Beruflich Dokumente

Kultur Dokumente

46 SOP - Fuel Tap Servicing

Hochgeladen von

Anonymous O9TX7YlOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

46 SOP - Fuel Tap Servicing

Hochgeladen von

Anonymous O9TX7YlCopyright:

Verfügbare Formate

Standard Operating Procedure

Fuel Tap Assembly SOP No : 46 ; Rev . No : 0

(Leakage & Not Working) Date : 09.04.15

Technical Support - Service Format No: F/STS/02

This document is the property of Royal Enfield. It shall not be communicated

DETAILS OF PROCEDURE

A. Leakage from mounting area (Flange area) and Bottom area

to or copied by anyone without the written approval of RE

1) Remove the Fuel Tap from Petrol tank if any mounting leak observed

Check the

mounting leak

Check the

Bottom leak

2) Check the position & Assembly of the 'O' ring in the Flange

Check for presence of O Ring and also check for any damage of the part

OK NG

3) Check the Mounting washer (Fiber washer) and also check for any damage and part missing

OK NG

4) If leak observed from the sediment bowl then Check presence of 'O' ring and any damage of the O Ring

OK NG

Tightening Torque Remove the Check the 'O' ring After 'O' ring change

30 to 50kgf-cm

sediment cup reassemble the cup

Prepared by: K.Vinodh simmon Approved by: B.Ganapathiraman

Standard Operating Procedure

Fuel Tap Assembly SOP No : 46 ; Rev . No : 0

(Leakage & Not Working) Date : 09.04.15

Technical Support - Service Format No: F/STS/02

This document is the property of Royal Enfield. It shall not be communicated

B. Not Working (Flow is not coming in Main & Reserve )

5) Remove the Fuel hose from fuel tap assy and check the flow

1. Keep the knob position at main and

check flow rate. Repeat the same in

to or copied by anyone without the written approval of RE

Reserved position and check flow rate.

2. If flow rate is less than 520ml/min,

then flow steps

Remove the Fuel hose Check the flow (Main & Reserve position)

6) Remove the Fuel Tap from Petrol tank

Apply of

Torque wrench-80 to100

kg-cm

7) Check the Air vent hole top in Filters (Main & Reserve)

Air vent hole checked by 1.5 measuring pin for Both filters

Step-5

8) Cleaning the Filters (Main & Reserve) - Top Side

* CHECK THE STRAINER SCREEN CONDITION FOR DAMAGE

* CHECK THE PETROL CONTAMINATION IN STRAINER AND CLEAN DUST

Sediment dust cleaning in petrol

Prepared by: K.Vinodh simmon Approved by: B.Ganapathiraman

Standard Operating Procedure

Fuel Tap Assembly SOP No : 46 ; Rev . No : 0

(Leakage & Not Working) Date : 09.04.15

Technical Support - Service Format No: F/STS/02

This document is the property of Royal Enfield. It shall not be communicated

9) Cleaning the Sediment Filter - Bottom Sediment cup Side

Step-1 Step-2 Step-3 Step-4 Step-5

to or copied by anyone without the written approval of RE

Remov e the f ilter cap by Af ter washing Air v ent

hand Sediment dust Re Assembled

cleaning in petrol hole

f ilter cap by checking

Tightening hand

Torque 30 to

Remove the

50kgf-cm sediment cup After petrol

1.SEPARATE THE STRAINER SCREEN AND FILTER FROM FUEL COCK ASSY cleaned and

2.PUT INTO PETROL BOWL FOR 5 MINUTES reassemble

3.THOROUGHLY CLEAN TILL THE DUST REMOVED FROM STRAINER

4.DO NoT APPLY THE HIGH PRESSURE AIR ON FILTER

10) Ensure filter cleaning as per service manual (From each service)

To avoid flow related issue.

11) Assemble the child parts as per the SOP to avoid part missing issues.

12) Don’t use any sharp tools or high pressure air as it may damage the filters.

13) Ensure proper mounting of the Fuel tap with the specified torque ( 80kgf – 100kgf)

and also the sediment cup torque ( 30kgf-50kgf) to avoid leakage.

Note : Ensure that all parts in good & Proper assemble condition

Prepared by: K.Vinodh simmon Approved by: B.Ganapathiraman

Das könnte Ihnen auch gefallen

- Hyd Pump HD785-7-3Dokument7 SeitenHyd Pump HD785-7-3Khairul UmamNoch keine Bewertungen

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Dokument9 Seiten88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemNoch keine Bewertungen

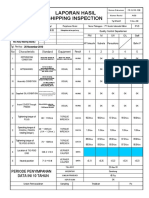

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukDokument4 SeitenLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanNoch keine Bewertungen

- 2008 Mazda MPV - Brake - Conventional Brake SystemDokument28 Seiten2008 Mazda MPV - Brake - Conventional Brake Systemlo mio es mio100% (1)

- MK Tron Auto Part: Procedure of Leak TestingDokument1 SeiteMK Tron Auto Part: Procedure of Leak Testingsachin kadamNoch keine Bewertungen

- Cat III Inspection Mud 2021Dokument56 SeitenCat III Inspection Mud 2021Fāōū ZīNoch keine Bewertungen

- Form HRSBDokument9 SeitenForm HRSBMehdi SoltaniNoch keine Bewertungen

- PCF Valve Guide Inspection GuideDokument13 SeitenPCF Valve Guide Inspection GuideoscarNoch keine Bewertungen

- Z80 WTG58 Punch List (NREA-GamesaDokument8 SeitenZ80 WTG58 Punch List (NREA-GamesaIbraHim RaGabNoch keine Bewertungen

- Sonnax 77701-076-InDokument2 SeitenSonnax 77701-076-InmiguelNoch keine Bewertungen

- 3176C Engine Inspection & Measurement SheetRev2Dokument15 Seiten3176C Engine Inspection & Measurement SheetRev2bumatio latiNoch keine Bewertungen

- Leakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Dokument6 SeitenLeakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Ahmad MohammadNoch keine Bewertungen

- AE Overhaul Guidance & ReportingDokument49 SeitenAE Overhaul Guidance & ReportingjoelandrewpintoNoch keine Bewertungen

- S028 - Rear Noise (Knocking)Dokument2 SeitenS028 - Rear Noise (Knocking)Ivan ZaytsevNoch keine Bewertungen

- TDD - YER.1.00000 Updated (TDS-11)Dokument5 SeitenTDD - YER.1.00000 Updated (TDS-11)Mohamed AnwarNoch keine Bewertungen

- TW - Tire and WheelDokument81 SeitenTW - Tire and WheelCarlos MafudNoch keine Bewertungen

- Montaje de Sello SLCDokument35 SeitenMontaje de Sello SLCChristianReinosoNoch keine Bewertungen

- Commissioning of Electrical SystemsDokument14 SeitenCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- Exterior Inspection B737-800Dokument14 SeitenExterior Inspection B737-800Me KeenNoch keine Bewertungen

- B737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFDokument604 SeitenB737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFMe Keen100% (1)

- Inspection Checklist NGS12 - GCN02Dokument5 SeitenInspection Checklist NGS12 - GCN02El D GraciaNoch keine Bewertungen

- Manual 600 NEWDokument5 SeitenManual 600 NEWabhayuietNoch keine Bewertungen

- Repport UT CS - 7Dokument1 SeiteRepport UT CS - 7daemsalNoch keine Bewertungen

- PM Check List - CB & BusbarDokument7 SeitenPM Check List - CB & BusbarRizky VidiyanaNoch keine Bewertungen

- Quality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingDokument2 SeitenQuality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingvinothNoch keine Bewertungen

- Final Inspection Report Buritica 金矿项目最终验收报告: Of Buritica Gold ProjectDokument5 SeitenFinal Inspection Report Buritica 金矿项目最终验收报告: Of Buritica Gold ProjectJUAN CARLOS SUAREZNoch keine Bewertungen

- Cpi Lube Prod Guide-US-4 12Dokument12 SeitenCpi Lube Prod Guide-US-4 12gustavo9810Noch keine Bewertungen

- RWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Dokument1 SeiteRWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Bart JohnNoch keine Bewertungen

- Rwrg0032en Us PDFDokument1 SeiteRwrg0032en Us PDFBart JohnNoch keine Bewertungen

- CBC AuditDokument4 SeitenCBC Auditfrenz2kiranNoch keine Bewertungen

- Cummins 2 - of - 3Dokument100 SeitenCummins 2 - of - 3totokNoch keine Bewertungen

- Tire Abd WheelDokument89 SeitenTire Abd WheelMirceaNoch keine Bewertungen

- List of InspectionDokument17 SeitenList of InspectionNQTNoch keine Bewertungen

- MAINTENANCEDokument6 SeitenMAINTENANCEshaktiNoch keine Bewertungen

- Group 2 Major Component: 1. Main PumpDokument9 SeitenGroup 2 Major Component: 1. Main PumpMauricio CalixtoNoch keine Bewertungen

- Bam 800 Nozzle Manual - Assembly ChecklistDokument2 SeitenBam 800 Nozzle Manual - Assembly Checklistapi-3752216Noch keine Bewertungen

- Guía de Ejecución Sistema de FrenosDokument11 SeitenGuía de Ejecución Sistema de FrenosJUAN CARLOS NOHAVA CASTANONoch keine Bewertungen

- Shut Down Job Schedule Jan 2023Dokument1 SeiteShut Down Job Schedule Jan 2023CaripahNoch keine Bewertungen

- 1721-V-0905 A - MergedDokument5 Seiten1721-V-0905 A - MergedvivekNoch keine Bewertungen

- Verif Epi Protraxion Procedure enDokument4 SeitenVerif Epi Protraxion Procedure eninternetNoch keine Bewertungen

- Tire - and - Wheel SystemDokument91 SeitenTire - and - Wheel SystemAlex GutierrezNoch keine Bewertungen

- Bomba de Vacío Rapco RASL-001 - Rev - CDokument1 SeiteBomba de Vacío Rapco RASL-001 - Rev - CNahuel LópezNoch keine Bewertungen

- Checklist For T&C of Chemical Fire Suppression SystemDokument2 SeitenChecklist For T&C of Chemical Fire Suppression Systembeho2000Noch keine Bewertungen

- GIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1Dokument19 SeitenGIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1junclarcNoch keine Bewertungen

- TF100-75 - Rynglok R5 Fittings AS-Cross ReferenceDokument4 SeitenTF100-75 - Rynglok R5 Fittings AS-Cross ReferenceLorenzoTanNoch keine Bewertungen

- Oil Contains Fuel: Shutdown SISDokument3 SeitenOil Contains Fuel: Shutdown SISOecox Cah DjadoelNoch keine Bewertungen

- Time Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Dokument6 SeitenTime Limits/Maintenance Checks Time Limits Inspection/Check: Maintenance Manual (Rev G12) 05-10-00 (Rev Apr 1/15)Nathaniel LuraNoch keine Bewertungen

- Form-HSE-TMR-005 Welding InspectionDokument1 SeiteForm-HSE-TMR-005 Welding Inspectionkenia info100% (1)

- Alternator Assembling Check Sheet3Dokument5 SeitenAlternator Assembling Check Sheet3Erik dwi KurniawanNoch keine Bewertungen

- Final Report - 1721-V-0905 BDokument5 SeitenFinal Report - 1721-V-0905 BvivekNoch keine Bewertungen

- 3 WH Drum Process ProjectDokument28 Seiten3 WH Drum Process ProjectBrandvision AdvertisementNoch keine Bewertungen

- Eot Ibl Crane Yearly ChecksheetDokument3 SeitenEot Ibl Crane Yearly ChecksheetAmit ThakurNoch keine Bewertungen

- Overhead Crane Inspection ProceduresDokument5 SeitenOverhead Crane Inspection ProceduresRonniNoch keine Bewertungen

- Filters: Pre-Commissioning Check SheetDokument1 SeiteFilters: Pre-Commissioning Check SheethrimklimNoch keine Bewertungen

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Dokument7 SeitenPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNoch keine Bewertungen

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDokument8 SeitenCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNoch keine Bewertungen

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDokument3 Seiten6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNoch keine Bewertungen

- Maintenance Checklist Shekar AugerDokument1 SeiteMaintenance Checklist Shekar Augershamsheer ikramNoch keine Bewertungen

- Test Procedure of Crane: Bos Shelf Llc. Work InstructionDokument11 SeitenTest Procedure of Crane: Bos Shelf Llc. Work InstructionJhun AquinoNoch keine Bewertungen

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersVon EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersBewertung: 5 von 5 Sternen5/5 (2)

- 25 Airlock Fuel Tank Thunder Bird SOPDokument1 Seite25 Airlock Fuel Tank Thunder Bird SOPAnonymous O9TX7YlNoch keine Bewertungen

- BS Iv Himalayan Parts Catalogue PDFDokument87 SeitenBS Iv Himalayan Parts Catalogue PDFAnonymous O9TX7Yl74% (19)

- Standard Operating Procedure Chain MaintenanceDokument4 SeitenStandard Operating Procedure Chain MaintenanceAnonymous O9TX7YlNoch keine Bewertungen

- Procedure For Checking Head Light FocusingDokument2 SeitenProcedure For Checking Head Light FocusingAnonymous nIcSGEwNoch keine Bewertungen

- Standard Operating Procedure for Fixing Engine Tik Tik NoiseDokument3 SeitenStandard Operating Procedure for Fixing Engine Tik Tik NoiseAnonymous O9TX7Yl100% (3)

- SOP For Pick Up Request RelatedDokument1 SeiteSOP For Pick Up Request RelatedAnonymous O9TX7YlNoch keine Bewertungen

- 50 SOP For TB - Service Remainder - After Cut Off ClusterDokument3 Seiten50 SOP For TB - Service Remainder - After Cut Off ClusterAnonymous O9TX7YlNoch keine Bewertungen

- SOP-Enquiry New RE ModelsDokument3 SeitenSOP-Enquiry New RE ModelsAnonymous O9TX7Yl75% (4)

- SOP 60 - Air Filter Drain Hole ProcessDokument11 SeitenSOP 60 - Air Filter Drain Hole ProcessAnonymous O9TX7Yl100% (1)

- 14 CO Setting Procedure For CarburetorDokument1 Seite14 CO Setting Procedure For CarburetorAnonymous O9TX7YlNoch keine Bewertungen

- 6 RH PullingDokument3 Seiten6 RH PullingAnonymous O9TX7YlNoch keine Bewertungen

- 27.sop Mudguard RubbingDokument3 Seiten27.sop Mudguard RubbingAnonymous O9TX7YlNoch keine Bewertungen

- Remap101 Introduction To ECU RemappingDokument29 SeitenRemap101 Introduction To ECU RemappingAnonymous O9TX7Yl100% (10)

- 9 Engine Smoking DiagnosisDokument4 Seiten9 Engine Smoking DiagnosisAnonymous O9TX7YlNoch keine Bewertungen

- DIY Kit BS4 IntroductionDokument1 SeiteDIY Kit BS4 IntroductionAnonymous O9TX7YlNoch keine Bewertungen

- 36 Wiring Harness - Conti-Gt SopDokument20 Seiten36 Wiring Harness - Conti-Gt SopAnonymous O9TX7YlNoch keine Bewertungen

- CPV Operating Manual 2011 95722Dokument28 SeitenCPV Operating Manual 2011 95722Ana Goreti Sousa TorresNoch keine Bewertungen

- Installation Instructions For DC and AC Electric Rewind ReelsDokument4 SeitenInstallation Instructions For DC and AC Electric Rewind ReelsGinoGuanNoch keine Bewertungen

- Power HydraulicsDokument75 SeitenPower HydraulicsKavinda Gehan100% (1)

- PC130 Part Cat NewDokument312 SeitenPC130 Part Cat NewsatyaNoch keine Bewertungen

- Unit 2B Speed and Velocity: Objective(s) : Main Ideas, Key Points, QuestionsDokument3 SeitenUnit 2B Speed and Velocity: Objective(s) : Main Ideas, Key Points, QuestionsHugo ZaldivarNoch keine Bewertungen

- 5) MastDokument24 Seiten5) Mastعلي اثمار ناهي سباهيNoch keine Bewertungen

- Combined Stress and Mohr'S Circle: James Doane, PHD, PeDokument41 SeitenCombined Stress and Mohr'S Circle: James Doane, PHD, PeGutierrez KennethNoch keine Bewertungen

- Design of Water Tank PDFDokument31 SeitenDesign of Water Tank PDFabdulqader100% (2)

- Superlight 125 Owner ManualDokument15 SeitenSuperlight 125 Owner Manualkot325Noch keine Bewertungen

- StaticDokument7 SeitenStatickirankumar9898Noch keine Bewertungen

- Portable Air Compressors with Deutz EnginesDokument20 SeitenPortable Air Compressors with Deutz EnginesTaz Juan GNoch keine Bewertungen

- Autodesk FUSION 360: Static Stress Analysis of A Mechanical SupportDokument5 SeitenAutodesk FUSION 360: Static Stress Analysis of A Mechanical SupportTimothy AgustinNoch keine Bewertungen

- L Series Position ControllerDokument2 SeitenL Series Position ControllerKaiser Iqbal100% (1)

- Csi 2130 WP Triaxal AccelerometerDokument13 SeitenCsi 2130 WP Triaxal AccelerometerOrlando MarucaNoch keine Bewertungen

- Stress Analysis Using Photoelasticity Technique - A ReviewDokument5 SeitenStress Analysis Using Photoelasticity Technique - A ReviewIJRASETPublicationsNoch keine Bewertungen

- Datasheet Encoder Optico Celesco ch25Dokument2 SeitenDatasheet Encoder Optico Celesco ch25Alexis DelgadoNoch keine Bewertungen

- TASK 71-00-00-811-831-A Low EPR N2 High - N2 To Governing Speed Before Rated EPR N1 Fuel Flow LowDokument1 SeiteTASK 71-00-00-811-831-A Low EPR N2 High - N2 To Governing Speed Before Rated EPR N1 Fuel Flow LowWidya DamayantiNoch keine Bewertungen

- Automobile Engineering: Unit Ii Part I - Fuel Systems Part Ii - Ci EnginesDokument103 SeitenAutomobile Engineering: Unit Ii Part I - Fuel Systems Part Ii - Ci EnginesNikhilraj rudraNoch keine Bewertungen

- Open Ended LAB: Name: Ayyan AhmadDokument7 SeitenOpen Ended LAB: Name: Ayyan AhmadMaheenNoch keine Bewertungen

- Dynamics of Rigid Bodies CE 002 (TIP Reviewer)Dokument7 SeitenDynamics of Rigid Bodies CE 002 (TIP Reviewer)James LindoNoch keine Bewertungen

- MZ Es 125 and Es 150 Repair Manual 1966 English 100Dokument80 SeitenMZ Es 125 and Es 150 Repair Manual 1966 English 100USUARIO1218Noch keine Bewertungen

- Bollhoff Amtec Threaded Inserts For PlasticsDokument34 SeitenBollhoff Amtec Threaded Inserts For PlasticsAce Industrial SuppliesNoch keine Bewertungen

- Application and Operating History of Moderate-Speed Api 618 Reciprocating CompressorsDokument10 SeitenApplication and Operating History of Moderate-Speed Api 618 Reciprocating CompressorsTrịnh Đức HạnhNoch keine Bewertungen

- Chapter 5 Gases PDFDokument49 SeitenChapter 5 Gases PDFAbou WalidNoch keine Bewertungen

- Um Renegade 20200 20dot 20usaDokument59 SeitenUm Renegade 20200 20dot 20usacokescokesNoch keine Bewertungen

- GEDokument36 SeitenGEGiulio AlessandroniNoch keine Bewertungen

- Laws of Motion-01Dokument34 SeitenLaws of Motion-01wixirepNoch keine Bewertungen

- Es HpiDokument48 SeitenEs HpidjworkingNoch keine Bewertungen

- AIRCONDITIONING BILL OF QUANTITY FOR BARBEQUE RESTAURANTDokument6 SeitenAIRCONDITIONING BILL OF QUANTITY FOR BARBEQUE RESTAURANTMohammed IqbalNoch keine Bewertungen