Beruflich Dokumente

Kultur Dokumente

Slegten Opticontrol PDF

Hochgeladen von

jorge1947Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Slegten Opticontrol PDF

Hochgeladen von

jorge1947Copyright:

Verfügbare Formate

GRINDING

®

OPTICONTROL :

THE ORIGINAL INTERMEDIATE

FLOWCONTROL DIAPHRAGM

THE MAGOTTEAUX/

SLEGTEN CONCEPT

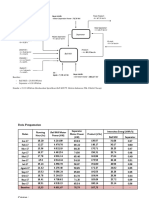

To adapt the level of material in the mill’s first

chamber by regulating the level of material contai-

ned in the diaphragm itself using a unique inte-

grated adjustable scoops controlling mechanism.

Mag_fichetech_OPTICONTROL_V3.indd 1 18/09/08 16:25:47

GRINDING

®

OPTICONTROL :

A UNIQUE, RELIABLE &

PERFORMING EQUIPMENT…

THE CHALLENGE

Insure the right amount of material in the mill first

chamber to maximize grind and throughput. OUR ADJUSTABLE

It is difficult to achieve it adequately without regu-

lating the amount of material in the diaphragm.

& INTEGRATED

SCOOP DESIGN

Modifying the level of material in the diaphragm

is attained with the use of our adjustable scoops

that are integrated in our Opticontrol®.

Without regulation

The diaphragm is getting empty:

insufficient material load in 1st cpt

REGULATION

OF MATERIAL

AMOUNT IN THE

DIAPHRAGM

Our design is based on the following principle:

Material level in 1st cpt next to diaphragm =

material level in the diaphragm as opening

slots in red are choked by the material in the

diaphragm in order to better fill 1st cpt,

the level is to be raised IN the diaphragm.

Mag_fichetech_OPTICONTROL_V3.indd 2 18/09/08 16:26:02

GRINDING

®

OPTICONTROL :

FOR EXCELLENCE IN PROCESS

In position A, the scoop “rakes” a small In position B, the scoop faces a wide

surface S but on a major height H. surface S but on a short height H.

By revolving the scoop by 90° (from position • Frame bolted to the shell.

B to position A), material level rises in • Sectors are pre-assembled in our workshops.

the diaphragm as well as in the 1st cpt. Welding on-site (to frame) is reduced

In both cases, the flow of material going to 2nd to a minimum;

cpt remains unchanged i.e. O = S x H = S x H. • Independant sole easy installation

Each scoop discharges its own out- even in a deformed mill shell.

put in the second chamber.

The result is a “loaded” diaphragm with, as a

consequence, a higher material filling degree in

THE OPTICONTROL ®

the 1st cpt whatever the permeability or density WEAR PARTS

of the 1st cpt grinding charge is and indepen- 1. Grates

dent of the size of the diaphragm grates slots. • Cast steel

• Hardness (core) = 52HRc

THE OPTICONTROL ® • Thickness = 50mm + lifter

• “Anti-leakage” overlapping system

FRAME 2. Backside plates*

The reliability of our Opticontrol® is guaranteed by • Cast iron

a top design and robust frame. • 13% hard carbides

• Thickness = 40mm + lifter

• ST 52.3 steel (in some cases, we recommend

• “Anti-leakage” overlapping system

one of our cast stainless steel);

* in the case of highly ventilated mills, we suggest to also equip backside of diaphragm

• Independent sectors (welded to the frame during with grates

installation) allows for several millimeters

deformation on the mill shell during rotation; 3. Air screen

• Strong structure of sectors (Ι-shaped); • Special wear-resistant alloy

Mag_fichetech_OPTICONTROL_V3.indd 3 18/09/08 16:26:02

GRINDING

OPTICONTROL® :

FOR YOUR BENEFIT

YOUR ADVANTAGE YOUR AVAILABLE

From a process viewpoint OPTIONS

1. Stainless steel cast frame

• Maximized performance in terms of t/h and 2. Reinforced bolt protection tubes in case of high

kWh/t abrasion material

• Material regulation independent from wear 3. Air screen with inspection door

mechanism remains constant in time hence 4. Backside grates in case of high air flow

keeping mill performance at optimum level 5. Grate slot sizes from 5 to 16mm

• Design ensures that no unground material

passes to 2nd cpt thanks to closed meshed

control screen and overlapping grates

• Design guarantees minimum air pressure drop

thanks to broad air screen and optimum size

grate slots

• Position of diaphragm determined by prior

Magotteaux circuit audit to ensure optimum 1st &

2nd cpt lengths

From a mechanical viewpoint

• Robust, reliable & flexible frame the design of

which allows composing elements to move and

absorb stresses

• Long lasting wear parts thanks to Magotteaux

alloys and castings design

• More than 2000 Opticontrol® installed so far

From an installation viewpoint

• Simple, quick & safe to install

• Reduced manpower during installation due to

preassembly in our workshops

In 3 words:

Performance, Reliability &

Reduced Overall Operating

Cost per ton produced

The information and data in this data sheet are accurate to the best of our

knowledge. They are intended for general information only. Applications

as suggested are described only to help readers make their own

assessment. They are neither guarantees nor to be construed as express or

implied warranties of suitability for these or other applications.

Mag_fichetech_OPTICONTROL_V3.indd 4 18/09/08 16:26:03

Das könnte Ihnen auch gefallen

- Overview of plant equipment trainingDokument31 SeitenOverview of plant equipment trainingДен СтаднікNoch keine Bewertungen

- Loesche Grinding Plants for Coal GasificationDokument45 SeitenLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- PFC - The Great CoolerDokument47 SeitenPFC - The Great CoolerM.IBRAHEEM100% (1)

- 15th NCB Technical PaperDokument10 Seiten15th NCB Technical PaperSalah RomdaniNoch keine Bewertungen

- Comminution 2Dokument159 SeitenComminution 2Kumar RajeshNoch keine Bewertungen

- 23 HaverDokument36 Seiten23 HaverkonstantasNoch keine Bewertungen

- D1P3-Mill Feed CharacteristicsDokument23 SeitenD1P3-Mill Feed CharacteristicsYhaneNoch keine Bewertungen

- Course 3 – Clinker Production FuelsDokument26 SeitenCourse 3 – Clinker Production FuelsAVcheerNoch keine Bewertungen

- Gear and equipment specification summaryDokument4 SeitenGear and equipment specification summaryprashant mishraNoch keine Bewertungen

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDokument6 SeitenGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- 154 Loesche Mills For Cement Raw Material E 2016Dokument28 Seiten154 Loesche Mills For Cement Raw Material E 2016faheemqcNoch keine Bewertungen

- 3-Days Training Course: September 26-28, 2011Dokument50 Seiten3-Days Training Course: September 26-28, 2011chibssa alemayehuNoch keine Bewertungen

- Impact of Process Parameters On QualityDokument25 SeitenImpact of Process Parameters On QualityDineshNoch keine Bewertungen

- Conveying SystemDokument33 SeitenConveying SystemYhaneNoch keine Bewertungen

- 9 - RAWGRINDING CementDokument28 Seiten9 - RAWGRINDING CementAnoop Tiwari100% (2)

- Coal Mill Wear Measurement 29.09.2014Dokument1 SeiteCoal Mill Wear Measurement 29.09.2014Durga PrasadNoch keine Bewertungen

- Atox 20 Coal Mill Critical Interlock SheetDokument6 SeitenAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNoch keine Bewertungen

- Kiln Mechanics Basics Action PlanDokument5 SeitenKiln Mechanics Basics Action PlanDiego AlejandroNoch keine Bewertungen

- VDZ - 0 - 0 - En-From Cement Production To ConcreteDokument34 SeitenVDZ - 0 - 0 - En-From Cement Production To ConcreteAndreea Ștefura100% (1)

- AUMUND Pan Conveyors Fd0a10Dokument24 SeitenAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Proceedings Rev A English - Print ResDokument130 SeitenProceedings Rev A English - Print ResRaúl Marcelo Veloz100% (1)

- Vertical Roller Mill State of The Art Raw GrindingDokument4 SeitenVertical Roller Mill State of The Art Raw GrindingzementheadNoch keine Bewertungen

- Ball Mill OptimiztionDokument8 SeitenBall Mill OptimiztionShakil AhmadNoch keine Bewertungen

- Cement Mill Grinding Media Wear Rate Calculation PDFDokument2 SeitenCement Mill Grinding Media Wear Rate Calculation PDFBùi Hắc HảiNoch keine Bewertungen

- Ball Mill GrindingDokument78 SeitenBall Mill GrindingFran jimenezNoch keine Bewertungen

- Neraca Massa dan Energi Ball Mill dan SeparatorDokument10 SeitenNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanNoch keine Bewertungen

- Ball Charge Design Methods GuideDokument12 SeitenBall Charge Design Methods GuidePaulo VidasNoch keine Bewertungen

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDokument1 SeiteRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanNoch keine Bewertungen

- VRM - PaperDokument9 SeitenVRM - PaperJoko Dewoto100% (1)

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDokument5 SeitenGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Visual inspection of HPGR rollers manualDokument1 SeiteVisual inspection of HPGR rollers manualRAVINoch keine Bewertungen

- CPB Brochure Diaphragms en 2Dokument12 SeitenCPB Brochure Diaphragms en 2ebrahimNoch keine Bewertungen

- MHR21924 CMC Chapter CCDokument48 SeitenMHR21924 CMC Chapter CCDede KaladriNoch keine Bewertungen

- KHD Praesentation ZementDokument19 SeitenKHD Praesentation ZementAnonymous Cxriyx9HIXNoch keine Bewertungen

- New Hardware Grinding Aid - ECOFORDokument5 SeitenNew Hardware Grinding Aid - ECOFORlovjnxNoch keine Bewertungen

- Polysiushpgr (HPGR)Dokument20 SeitenPolysiushpgr (HPGR)Alexis GodoyNoch keine Bewertungen

- Factors Influencing The Grinding EfficiencyDokument27 SeitenFactors Influencing The Grinding Efficiencygrameshkreddy2013Noch keine Bewertungen

- PR RFR P06-06 v1-1 How To Ensure Safety For Brick CuttingDokument6 SeitenPR RFR P06-06 v1-1 How To Ensure Safety For Brick CuttingJuan Nacimba NacimbaNoch keine Bewertungen

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDokument44 SeitenGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Determination of The Nip Zone Angle in High-Pressure Grinding RollsDokument12 SeitenDetermination of The Nip Zone Angle in High-Pressure Grinding RollsKroya HunNoch keine Bewertungen

- 00 Introduction Polysius-HistoryDokument17 Seiten00 Introduction Polysius-HistoryEnrique BandaNoch keine Bewertungen

- Cement Milling I Blue Circle PDFDokument24 SeitenCement Milling I Blue Circle PDFIrshad HussainNoch keine Bewertungen

- VDZ-Onlinecourse 2 2 en PDFDokument22 SeitenVDZ-Onlinecourse 2 2 en PDFAnonymous iI88LtNoch keine Bewertungen

- 09.30 Cemengal Tanger BK6 FDDokument18 Seiten09.30 Cemengal Tanger BK6 FDMohd AliNoch keine Bewertungen

- 08 Polycom InspectionDokument33 Seiten08 Polycom InspectionAnita Fernandez C.100% (3)

- Monitoring, Inspection & Evaluation of Ball Cement MillsDokument6 SeitenMonitoring, Inspection & Evaluation of Ball Cement MillsMin MCLNoch keine Bewertungen

- Precalciner Kilns Systems & OperationDokument58 SeitenPrecalciner Kilns Systems & OperationYhaneNoch keine Bewertungen

- Rotary Kiln Reconditioning Tyre and Roller GrindingDokument8 SeitenRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposNoch keine Bewertungen

- A4-P 1.0 enDokument21 SeitenA4-P 1.0 enmkpqNoch keine Bewertungen

- Energy Efficiency with IKN Pendulum CoolerDokument28 SeitenEnergy Efficiency with IKN Pendulum CoolerJunaid MazharNoch keine Bewertungen

- Cooler ETA Vs Grate JG (Dokument39 SeitenCooler ETA Vs Grate JG (NaelNoch keine Bewertungen

- Presentation-Hydraulic System in VRPMDokument24 SeitenPresentation-Hydraulic System in VRPMmsvprasadNoch keine Bewertungen

- Bogiflex KGD20 - For PlantDokument13 SeitenBogiflex KGD20 - For PlantAnonymous PVXBGg9TNoch keine Bewertungen

- Kiln Readings 23 06 17Dokument4 SeitenKiln Readings 23 06 17zain140Noch keine Bewertungen

- Installation - Gocht 2015Dokument208 SeitenInstallation - Gocht 2015vũ minh tâm100% (1)

- R A R F U: % Passing Size, M Feed Coarse FinesDokument3 SeitenR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNoch keine Bewertungen

- Alternative To "Cork" Isolation at Pump PlinthDokument4 SeitenAlternative To "Cork" Isolation at Pump PlinthMahmoud El-KatebNoch keine Bewertungen

- Hanwha Q CELLS Data Sheet QPEAK-G3 265-280Dokument2 SeitenHanwha Q CELLS Data Sheet QPEAK-G3 265-280manishpunjabi269Noch keine Bewertungen

- 92 Fiche Optiflow Magotteaux LRDokument2 Seiten92 Fiche Optiflow Magotteaux LRChristian CastilloNoch keine Bewertungen

- TDS LF-375Dokument2 SeitenTDS LF-375Ofer ShochetNoch keine Bewertungen

- Ball Mill Inspection ProcedureDokument28 SeitenBall Mill Inspection ProcedureRolando Quispe100% (6)

- CASAR - Wire Rope End ConnectionsDokument76 SeitenCASAR - Wire Rope End ConnectionsSholhan Aziz100% (4)

- Lime Kiln Principles and OperationsDokument0 SeitenLime Kiln Principles and OperationsDaniel Alexander Osorio MartinezNoch keine Bewertungen

- Belt Conveyor Design-DunlopDokument161 SeitenBelt Conveyor Design-Dunlopadi_ganteng12100% (36)

- Steel Threaded Pipe Fittings: British Standard Bs en 10241:2000Dokument34 SeitenSteel Threaded Pipe Fittings: British Standard Bs en 10241:2000jorge1947Noch keine Bewertungen

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Dokument11 SeitenBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxNoch keine Bewertungen

- Cement Grinding OPtimizationDokument13 SeitenCement Grinding OPtimizationTgemunuNoch keine Bewertungen

- Guidelines For Solid FuelsDokument81 SeitenGuidelines For Solid Fuelsjorge1947Noch keine Bewertungen

- Sample - Belt Bucket Elevator DesignDokument7 SeitenSample - Belt Bucket Elevator Designmfhasnain100% (1)

- Effect of Solution Annealing Heat Treatm PDFDokument3 SeitenEffect of Solution Annealing Heat Treatm PDFaltieri1Noch keine Bewertungen

- Product Range - Priminox.Dokument1 SeiteProduct Range - Priminox.Farooq GoundiNoch keine Bewertungen

- ASTM A249 Stainless Steel TubesDokument10 SeitenASTM A249 Stainless Steel TubesLe VinhNoch keine Bewertungen

- Types of Welding DefectsDokument7 SeitenTypes of Welding DefectsPradip Erande100% (1)

- SSP Rotary Lobe Pump Databook PDFDokument94 SeitenSSP Rotary Lobe Pump Databook PDFVishal SalveNoch keine Bewertungen

- Welding Procedure Specification (WPS)Dokument6 SeitenWelding Procedure Specification (WPS)Mohamad Marwan HamwiNoch keine Bewertungen

- Heaters PDFDokument624 SeitenHeaters PDFReza JabbarzadehNoch keine Bewertungen

- Isi Handbook For Structural Engineers PDFDokument124 SeitenIsi Handbook For Structural Engineers PDFRoyer JuarezNoch keine Bewertungen

- Cast Iron Valves: JIS 5K/10K, Class 125Dokument20 SeitenCast Iron Valves: JIS 5K/10K, Class 125Alexjohn2009Noch keine Bewertungen

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Dokument2 SeitenAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNoch keine Bewertungen

- Astm A999Dokument12 SeitenAstm A999Gustavo FreitasNoch keine Bewertungen

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDokument6 SeitenNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification Forakib belNoch keine Bewertungen

- Thermal Insulation SpecificationDokument46 SeitenThermal Insulation SpecificationJohn GilNoch keine Bewertungen

- Boegger Industrial LimitedDokument7 SeitenBoegger Industrial Limitedshusongdai78Noch keine Bewertungen

- Properties of MatterDokument4 SeitenProperties of MatterUbeia Estrella PerezNoch keine Bewertungen

- Astm A99-82-2000Dokument3 SeitenAstm A99-82-2000NadhiraNoch keine Bewertungen

- ASME SA213M / SA213 T9 Seamless Alloy Steel TubesDokument7 SeitenASME SA213M / SA213 T9 Seamless Alloy Steel TubesJayminNoch keine Bewertungen

- Insulating Coatings For Electrical Steels by Composition, Relative Insulating Ability and ApplicationDokument4 SeitenInsulating Coatings For Electrical Steels by Composition, Relative Insulating Ability and ApplicationjalilemadiNoch keine Bewertungen

- Racing Sports Car Chassis Design - 0837602963Dokument167 SeitenRacing Sports Car Chassis Design - 0837602963dineshtej7768100% (23)

- Long seam weld estimationDokument16 SeitenLong seam weld estimationTiago FerreiraNoch keine Bewertungen

- DCVG PDFDokument215 SeitenDCVG PDFSultana KhanumNoch keine Bewertungen

- Kennametal Feed Speed 3Dokument12 SeitenKennametal Feed Speed 3absalon_jarvNoch keine Bewertungen

- Bojleri RYCROFT 800 LitDokument8 SeitenBojleri RYCROFT 800 Litzekson10% (1)

- Norma Astm A270 1Dokument6 SeitenNorma Astm A270 1Ricardo Ramírez ZapataNoch keine Bewertungen

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDokument11 SeitenSpecification For Wrought Austenitic Stainless Steel Piping Fittingssudeep dsouzaNoch keine Bewertungen

- Surface Preparation Standards (SSPC)Dokument6 SeitenSurface Preparation Standards (SSPC)ro snNoch keine Bewertungen

- Complete: ChemistryDokument26 SeitenComplete: ChemistryDavid DarkoNoch keine Bewertungen

- Welding Processes PresentationDokument101 SeitenWelding Processes PresentationKentDemeterio100% (1)

- Technical Specifications For ValvesDokument32 SeitenTechnical Specifications For ValvesEr Hussain GhadialiNoch keine Bewertungen

- Steel Making Process RoutesDokument7 SeitenSteel Making Process Routespkn_pnt9950Noch keine Bewertungen