Beruflich Dokumente

Kultur Dokumente

(Cold Formed) : Steel Is Our Business

Hochgeladen von

cariterOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(Cold Formed) : Steel Is Our Business

Hochgeladen von

cariterCopyright:

Verfügbare Formate

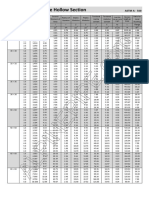

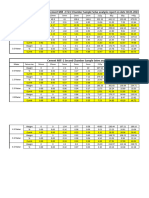

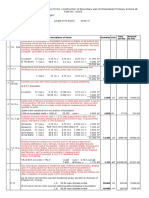

UNEQUAL ANGLE

PT. GUNUNG RAJA PAKSI

Steel Is Our Business

(COLD FORMED)

METRIC SIZE

STANDARD INFORMATIVE REFERENCE

SECTION

SECTIONAL UNIT CENTER GEOMETRICAL MOMENT RADIUS OF GYRATION MODULUS

AREA OF

DIMENSIONS WEIGHT GRAVITY OF INERTIA OF AREA OF SECTION

H x B t A Cx Cy Ix Iy Min Iu Min Iv ix iy Min iu Min iv Zx Zy

mm x mm mm cm2 kg/m cm cm cm4 cm4 cm4 cm4 cm cm cm cm cm3 cm3

3.0 4.05 3.18 2.43 1.42 27.29 13.53 33.99 6.83 2.60 1.83 2.90 1.30 4.90 2.95

80 x 60 3.5 4.70 3.69 2.46 1.44 31.47 15.57 39.22 7.82 2.59 1.82 2.89 1.29 5.68 3.42

4.0 5.34 4.19 2.48 1.46 35.54 17.56 44.32 8.78 2.58 1.81 2.88 1.28 6.44 3.87

5.0 6.59 5.17 2.53 1.51 43.38 21.37 54.16 10.59 2.57 1.80 2.87 1.27 7.93 4.76

3.0 4.56 3.65 3.28 1.25 50.04 14.37 56.20 8.21 3.28 1.76 3.51 1.33 7.44 3.03

3.5 5.40 4.24 3.30 1.28 57.79 16.56 64.93 9.42 3.27 1.75 3.47 1.32 8.63 3.50 Y

100 x 60 4.0 6.14 4.82 3.33 1.30 65.37 18.68 73.46 10.59 3.26 1.74 3.46 1.31 9.80 3.97

V U

5.0 7.59 5.96 3.38 1.34 80.05 22.76 89.99 12.82 3.25 1.73 3.44 1.30 12.10 4.89

6.0 9.01 7.07 3.44 1.38 94.09 26.63 105.82 14.90 3.23 1.72 3.43 1.29 14.33 5.77 H

3.0 5.25 4.12 2.92 1.91 55.25 32.12 71.79 15.58 3.24 4.27 3.70 1.72 7.80 5.27 X

Cx

3.5 6.10 4.79 2.95 1.93 63.87 37.10 83.05 17.92 3.24 2.47 3.69 1.71 9.05 6.11

100 x 80 4.0 6.94 5.45 2.97 1.95 72.32 41.97 94.10 20.19 3.23 2.46 3.68 1.71 10.29 6.94 Cy

U V

5.0 8.59 6.74 3.02 2.00 88.75 51.40 115.61 24.54 3.21 2.45 3.67 1.69 12.71 8.57 Y

B

6.0 10.21 8.01 3.07 2.04 104.53 60.43 136.32 28.64 3.20 2.43 3.65 1.67 15.08 10.15

3.0 6.15 4.83 5.53 0.98 149.61 15.77 155.08 10.30 4.93 1.60 5.02 1.29 15.79 3.14

3.5 7.15 5.61 5.56 1.01 173.18 18.17 179.50 11.85 4.92 1.59 5.01 1.29 18.34 3.64

150 x 60 4.0 8.14 6.39 5.58 1.03 196.36 20.52 203.53 13.35 4.91 1.59 5.00 1.28 20.86 4.13

5.0 10.09 7.92 5.64 1.07 241.58 25.05 250.39 16.24 4.89 1.58 4.98 1.27 25.81 5.08 TOLERANCE (mm)

6.0 12.01 9.43 5.70 1.11 285.26 29.36 295.64 18.98 4.87 1.56 4.96 1.26 30.67 6.01 t H, B

3.0 6.75 5.30 5.05 1.52 165.42 35.75 179.67 21.50 4.95 2.30 5.16 1.78 16.62 5.52 + 0.5 +2

3.5 7.85 6.16 5.08 1.54 191.65 41.31 208.17 24.79 4.94 2.29 5.15 1.78 19.31 6.40

150 x 80 4.0 8.94 7.02 5.10 1.56 217.49 46.77 236.26 28.00 4.93 2.29 5.14 1.77 21.97 7.27

5.0 11.09 8.70 5.16 1.60 268.05 57.38 291.24 34.19 4.92 2.27 5.12 1.76 27.23 8.97

1. Non standard length is available request

6.0 13.21 10.37 5.21 1.65 317.11 67.57 344.60 40.08 4.90 2.26 5.11 1.74 32.39 10.64 subject to minimum quantity

2. We provide additional services for

HEAD OFFICE & FACTORY

4.0 10.94 8.59 7.37 1.31 472.85 49.83 490.14 32.54 6.58 2.13 6.69 1.72 37.44 7.45 standard drilling and punching (for detail,

120 x 80 5.0 13.59 10.67 7.43 1.36 584.12 61.17 605.45 39.84 6.56 2.12 6.67 1.71 46.46 9.21 please refer to “standard drilling /

Jl. Imam Bonjol 4, Warung Bongkok,

punching for lip channel” data sheet)

Sukadanau, Cikarang Barat, 6.0 16.21 12.72 7.48 1.40 692.66 72.11 717.94 46.83 6.54 2.11 6.66 1.70 55.34 10.92 3. Shot blasting, painting and galvanizing

Bekasi 17520, West Java, INDONESIA are available on request

Forming Department

TECHNICAL SPECIFICATION

Phone DID : (62-21) 898 38 291 - 296

Phone Flexy : (021) 7085 3154 - 158 Material : JIS G3101, JIS 3131 Technical data : Yield point : 25 kg/mm2 (minimum)

Symbol : SS 400, SPHC Tensile Strength 41-55 kg/mm2

Fax. : (62-21) 898 38 298 Chemical Component : C. 0.25% (Maximum) Standard length : 6.00 m

e-mail : pjl01@grdsteel.com P. 0.05% (Maximum)

S. 0.05% (Maximum)

pjl02@grdsteel.com

Grade : SS 400, SPHC www.grdsteel.com

Das könnte Ihnen auch gefallen

- List RDSO DrawingsDokument52 SeitenList RDSO Drawingsprasagnihotri75% (4)

- Interior Work Tender BOQ - Revised SummaryDokument1 SeiteInterior Work Tender BOQ - Revised Summarymisipl00750% (2)

- GRP UNEQUAL ANGLE (Cold Formed)Dokument1 SeiteGRP UNEQUAL ANGLE (Cold Formed)Bagus KrisnawanNoch keine Bewertungen

- 19 - Unequal Angle (Cold Formed) PDFDokument1 Seite19 - Unequal Angle (Cold Formed) PDFIdaa Saida RasmiNoch keine Bewertungen

- GRP Unequal Angle (Cold Formed)Dokument1 SeiteGRP Unequal Angle (Cold Formed)Nurul LailyahNoch keine Bewertungen

- Carbon Steel Rectangular Pipes For General Structural PurposesDokument2 SeitenCarbon Steel Rectangular Pipes For General Structural Purposescurt volvoNoch keine Bewertungen

- Carbon Steel Rectangular Pipes: For General Structural PurposesDokument2 SeitenCarbon Steel Rectangular Pipes: For General Structural Purposesibson045001256Noch keine Bewertungen

- Section Properties of Tata Structura (Rectangular Hollow SectionsDokument2 SeitenSection Properties of Tata Structura (Rectangular Hollow SectionsSudipta Sarkar100% (1)

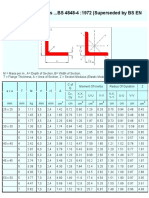

- Section Properties - Dimensions & Properties - Blue Book - Steel For LifeDokument1 SeiteSection Properties - Dimensions & Properties - Blue Book - Steel For LifeDoroftei CiprianNoch keine Bewertungen

- Tropmh Curve3Dokument2 SeitenTropmh Curve3MuhammadShoaibNoch keine Bewertungen

- Ringformationinkilns 140529065933 Phpapp01Dokument2 SeitenRingformationinkilns 140529065933 Phpapp01Abul Qasim QasimNoch keine Bewertungen

- Consteel Hot Finished Hollow SectionsDokument13 SeitenConsteel Hot Finished Hollow SectionsAnonymous dWa1xtpKmfNoch keine Bewertungen

- Angle PDFDokument1 SeiteAngle PDFWai Wai LeeNoch keine Bewertungen

- Advance® UKA - Equal: Dimensions and PropertiesDokument1 SeiteAdvance® UKA - Equal: Dimensions and PropertiesWai Wai LeeNoch keine Bewertungen

- Section Properties: Properties of Tata Structura (Rectangular Hollow Sections) YST 310 GradeDokument2 SeitenSection Properties: Properties of Tata Structura (Rectangular Hollow Sections) YST 310 GradeSudipta SarkarNoch keine Bewertungen

- Wing - Updated Dimensions - Jan 23 2017Dokument5 SeitenWing - Updated Dimensions - Jan 23 2017Karteek RaghuNoch keine Bewertungen

- Carbon Steel Pipe Dimension Tolerance ChartDokument3 SeitenCarbon Steel Pipe Dimension Tolerance Chartsaravoot_jNoch keine Bewertungen

- Book - Steel TableDokument120 SeitenBook - Steel Tablevisarut100% (1)

- Tata Hallow Steel SectionsDokument9 SeitenTata Hallow Steel Sectionsrangarajan100% (1)

- Astm A500 SHS 1Dokument4 SeitenAstm A500 SHS 1Wong JowoNoch keine Bewertungen

- Light Lip Pped ChannelDokument3 SeitenLight Lip Pped ChannelArif RusyanaNoch keine Bewertungen

- OMS17-3328 Pocket Blast Guide CS6 2021 WebDokument66 SeitenOMS17-3328 Pocket Blast Guide CS6 2021 Webyanromulo@gmail.com100% (1)

- Single-Span Support: Negative PositionDokument1 SeiteSingle-Span Support: Negative PositionmikeshiiNoch keine Bewertungen

- Astm A500-3Dokument1 SeiteAstm A500-3asnawi89Noch keine Bewertungen

- Formula Perhitungan SP 08 BLPDokument50 SeitenFormula Perhitungan SP 08 BLPImam GozaliNoch keine Bewertungen

- Standard Sectional Dimension of Equal Angle Steel and Its Sectional PropertiesDokument3 SeitenStandard Sectional Dimension of Equal Angle Steel and Its Sectional PropertiesTantyNoch keine Bewertungen

- BombeoDokument17 SeitenBombeoNicolas Cediel LopezNoch keine Bewertungen

- RectangularPipe PDFDokument2 SeitenRectangularPipe PDFAndhika MaulanaNoch keine Bewertungen

- Rectangular Pipe Specifications and PropertiesDokument2 SeitenRectangular Pipe Specifications and PropertiesYohan S.Noch keine Bewertungen

- Brosur Baja Gunung Raja Paksi Rectangular PipeDokument2 SeitenBrosur Baja Gunung Raja Paksi Rectangular PipeRobbi Shobri Rakhman100% (1)

- Rectangular PipeDokument2 SeitenRectangular PipeDeri FerdinaNoch keine Bewertungen

- P WC Cat Ed 10 Page 172 2Dokument1 SeiteP WC Cat Ed 10 Page 172 2Satisfying VdoNoch keine Bewertungen

- Carbon Steel Pipe and Rectangular Tube Dimension ChartDokument41 SeitenCarbon Steel Pipe and Rectangular Tube Dimension Chartสิทธิชัย หอมจรรย์Noch keine Bewertungen

- Vane Shear Log AnalysisDokument3 SeitenVane Shear Log AnalysisAndrianto Handoko NugrohoNoch keine Bewertungen

- Carbon Steel Square Tubes GuideDokument1 SeiteCarbon Steel Square Tubes GuideDio Rian PrambudiNoch keine Bewertungen

- JIS G3466 - Thailand - CONTENT1011579693989745Dokument1 SeiteJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngNoch keine Bewertungen

- Hollow Rectangular Section: X X X y y y M T / 2 4 3 4 3 4 - 2 2 / 2Dokument1 SeiteHollow Rectangular Section: X X X y y y M T / 2 4 3 4 3 4 - 2 2 / 2Alden CayagaNoch keine Bewertungen

- Square and Rectangular SectionsDokument2 SeitenSquare and Rectangular SectionsThe rock newNoch keine Bewertungen

- Cement Mill-2 Chamber Sample 30.01.2024Dokument6 SeitenCement Mill-2 Chamber Sample 30.01.2024suryansh agnihotriNoch keine Bewertungen

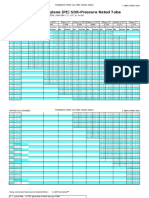

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDokument24 SeitenPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsqastroqNoch keine Bewertungen

- Section Properties: Properties of Tata Structura (Square Hollow Sections) YST 310 GradeDokument2 SeitenSection Properties: Properties of Tata Structura (Square Hollow Sections) YST 310 GradeSudipta SarkarNoch keine Bewertungen

- Data Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fDokument4 SeitenData Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fFuneral Shop NilaNoch keine Bewertungen

- EN 10210 S355J2H Properties Hot Formed Circular Hollow SectionsDokument3 SeitenEN 10210 S355J2H Properties Hot Formed Circular Hollow SectionsBobNobbitsNoch keine Bewertungen

- Wave Contact Width and Contact Time-4Dokument4 SeitenWave Contact Width and Contact Time-4smtdrkdNoch keine Bewertungen

- High Tensile C Purlin: Steel Grade Equivalent To ASTM 446 Grade DDokument2 SeitenHigh Tensile C Purlin: Steel Grade Equivalent To ASTM 446 Grade DRodolfo ZazuetaNoch keine Bewertungen

- Square Hs Final EnglishDokument3 SeitenSquare Hs Final EnglishVasilis LappasNoch keine Bewertungen

- L Angle Data SheetDokument2 SeitenL Angle Data SheetSaleem BashaNoch keine Bewertungen

- Steel ListDokument11 SeitenSteel Listchhay longNoch keine Bewertungen

- Polyethylene friction loss chartDokument18 SeitenPolyethylene friction loss chartprasadnn2001Noch keine Bewertungen

- Steel Designers' Manual - Dimensions and Properties of Cold-Formed Square Hollow SectionsDokument1 SeiteSteel Designers' Manual - Dimensions and Properties of Cold-Formed Square Hollow SectionsEndot Junior100% (1)

- (Gratis) Tabel Baja Lengkap ExcelDokument26 Seiten(Gratis) Tabel Baja Lengkap ExcelIsa PurbayuNoch keine Bewertungen

- PDA001Way Galih Sindang Sari Tanjung Bintang (Version 1)Dokument80 SeitenPDA001Way Galih Sindang Sari Tanjung Bintang (Version 1)mukhlisNoch keine Bewertungen

- Cornier cu laturi inegaleDokument2 SeitenCornier cu laturi inegalePal BarniNoch keine Bewertungen

- TA VI JEMBATAN XLSXDokument66 SeitenTA VI JEMBATAN XLSXboonico NiccoNoch keine Bewertungen

- Data Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fDokument3 SeitenData Set 13b: New Feed To Cyclone BM CCT Feed Cyclone Feed Cyclone U/f BM Discharge Cyclone O/fMarko Meneses PlascenciaNoch keine Bewertungen

- L ProfileDokument2 SeitenL ProfileHang Nguyen ThiNoch keine Bewertungen

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesVon EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesBewertung: 5 von 5 Sternen5/5 (3)

- 101 Reasons Why I Lost My Homework Again: The Snotty SnailVon Everand101 Reasons Why I Lost My Homework Again: The Snotty SnailNoch keine Bewertungen

- Econolite CastableDokument1 SeiteEconolite CastableJosue MorenoNoch keine Bewertungen

- Astm D3163 01 2023Dokument2 SeitenAstm D3163 01 2023Georgiy MakedonovNoch keine Bewertungen

- Urban Open SpacesDokument49 SeitenUrban Open SpacesRitika RituNoch keine Bewertungen

- Common SCDF Audit IssuesDokument48 SeitenCommon SCDF Audit IssuesSheilly SheillyNoch keine Bewertungen

- News 01 08 01 2019 PDFDokument109 SeitenNews 01 08 01 2019 PDFShaileshRastogiNoch keine Bewertungen

- J4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Dokument43 SeitenJ4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Boy LiverpoolNoch keine Bewertungen

- DEAP Manual Version 4.2.3 FinalDokument212 SeitenDEAP Manual Version 4.2.3 FinalSean WalshNoch keine Bewertungen

- Precast Concrete Girder BridgesDokument30 SeitenPrecast Concrete Girder BridgesPacha Khan KhogyaniNoch keine Bewertungen

- Shear and Moment Diagrams for Structural FramesDokument2 SeitenShear and Moment Diagrams for Structural FramesAndrei AlidoNoch keine Bewertungen

- Vernacular ArchitectureDokument22 SeitenVernacular ArchitectureSharmae Rongavilla100% (1)

- Panel ZonesDokument10 SeitenPanel ZonesGabriel PatileaNoch keine Bewertungen

- 2034 Kshirsagar Kunal (Cafeteria)Dokument32 Seiten2034 Kshirsagar Kunal (Cafeteria)RISHABH JAISWAL0% (1)

- Reinterpreting Vernacular Architecture Through Contemporary.Dokument27 SeitenReinterpreting Vernacular Architecture Through Contemporary.kansha23010% (1)

- Foundation PresentationDokument34 SeitenFoundation PresentationAbubakar Ashraf AnjumNoch keine Bewertungen

- AAHE Bibo BrochureDokument16 SeitenAAHE Bibo BrochureBANGUN RAHMAT TEKNIKNoch keine Bewertungen

- Sleepers (RBT)Dokument85 SeitenSleepers (RBT)Shonak G PurohitNoch keine Bewertungen

- Chapter 1 - 5 PDFDokument43 SeitenChapter 1 - 5 PDFYARLAGADDA_NANINoch keine Bewertungen

- Design of PurlinsDokument7 SeitenDesign of Purlinsjiyad100% (1)

- Proper Handling and Installation of Diaphragm Seal SystemsDokument0 SeitenProper Handling and Installation of Diaphragm Seal Systemsyousaf_zai_khan81995Noch keine Bewertungen

- Architectural Record - 06 - 2023Dokument208 SeitenArchitectural Record - 06 - 2023Roumen DonevNoch keine Bewertungen

- Environment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterDokument1 SeiteEnvironment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterAndrew RobertsNoch keine Bewertungen

- WWT6 - Colection and Conveyance of SewageDokument37 SeitenWWT6 - Colection and Conveyance of SewageHelder MbidiNoch keine Bewertungen

- Crackwidth For Wall (Combined Bending and Tension)Dokument3 SeitenCrackwidth For Wall (Combined Bending and Tension)mukhleshNoch keine Bewertungen

- Boundary Wall NIT 3-1Dokument2 SeitenBoundary Wall NIT 3-1Er Soumen Dey KhanNoch keine Bewertungen

- Checklist For Preliminary Bridge DesignDokument2 SeitenChecklist For Preliminary Bridge DesignbkgossNoch keine Bewertungen

- Study - Id116925 - Construction Costs in The United Kingdom UkDokument49 SeitenStudy - Id116925 - Construction Costs in The United Kingdom Ukmohamed-yahya.taifNoch keine Bewertungen

- Cengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 3Dokument1 SeiteCengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 3Benjamin EngelNoch keine Bewertungen