Beruflich Dokumente

Kultur Dokumente

Body of Knowledge: Certified Welding Engineer

Hochgeladen von

Malcolm DiamondOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Body of Knowledge: Certified Welding Engineer

Hochgeladen von

Malcolm DiamondCopyright:

Verfügbare Formate

BODY OF KNOWLEDGE

Certified Welding Engineer

The AWS Certified Welding Engineer (CWEng) examination is four parts. Parts 1 and 2 must be successfully completed in order

to take Parts 3 and 4. The first two parts of the exam are closed book and cover basic science fundamentals and applied science

fundamentals. Parts 1 and 2 are each two hour written multiple-choice exams (total time of four hours). Part 1 is a 35 question

multiple choice exam and Part 2 is a 25 question multiple choice exam. They are given together and must be passed together. If

the candidate fails only one part, only that part must be repeated.

Parts 3 and 4 of the exam are open book examinations on welding related disciplines and practical welding and related

applications. They are each three hours in length. Part 3 is a 45 question essay exam. Part 4 is a 39 question multiple choice

exam. Candidates that successfully pass Parts 1 and 2 will be invited to sit for these exams and a separate application must be

submitted to AWS.

The exams may be taken at any location where the CWI examinations are given. Candidates may bring any textbooks, articles or

codes in their library that are published and publicly available. All reference materials must be bound and remain bound during

the exam. Bound refers to (1) materials permanently bound, as by stitching or glue, and (2) materials securely fastened in

their covers by fasteners that penetrate all papers. Ring binders, spiral binders, plastic snap binders, brads, and screw posts

are acceptable fasteners. Staples are not acceptable fasteners. Writing tablets and legal pads are not allowed. Examinees may

tab reference books before the exam with Post-it type notes and flags, but pads of Post-it notes and flags are not permitted in

the exam room.

To protect the integrity of its exams, AWS limits the types of calculators you may bring to exam sites for this exam. The only

calculator models acceptable for use during the CWEng exams are as follows.

Casio: All fx-115 and fx-991 models (Any Casio calculator must have “fx-115” or “fx-991” in its model name.)

Hewlett Packard: The HP 33s and HP 35s models, but no others

Texas Instruments: All TI-30X and TI-36X models (Any Texas Instruments calculator must have “TI-30X” or “TI-

36X” in its model name.)

Candidates must pass each of the four examinations with an individual score no less than 60% and attain a minimum weighted

percentage of 70% for all 4 parts. Note: The D1.1 2010 edition is applicable to the current CWEng Part 4 exam only (subject to

change). All applicants shall successfully meet the CWEng requirements as contained in clauses 6 and 7 of AWS B5.16,

Specification for the Qualification of Welding Engineers.

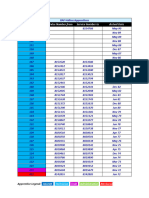

Approximate subject weights for the four examination parts are as follows:

Part 1 – Basic Science Fundamentals Part 2 – Applied Science Fundamentals

Mathematics 25% Strength of Materials 40%

Physics 50% Heat Transfer and Fluid Mechanics 30%

Chemistry 25% Electricity 30%

Part 3 – Welding Related Disciplines (Essay Exam) Part 4 – Practical Welding and Related Applications

NDE/Weld Discontinuities 10% Exam using references on the application of welding 100%

Welding Heat Sources and Arc Physics 20% engineering concepts in the areas of:

Welding Processes and Controls 20%

Welding safety, weldment design, welding metallurgy,

Welding and Joining Metallurgy 20%

materials, welding process selection, NDE including

Weld Design 20%

visual weld inspection, quality assurance, quality

Brazing and Soldering 5%

control in accordance with codes, specifications, other

Safety 5%

standards, and/or drawings.

CWEng BOK_2253 May 11, 2017

Body of Knowledge – Extended Subject Areas as per AWS B5.16:

8.1 Basic Sciences Fundamentals 8.2.2 Heat Transfer and Fluid Mechanics:

8.1.1 Mathematics: heat conduction, convection, and radiation, thermal

simple calculations (multiple choice) conductivity and diffusivity, heat transfer coefficients of

special functions (exp, log) engineering materials, Fourier’s Law

trigonometric functions (sin, cos, tan, cot, sec, csc, degrees, heating rate and cooling rate

radians) industrial heating methods and power consumption, gas

algebraic equations (linear, quadratic, polynomial) flow rates

graphs and equations (slope, intercept, roots, derivatives, laminar and turbulent flow (Reynold’s Number), dew point

minimum, maximum, interpolation, and extrapolation) and relative humidity, pressure and regulators

geometry (common geometric shapes) venturi effect and gas velocity calculation

hyperbola, parabola atmospheric pressure and hyperbaric conditions

complex numbers vacuum equipment and measurements

calculus (fundamentals of differential equations) 8.2.3 Electricity:

statistics (population and samples: normal distribution, current, voltage, resistance, impedance, and circuits

mean, standard deviation, variance Ohm’s Law

simple correlation: linear regression via least squares Kirchoff’s Law

method, r2 correlation) Resistance loss and current rectification

8.1.2 Physics: power generation

unit conversion (dimension, mass, temperature, time, AC/DC, polarity

energy, power) power factor

mass, weight, volume, density electromagnetic properties,

force, energy, work done, power right-hand rule

stress, strain, Hooke’s Law (elasticity) current and voltage measurements (devices and principles)

moment and momentum

temperature, heat, temperature measurement,

thermocouples, pyrometers

thermal properties of materials (thermal conductivity,

thermal expansion, thermal stress and strain)

8.1.3 Chemistry:

symbols (elements and inorganic compounds—gases,

fluxes, etc.)

molecular weight and stoichiometry

acids and bases

balance chemical equations

gas combustion reactions (chemical heat generation) and

oxidation-reduction reactions

ideal gas law (pressure, volume, temperature)

mass balance (as in E7018 coating decomposition to gas,

slag and metal)

bulk and chemical analysis methodologies)

reactivity, toxicity, environmental effect, disposal.

8.2 Applied Sciences

8.2.1 Strength of Materials:

load, deformation (elastic and plastic, buckling), stress-

strain, Young’s Modulus, shear modulus, stress-strain curve

(yield stress, ultimate tensile stress, elongation), tensile

stress and

shear stress computation

welded member cross-section effect

mechanical testing (tensile, bend, fracture toughness,

hardness, creep, and fatigue) and data interpretation

Law of Conservation of Energy/Momentum

stress analysis

typical engineering material properties

CWEng BOK_2253 May 11, 2017

8.3 Welding Related Disciplines fluxmetal reactions (oxygen and sulfur control in weld pool)

8.3.1 NDE/Weld Discontinuities: typical temperature range of a heat source

NDE processes (radiographic, ultrasonic, magnetic particle, temperature distribution in a weldment

liquid penetrant, HAZ formation

eddy current, etc.—characteristics, advantages, and multipass thermal experience, reheated weld metal

limitations) properties

NDE symbols8.3.2 Welding Heat Sources and Arc Physics: weld macro and micro-graph interpretation

power source static and dynamic characteristics (open solidification profile and preferred grain orientation

circuit voltage and short circuiting current, slope) (epitaxial growth)

differences between CC and CV designs (principle of self- origin of weld ripples

adjusting) special attributes of base metal (as-cast structure,

welding arc characteristics (current and voltage deformation texture, oxide on flamecut surfaces)

relationship, arc length effect)

electron emission (ionization potential, work function, 8.3.4 Welding and Joining Metallurgy (continued):

electrode material, shielding gas, arc stability) thermal treatments (preheat, postheat, interpass influence

arc temperature and degree of ionization (shielding gas on weld cooling rate and residual stress distribution)

influence) solid-state transformations in welds (different forms of

magnetic arc blow (work lead location and condition) ferrite, bainite, and martensite, sigma phase in stainless

Lorentz Force (effect on droplet detachment and on steels, Guinier-Preston type precipitates zones and aging in

adjacent power cables) aluminum alloys)

shielding gas drag force (effect on droplet detachment and corrosion (sensitization in stainless steel welds, stress

metal transfer mode) weld penetration and width for corrosion cracking in welds)

different shielding gases 8.3.5 Weld Design:

8.3.3 Welding Processes and Controls: structural fabrication requirements, sectional properties,

arc welding processes (SMAW, GMAW, FCAW, GTAW, SAW, stress gradient

PAW) stress triaxiality, weld symbols, hardness and

resistance welding processes (RW, high frequency RW), microhardness (e.g., across a weld cross section)

high energy density welding processes (LBW, EBW) tensile properties, ductility, toughness, fillet break test

cutting processes (OFC, CAC, and PAC) (influence of second phase and porosity), ductile fracture,

surfacing processing (SW, THSP) brittle fracture, fatigue (initiation, propagation, failure,

solid-state welding processes (FRW, FW) high-cycle, low-cycle), temperature and strain rate effect

8.3.4 Welding and Joining Metallurgy: 8.3.6 Brazing and Soldering:

crystal structure of metals (FCC, BCC, HCP, unit cells, lattice characteristics of brazing and soldering

parameter, c/a ratio, atom positions, interstitial positions) fluxes and substrates

melting, and solidification, phase transformations and capillary action

phase diagrams (eutectic, eutectoid, peritectic and wetting and spreading

monotectic, lever rule calculation) metallurgy and contact angle

weldability of typical engineering materials (low carbon joint clearance

structural steels, cast irons, stainless steels, nickel alloys, viscosity

aluminum alloys, titanium alloys, etc.) microstructure (e.g., liquidus and solidus

ferrous alloys—grain boundary ferrite, acicular ferrite, flow of molten filler in horizontal and vertical joints

bainite, martensite, austenite, delta ferrite, etc.) and (maximum penetration and rate)

mechanical properties filler metal systems (Sn-Pb solders, Ni and Cu based alloys,

carbon equivalent (CEIIW, Pcm, expressions, alloying Ag-Cu based brazing alloys)

content and carbon content effect) intermetallic compound formation

hydrogen assisted cracking (heat-affected zone cracking, 8.3.7 Safety:

cold cracking) base metal matching (e.g., electrodes with recognize health hazards relating to welding (fumes, toxic

high strength steels) gases, noise, radiation)

solidification cracking (segregation of impurity atoms, recognize safety hazards (electric shock, compressed gases,

shrinkage cracking, lamellar tearing) fire, welding in a confined space, welding on containers and

delta ferrite in stainless consumables, specifications for piping, moving equipment)

consumables (categories; all position, rutile, basic) recognize precautions to avoid injury

possess a working knowledge of safety and fire codes

CWEng BOK_2253 May 11, 2017

AWS Welding Engineer Examination Preparatory Material

Reference Title Author Publisher

ANSI Z49.1 Safety in Welding, Cutting and Allied Processes AWS

Applied Fluid Mechanics, 4th Ed. Mott Merrill Publishing Company

ASM Handbook Vol. 17, NDE ASM

ASM Handbook Vol. 6 Welding/ Brazing 10th Ed. ASM

AWS D1.1 Structural Welding Code—Steel AWS

Design of Weldments Omer W. The James F. Lincoln Arc Welding

Blodgett Foundation

Engineer in Training Manual

Essentials of Engineering Economics, 2nd ed. Riggs & West McGraw Hill

Fracture & Fatigue Control in Structures, Application of John M. Barson & Prentice Hall - Second Edition, 1987

Fracture Mechanics Stanley T. Rolfe

Fundamentals of Engineering: The Most Effective FE/EIT Merle C. Potter Great Lakes Press

Review

Fundamentals of Welding Technology, Modules 1 - 9 CWB Group – cwbstore.org

Handbook of Arc Welding James F. Lincoln Arc Welding Foundation

HB for Mechanical Engineers Mark Standard Avallone or Baumeister

Introduction to the Practice of Statistics Moore & McCabe Freeman

ISBN 0 7167 2250 X

Introductory Physical Metallurgy of Welding Easterling Butterworths

Introductory Welding Metallurgy AWS

Manufacturing, Engineering & Technology Serope and Addison Wesley

ISBN 0 201 538460 Kalpakjian

Mechanical Metallurgy Dieter McGraw Hill

Metals and How to Weld Them James F. Lincoln Arc Welding Foundation,

Second Edition, 1990

Modern Welding Technology Cary Prentice Hall

Physics of Arc Welding J. Lancaster Pergamon

Product Design for Manufacture and Assembly Boothroyd, Marcel Dekker

ISBN 0 8247 9176 2 Dewhust & Knight

Quality Control, 5th Ed. Besterfield Prentice Hall

Robots & Manufacturing Automation Asfahl John Wiley

Stainless Steel R.A. Lula ASM International, 1986

Reference Title Author Publisher

Statics & Strength of Materials, 3rd Edition, ISBN 0-13- Morrow Prentice Hall

453201-5

Statics & Strength of Materials: A Parallel Approach to Lawrence J. Wolf Merrill Publishing Company

Understanding Structures

Weldability of Steels Stout & Doty Welding Research Council

Welding Aluminum: Theory and Practice The Aluminum Association, Second

Edition, June 1991

Welding Design, Modules 30-39 CWB Group – cwbstore.org

Welding Encyclopedia Jefferson AWS

Welding Handbook Vol. 1, 2, 3, 8th Ed. AWS

Welding Metallurgy Sindo Kou John Wiley & Sons

Welding Metallurgy Linnert AWS

Welding Metallurgy J. Lancaster Pergamon

Welding Metallurgy, Modules 8, 9, 12, 20-23, 30 CWB Group – cwbstore.org

TO ORDER ANY OF THE ABOVE AWS PUBLICATIONS:

Contact Technical Standards Sales at 305-443-9353, Ext. 280

Or visit the AWS Bookstore

CWEng BOK_2253 May 11, 2017

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Welding Engineer Exam SyllubusDokument2 SeitenWelding Engineer Exam SyllubuskapsarcNoch keine Bewertungen

- AWS R I C P: Adiographic Nterpreter Ertification RogramDokument4 SeitenAWS R I C P: Adiographic Nterpreter Ertification RogramSharat Chandra100% (1)

- Question 1 of 25Dokument7 SeitenQuestion 1 of 25antonio larotta100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- QW 442 A Number PDFDokument1 SeiteQW 442 A Number PDFMadidj_2014Noch keine Bewertungen

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingVon EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNoch keine Bewertungen

- Aws Cwe Exam SampleDokument2 SeitenAws Cwe Exam SampleEmad A.AhmadNoch keine Bewertungen

- Painting Inspector: Passbooks Study GuideVon EverandPainting Inspector: Passbooks Study GuideNoch keine Bewertungen

- Submerged Arc Welding (Saw)Dokument5 SeitenSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNoch keine Bewertungen

- Metallurgy and Steel Properties: Electron (-)Dokument10 SeitenMetallurgy and Steel Properties: Electron (-)Ashish ManeNoch keine Bewertungen

- ASME P-NumbersDokument9 SeitenASME P-NumbersAamer MohammedNoch keine Bewertungen

- Geometric Unsharpness FormulaDokument2 SeitenGeometric Unsharpness FormulaJayaneela Prawin0% (1)

- Cigweld-Deposited Rates PDFDokument7 SeitenCigweld-Deposited Rates PDFNam_HitechNoch keine Bewertungen

- Asset Integrity Daily ReportDokument1 SeiteAsset Integrity Daily Reportعصمت ضيف اللهNoch keine Bewertungen

- ASME 9 Multi Process Welding Procedures QW200Dokument2 SeitenASME 9 Multi Process Welding Procedures QW200Teodor EzaruNoch keine Bewertungen

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsDokument11 SeitenTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DareNoch keine Bewertungen

- Nbic IsDokument2 SeitenNbic IsDivakar PanigrahiNoch keine Bewertungen

- Add02 1060.1Dokument14 SeitenAdd02 1060.1Diego Calderón AlvaradoNoch keine Bewertungen

- Uphill Versus Downhill Welding PDFDokument4 SeitenUphill Versus Downhill Welding PDFPatrick DominguezNoch keine Bewertungen

- CSWIP 3 1 Syllabus Exam PatternDokument3 SeitenCSWIP 3 1 Syllabus Exam PatternTaufik AliNoch keine Bewertungen

- CE Equations For Weldability of SteelsDokument1 SeiteCE Equations For Weldability of SteelsVivek Panse100% (1)

- API 510 Case Study - 7Dokument2 SeitenAPI 510 Case Study - 7Khaled FatnassiNoch keine Bewertungen

- Convexity Aws PDFDokument4 SeitenConvexity Aws PDFHJ SJNoch keine Bewertungen

- CWI TEST Flashcards PDFDokument30 SeitenCWI TEST Flashcards PDFGary Oporto cabasNoch keine Bewertungen

- CWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)Dokument8 SeitenCWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNoch keine Bewertungen

- 625 CRO - SAW Study - Final Report PDFDokument21 Seiten625 CRO - SAW Study - Final Report PDFAnouar AbdelmoulaNoch keine Bewertungen

- 0301e - Guidebook For Inspectors - 2018-3Dokument6 Seiten0301e - Guidebook For Inspectors - 2018-3FranciscoNoch keine Bewertungen

- Examen AwsDokument9 SeitenExamen AwsRodrigo CarizNoch keine Bewertungen

- Exam Narative Cswip 3.2Dokument5 SeitenExam Narative Cswip 3.2yuwantoniNoch keine Bewertungen

- 25 Macro Micro ExaminationDokument14 Seiten25 Macro Micro ExaminationAdhanom G.100% (1)

- MTC Er70s 2Dokument1 SeiteMTC Er70s 2Mirza BaigNoch keine Bewertungen

- Penetrants TESTINGDokument86 SeitenPenetrants TESTINGsankaran_muthukumarNoch keine Bewertungen

- Api 1104 VT TestDokument2 SeitenApi 1104 VT TestKali AbdennourNoch keine Bewertungen

- TI 36X ProDokument6 SeitenTI 36X ProRem MessimerNoch keine Bewertungen

- 3.4 Arc Length: The Distance From The Tip of The WeldingDokument7 Seiten3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinNoch keine Bewertungen

- Case Study - 7: Numerical in API 510 CodeDokument4 SeitenCase Study - 7: Numerical in API 510 CodeVishal BailurNoch keine Bewertungen

- Ost Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureDokument6 SeitenOst Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureshifaNoch keine Bewertungen

- Cswip 3.1Dokument2 SeitenCswip 3.1Anna PariniNoch keine Bewertungen

- Welding Inspection Questions WisDokument5 SeitenWelding Inspection Questions WisBhavani PrasadNoch keine Bewertungen

- Twi Course Name and Description: BGAS/CSWIP CoursesDokument5 SeitenTwi Course Name and Description: BGAS/CSWIP Courseskhalidmh100% (1)

- API 1104 - Sample Quiz - 2012Dokument42 SeitenAPI 1104 - Sample Quiz - 2012장재성Noch keine Bewertungen

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDokument1 Seite22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNoch keine Bewertungen

- Asme Boiler & Pressure Section ViiiDokument22 SeitenAsme Boiler & Pressure Section ViiiHesham ismail SeddikNoch keine Bewertungen

- CSWIP 3.1U RevisionDokument12 SeitenCSWIP 3.1U Revisionayman coreNoch keine Bewertungen

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDokument4 SeitenWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedSurendra KamalNoch keine Bewertungen

- Welding - Joint - Symbols ISO 2553Dokument32 SeitenWelding - Joint - Symbols ISO 2553Silvio ZappinoNoch keine Bewertungen

- NACE-Stress Corrosion Cracking (SCC)Dokument3 SeitenNACE-Stress Corrosion Cracking (SCC)Mohamed AtefNoch keine Bewertungen

- CH 7 Weld ProcessesDokument62 SeitenCH 7 Weld Processesho1971Noch keine Bewertungen

- Cswip 3.1 Q1Dokument2 SeitenCswip 3.1 Q1Mustafa ElfatihNoch keine Bewertungen

- Multi - Choice Question Paper (MSR-WI-1)Dokument8 SeitenMulti - Choice Question Paper (MSR-WI-1)Karit Hawichit100% (1)

- Weld Joint Design and Symbols PresentationDokument110 SeitenWeld Joint Design and Symbols PresentationEric WoodsNoch keine Bewertungen

- Data Sheet API 2W Grade 50Dokument3 SeitenData Sheet API 2W Grade 50sagitroseNoch keine Bewertungen

- Multi Choice Question Paper (MSR - WI - 4)Dokument6 SeitenMulti Choice Question Paper (MSR - WI - 4)BudimanNoch keine Bewertungen

- Weld AbilityDokument34 SeitenWeld AbilityGauthamSarangNoch keine Bewertungen

- Module3 - Welding ProcessesDokument155 SeitenModule3 - Welding ProcessesPurvesh NanavatiNoch keine Bewertungen

- Cswip Question and Answers: ResponsibilitiesDokument11 SeitenCswip Question and Answers: Responsibilitiesfery0% (1)

- 03-Symbols Mock ExamDokument5 Seiten03-Symbols Mock ExamCRISTIAN SILVIU IANUC100% (1)

- Decinal To Metric ConversionDokument1 SeiteDecinal To Metric ConversionMalcolm DiamondNoch keine Bewertungen

- RAF ApprenticeDokument6 SeitenRAF ApprenticeMalcolm DiamondNoch keine Bewertungen

- Welding Abreviation and SymbolsDokument1 SeiteWelding Abreviation and SymbolsMalcolm DiamondNoch keine Bewertungen

- Metric and Pressure Conversion ChartDokument1 SeiteMetric and Pressure Conversion ChartMalcolm DiamondNoch keine Bewertungen

- US and Metric Standard UnitsDokument2 SeitenUS and Metric Standard UnitsMalcolm DiamondNoch keine Bewertungen

- Safe Shooting MapDokument2 SeitenSafe Shooting MapMalcolm DiamondNoch keine Bewertungen

- Project Libre TutorialDokument34 SeitenProject Libre TutorialMalcolm Diamond100% (1)

- Cisco Router WRT160N v2Dokument38 SeitenCisco Router WRT160N v2SDaroosterNoch keine Bewertungen

- Things Every Press Brake Operator Should KnowDokument4 SeitenThings Every Press Brake Operator Should KnowMalcolm DiamondNoch keine Bewertungen

- 4140 HandoutDokument5 Seiten4140 HandoutMalcolm DiamondNoch keine Bewertungen

- SS SinksDokument8 SeitenSS SinksMalcolm DiamondNoch keine Bewertungen

- Welding Inspection and CertificationDokument30 SeitenWelding Inspection and CertificationtuvuNoch keine Bewertungen

- Corona Checklist Teaching OnlineDokument10 SeitenCorona Checklist Teaching OnlineMalcolm DiamondNoch keine Bewertungen

- Project Libre TutorialDokument36 SeitenProject Libre TutorialMalcolm DiamondNoch keine Bewertungen

- Chapter 1 - Welding DefinedDokument2 SeitenChapter 1 - Welding DefinedAnonymous dh6DITNoch keine Bewertungen

- AWS D1.1 Table 5.8 & 5.9 Exam QuestionsDokument2 SeitenAWS D1.1 Table 5.8 & 5.9 Exam QuestionsMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Skewed T-Joint Exam QuestionsDokument3 SeitenAWS D1.1 Skewed T-Joint Exam QuestionsMalcolm DiamondNoch keine Bewertungen

- DIY Bench Top Tubing BenderDokument17 SeitenDIY Bench Top Tubing BenderMalcolm DiamondNoch keine Bewertungen

- Frame Jig Assembly GuideDokument12 SeitenFrame Jig Assembly GuideMalcolm DiamondNoch keine Bewertungen

- Rigid Bobber Frame Assembly GuideDokument15 SeitenRigid Bobber Frame Assembly GuideMalcolm Diamond100% (1)

- Chapter 1 - SelectionDokument1 SeiteChapter 1 - SelectionMalcolm DiamondNoch keine Bewertungen

- Chapter 1 - ProcessesDokument6 SeitenChapter 1 - ProcessesAnonymous dh6DITNoch keine Bewertungen

- The History of WeldingDokument18 SeitenThe History of WeldingMalcolm Diamond100% (1)

- Rigid Sportster Frame Assembly GuideDokument14 SeitenRigid Sportster Frame Assembly GuideMalcolm DiamondNoch keine Bewertungen

- Bike Lift Assembly GuideDokument15 SeitenBike Lift Assembly GuideMalcolm DiamondNoch keine Bewertungen

- Answers Short Test AnswersDokument2 SeitenAnswers Short Test AnswersMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Structural Welding Code - SteelDokument8 SeitenAWS D1.1 Structural Welding Code - SteelMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Short Code Tests #3Dokument4 SeitenAWS D1.1 Short Code Tests #3Malcolm DiamondNoch keine Bewertungen

- Calculating Development ErrorDokument6 SeitenCalculating Development ErrorMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Short Code Tests #4Dokument3 SeitenAWS D1.1 Short Code Tests #4Malcolm DiamondNoch keine Bewertungen

- MaterialData - 56973 2Dokument2 SeitenMaterialData - 56973 2red_beastNoch keine Bewertungen

- Cement Consistency and Setting Time PDFDokument5 SeitenCement Consistency and Setting Time PDFvelmurug_balaNoch keine Bewertungen

- Davco Grout 280 ECO - BROCHURE - 2 PDFDokument2 SeitenDavco Grout 280 ECO - BROCHURE - 2 PDFbenjaminNoch keine Bewertungen

- Cable Slickline SUPA 40Dokument1 SeiteCable Slickline SUPA 40Rafael EspinosaNoch keine Bewertungen

- 01 Energetics Notes 2022Dokument34 Seiten01 Energetics Notes 2022Waniya FaisalNoch keine Bewertungen

- 051223Dokument5 Seiten051223Lucas EmmanoelNoch keine Bewertungen

- Act 6 - Water Hardness Determination - WorksheetDokument4 SeitenAct 6 - Water Hardness Determination - WorksheetNitrogenNoch keine Bewertungen

- Distantieri GermanyDokument31 SeitenDistantieri Germanyrad701Noch keine Bewertungen

- Theoretical and Applied Fracture MechanicsDokument13 SeitenTheoretical and Applied Fracture MechanicsMario ChavezNoch keine Bewertungen

- Pouring Time CalculationDokument5 SeitenPouring Time CalculationKaarthicNatarajan100% (1)

- Work Inspection Request Template (Construction)Dokument4 SeitenWork Inspection Request Template (Construction)prerna93100% (1)

- Unit 3 Fabric PrintingDokument57 SeitenUnit 3 Fabric PrintingCarlo Gojo Cruz HalasanNoch keine Bewertungen

- Dga Hic Sohic PDFDokument16 SeitenDga Hic Sohic PDFEur-Ing Nicola GalluzziNoch keine Bewertungen

- Iso 8502 6 2006Dokument9 SeitenIso 8502 6 2006Evan YushavaNoch keine Bewertungen

- GSQ/M-20 Chemistry Paper XVIII (CH-304) Inorganic ChemistryDokument3 SeitenGSQ/M-20 Chemistry Paper XVIII (CH-304) Inorganic ChemistryDuryodhanNoch keine Bewertungen

- Operational and Process ParametersDokument58 SeitenOperational and Process Parametersalireza vahabiNoch keine Bewertungen

- Alloy Design For Additive Manufacturing: Eric. A. JägleDokument43 SeitenAlloy Design For Additive Manufacturing: Eric. A. JäglePopa Nicolea MirelaNoch keine Bewertungen

- Handbook For CLT Buildings en PDFDokument178 SeitenHandbook For CLT Buildings en PDFTanase MariusNoch keine Bewertungen

- Fundamentals of Mobile Heavy EquipmentDokument9 SeitenFundamentals of Mobile Heavy Equipmentwin min soeNoch keine Bewertungen

- Formulasi Sediaan Pasta Gigi Karbon Aktif DENGAN BASIS Virgin Coconut Oil (VCO)Dokument10 SeitenFormulasi Sediaan Pasta Gigi Karbon Aktif DENGAN BASIS Virgin Coconut Oil (VCO)Ghina Mukti LuthfiaNoch keine Bewertungen

- Furniture Design Terminology Part 1Dokument15 SeitenFurniture Design Terminology Part 1Majeda AbdNoch keine Bewertungen

- Australian Standard: Methods of Testing Concrete Method 2: Preparation of Concrete Mixes in The LaboratoryDokument3 SeitenAustralian Standard: Methods of Testing Concrete Method 2: Preparation of Concrete Mixes in The LaboratoryM. Gunawan BudisusilaNoch keine Bewertungen

- BS en 13238 2010Dokument14 SeitenBS en 13238 2010Yeung davidNoch keine Bewertungen

- Ramme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFDokument68 SeitenRamme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFerosNoch keine Bewertungen

- Paes 310Dokument9 SeitenPaes 310Jemina Jean Dorado SensanoNoch keine Bewertungen

- 03 Johnsonite Base Warranty PDFDokument1 Seite03 Johnsonite Base Warranty PDFmotaNoch keine Bewertungen

- 17AD100 Nexgear Tango Fabrication GuideDokument32 Seiten17AD100 Nexgear Tango Fabrication Guidekh9d676k6jNoch keine Bewertungen

- 7862 enDokument16 Seiten7862 enMarcus NguyễnNoch keine Bewertungen

- Kel F3 - Ca Laktat KompleksometriDokument10 SeitenKel F3 - Ca Laktat Kompleksometridavidkenny fanyNoch keine Bewertungen

- BT4 Guardhouse Specifications PDFDokument4 SeitenBT4 Guardhouse Specifications PDFFrancis Anne DoradoNoch keine Bewertungen

- Cyber War: The Next Threat to National Security and What to Do About ItVon EverandCyber War: The Next Threat to National Security and What to Do About ItBewertung: 3.5 von 5 Sternen3.5/5 (66)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityVon EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityBewertung: 5 von 5 Sternen5/5 (1)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (55)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- Generative AI: The Insights You Need from Harvard Business ReviewVon EverandGenerative AI: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (2)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessVon EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNoch keine Bewertungen

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyVon EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyBewertung: 3.5 von 5 Sternen3.5/5 (111)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziVon Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziNoch keine Bewertungen

- Demystifying Prompt Engineering: AI Prompts at Your Fingertips (A Step-By-Step Guide)Von EverandDemystifying Prompt Engineering: AI Prompts at Your Fingertips (A Step-By-Step Guide)Bewertung: 4 von 5 Sternen4/5 (1)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (227)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewVon EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (104)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldVon EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (107)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideVon EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideBewertung: 5 von 5 Sternen5/5 (2)

- Power and Prediction: The Disruptive Economics of Artificial IntelligenceVon EverandPower and Prediction: The Disruptive Economics of Artificial IntelligenceBewertung: 4.5 von 5 Sternen4.5/5 (38)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectVon EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectBewertung: 4.5 von 5 Sternen4.5/5 (20)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesVon EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Dark Data: Why What You Don’t Know MattersVon EverandDark Data: Why What You Don’t Know MattersBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesVon EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesNoch keine Bewertungen

- The Internet Con: How to Seize the Means of ComputationVon EverandThe Internet Con: How to Seize the Means of ComputationBewertung: 5 von 5 Sternen5/5 (6)

- AI Prompting Mastery: Strategies and Techniques for Effective PromptingVon EverandAI Prompting Mastery: Strategies and Techniques for Effective PromptingNoch keine Bewertungen