch keine Bewertungen

- Throttle Komatsu-PC200-6-Shop-ManualDokument1 SeiteThrottle Komatsu-PC200-6-Shop-ManualMaldwin MenorcaNoch keine Bewertungen

- Off LeakDokument26 SeitenOff LeakPatriciaH20Noch keine Bewertungen

- Cat 120 H 9FN PDFDokument2.885 SeitenCat 120 H 9FN PDFAnonymous ByaV1fNoch keine Bewertungen

- TROUBLESHOOTING / Troubleshooting A: Fault Code List MCDokument47 SeitenTROUBLESHOOTING / Troubleshooting A: Fault Code List MCPoyraz Poyraz100% (1)

- 120H and 135H Motor GraderDokument2 Seiten120H and 135H Motor GraderMarvin Melendez Vanegas100% (4)

- D31!37!39ShopM T&a BeforeProof 1Dokument74 SeitenD31!37!39ShopM T&a BeforeProof 1data9999Noch keine Bewertungen

- Fault Code 268 Injector Metering Rail 1 Pressure - Data Erratic, Intermittent, or IncorrectDokument10 SeitenFault Code 268 Injector Metering Rail 1 Pressure - Data Erratic, Intermittent, or IncorrectAhmedmahNoch keine Bewertungen

- 002-004 Cylinder Head Cummins 6BTA5.9 G2Dokument10 Seiten002-004 Cylinder Head Cummins 6BTA5.9 G2AleksaNoch keine Bewertungen

- D3 K XL Cat - Sis Electrico PDFDokument6 SeitenD3 K XL Cat - Sis Electrico PDFFranco Korn100% (7)

- Caterpillar 740 Electric SchematicDokument7 SeitenCaterpillar 740 Electric SchematicAdhont100% (1)

- Operacion de Sistemas 928F Contraeje PDFDokument43 SeitenOperacion de Sistemas 928F Contraeje PDFBETOVN BETOVENNoch keine Bewertungen

- ATA/J1939 Diagnostic Code Quick Reference: Refer To Troubleshooting Manual For Recommended Service ProceduresDokument9 SeitenATA/J1939 Diagnostic Code Quick Reference: Refer To Troubleshooting Manual For Recommended Service ProceduresM. ShaatNoch keine Bewertungen

- Cat Electronic Technician 2018C v1.0 Product Status ReportDokument6 SeitenCat Electronic Technician 2018C v1.0 Product Status ReportRodolft Rodolft100% (1)

- Event CodeDokument9 SeitenEvent CodeDe Javu100% (1)

- Deep Sea 4610 ManualDokument86 SeitenDeep Sea 4610 ManualAd-On MEDIANoch keine Bewertungen

- 3066testing & AdjustingDokument129 Seiten3066testing & AdjustingjamcaNoch keine Bewertungen

- 320D2 Troubleshooting2Dokument5 Seiten320D2 Troubleshooting2evan100% (1)

- Check and Adjust Valve Lash 320D2Dokument4 SeitenCheck and Adjust Valve Lash 320D2MrizkynabawiNoch keine Bewertungen

- Cat E200-2Dokument2 SeitenCat E200-2julianmata100% (2)

- Mg330-Control ValveDokument6 SeitenMg330-Control ValveSama TradingNoch keine Bewertungen

- CAT 320C ANB 3064 and 3066 Systems Operation Fuel SystemDokument26 SeitenCAT 320C ANB 3064 and 3066 Systems Operation Fuel SystemMartina Famb100% (2)

- Diagnostic Code List: TroubleshootingDokument17 SeitenDiagnostic Code List: TroubleshootingNova kurniawan 34Noch keine Bewertungen

- Electrical Component LocationDokument5 SeitenElectrical Component LocationNova kurniawan 34Noch keine Bewertungen

- 320 Shop Manual PDFDokument880 Seiten320 Shop Manual PDFThemune Azaa100% (4)

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDokument20 SeitenTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemEdwin MelendezNoch keine Bewertungen

- DZR 02 - 650J - English PDFDokument220 SeitenDZR 02 - 650J - English PDFdavidNoch keine Bewertungen

- 939c PDFDokument24 Seiten939c PDFLuis Fernando Vasquez RamosNoch keine Bewertungen

- 920E (Tier 2) - Cummins - 东康Dokument2 Seiten920E (Tier 2) - Cummins - 东康Michael Wang Xinbin100% (1)

- 2010-09-26 202624 NEHS0610-09 3100 Fuel Setting ToolingDokument32 Seiten2010-09-26 202624 NEHS0610-09 3100 Fuel Setting ToolingRoberto Manriques Estrada100% (3)

- Komatsu PC200-7 Error Code On The Monitor, CMP Technology Co., LimitedDokument5 SeitenKomatsu PC200-7 Error Code On The Monitor, CMP Technology Co., Limitedkiagengbrantas heavyequipmentNoch keine Bewertungen

- PC220LC-8 Error Code E989M00Dokument2 SeitenPC220LC-8 Error Code E989M00Julio Perez PerezNoch keine Bewertungen

- 950H Localizacion de Sensores Del MotorDokument5 Seiten950H Localizacion de Sensores Del MotorEduardo Vargas100% (1)

- PC78US-8 SEN04555-01 TroubleshootingDokument332 SeitenPC78US-8 SEN04555-01 TroubleshootingdatphuongNoch keine Bewertungen

- CAT C13, C15, and C18 Tier 4 Final Engine Fault CodesDokument14 SeitenCAT C13, C15, and C18 Tier 4 Final Engine Fault CodesDamatNoch keine Bewertungen

- Cat 312 Service ManualDokument1 SeiteCat 312 Service ManualДмитрий0% (2)

- Governor Actuator - Calibrate: Página 1 de 18 320C & 320C L Excavators SBN00001-UP (MACHINE) POWERED BY 3066 Engine..Dokument18 SeitenGovernor Actuator - Calibrate: Página 1 de 18 320C & 320C L Excavators SBN00001-UP (MACHINE) POWERED BY 3066 Engine..Diego Orlando Santos BuitragoNoch keine Bewertungen

- Using The Diagnostic Indicator To Determine Diagnostic CodesDokument4 SeitenUsing The Diagnostic Indicator To Determine Diagnostic CodesRocko CallejasNoch keine Bewertungen

- Codigos de Error 320CDokument4 SeitenCodigos de Error 320CCDECOSSGNoch keine Bewertungen

- Instrument Panel PDFDokument54 SeitenInstrument Panel PDFred eagle winsNoch keine Bewertungen

- Cid Mid FmiDokument11 SeitenCid Mid FmiLuis Enrique Castro Manzaneda100% (1)

- Codigo de Fallas FBC25N2Dokument101 SeitenCodigo de Fallas FBC25N2Sebastian RamirezNoch keine Bewertungen

- DSGDokument8 SeitenDSGSergio SambuelliNoch keine Bewertungen

- Dokumen - Tips - Codigos Fallas NavistarDokument14 SeitenDokumen - Tips - Codigos Fallas NavistarVale Olivo RuizNoch keine Bewertungen

- p7 Subminiature Pushbuttons Catalog PageDokument3 Seitenp7 Subminiature Pushbuttons Catalog PageX'mix ĐreamerNoch keine Bewertungen

- Spareparts, Service and Technical Supplay ForDokument1 SeiteSpareparts, Service and Technical Supplay ForX'mix ĐreamerNoch keine Bewertungen

- BdjsjjaDokument10 SeitenBdjsjjaX'mix ĐreamerNoch keine Bewertungen

- MineStar Health Connectivity MatrixDokument11 SeitenMineStar Health Connectivity MatrixX'mix ĐreamerNoch keine Bewertungen

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDokument4 SeitenSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationX'mix ĐreamerNoch keine Bewertungen

- Battery SpecsDokument2 SeitenBattery SpecsAbraham SaucedoNoch keine Bewertungen

- Adjust Valve Lash PDFDokument7 SeitenAdjust Valve Lash PDFX'mix ĐreamerNoch keine Bewertungen

- Spareparts, Service and Technical Supplay ForDokument1 SeiteSpareparts, Service and Technical Supplay ForX'mix ĐreamerNoch keine Bewertungen

- Product Knowledge 2 Engine 4JB1: Isuzu Training Center - 1Dokument14 SeitenProduct Knowledge 2 Engine 4JB1: Isuzu Training Center - 1X'mix ĐreamerNoch keine Bewertungen

- Hydraulic Breaker Specification PDFDokument1 SeiteHydraulic Breaker Specification PDFX'mix ĐreamerNoch keine Bewertungen

- Product Knowledge 2 Engine 4JB1: Isuzu Training Center - 1Dokument14 SeitenProduct Knowledge 2 Engine 4JB1: Isuzu Training Center - 1X'mix ĐreamerNoch keine Bewertungen

- IGS NT 2.4 Troubleshooting Guide ADokument39 SeitenIGS NT 2.4 Troubleshooting Guide ARicardo Nunes Pereira Junior100% (1)

- 01 Engine4jb1Dokument5 Seiten01 Engine4jb1X'mix ĐreamerNoch keine Bewertungen

- Ds Da T en Ma 20171107 HeDokument36 SeitenDs Da T en Ma 20171107 HeX'mix ĐreamerNoch keine Bewertungen

- DS/DA-T Series: Instruction ManualDokument1 SeiteDS/DA-T Series: Instruction ManualX'mix ĐreamerNoch keine Bewertungen

- Sensor Cat BrochureDokument16 SeitenSensor Cat Brochuremarioz25Noch keine Bewertungen

- DS/DA-T Series: Instruction ManualDokument1 SeiteDS/DA-T Series: Instruction ManualX'mix ĐreamerNoch keine Bewertungen

- DS/DA-T Series: Instruction ManualDokument1 SeiteDS/DA-T Series: Instruction ManualX'mix ĐreamerNoch keine Bewertungen

- Ds Da T en Ma 20171107 HeDokument36 SeitenDs Da T en Ma 20171107 HeX'mix ĐreamerNoch keine Bewertungen

- DS/DA-T Series: Instruction ManualDokument1 SeiteDS/DA-T Series: Instruction ManualX'mix ĐreamerNoch keine Bewertungen

- IGS NT 2.4 Troubleshooting Guide ADokument39 SeitenIGS NT 2.4 Troubleshooting Guide ARicardo Nunes Pereira Junior100% (1)

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Dokument12 SeitenHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNoch keine Bewertungen

- GetApplicationAttachment PDFDokument216 SeitenGetApplicationAttachment PDFX'mix ĐreamerNoch keine Bewertungen

- An001 Spi enDokument11 SeitenAn001 Spi enX'mix ĐreamerNoch keine Bewertungen

- EC25C32 32kbits SPI Serial EEPROM: General DescriptionDokument16 SeitenEC25C32 32kbits SPI Serial EEPROM: General DescriptionX'mix ĐreamerNoch keine Bewertungen

- RM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusDokument36 SeitenRM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusX'mix ĐreamerNoch keine Bewertungen

- Heui CatDokument27 SeitenHeui CatVago Si BeerNoch keine Bewertungen

- S29CD-J & S29CL-J Flash FamilyDokument76 SeitenS29CD-J & S29CL-J Flash FamilyX'mix ĐreamerNoch keine Bewertungen

- Percobaan Penggunaan Multimeter Dan OsiloskopDokument26 SeitenPercobaan Penggunaan Multimeter Dan OsiloskopX'mix ĐreamerNoch keine Bewertungen

- Caterpillar EMCPDokument40 SeitenCaterpillar EMCPrealwild93% (59)

- Stokerchapter25lipidmetabolism 160320032037Dokument29 SeitenStokerchapter25lipidmetabolism 160320032037Dawlat SalamaNoch keine Bewertungen

- HBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris PavlidisDokument4 SeitenHBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris Pavlidissagacious.ali2219Noch keine Bewertungen

- What's The Use of Neuroticism?: G. Claridge, C. DavisDokument18 SeitenWhat's The Use of Neuroticism?: G. Claridge, C. DavisNimic NimicNoch keine Bewertungen

- DiodeDokument3 SeitenDiodeManishNoch keine Bewertungen

- Notice: Environmental Statements Notice of Intent: Eldorado National Forest, CADokument2 SeitenNotice: Environmental Statements Notice of Intent: Eldorado National Forest, CAJustia.comNoch keine Bewertungen

- Your Heart: Build Arms Like ThisDokument157 SeitenYour Heart: Build Arms Like ThisNightNoch keine Bewertungen

- Coca ColaDokument50 SeitenCoca Colamariyha PalangganaNoch keine Bewertungen

- Phineas Gage: From The Passage of An Iron Rod Through The Head"Dokument1 SeitePhineas Gage: From The Passage of An Iron Rod Through The Head"GlupiaSprawaNoch keine Bewertungen

- HardikDokument21 SeitenHardikGohil HardikNoch keine Bewertungen

- The Ecological Effects of Eucalyptus PDFDokument97 SeitenThe Ecological Effects of Eucalyptus PDFgejuinaNoch keine Bewertungen

- Refrigeration Engineer Quick ReferenceDokument2 SeitenRefrigeration Engineer Quick ReferenceventilationNoch keine Bewertungen

- 520L0586 MMF044Dokument48 Seiten520L0586 MMF044vendas servicosNoch keine Bewertungen

- EET - Formulas - Christmas TermDokument3 SeitenEET - Formulas - Christmas TermJMDNoch keine Bewertungen

- Scientific Exploration and Expeditions PDFDokument406 SeitenScientific Exploration and Expeditions PDFana_petrescu100% (2)

- Collage Lab PDFDokument145 SeitenCollage Lab PDFmaa siddhi92% (12)

- AC350 Specs UsDokument18 SeitenAC350 Specs Uskloic1980100% (1)

- Complicaciones Postoperatorias en Esofagectomía Por Cáncer. Evaluación de 215 Casos Según Definiciones Del Grupo de Consenso InternacionalDokument7 SeitenComplicaciones Postoperatorias en Esofagectomía Por Cáncer. Evaluación de 215 Casos Según Definiciones Del Grupo de Consenso InternacionalPaulo RoseroNoch keine Bewertungen

- Diablo Watch Newsletter, FALL 2009 Save Mount DiabloDokument16 SeitenDiablo Watch Newsletter, FALL 2009 Save Mount DiabloIoannqisHatzopoulosNoch keine Bewertungen

- ScilabDokument4 SeitenScilabAngeloLorenzoSalvadorTamayoNoch keine Bewertungen

- Paper 2 With Solution MathematicsDokument17 SeitenPaper 2 With Solution MathematicsFaiz AhmadNoch keine Bewertungen

- 100 Yer PM PPM 0605Dokument40 Seiten100 Yer PM PPM 0605biplabpal2009Noch keine Bewertungen

- DHT, VGOHT - Catloading Diagram - Oct2005Dokument3 SeitenDHT, VGOHT - Catloading Diagram - Oct2005Bikas SahaNoch keine Bewertungen

- Aplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanDokument18 SeitenAplikasi Sistem Penuaian Air Hujan (Spah) Di Kawasan PerumahanFarid Che DeramanNoch keine Bewertungen

- 19 Work Energy TNDokument2 Seiten19 Work Energy TNAna DorueloNoch keine Bewertungen

- Ketu in 12th HousesDokument10 SeitenKetu in 12th HousesSanket MishraNoch keine Bewertungen

- Tamil NaduDokument64 SeitenTamil Nadushanpaga priyaNoch keine Bewertungen

- Pi 0614 Hiblack f890b en WebDokument2 SeitenPi 0614 Hiblack f890b en Web王偉仲Noch keine Bewertungen

- Microscope MaintenanceDokument2 SeitenMicroscope MaintenanceCharlyn KeithNoch keine Bewertungen

- 1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016Dokument3 Seiten1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016api-292307509Noch keine Bewertungen

- Genie Z45/22Dokument58 SeitenGenie Z45/22jonny david martinez perezNoch keine Bewertungen