Beruflich Dokumente

Kultur Dokumente

CL 74 C Eng PDF

Hochgeladen von

ionut2007Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CL 74 C Eng PDF

Hochgeladen von

ionut2007Copyright:

Verfügbare Formate

Operation Manual

CL 74C Winch Motor

Code no: 99-97-7264

Edition: 07/2013 GB

CL 74C Winch Motor

4 Operation manual

Program Version

The product described in this manual holds software. This manual corresponds to:

• Software version 3.3

• It was released in 2013.

Product and Documentation Changes

Big Dutchman reserve the right to change this document and the product herein described without further notice. In

case of doubt, please contact Big Dutchman.

Date of change appears from the back of this manual.

Note

• All rights reserved Big Dutchman. No part of this manual may be reproduced in any manner

whatsoever without the express written permission from Big Dutchman.

• Big Dutchman has made all reasonable efforts to ensure the accuracy of the information contained in

this manual. Should any mistakes or imprecise information occur in spite of this, Big Dutchman would

appreciate being notified thereof.

• Irrespective of the above, shall not accept any liability with regard to loss or damage caused or alleged

to be caused by reliance on any information contained herein.

• Copyright 2013 by Big Dutchman.

CL 74C Winch Motor

Operation manual 5

PRODUCT DESCRIPTION .................................................................................... 7

GENERAL INFORMATION ................................................................................... 8

1 Recommended Tools ....................................................................................... 8

2 Warnings and Symbols .................................................................................... 8

MOUNTING GUIDE ............................................................................................... 9

3 Mounting CL 74C .............................................................................................. 9

3.1 On the Inlet Funnel ........................................................................................................ 9

3.2 Mounting in Chimney .................................................................................................... 9

3.3 Mounting the Cover .................................................................................................... 10

3.4 Checking Manual Operation ....................................................................................... 10

3.5 Before Putting the System into Use the First Time.................................................. 10

INSTALLATION GUIDE ...................................................................................... 10

4 Electrical Connection ..................................................................................... 10

4.1 Cable Routing .............................................................................................................. 10

4.2 Setting the Jumper ...................................................................................................... 11

IMPORTANT!! .............................................................................................. 12

4.3 Connection and Circuit Diagram for CL 74C ............................................................ 13

4.3.1 Connection in CL 74CO ON/OFF 230 V ......................................................................................13

4.3.2 Circuit Diagram for CL 74CO ON/OFF 230V ...............................................................................13

4.3.3 Connection in CL 74CO ON/OFF 230 V with external capacitor .................................................14

4.3.4 Circuit Diagram for CL 74CO ON/OFF 230 V with external capacitor .........................................14

4.3.5 Connection in CL 74CO ON/OFF 400 V ......................................................................................15

4.3.6 Circuit Diagram for CL 74CO ON/OFF 400 V ..............................................................................15

4.3.7 Connection in CL 74CV stepless 230 V .......................................................................................16

4.3.8 Circuit Diagram for CL 74CV stepless 230 V ...............................................................................16

4.3.9 Connection in CL 74CV stepless with external capacitor ............................................................17

4.3.10 Circuit Diagram for CL 74CV stepless with external capacitor ....................................................17

4.3.11 Connection in CL 74CVA 0-10 V..................................................................................................18

4.3.12 Circuit Diagram for CL 74CVA 0-10 V..........................................................................................18

4.3.13 Connection in CL 74C to CL600 LPC ..........................................................................................22

4.3.14 Circuit Diagram for CL 74C to CL600 LPC ..................................................................................22

4.3.15 Connection in CL 74C to CL600 LPC Dynamic Multistep ............................................................23

4.3.16 Circuit Diagram for CL 74C to CL600 LPC Dynamic Multistep ....................................................23

MAINTENANCE GUIDE ...................................................................................... 24

5 Cleaning .......................................................................................................... 24

5.1 Annual Inspection ....................................................................................................... 24

5.2 Replacing the Motor .................................................................................................... 25

5.3 Recycling ..................................................................................................................... 25

6 Dismantling for Recycling / Disposal ........................................................... 26

6.1 LED Indication ............................................................................................................. 26

CL 74C Winch Motor

6 Operation manual

7 Troubleshooting / Remedy ............................................................................ 26

8 Technical Data ................................................................................................ 27

EC - DECLARATION OF INCORPORATION ..................................................... 28

CL 74C Winch Motor

Operation manual 7

PRODUCT DESCRIPTION

The CL 74CV is a winch motor for stepless regulation of swivel shutters in house ventilation systems.

The CL 74CO is a winch motor for ON/OFF regulation of swivel shutters in house ventilation systems.

The CL 74CVA is a winch motor for analog stepless regulation of swivel shutters in house ventilation

systems.

When it says CL 74C, it applies to all winch motor variants.

The CL 74C can be mounted directly on the swivel shutter shaft and operated manually. The CL 74C has

been developed specifically for installation in the very harsh house environment.

The CL 74C supports the range of our computers capable of controlling MultiStep® functions.

The CL 74C can open the swivel shutter manually if you press the manual release.

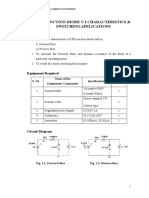

11

10

2 5 9 3 4 6 7

Figure 1: CL 74C

Position Article no. Winch motor CL 74C

1 527273 CL 74 cover

2 301074 Relay cable 0.75 mm 2x300 + 1x80

3 Retaining disc

4 Locking screw

5 310330 DIN terminal block

6 60-43-2975 Mot-g for winch motor CL-74C stepless 0-10V on/off cpl

7 60-43-2976 Motor mini 24V with PCB for CL 74C

8 Connection terminals on PCB

9 60-40-2051 Contactor 3-pole, 1s, 50Hz, 16AV (CL 74/AM2/CL 74C)

10 60-40-2952 Motor mini without PCB

11 Push rod manual release

Table 1: Partslist

CL 74C Winch Motor

8 Operation manual

GENERAL INFORMATION

1 Recommended Tools

The following or similar tools are required to troubleshoot and service the CL 74C. The tools are not

supplied by Big Dutchman.

Item Description

Multimeter

Screwdriver set

Side cutting pliers

Long-nose pliers

Knife

Water pump pliers

Cordless drill

Drill bits, various sizes

Adjustable spanner

Ladder

Table 2: The most necessary tools for servicing the CL 74C.

2 Warnings and Symbols

This manual uses the following symbols:

Warns of general dangers

CL 74C Winch Motor

Operation manual 9

MOUNTING GUIDE

Check that all parts are present and undamaged before mounting the CL 74C winch motor.

3 Mounting CL 74C

3.1 On the Inlet Funnel

If, on delivery, the CL 74C is not mounted on the inlet funnel or it has to be retrofitted, follow the

instructions below.

Turn the swivel shutter to closed position.

The factory has prepared the winch motor for mounting on a

closed swivel shutter.

Figure 2: Swivel shutter in closed position

(C) Click the CL 74C onto the swivel shutter shaft.

Mount the retaining disc (A) and locking screw(B) .

Check the position by activating the manual release (C),

and turn the swivel shutter counter- clockwise until it

opens against the mechanical end stop, Figure 4.

(B) (A)

Figure 3: CL 74C

Activate the manual release (C), and turn the swivel shutter

clockwise until it is in closed position, Figure 2.

Figure 4: Swivel shutter in open position

3.2 Mounting in Chimney

Push the inlet funnel vertically upwards into place and lock it

using the four screws and washers included. See Figure 5.

Figure 5: Mounting the inlet funnel in the chimney

CL 74C Winch Motor

10 Operation manual

3.3 Mounting the Cover

Mount the cover before putting the CL 74C winch motor into use. Check that the seal is undamaged and

placed correctly. Then mount the cover. Secure the cover by turning the six click screws, Figure 6 (A).

3.4 Checking Manual Operation

Check the release when the cover has been mounted. Press the push button, Figure 6 (B) and check by

turning the swivel shutter.

3.5 Before Putting the System into Use the First Time

(B)

(C)

To provide the winch motors with numbers, attach the included set

(A) of stickers to the flat part of the cabinet, Figure 6 (C).

Figure 6: CL 74C

INSTALLATION GUIDE

4 Electrical Connection

Installation, service and troubleshooting of electrical equipment must be carried out by

expert staff in compliance with applicable national regulations – in Europe, this would

be the EN 60204-1 or other current EU regulations.

A supply separator must be installed for each motor and power supply to facilitate

voltage-free work on the electrical equipment. Supply separators are not supplied by

Big Dutchman.

4.1 Cable Routing

All cables must be mounted in M25 glands according to Figure 7, protection class minimum IP65. Cables

are to be secured in the usual way outside the cabinet. Close holes which are not used with IP65 safety

plugs.

Correct Incorrect

Figure 7: Placement of cable

CL 74C Winch Motor

Operation manual 11

4.2 Setting the Jumper

REVERSE

Jumper setting on the PCB to give the CL 74C the desired function.

90º 0º

0º 90º

Figure 8: Jumper setting

O.C. = Open Collector (transistor output)

ON/OFF

Control voltage +24 V => Close.

Control voltage 0 V => Open.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 1.8 V (15 degree opening) => relay turns ON.

STEPLESS

Control voltage +24 V/0 V => Open. 0 V/24 V => Close.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 9.2 V (85 degree opening) => relay turns ON.

0-10 V ANALOG

The control voltage increases together with the opening degree. 2.3 V = 23% open.

The feedback signal increases together with the opening degree.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 0.5 V => relay turns ON.

ON/OFF REVERSE

Control voltage +24 V => Close.

The feedback signal increases together with the opening degree 0.25 V= closed=90°.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 1.8 V (15 degree opening) => relay turns ON.

ANALOG REVERSE

The control voltage increases reverse the opening degree. 2.3 V = 77% open.

The feedback signal increases reverse the opening degree.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 0.5 V => relay turns ON.

STEPLESS – 15°

Control voltage +24 V/0 V => Open. 0 V/24 V => Close.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 1.8 V (15 degree opening) => relay turns ON.

STEPLESS REVERSE

Control voltage +24 V/0 V => Open. 0 V/24 V => Close.

Feedback signal > 0.5 V => O.C. turns ON.

Feedback signal > 9.2 V (85 degree opening) => relay turns ON.

CL 74C Winch Motor

12 Operation manual

IMPORTANT!!

The power supply of the potentiometer is no longer 10V,

please see the instructions below.

When using temperature controlled emergency opening (78T,278T and

378T), move the following wires in the house computer and emergency

opening.

Move wire F from +10 V to +24 V power supply in emergency opening. (F6 or N7)

Move wire D from 0 V to 0 V power supply from emergency opening. (Q1)

When using emergency opening ON/OFF (78M, 278M and 378M), move the

following wires in the house computer.

Move wire F from +10 V to +24 V power supply from emergency opening. (Q2, Q3, Q4 or Q5)

Move wire D from 0 V to 0 V power supply from emergency opening (Q1) and connect it to

C17/B17 on the main module.

CL 74C Winch Motor

Operation manual 13

4.3 Connection and Circuit Diagram for CL 74C

4.3.1 Connection in CL 74CO ON/OFF 230 V

230 V N

PE H10 H11 H12 H13 H14 H15

L1

H1 24V

H2 ON/OFF

H3 0V

+ H6

230 V N H7

L1 H8

H9

ON/OFF

CALIBRATE

N H 10

11

H12

BN

BK

Figure 9: Connection ON/OFF 230 V

4.3.2 Circuit Diagram for CL 74CO ON/OFF 230V

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency opening or Q2-Q5

internal 24 V Q1

Figure 10: Circuit diagram ON/OFF 230 V

CL 74C Winch Motor

14 Operation manual

4.3.3 Connection in CL 74CO ON/OFF 230 V with external capacitor

230 V N

PE H10 H11 H12 H13 H14 H15

L1

H1 24V

H2 ON/OFF

H3 0V

+ H6

230 V N H7

H8

L1

H9

ON/OFF

H 10

Calibrate

N 11

H12

L

BN

BK

Figure 11: Connection ON/OFF 230 V external capacitor

4.3.4 Circuit Diagram for CL 74CO ON/OFF 230 V with external

capacitor

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency opening or Q2-Q5

internal 24 V Q1

Figure 12: Circuit diagram ON/OFF 230 V external capacitor

CL 74C Winch Motor

Operation manual 15

4.3.5 Connection in CL 74CO ON/OFF 400 V

PE H10 H11 H12 H13 H14 H15

400 V L1

L2

L3

H1 24V

H2 ON/OFF

H3 0V

N + H6

400 V L1 H7

L2 H8

L3 H9

CALIBRATE

H 10

11

H12

A2 14 L3 L2 L1

BN

BK

A1 13 W V U

Figure 13: Connection ON/OFF 400 V

4.3.6 Circuit Diagram for CL 74CO ON/OFF 400 V

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency Q2-Q5

opening or internal 24 V Q1

Figure 14: Circuit diagram ON/OFF 400 V

CL 74C Winch Motor

16 Operation manual

4.3.7 Connection in CL 74CV stepless 230 V

230 V N

PE H10 H11 H12 H13 H14 H15

L1

H1 +/-24V

H2 +/-24V

230 V N H3

L1 + H6 24V

H7 0-10V

L1 H8 0V

N H9

CALIBRATE

H 10

11

H12

Figure 15: Connection stepless 230 V

4.3.8 Circuit Diagram for CL 74CV stepless 230 V

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency Q2-Q5

opening or internal 24 V Q1

Figure 16: Circuit diagram stepless 230 V

CL 74C Winch Motor

Operation manual 17

4.3.9 Connection in CL 74CV stepless with external capacitor

230 V N

PE H10 H11 H12 H13 H14 H15

L1

H1 +/-24V

H2 +/-24V

H3

230 V N

L1

+ H6 24V

H7 0-10V

L1 H8 0V

N H9

CALIBRATE

H 10

11

L H12

Figure 17: Connection stepless 230 V external capacitor

4.3.10 Circuit Diagram for CL 74CV stepless with external capacitor

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency Q2-Q5

opening or internal 24 V Q1

Figure 18: Circuit diagram stepless 230 V external capacitor

CL 74C Winch Motor

18 Operation manual

4.3.11 Connection in CL 74CVA 0-10 V

.

H1

PE H10 H11 H12 H13

H2 0-10V

0-10V

H3 0V

0-10V + H6 24V

H7 0-10V

H8

24V

H9

CALIBRATE

0V H 10

11

H12

Figure 19: Connection 0-10 V winch motor

4.3.12 Circuit Diagram for CL 74CVA 0-10 V

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency opening

or internal 24 V

Q2-Q5

Q1

Figure 20: Circuit diagram 0-10 V winch motor

CL 74C Winch Motor

Operation manual 19

4.3.12.1 CL 74CVA 0-10 V without emergency opening

Figure 21: 0-10 V winch motor without emergency opening

CL 74C Winch Motor

20 Operation manual

4.3.12.2 CL 74CVA 0-10 V with emergency opening

Figure 22: 0-10 V winch motor with emergency opening

CL 74C Winch Motor

Operation manual 21

4.3.12.3 CL 74CVA 0-10 V with emergency opening / manual switch

Figure 23: 0-10 V winch motor with emergency opening / manual switch

CL 74C Winch Motor

22 Operation manual

4.3.13 Connection in CL 74C to CL600 LPC

For connecting wires to winch motors, see mounting of ON/OFF, stepless and 0-10 V CL 74C.

H1

PE H10 H11 H12 H13

H2

N

H3

L1 + H6

H7

H8

H9

CALIBRATE

RJ12 H 10

11

H12

BN

BK

6

5

4

3 0V

2 0-10V

1

Figure 24: Connection CL600 LPC

4.3.14 Circuit Diagram for CL 74C to CL600 LPC

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Figure 25: Circuit diagram CL600 LPC

CL 74C Winch Motor

Operation manual 23

4.3.15 Connection in CL 74C to CL600 LPC Dynamic Multistep

For connecting wires to winch motors, see mounting of ON/OFF, stepless and 0-10 V CL 74C.

H1

PE H10 H11 H12 H13

H2

H3

+ H6

H7

H8

H9

CALIBRATE

H 10

11

H12

Figure 26: Connection CL600 LPC Dynamic MultiStep

4.3.16 Circuit Diagram for CL 74C to CL600 LPC Dynamic Multistep

Example of terminal no.

For correct connection,

see the setup menu

Show Installation in Computer

Supply from emergency opening (+24V-1)

Temp. 78T, 278T and 378T = F6 or N7

ON/OFF 78M, 278M and 378M = Q2-Q5

Supply from emergency opening Q2-Q5

or internal 24 V Q1

Figure 27: Circuit diagram CL600 LPC Dynamic MultiStep

CL 74C Winch Motor

24 Operation manual

MAINTENANCE GUIDE

The CL 74C does not require any special maintenance, however we recommend that the system be

serviced once a year.

5 Cleaning

The CL 74C can be cleaned with common detergents and

disinfectants.

Figure 28: Cleaning

When cleaning, it is important not to damage seals.

Pay special attention when cleaning the shaft seal.

Figure 29: Cleaning seals

5.1 Annual Inspection

1. Open the cabinet cover to check the inside functions; check also that no fluid can penetrate into

the cabinet as this may damage gears and other components. Pay attention to the shaft sealing

and the sealing of cable lead-throughs.

In case of sign of leakages, seal using silicone or replace the glands.

2. Activate the manual release and check that the swivel shutter moves unobstructedly in its entire

working range.

3. For units with a contactor, check that the contactor is intact and can start and stop the fan when

activating / deactivating.

CL 74C Winch Motor

Operation manual 25

5.2 Replacing the Motor

The service life of the motor in a CL 74CV is limited, especially when it is used in connection with a

MultiStep fan system in a large broiler house.

The wearing part is the small round motor which should therefore be replaced every three years in order to

ensure smooth operation.

The service life of the CL 74CO is typically more than 10 years.

Before removing the cover, switch off the power supply using the safety switch.

1. Disconnect the power supply and remove the cover.

2. Remove the motor plug (A).

(A) 3. Loosen the shackle retaining the motor (B).

4. Remove the motor.

5. Insert a new motor.

(B)

6. Tighten the shackle.

7. Mount the motor plug.

8. Position the plug correctly.

9. Mount the cover.

10. Connect the power supply.

Figure 30: Replacing the motor

5.3 Recycling

Before dismantling, switch off the power supply for the CL 74C.

1. Disconnect the power supply and remove the cover.

2. Remove wires.

(A)

3. Loosen the screw retaining the disc, Figure 31 (A).

4. Pull the CL 74C winch motor off the shaft.

Figure 31: Recycling

Disassemble the CL 74C into the following parts:

• Gear unit

• Plastic box and glands

• Electric components

Deliver all the parts to a recycling system.

You can also return the winch motor to Big Dutchman who will then deliver it for reprocessing in the

normal recycling system.

CL 74C Winch Motor

26 Operation manual

6 Dismantling for Recycling / Disposal

Big Dutchman' products which are suited for recycling are marked with a pictogram

showing a refuse bin that is crossed over. See picture.

Customers can dispose of Big Dutchman products at local collecting points / recycling stations according

to local directions. The recycling station will then send the products to an approved plant for recycling and

reuse.

6.1 LED Indication

OK = slow flashing

Calibration = constantly on

Fault = quick flashing

7 Troubleshooting / Remedy

Even though the CL 74C has been designed to work without supervision, malfunctioning may occur.

Should this be the case, check and remedy according to the following:

Symptom Reason Solution

The winch motor does not No power supply or power supply Check supply voltage.

run, the LED does not below 12 V? Check fuses.

flash at all.

Check assembly according to

connection and circuit diagram.

! Remember

When using emergency openings 78T,

278T and 378T the +24 V supply must

come from terminal (Q2, Q3, Q4 or

Q5) and the 0 V supply from terminal

(Q1) in the house computer.

When using emergency openings

78M, 278M and 378M the +24 V

supply must come from terminal (Q2,

Q3, Q4 or Q5) and the 0 V supply

from terminal (Q1) in the house

computer. Also connect Q1 to

C17/B17 on the main module.

Has the motor plug been mounted? Mount the plug.

Has calibration been forgotten? Press the CALIBRATE button; the

LED must be constantly on while the

winch motor opens and closes.

CL 74C Winch Motor

Operation manual 27

Symptom Reason Solution

The LED (A) flashes Has calibration been forgotten? Press the CALIBRATE button; the

quickly 10 times/second. LED must be constantly on while the

winch motor opens and closes.

The motor stutters. Remove any object which may have

been trapped in the swivel shutter.

Swivel shutter not fully Perform a calibration; if that does not

open / closed. help, see section 3.

No feedback signal from Connect Q1 to C17 / B17 on the main

the house computer. module.

Table 3: Troubleshooting / remedy

8 Technical Data

Technical data CL 74C

Power supply 24 V DC ± 20 %

Running time, no load 70 sec.

Running time, max. load 90 sec.

Max. torque 24 Nm.

Max. power consumption 0.1 A

Feedback signal 0-10 V - impedance 2.2 KΩ

O.C. (open collector) output max 20 mA - 30 V DC

Cabinet insulation class IP 65

Table 4: Technical data

Chimney CL 920 and smaller Bigger than CL 920

Winchmotor CL 75 CL 74 CL 75 CL 74

135/235Pro 1 A 0 7 0 4

Viper Touch 3 A 0 20 0 14

1 24 1 16

278T/378T 4.2 A

2 10 2 6

1 38 1 25

2 28 2 18

278T/378T 8.0 A

3 18 3 12

4 8 4 5

Table 5: Number of winch motors compared with the type of chimney, house computer and emergency

opening.

CL 74C Winch Motor

28 Operation manual

EC - DECLARATION OF INCORPORATION

Manufacturer: Big Dutchman

Address: Hedelund 4, DK-7870 Roslev, Denmark

Telephone: +45 72 17 55 55

hereby declares that the CL 74C Winch motor

including item numbers 432071, 432073 and 432074.

conform with the following EU directives:

2006/95/EC (The directive on Low voltage current)

2004/108/EC (The EMC directive)

2006/42/EC (The directive on Machinery)

The unit is for incorporation in a complete system and should not be started before

the system is declared to conform with the directive on machinery.

Location: Hedelund 4, DK-7870 Roslev

Date: 2013.06.27

Leo Østergaard

R&D Manager

CL 74C Winch Motor

07/2013 • GB

Big Dutchman International GmbH • Calveslage • Auf der Lage 2 • 49377 Vechta

Tel. +49(0)4447/801-0 • Fax +49(0)4447/801-237 • www.bigdutchman.com • big@bigdutchman.com

Das könnte Ihnen auch gefallen

- D10T (RJG) Service TrainingDokument208 SeitenD10T (RJG) Service Trainingmliugong100% (36)

- Kioti CS2210, CS2510 Tractor Operator's ManualDokument15 SeitenKioti CS2210, CS2510 Tractor Operator's ManualLisakolyNoch keine Bewertungen

- Hobart Dishwasher AMX/AUXDokument20 SeitenHobart Dishwasher AMX/AUXIgor GrytsenkoNoch keine Bewertungen

- Instruction Manual Modbus Protocol: October 2013 Part No.: 4416.527 Rev. 4Dokument32 SeitenInstruction Manual Modbus Protocol: October 2013 Part No.: 4416.527 Rev. 4mNoch keine Bewertungen

- User Guide PRONTO SAT EN PDFDokument7 SeitenUser Guide PRONTO SAT EN PDFloriromNoch keine Bewertungen

- Manual de Operador ASE350 PDFDokument232 SeitenManual de Operador ASE350 PDFFreddy Guerrero0% (1)

- S12u16 User ManualDokument41 SeitenS12u16 User Manualelrond.projects0% (1)

- A 700 ManualDokument12 SeitenA 700 ManualkazkarimNoch keine Bewertungen

- G 240 4/5/6/7 Planer Spare Parts and InstructionsDokument30 SeitenG 240 4/5/6/7 Planer Spare Parts and InstructionsFlorin GabroveanuNoch keine Bewertungen

- 1698613-8000SRM1387 - (11-2016) - Uk-En HysterDokument70 Seiten1698613-8000SRM1387 - (11-2016) - Uk-En HysterGioeNoch keine Bewertungen

- Liebherr R904C Litronic Crawler Excavator Service Repair Manual SN23072 PDFDokument70 SeitenLiebherr R904C Litronic Crawler Excavator Service Repair Manual SN23072 PDFjfjkskemmdm0% (4)

- Veterinary MicrobiologyDokument482 SeitenVeterinary MicrobiologyCathy Vera IterNoch keine Bewertungen

- Saeco Gr500 ManualDokument56 SeitenSaeco Gr500 ManualBront Paul100% (2)

- Curs Limba Engleză An 2 Sem 1Dokument88 SeitenCurs Limba Engleză An 2 Sem 1Beatrice RenataNoch keine Bewertungen

- Manual Del Detector de HolgurasDokument33 SeitenManual Del Detector de HolgurasEdisonMartinezNoch keine Bewertungen

- s7300 fm352 Operating Instructions en en-US PDFDokument226 Seitens7300 fm352 Operating Instructions en en-US PDFABNoch keine Bewertungen

- STUDIU DE CAZ +MASURATORI PROIECT AWADUKT THERMO SUPERMARKET TESCO POLONIA English (Compatibility Mode)Dokument30 SeitenSTUDIU DE CAZ +MASURATORI PROIECT AWADUKT THERMO SUPERMARKET TESCO POLONIA English (Compatibility Mode)Andrei MartinasNoch keine Bewertungen

- HCC80R Installation GuideDokument44 SeitenHCC80R Installation GuideBogdan SandulacheNoch keine Bewertungen

- Counting Service Manual ccb9Dokument17 SeitenCounting Service Manual ccb9Kamalco ScaleNoch keine Bewertungen

- C1, F/G650GS/X BMS/ECU InformationDokument6 SeitenC1, F/G650GS/X BMS/ECU Informationinforlex100% (1)

- A4 Profile Formate La ReceDokument8 SeitenA4 Profile Formate La ReceraduonoNoch keine Bewertungen

- CV S.mishra Mechanical 19.12.19Dokument3 SeitenCV S.mishra Mechanical 19.12.19souradipmishraNoch keine Bewertungen

- Service: Mașină de Spălat Cu TamburDokument44 SeitenService: Mașină de Spălat Cu TamburRacoviţă Ionuţ-LucianNoch keine Bewertungen

- SRX 75 ManualDokument24 SeitenSRX 75 ManualLucasNoch keine Bewertungen

- Haulotte CompactDokument118 SeitenHaulotte CompactAdam SchwemleinNoch keine Bewertungen

- Battery Analyzer, 88890075 EXP, User ManualDokument34 SeitenBattery Analyzer, 88890075 EXP, User ManualBùi Xuân Đức0% (1)

- Romania - SBA Fact Sheet 2019Dokument20 SeitenRomania - SBA Fact Sheet 2019ClaudiuNoch keine Bewertungen

- Canon iPF610 Service Manual PDFDokument274 SeitenCanon iPF610 Service Manual PDFMircea Stefan BogdanNoch keine Bewertungen

- MELSEC iQ-R Structured Text (ST) Programming Guide BookDokument106 SeitenMELSEC iQ-R Structured Text (ST) Programming Guide BookyounesNoch keine Bewertungen

- Digital Revolution Counter - RPMDokument2 SeitenDigital Revolution Counter - RPMYonathan OrozcoNoch keine Bewertungen

- Oandm Manual Mec 100 Digital Voltage RegulatorDokument248 SeitenOandm Manual Mec 100 Digital Voltage RegulatorKaiser IqbalNoch keine Bewertungen

- RAtionalG0168 PDFDokument200 SeitenRAtionalG0168 PDFBKK2NDNoch keine Bewertungen

- Maintenance Manuals - New Wheels - HA - 231013 - 121559Dokument213 SeitenMaintenance Manuals - New Wheels - HA - 231013 - 121559Produção PelotasNoch keine Bewertungen

- High Performance Injection System: Installation ManualDokument23 SeitenHigh Performance Injection System: Installation ManualJunior SalazarNoch keine Bewertungen

- Automatic Cutting Machine: Powercut 3700Dokument118 SeitenAutomatic Cutting Machine: Powercut 3700Dionisio M. RiveraNoch keine Bewertungen

- Kioti Daedong MEC2200, MEC2210, MEC2230 UTV (Utility Vehicle) Service Manual 04-2014Dokument19 SeitenKioti Daedong MEC2200, MEC2210, MEC2230 UTV (Utility Vehicle) Service Manual 04-2014LisakolyNoch keine Bewertungen

- Kioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019Dokument19 SeitenKioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019LisakolyNoch keine Bewertungen

- User Manual: Combistar Scissor Lift HL-275 D27 4WD/P/N M-250DL27 4WD/P/NDokument56 SeitenUser Manual: Combistar Scissor Lift HL-275 D27 4WD/P/N M-250DL27 4WD/P/NKrum KashavarovNoch keine Bewertungen

- Gunson Gas Tester Mk2Dokument16 SeitenGunson Gas Tester Mk2Rohan Simon100% (1)

- Grile Management StrategicDokument6 SeitenGrile Management StrategicAlecsandru AndreiNoch keine Bewertungen

- Manuale Eco Gas enDokument79 SeitenManuale Eco Gas ennicutaxNoch keine Bewertungen

- URSUSDokument12 SeitenURSUSvivek6020100% (1)

- UI Communication Protocol FISCAL PRINTERSDokument52 SeitenUI Communication Protocol FISCAL PRINTERSAshok BezawadaNoch keine Bewertungen

- Ha15ip Manual ServicioDokument65 SeitenHa15ip Manual ServicioP GNoch keine Bewertungen

- R934CDokument26 SeitenR934Cequipment9278Noch keine Bewertungen

- Terex TL160 Wheel Loader Operator's Manual PDFDokument114 SeitenTerex TL160 Wheel Loader Operator's Manual PDFandrzej gołdaNoch keine Bewertungen

- FAStron MEC-110 SPMDokument16 SeitenFAStron MEC-110 SPMDaniel BarleNoch keine Bewertungen

- Open Modbus TCP For NCM - CP Redundant EnglishDokument71 SeitenOpen Modbus TCP For NCM - CP Redundant EnglishJose LunaNoch keine Bewertungen

- Grundfosliterature 5439390Dokument108 SeitenGrundfosliterature 5439390ptlNoch keine Bewertungen

- Bonfiglioli W Series Owners ManualDokument68 SeitenBonfiglioli W Series Owners ManualDhaman A Koka100% (1)

- Briggs and Stratton 294442Dokument29 SeitenBriggs and Stratton 294442FRNoch keine Bewertungen

- Atos 2016 Financial Report PDFDokument108 SeitenAtos 2016 Financial Report PDFandre1983Noch keine Bewertungen

- Inverter 201 Ultra PFC ManualDokument44 SeitenInverter 201 Ultra PFC ManualParadox UtopiaNoch keine Bewertungen

- M400 M600 M800 M880 Manual A5Dokument101 SeitenM400 M600 M800 M880 Manual A5Hoff ZhangNoch keine Bewertungen

- x20 System-Eng v3.60Dokument3.830 Seitenx20 System-Eng v3.60Sem FadeyNoch keine Bewertungen

- TLB30Dokument11 SeitenTLB30Victor GuzmanNoch keine Bewertungen

- BC-2800Vet Operator's Manual 12.0 EN H-2810-20-47202 ECM12.0 PDFDokument246 SeitenBC-2800Vet Operator's Manual 12.0 EN H-2810-20-47202 ECM12.0 PDFEr Nitin SinghNoch keine Bewertungen

- CL 74C Winch Motor: Operation ManualDokument32 SeitenCL 74C Winch Motor: Operation ManualИльнур ТагировNoch keine Bewertungen

- John Deer CS56Dokument92 SeitenJohn Deer CS56R David MooreNoch keine Bewertungen

- v3 enDokument69 Seitenv3 enEdward ShortNoch keine Bewertungen

- Grove Rt-880e-Service ManualDokument346 SeitenGrove Rt-880e-Service Manualramiro serrano olliscoNoch keine Bewertungen

- Acid-Base Balance in BroilersDokument10 SeitenAcid-Base Balance in Broilersionut2007Noch keine Bewertungen

- Poultry HandbookDokument210 SeitenPoultry Handbookedmondns100% (5)

- Stress and Acid Base Balance in ChickenDokument9 SeitenStress and Acid Base Balance in Chickenionut2007Noch keine Bewertungen

- Acid-Base Balance in BroilersDokument10 SeitenAcid-Base Balance in Broilersionut2007Noch keine Bewertungen

- (Animal Science, Issues and Professions - Global Argriculture Developments) Catherine T. Hernandez-Dairy Cows - ReproductionDokument174 Seiten(Animal Science, Issues and Professions - Global Argriculture Developments) Catherine T. Hernandez-Dairy Cows - Reproductionionut2007100% (1)

- CL 74C Winch Motor: Operation ManualDokument29 SeitenCL 74C Winch Motor: Operation Manualionut2007Noch keine Bewertungen

- Effect of A Selected Lactobacillus Spp.-Based Probiotic On Salmonella Enterica Serovar Enteritidis-Infected Broiler ChicksDokument2 SeitenEffect of A Selected Lactobacillus Spp.-Based Probiotic On Salmonella Enterica Serovar Enteritidis-Infected Broiler Chicksionut2007Noch keine Bewertungen

- cl74 0 10VDokument15 Seitencl74 0 10Vionut2007Noch keine Bewertungen

- Meta-Analyses of Experimental Data in The Animal Sciences PDFDokument16 SeitenMeta-Analyses of Experimental Data in The Animal Sciences PDFionut2007Noch keine Bewertungen

- Fullfat Soya Bibliography14Dokument6 SeitenFullfat Soya Bibliography14ionut2007Noch keine Bewertungen

- Color Atlas of Diagnostic MicrobiologyDokument223 SeitenColor Atlas of Diagnostic MicrobiologyRubén Méndez83% (24)

- Admisie Aer-En 2013Dokument8 SeitenAdmisie Aer-En 2013ionut2007Noch keine Bewertungen

- Effects of Alternative Protein Sources On Nutrient Digestibility, Performance, Carcass Traits and Serum Hormone Profiles of Growing-Finishing Pigs PDFDokument11 SeitenEffects of Alternative Protein Sources On Nutrient Digestibility, Performance, Carcass Traits and Serum Hormone Profiles of Growing-Finishing Pigs PDFionut2007Noch keine Bewertungen

- Hormones and Pharmaceuticals Generated by Concentrated Animal Feeding Operations, Transport in Water and SoilDokument149 SeitenHormones and Pharmaceuticals Generated by Concentrated Animal Feeding Operations, Transport in Water and Soilionut2007Noch keine Bewertungen

- Handbook of Poultry DiseaseDokument376 SeitenHandbook of Poultry Diseaseionut2007Noch keine Bewertungen

- Feeding Management For Show Lambs: E TensionDokument9 SeitenFeeding Management For Show Lambs: E Tensionionut2007Noch keine Bewertungen

- Poultry ScienceDokument7 SeitenPoultry Scienceionut2007Noch keine Bewertungen

- An16sheepfeeding PDFDokument21 SeitenAn16sheepfeeding PDFionut2007Noch keine Bewertungen

- Fattening Lambs: University of MinnesotaDokument26 SeitenFattening Lambs: University of Minnesotaionut2007Noch keine Bewertungen

- 011B - Feed Efficiency in Swine PDFDokument281 Seiten011B - Feed Efficiency in Swine PDFionut2007Noch keine Bewertungen

- Broiler Performance Objectives GuideDokument24 SeitenBroiler Performance Objectives GuideIoana Corbu Costache100% (1)

- CL20 Aspects of Feed Efficiency and Feeding Behaviour in Turkeys en V4Dokument9 SeitenCL20 Aspects of Feed Efficiency and Feeding Behaviour in Turkeys en V4ionut2007Noch keine Bewertungen

- Fattening Lambs: University of MinnesotaDokument26 SeitenFattening Lambs: University of Minnesotaionut2007Noch keine Bewertungen

- Admisie Aer-En 2013Dokument8 SeitenAdmisie Aer-En 2013ionut2007Noch keine Bewertungen

- Legislation Booklet (GB01 - Mar 10)Dokument8 SeitenLegislation Booklet (GB01 - Mar 10)ionut2007Noch keine Bewertungen

- Program Transformare Stereo 70-UTMDokument8 SeitenProgram Transformare Stereo 70-UTMAntoniuDragneaNoch keine Bewertungen

- Lohmann Brown Classic Management Guide for Colony SystemsDokument25 SeitenLohmann Brown Classic Management Guide for Colony Systemsionut2007Noch keine Bewertungen

- Effects of Alternative Protein Sources On Nutrient Digestibility, Performance, Carcass Traits and Serum Hormone Profiles of Growing-Finishing PigsDokument11 SeitenEffects of Alternative Protein Sources On Nutrient Digestibility, Performance, Carcass Traits and Serum Hormone Profiles of Growing-Finishing Pigsionut2007Noch keine Bewertungen

- TMS320F2812 - FIR FilterDokument36 SeitenTMS320F2812 - FIR FilterPantech ProLabs India Pvt LtdNoch keine Bewertungen

- Balanza Mettler Toledo Id5 PDFDokument16 SeitenBalanza Mettler Toledo Id5 PDFBauCamposGNoch keine Bewertungen

- ONU AlarmsDokument212 SeitenONU AlarmsEdwinMeoñezNoch keine Bewertungen

- VI Characteristics of DiodeDokument5 SeitenVI Characteristics of DiodeRashid Rind Rashid RindNoch keine Bewertungen

- Gigabyte - Mobo TrainningDokument17 SeitenGigabyte - Mobo TrainningEverton DoradoNoch keine Bewertungen

- Shelly 25 Multi LanguageDokument2 SeitenShelly 25 Multi Languagesergio alejandro trujillo perezNoch keine Bewertungen

- 2004 Conference Proceedings on Microwave TechnologyDokument4 Seiten2004 Conference Proceedings on Microwave TechnologyNajmi Najib Nasrulloh KurniadiNoch keine Bewertungen

- Parameter Extraction Procedure For A Physics-Based Power Sic Schottky Diode ModelDokument11 SeitenParameter Extraction Procedure For A Physics-Based Power Sic Schottky Diode ModelKrishna KumarNoch keine Bewertungen

- RLFDokument5 SeitenRLFPritam ModakNoch keine Bewertungen

- Semiconductor Devices and Circuits LaboratoryDokument53 SeitenSemiconductor Devices and Circuits LaboratoryKaryampudi RushendrababuNoch keine Bewertungen

- Profibus-Dp: Installation ManualDokument38 SeitenProfibus-Dp: Installation ManualLeandroNoch keine Bewertungen

- Power Factor Improvement Using Dual Boost Converter: Miss. R. S. More, Prof .D.D.AhireDokument6 SeitenPower Factor Improvement Using Dual Boost Converter: Miss. R. S. More, Prof .D.D.Ahiresai charanNoch keine Bewertungen

- TCC CATV - e Catalgoue VDokument91 SeitenTCC CATV - e Catalgoue VlehongphuNoch keine Bewertungen

- Quick Manual v1.4: Advanced Tracker With Flexible Inputs ConfigurationDokument16 SeitenQuick Manual v1.4: Advanced Tracker With Flexible Inputs ConfigurationFrank Foord Valencia RiveraNoch keine Bewertungen

- Heathkit Test Equipment 1954Dokument44 SeitenHeathkit Test Equipment 1954Vasco MelloNoch keine Bewertungen

- Site Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionDokument20 SeitenSite Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionkrishkarnNoch keine Bewertungen

- 8085 and 8051Dokument25 Seiten8085 and 8051Rajarshi RoyNoch keine Bewertungen

- RTHD and Rtac: Diagnostic Troubleshooting RepairDokument74 SeitenRTHD and Rtac: Diagnostic Troubleshooting RepairMarko BukovčanNoch keine Bewertungen

- Gaming Content Picture Settings and Tips For: Samsung Nu7100 Nuxxxx TV Series (European)Dokument7 SeitenGaming Content Picture Settings and Tips For: Samsung Nu7100 Nuxxxx TV Series (European)Lougan LuzNoch keine Bewertungen

- Arabsat 5CDokument5 SeitenArabsat 5Chidrogen.h.786786Noch keine Bewertungen

- Capacitance and Inductance Measurements Using An Oscilloscope and A Function GeneratorDokument9 SeitenCapacitance and Inductance Measurements Using An Oscilloscope and A Function Generatoralex castroNoch keine Bewertungen

- 5 A 0105 EE486 DigitalDokument1 Seite5 A 0105 EE486 DigitalNagarjuna MalladhiNoch keine Bewertungen

- Eaget M880-User Manual v1.0.3Dokument44 SeitenEaget M880-User Manual v1.0.3NewNoch keine Bewertungen

- PT2313L PDFDokument3 SeitenPT2313L PDFMaugrys Castillo100% (1)

- Man Handwheel UfoDokument2 SeitenMan Handwheel UfoAloisio GonzagaNoch keine Bewertungen

- Variable speed drive ATV12 - 1.5kW - 2hp - 200..240V - 3ph - with heat sinkDokument11 SeitenVariable speed drive ATV12 - 1.5kW - 2hp - 200..240V - 3ph - with heat sinkLeví StrataNoch keine Bewertungen

- RN-AC106-3A: Low Frequency Accelerometer, Side Connector, 500 MV/GDokument1 SeiteRN-AC106-3A: Low Frequency Accelerometer, Side Connector, 500 MV/GkylegazeNoch keine Bewertungen

- Intelsat 902 Satellite Footprints PDFDokument5 SeitenIntelsat 902 Satellite Footprints PDFThee MaungNoch keine Bewertungen

- BENZING M1 Pigeon Clock RevolutionDokument2 SeitenBENZING M1 Pigeon Clock RevolutionverschelderNoch keine Bewertungen

- Service News: AudioDokument2 SeitenService News: Audioprashantbabu7780Noch keine Bewertungen