Beruflich Dokumente

Kultur Dokumente

Umoja Warehouse Management: User Guide

Hochgeladen von

Rakesh Kumar BeheraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Umoja Warehouse Management: User Guide

Hochgeladen von

Rakesh Kumar BeheraCopyright:

Verfügbare Formate

User

Umoja Warehouse Management

Guide

User

Guide

Umoja Warehouse Management

Table of Contents

Processes in Warehouse Management ................................................... 1

Main processes in Warehouse Management .......................................................................... 1

Put-Away Goods .................................................................................................................... 1

Pick Goods ............................................................................................................................. 3

Move Goods Internally............................................................................................................ 4

Manage Bins .......................................................................................................................... 6

Execute Disposal of Goods .................................................................................................... 7

Perform Physical Count .......................................................................................................... 9

Transfer Order Creation ......................................................................... 12

Create Transfer Order for Put-Away – LT06 ..........................................................................12

Create Transfer Order for Put-Away in Multiple Storage Bins – LT06 ....................................14

Selecting Material Documents Lines for TO Processing – LT06 ............................................22

Create Transfer Order for Transfer Posting – LT06 ...............................................................26

Create Transfer Order for Picking – LT06 ..............................................................................28

Create Transfer Order for Picking from Multiple Bins – LT06 .................................................31

Transfer Order Processing..................................................................... 34

Print Transfer Order – LT31...................................................................................................34

Confirm Transfer Order – LT12..............................................................................................36

Change Storage Bin during Transfer Order confirmation – LT12 ...........................................37

Partial Confirmation of Transfer Order – LT11 .......................................................................38

Manage quantity change during TO confirmation – LT12.......................................................45

Display Transfer Order – LT21 ..............................................................................................49

Cancel not confirmed Transfer Orders – LT15 .......................................................................49

Goods Transfers in the Warehouse....................................................... 52

Create Transfer Order – LT01 ...............................................................................................52

Stock Transfer Bin to Bin from a list – LT10 ...........................................................................54

Outbound Delivery Processing .............................................................. 57

Create Transfer Order for Outbound Delivery – LT03 ............................................................57

Goods Reversal from Delivery – LT0G ..................................................................................58

Warehouse Internal Maintenance .......................................................... 60

Create Storage Bin Manually – LS01N ..................................................................................60

User

Guide Umoja Warehouse Management

Change Storage Bin Manually – LS02N ................................................................................62

Physical Count ........................................................................................ 64

Create System Inventory Record – LI01N .............................................................................64

Print Inventory List – LI04 ......................................................................................................65

Enter Inventory Count – LI11N ..............................................................................................67

Start Recount – LI14..............................................................................................................69

Clear Differences in WM – LI20 .............................................................................................71

Clearing of Differences in IM (Serialized Materials) – ZLE_LI21 ............................................72

Reports .................................................................................................... 76

Stock Overview WM – LS26 ..................................................................................................76

Bin Status Report – LX03 ......................................................................................................78

List of Empty Bins Report – LX01 ..........................................................................................81

Stock per Material WM – LS24 ..............................................................................................83

Stock for All Material WM – LX02 ..........................................................................................84

Transfer Orders for Material – LT24 ......................................................................................87

Difference List per Storage Type – LX17 ...............................................................................88

Transfer Requirements List for Storage Type – LB10 ............................................................91

List of Open Transfer Orders – LT23 .....................................................................................93

Inventory Overview – LX22..................................................................................................94

UN Umoja Training Umoja Warehouse Management Page 1

User

Guide

Processes in Warehouse Management

Processes in Warehouse Management

Main processes in Warehouse Management

The main processes in warehouse management are:

Put-Away Goods

Pick Goods

Move Goods Internally

Manage Bins

Execute Disposal of Goods

Perform Physical Count

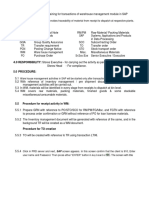

Put-Away Goods

Check Analyses Create

Checks Open

Received available Transfer Order Print Transfer

Transfer

Items for Put- space / items for Put-Away Order

Orders

Away for put-away

Execute Confirm

Transfer Transfer

Order Order

The Put Away process is triggered by the receipt of goods in the warehouse related to a vendor

Purchase Order or to returned or transferred items. As soon as the goods receipt is performed,

the system generates a transfer requirement in the warehouse, in the interim storage type 902 -

GR Area External Rcpts. The Put Away process is an integrated process between Inventory

Mnagement and Warehouse Management since some steps, like goods receipt, are performed

in Inventory management and reflected in Warehouse Management.

You can find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

Step 1: Check Received Items for Put-Away

Responsible: Warehouse Senior User

Description: Warehouse Senior User plans the WH activities based on outstanding

Transfer Requirements for put-away, picking and internal WH movements; executes

the Umoja reports to list the open Transfer Requirements

Transactions: LB10

Link to step by step instructions: Transfer Requirements List For Storage Type –

LB10

UN Umoja Training Umoja Warehouse Management Page 1

User

Guide

Processes in Warehouse Management

Step 2: Analyse available space / items to select the proper location in WH

Responsible: Warehouse Senior User

Description: Warehouse Senior User analyses the items that needs to be put away

(commodity, date, owner), the available space in the system / with visual inspection,

and decides bins locations and operational priorities

Transactions: LX01, LX02, LX03

Link to step by step instructions: List of Empty Bins – LX01, Stock Per All

Material WM – LX02, Bin Status Report – LX03

Step 3: Create Transfer Order(s) in Umoja for put-away received items

Responsible: Warehouse Senior User

Description: Warehouse Senior User creates the Transfer Order in Umoja with

reference to the Material Document

Transactions: LT06

Link to step by step instructions: Create Transfer Order for Put-Away – LT06

Step 4: Check Open Transfer Orders (TO) to be executed

Responsible: Warehouse User

Description: Warehouse User reviews the list of open Transfer Orders that have to

be executed

Transactions: LT23 (list of TO, open, by date)

Link to step by step instructions: List of Open Transfer Orders – LT23

Step 5: Print TO for execution

Responsible: Warehouse User

Description: Warehouse User prints the Transfer Orders to be executed. NOTE:

the TO can be printed in multiple copies and affixed to carton or boxes as labels for

tracking purposes

Transactions: LT31

Link to step by step instructions: Print Transfer Order – LT31

Step 6: Confirm Transfer Order

Responsible: Warehouse User

Description: After the TO is executed, it is to be confirmed in Umoja

Transactions: LT12

Link to step by step instructions: Confirm Transfer Order – LT12

UN Umoja Training Umoja Warehouse Management Page 2

User

Guide Processes in Warehouse Management

Pick Goods

Analyze Analyze WH Create Checks Open

Transfer Print Transfer

outstanding stock to Transfer

Order(s) in Order

goods issues identify Picking Orders

for picking Location Umoja

Execute Confirm

Transfer Transfer

Order Order

The Pick Goods process is triggered by the issuance of stock from the warehouse. As soon as

the goods issue is performed in Inventory Management in Umoja, the system generates a

transfer requirement in the warehouse; the transfer requirments are created in different interim

storage types, e.g., 911 GI Area for Cost Center, 914 GI Area Production Orders, 916 Shipping

Area Deliveries, etc. The Pick goods process is an integrated process between Inventory

Mnagement and Warehouse Management since some steps, like goods issue, are performed in

Inventory management and reflected in Warehouse Management.

You can find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

Step 1: Analyze outstanding goods issues for picking and select the proper location in

Warehouse

Responsible: Warehouse Senior User

Description: Warehouse Senior User analyses the open transfer requirements the

items that needs to be picked (commodity, date, owner), determines the source

storage bins; can combine multiple goods issues for picking and generate pick list

Transactions: LB10

Link to step by step instructions: Transfer Requirements List For Storage Type –

LB10

Step 2: Analyse Warehouse Stock to identify picking locations

Responsible: Warehouse Senior User

Description: Warehouse Senior User analyses the items that needs to be picked

and where they are available in the warehouse

Transactions: LX02, LX03

Link to step by step instructions: Stock Per All Material WM – LX02, Bin Status

Report – LX03

Step 3: Create Transfer Order(s) in Umoja for picking items to be issued from warehouse

Responsible: Warehouse Senior User

UN Umoja Training Umoja Warehouse Management Page 3

User

Guide

Processes in Warehouse Management

Description: Warehouse Senior User creates the Transfer Order in Umoja

Transactions: LT06

Link to step by step instructions: Create Transfer Order for Picking – LT06

Step 4: Check Open Transfer Orders (TO) to be executed

Responsible: Warehouse User

Description: Warehouse User review the list of Transfer Orders that have to be

executed in WH

Transactions: LT23 (list of TO, open, by date)

Link to step by step instructions: List of Open Transfer Orders – LT23

Step 5: Print TO for execution

Responsible: Warehouse User

Description: Warehouse User prints the Transfer Orders to be executed. NOTE:

the TO can be printed in multiple copies and affixed to carton or boxes as labels for

tracking purposes

Transactions: LT31

Link to step by step instructions: Print Transfer Order – LT31

Step 6: Confirm Transfer Order

Responsible: Warehouse User

Description: After the TO is executed it is to be confirmed in Umoja.

Transactions: LT12

Link to step by step instructions: Confirm Transfer Order – LT12

Move Goods Internally

Create Checks Execute

Print Transfer Confirm

Transfer Open Transfer

Order Transfer

Order(s) in Transfer order

Orders Order

Umoja

Move Goods Process initiated in Inventory Management: In some cases, the Move goods

process is triggered by the change of the stock status (e.g., stock transfer from unrestricted to

blocked or viceversa). In other cases, there is a transfer posting from storage location to

storage location. In these scenarios, the Move Goods is an integrated process between

Inventory Mnagement and Warehouse Management since some steps are performed in

Inventory management and reflected in Warehouse Management.

Move Goods process initiated in the Warehouse: In this case, the trigger for this process is

the need of changing the physical location of goods internally in the warehouse.

UN Umoja Training Umoja Warehouse Management Page 4

User

Guide Processes in Warehouse Management

There are different modalities of performing the Transfer Order creation.

You can find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

Step 1(a): Create Transfer Order(s) in Umoja following stock transfers (e.g.,from unrestricted

stock to blocked stock) – Posting Change case

Responsible: Warehouse Senior User

Description: Warehouse Senior User creates the Transfer Order in Umoja with

reference to the material document (e.g., stock transfer); in this case the Transfer

Order is automatically confirmed. No need to further process

Transactions: LT06

Link to step by step instructions: Create Transfer Order for Transfer Posting –

LT06

Step 1(b): Create Transfer Order(s) in Umoja following the physical move of the items to

different / new bins

Responsible: Warehouse Senior User

Description: Warehouse Senior User creates the Transfer Order in Umoja indicating

the source bin and the destination bin

Transactions: LT01

Link to step by step instructions: Create Transfer Orderc LT01

Step 3: Check Open Transfer Orders (TO) to be executed

Responsible: Warehouse User

Description: Warehouse User review the list of Transfer Orders that have to be

executed in WH

Transactions: LT23 (list of TO, open, by date)

Link to step by step instructions: List of Open Transfer Orders – LT23

Step 4:: Print TO for execution

Responsible: Warehouse User

Description: Warehouse User prints the Transfer Orders to be executed. NOTE:

the TO can be printed in multiple copies and affixed to carton or boxes as labels for

tracking purposes

Transactions: LT31

Link to step by step instructions: Print Transfer Order – LT31

Step 5: Confirm Transfer Order

UN Umoja Training Umoja Warehouse Management Page 5

User

Guide

Processes in Warehouse Management

Responsible: Warehouse User

Description: After the TO is executed it is to be confirmed in Umoja

Transactions: LT12

Link to step by step instructions: Confirm Transfer Order – LT12

Manage Bins

Display /

Warehouse Execute

Execute Bins Create new Change /

Visual Empty Bins

Status Report bins Delete

Inspection Report

existing bins

The Manage Bins process is triggered by the need of creating new storage bins or delete no

longer used storage bins.

You find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

Step 1: Execute Bin Status Report

Responsible: Warehouse Senior User

Description: The Warehouse Senior User, after performing for instance a visual

inspection of the warehouse, decides to review the bins status in the system in order

to optimize the space allocation, etc.

Transactions: LX03

Link to step by step instructions: Bin Status Report – LX03

Step 2: Execute Empty Bins Report

Responsible: Warehouse Senior User

Description: The Warehouse Senior User, can further check the bins status

executing for instance the Empty Bins report, to identify empty bins that can be

utilised or that should be deleted

Transactions: LX01

Link to step by step instructions: List of Empty Bins Report – LX01

Step 3: Create new bins

Responsible: Warehouse Senior User

Description: The Warehouse Senior User, based on the results of his analysis on

the space and bins status in the system, may decide to create new storage bins

Transactions: LS01N

UN Umoja Training Umoja Warehouse Management Page 6

User

Guide Processes in Warehouse Management

Link to step by step instructions: Create Storage Bin Manually – LS01N

Step 4: Display / change / delete new bins

Responsible: Warehouse Senior User

Description: The Warehouse Senior User, based on the results of his analysis on

the space and bins status in the system, may display / change or delete storage bins;

note that in order to delete a bin, this must be empty

Transactions: LS02N

Link to step by step instructions: Change Storage Bin Manually – LS02N

Execute Disposal of Goods

Create TO

Create TO for

for Print TO for Confirm TO Stock transfer: Create TO to

segregating

segregating moving goods for moving Unrestricted align IM and

goods in

goods in aa WH

WH to disposal goods to Blocked (IM) WM

area

area area disposal area

Create Confirm

Issue stock to Transfer Print Transfer Transfer

scrap (IM) Order for final Order Order

disposal

The Disposal of Goods process is triggered by the identification of damaged, expired or

obsolete items requiring disposal. Once the disposal action and method are approved, the

disposal process in the warehouse is performed; the example provided below refers to disposal

from stock via scrap. The disposal process is an integrated process between Inventory

management and Warehouse management since some steps, like goods transfer from

unrestricted stock or goods issue to scrap are performed in Inventory Management and in

Warehouse Management.

You can find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

Step 1: Create TO for segregating the goods in a dedicated WH area

Responsible: Warehouse Senior User

Description: The Warehouse Senior User creates a Transfer Order as a order to

remove the items from their current location and put them in a dedicated area in the

warehouse; note: the destination storage type for this transfer order is “DSP”;

the destination storage bin can be indicated by the user, if existing/known, or it will

be created by the system.

Transactions: LT01

Link to step by step instructions: Create Transfer Order – LT01

Step 2: Print TO for moving goods to disposal area

UN Umoja Training Umoja Warehouse Management Page 7

User

Guide

Processes in Warehouse Management

Responsible: Warehouse User

Description: Warehouse User prints Transfer Order for execution

Transactions: LT31

Link to step by step instructions: Print Transfer Order – LT31

Step 3: Confirm TO for moving goods to disposal area

Responsible: Warehouse User

Description: After the TO is executed it is to be confirmed in Umoja

Transactions: LT12

Link to step by step instructions: Confirm Transfer Order – LT12

Step 4: Transfer stock from Unrestricted to Blocked in Inventory Management

Responsible: Inventory User, isntructed by Inventory Senior user

Description: As the goods are segregated in a disposal area in Warehouse

Management, the same action is performed in Inventory Management, transferring

the stock to be disposed from status Unrestricted to status Blocked.

Transactions: MIGO, movement type 344

Link to step by step instructions: Refer to SC339 User Guide, Module 4 and

Module 5

Step 5: Create TO to align IM and WM

Responsible: Warehouse Senior User

Description: Warehouse Senior user performs the Transfer Order required to

confirm the posting change in WH management; this is performed with reference to

the Transfer Posting Material document; this is required in all cases where, for

instance, the Inventory user has performed a stock transfer from Unrestricted stock

to blocked stock for the inventory items to be disposed

Transactions: LT06

ink to step by step instructions: Create Transfer Order for Transfer Posting –

LT06

Step 6: Issue stock to be disposed to scrap in Inventory management

Responsible: Inventory User, isntructed by Inventory Senior user

Description: As the goods are segregated in a disposal area in Warehouse

Management, the same action is performed in Inventory Management, transferring

the stock to be disposed from status Unrestricted to status Blocked.

Transactions: MIGO, movement type 555 (scrap from blocked)

Link to step by step instructions: Refer to SC339 User Guide, Module 5

UN Umoja Training Umoja Warehouse Management Page 8

User

Guide Processes in Warehouse Management

Step 7: Create Transfer Order for final disposal of goods from warehouse

Responsible: Warehouse Senior User

Description: The Warehouse Senior User creates a TO as a order to dispose the

items, in line with the approved disposal notification; note: the destination storage

type for this transfer order is “999”; the destination storage bin SCRAP.

Transactions: LT01

Link to step by step instructions: Create Transfer Order – LT01

Step 6: Print Transfer Order for execution

Responsible: Warehouse User

Description: Warehouse User prints the Transfer Orders to be executed.

Transactions: LT31

Link to step by step instructions : Print Transfer Order – LT31

Step 7: Confirm Transfer Order

Responsible: Warehouse User

Description: After the Transfer Order is executed, it is to be confirmed in Umoja

Transactions: LT12

Link to step by step instructions: Confirm Transfer Order – LT12

Perform Physical Count

Execute Create Executes

report to Warehouse Print Count Enter count count

review bins Count document results differences

for count Document report

Clear Clear

Initiates Monitor

Perform differences in differences in

recount as/if Inventory

recount steps Warehouse Inventory

applicable Count Docs.

Management Management

The Physical Count process is triggered by the regular schedule of counts in the warehouse or

by an ad-hoc request. The physical count requires planning since the bins being counted are

blocked for any movement in the warehouse until the difference are posted. The Physical

Count process is an integrated process between Inventory Management and Warehouse

Management since the differences identified during the count have to be cleared in Warehouse

Management and in Inventory management, in order to align the stock figures in both

environments.

You find below the list of process steps, along with the responsible user role, the system

transaction and the link to the user guide step by step instructions:

UN Umoja Training Umoja Warehouse Management Page 9

User

Guide

Processes in Warehouse Management

Step 1: Execute warehouse stock report to review and confirm bins for count

Responsible: Warehouse Senior User

Description: The Warehouse Senior User executes a warehouse stock report to

review and confirm the bins to be counted. The report is printed in order to

additionally serve as a reference in case of issues / discrepancies during or after the

count

Transactions: LX02

Link to step by step instructions: Stock Per All Material WM – LX02

Step 2: Create Warehouse Count Document

Responsible: Warehouse Senior User

Description: The Warehouse Senior User creates the warehouse count documents

as per confirmed plan and schedule, indicating the bin(s) to be counted

Transactions: LI01N

Link to step by step instructions: Create System Inventory Record – LI01N

Step 3: Print Count document as instructed by Warehouse Senior User

Responsible: Warehouse User

Description: Warehouse User prints the physical count document as instructed by

the Warehouse Senior User in order to perform the count

Transactions: LI04

Link to step by step instructions: Print Inventory List – LI04

Step 4: Enter count results

Responsible: Warehouse User

Description: Warehouse User enters the count results In Umoja

Transactions: LI11N

Link to step by step instructions: Enter Inventory Count – LI11N

Step 5: Executes count differences report

Responsible: Warehouse Senior User

Description: Warehouse Senior User executes the count difference report and

performs the initial analysis of differences in order to determine next steps

Transactions: LX17

Link to step by step instructions: Difference List Per Storage Type – LX17

UN Umoja Training Umoja Warehouse Management Page 10

User

Guide Processes in Warehouse Management

Step 6: Initiates recount as/if applicable

Responsible: Warehouse Senior User

Description: Warehouse Senior User initiates the recount as/if applicable

Transactions: LI14

Link to step by step instructions: Start Recount – LI14

Step 7: Perform recount steps (same as initial count)

Responsible: Warehouse User

Description: Warehouse User performs the recount steps as/if applicable; steps are

same as those executed for the initial count

Transactions: LI04, LI11N, LX17

Link to step by step instructions: Print Inventory List – LI04, Enter Inventory

Count – LI11N, Difference List Per Storage Type – LX17

Step 8: Clear differences in Warehouse Management

Responsible: Property Control User

Description: As a first step to complete the warehouse count, the Property Control

User clear the differences in WM.

Transactions: LI20

Link to step by step instructions: Clear Differences in WM LI20

Step 9: Clear differences in Inventory Management

Responsible: Property Control User

Description: Property Control User clear the differences in Inventory Management

Transactions: ZLE_LI21

Link to step by step instructions: Clearing of Differences in IM (Serialized

Materials) – ZLE_LI21

Step 10: Monitor the status of the Physical Inventory Count documents

Responsible: Warehouse Senior User

Description: The Warehouse Senior User monitor the status of the count

documents

Transactions: LX22

Link to step by step instructions: Inventory Overview – LX22

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 11

User

Guide

Transfer Order Creation

Transfer Order Creation

Create Transfer Order for Put-Away – LT06

Step-by-Step Instructions

The steps to create a Transfer Order from a Material Document for put-away (good receipts) are

as follows:

Enter LT06 in the Command field

Click the Enter icon

Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the goods to be put-

away (e.g., Goods Receipt material document)

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 12

User

Guide Transfer Order Creation

The following screen will be displayed, click on the StockPut Awayl Foreground button. The

system will take you to a new screen where you shall specify the exact warehouse location

where the material is to be stored

For creating a TO for put-away (good receipt), populate the following fields in the Basic Data

tab:

Destination storage type

Destination storage section (optional)

Destination storage bin

UN Umoja Training Umoja Warehouse Management Page 13

User

Guide

Transfer Order Creation

Click the Enter icon. Note: Message “Check your entries” will be displayed below. Click the

Enter Icon again

Click the Save icon to post the Transfer order

Note1: If the Goods Receipt Material Document includes multiple line items, the system will

take you to a new screen where you can repeat the above steps for the new item.

Note2: Storage Types "DSP"(for goods to be disposed) and "TRN" (for in-transit goods) allow

for dynamic bin creation: to do so, enter the storage types code in the storage type field, and

press enter; the system will populate the storage section field automatically; now specify a

storage bin name; the system will automatically create a bin with the name specified.

Create Transfer Order for Put-Away in Multiple Storage Bins – LT06

Apply these steps when the quantity received is to be put-away in multiple storage bins.

The initial steps are same as those for creating a TO with transaction LT06; since the quantity

received is more than what can be put-away in a single storage bin, it will be split across

multiple bins. 2 scenarios are considered.

Case 1: Put-away the total quantity subdividing it in multiple storage units (SU) with the same

quantity.

Case 2: Put-away the total quantity subdividing it in multiple storage units (SU) with the different

quantity.

The steps to create a Transfer Order from a Material Document for put-away (good receipts) are

as follows:

UN Umoja Training Umoja Warehouse Management Page 14

User

Guide Transfer Order Creation

Step-by-Step Instructions

Enter LT06 in the Command field

Click the Enter icon

Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the goods to be put-

away (e.g., Goods Receipt material document)

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

Click the Enter icon.

The system will display a screen with the total quantity to be put away, in this example 80.

UN Umoja Training Umoja Warehouse Management Page 15

User

Guide

Transfer Order Creation

Case 1: Put-away the total quantity subdividing it in multiple storage units with the same

quantity.

In this example the total quantity is split in 4 bins, 20 pieces in each bin. In order to do so,

specify 4 in the Storage Unit (SU) field and 20 in the field Qty per SUnit:

UN Umoja Training Umoja Warehouse Management Page 16

User

Guide Transfer Order Creation

The system will apportion the quantity into 4 SU and display them in the below part of the

screen.

The destination storage type, section and bin for each of the 4 SU can be indicated directly in

the same screen (refer to the area highlighted in blue in the above screen) or individually for

each SU.

Click on Putaway Foreground button to indicate the destination bin for each SU

individually; the system will display the below screen for each SU created in previous steps.

UN Umoja Training Umoja Warehouse Management Page 17

User

Guide

Transfer Order Creation

Indicate the destination storage type and storage bin. The system will display a new screen for

each SU. Press Enter to move to the next one. When the last SU is reached, the system will

display the overview of the put away in the different bin. Save the TO and take note of the

TO number for next steps (confirmation).

UN Umoja Training Umoja Warehouse Management Page 18

User

Guide Transfer Order Creation

Case 2: Put-away the total quantity subdividing it in multiple storage units with the different

quantity

In this case, the total quantity will be split in mutiple Storage Units (SU) with different quantities.

The open quantity to be put away is 80; the decision to split the quantity according to the

available space in a set of bins; the first quantity to put away is 5 (1 SU of 5).

Specify 5 in the field Qty per SUnit and press Enter. The system will create an entry in the Items

overview with quantity 5. Once this is done, the open quantity for put away is reduced to 75.

UN Umoja Training Umoja Warehouse Management Page 19

User

Guide

Transfer Order Creation

The decision is to create 2 SU with quantity 10 each. Enter 2 in the SU field and 10 in the

Qty per SUnit. Press Enter. The system will populate the Items overview with 2 additional

SU of 10 each:

Once this is done, the open quantity for put away is reduced to 55. Proceed in the same way

until the full quantity for put-away is reached. It is not possible to exceed the original quantity

for put away.

The destination storage type, section and bin for each of the SU can be indicated directly in the

same overview screen or individually for each SU. Here below the details for putting each

SU away individually.

Click on Putaway Foreground button to indicate the destination bin for each SU

individually; the system will display the below screen for each SU created in previous steps.

UN Umoja Training Umoja Warehouse Management Page 20

User

Guide Transfer Order Creation

Indicate the destination storage type and storage bin in the “Destinat.” Area of the screen. The

system will display a new screen for each SU created earlier. Press Enter to move to the

next SU and repeat the data entry for all SU/storage bins.

When the last SU is reached, the system will display the overview of the put away in the

different bins. Save the TO and take note of the TO number for next steps (confirmation).

UN Umoja Training Umoja Warehouse Management Page 21

User

Guide

Transfer Order Creation

Selecting Material Documents Lines for TO Processing – LT06

Use these steps for putting away (or picking) only selected line items of a Material Document.

Step-by-Step Instructions

Enter LT06 in the Command field

Click the Enter icon

Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the goods to be put-

away (e.g., Goods Receipt material document)

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

Click the Enter icon.

The system will display a screen with all the Material Document line items:

UN Umoja Training Umoja Warehouse Management Page 22

User

Guide Transfer Order Creation

In order to select only specific line items for put-away, select the lines to be processed at a later

stage and click on Inactive; in this example only the first line item will be processed:

The system will show the line items not selected for processing in the Inactive Items tab:

UN Umoja Training Umoja Warehouse Management Page 23

User

Guide

Transfer Order Creation

In order to put-away only the selected item(s) click on Active Worklist tab; if the entire quantity is

to be put away in a single storage type/storage bin click Generate TO Item and follow the

steps described in previous sections (e.g. Create Transfer Order for Put-Away – LT06); if the

quantity is to be split across muliple bins click on Palletization and follow the steps

described in previous sections (e.g. Create Transfer Order for Put-Away in Multiple Storage

Bins – LT06).

The remaining Material Document line items can be processed when required. Execute LT06

indicating the Material Document number. The system will display the line items previously

indicated as inactive, ready for put-away:

UN Umoja Training Umoja Warehouse Management Page 24

User

Guide Transfer Order Creation

It is possible to put away only partial quantity for a Material Document line item; in the example

below, one of the 2 line items has been set as inactive. The quantity of the other is reduced to 5

(the quantity for put-away):

Put the item with the quantity 5 away in a single (Generate TO Item) or multiple bins

(Palletization). Once the put away storage type and storage bin are indicated as explained in

previous sections, the system displays a screen with the Processed Items:

UN Umoja Training Umoja Warehouse Management Page 25

User

Guide

Transfer Order Creation

The leftover quantity is now available in the Active Worklist tab:

If the remaining quantity can be put away immediately, proceed as explained (single storage

bin (Generate TO Item) or multiple bins (Palletization)). If the remaining quantity is to be put

away later, select the line item and click on Inactive .

Note: when executing the report LB10, in order to retrieve a Material Document / Transfer

requirement already partially processed, please tick the “Partially Delivered” check box.

Create Transfer Order for Transfer Posting – LT06

Step-by-Step Instructions

The steps of carring out a Transfer Posting are as follows:

1. Enter LT06 in the Command field

2. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 26

User

Guide Transfer Order Creation

3. Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the stock transfer

posting (e.g., stock transfer from “Unrestricted” to “Blocked”

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

4. Click the Enter icon

5. The system displays an overview screen, you will find a number of storage types; select

the Storage Type from where you would like stock to be moved (e.g., the storage type

where the items for which the stock transfer took place are located in the warehouse)

6. Click the Save button; the system will display a new screen where you can populate the

destination information; if the items for which the stock transfer took place are not to be

UN Umoja Training Umoja Warehouse Management Page 27

User

Guide

Transfer Order Creation

moved elsewhere, please indicate as destination the same storage type, section and bin

where the items are located

7. Enter the Destination Information:

Destination storage type

Destination storage section (optional)

Destination storage bin

8. Click the Enter icon

Note1: If the Transfer posting includes multiple line items, the system will take you to a new

screen where you can repeat the above steps for the new item.

Note2: Storage Types "DSP"(for goods to be disposed) and "TRN" (for in-transit goods) allow

for dynamic bin creation: to do so, enter the storage types code in the storage type field, and

press enter; the system will populate the storage section field automatically; now specify a

storage bin name; the system will automatically create a bin with the name specified.

Create Transfer Order for Picking – LT06

Step-by-Step Instructions

The steps describe how to perform the picking:

UN Umoja Training Umoja Warehouse Management Page 28

User

Guide Transfer Order Creation

The steps to create a Transfer Order from a Material Document) for picking are as follows:

1. Enter LT06 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the goods issue that

needs to be picked in the warehouse

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

4. Click the Enter icon

The system will take you to a new screen where you shall specify the type of Transfer

Order creation.

5. Click on Stock removal Background (picking using FIFO strategy in WM, no

manual update) or Stock removal Foreground (the system will propose source

data based on FIFO, but it can be manually updated as/if required)

UN Umoja Training Umoja Warehouse Management Page 29

User

Guide

Transfer Order Creation

6. If you select Stock Removal Foreground, the system will take you to a new screen

where you can review, accept or modify the system proposal (based on FIFO):

From Storage Type

From Storage Section

From Storage Bin

7. The system may issue a warning message “Check your entries”; click the Enter icon to

continue

8. Click the Save button to save the Transfer Order

UN Umoja Training Umoja Warehouse Management Page 30

User

Guide Transfer Order Creation

Create Transfer Order for Picking from Multiple Bins – LT06

Use these steps when the quantity to be issued is to be picked from multiple storage

types/storage bins.

Step-by-Step Instructions

The steps to create a Transfer Order from a Material Document) for picking are as follows:

1. Enter LT06 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Material Document No: material document number related to the goods issue that

needs to be picked in the warehouse

Material Document Year: year of the material document

Warehouse Number

Foreground/ Background/System-Guided: The system defaults the control as

System-Guided. Don’t change it

4. Click the Enter icon

The system will take you to a new screen where you shall specify the type of Transfer

Order creation.

UN Umoja Training Umoja Warehouse Management Page 31

User

Guide

Transfer Order Creation

5. Click on Stock Figures icon .

The system will take you to a new screen where it is possible to indicate the quantity of

stock to be removed from the storage types / storage sections and storage bins where the

required material is available; it is possible to indicate the quantity to be picked from one

single bin or from multiple bins. Do not select interim storage types (e.g., 902) for picking.

6. Click on to process the next material to be picked, as applicable.

7. The system will display a screen with the total quantity picked

UN Umoja Training Umoja Warehouse Management Page 32

User

Guide Transfer Order Creation

8. When all materials in the material document have been processed, click on the Save

icon to save the Transfer Order. The system will issue a message with the number of

the transfer order created

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 33

User

Guide

Transfer Order Processing

Transfer Order Processing

Print Transfer Order – LT31

Step-by-Step Instructions

The steps to print a Transfer Order are as follows:

1. Enter LT31 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

TO No: This is the Transfer Order number to be printed

Print Code: Z1 for printing one TO line item per page; Z2 for printing multiple TO

line items

Printer: Recommend to use LOCL, this will print on windows default printer

Spool Control Data: 01 for printing immediately; 02 for creating the spool request

UN Umoja Training Umoja Warehouse Management Page 34

User

Guide Transfer Order Processing

4. Click the Enter icon

5. Click the Transfer Order Menu

6. Click Print

7. You will get the following pop-up screen, click the Print button. The transfer order is

printed

UN Umoja Training Umoja Warehouse Management Page 35

User

Guide

Transfer Order Processing

Confirm Transfer Order – LT12

Step-by-Step Instructions

The steps to confirm a Transfer Order are as follows:

1. Enter LT12 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

TO No: This is the Transfer Order number to be confirmed

4. Click the Enter icon

Note: Select the Pick + Transfer, Pick, or Transfer radio button for your case.

UN Umoja Training Umoja Warehouse Management Page 36

User

Guide Transfer Order Processing

5. The system will display the Transfer Order items need to be confirmed. Click the

Confirm Internally button

6. Click the Save button

Note: If you receive a message "Transfer order XXXXXXXX already confirmed...",

the Transfer Order may have been automatically confirmed.

Change Storage Bin during Transfer Order confirmation – LT12

During the Put Away TO confirmation it is possible to change the Dest. Storage Bin:

This may happen if, during the execution of the Put-Away, the same quantity of stock had to be

put away in a different storage bin. In order to change the storage bin during confirmation, it is

possible to overwrite the storage bin from the TO.

UN Umoja Training Umoja Warehouse Management Page 37

User

Guide

Transfer Order Processing

Confirm the TO; the storage bin manually included by the user is confirmed:

Note1: Any change of quantity during confirmation will result into an inventory quantity change

(i.e. a loss and or a gain).

Note2: The Source bins cannot be changed during confirmation of Picking transfer orders. The

pick quantity can be changed to confirm actual quantity picked.

Partial Confirmation of Transfer Order – LT11

For TOs that can be executed and confirmed only partially, it is possible to perform a partial

confirmation for selected items.

The below TO with multiple line items is still to be confirmed (red traffic light):

The T-code LT11 (Confirm TO Line Item) can be used for this purpose.

Step-by-Step Instructions

The steps to confirm a Transfer Order are as follows:

7. Enter LT11 in the Command field

8. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 38

User

Guide Transfer Order Processing

9. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

TO No: This is the Transfer Order number to be confirmed

Item Number: this is the line item to be confirmed

10. Click the Enter icon

The system displays the next screen in which it is possible to review and confirm the destination

storage type, storage section and storage bin for the selected item:

UN Umoja Training Umoja Warehouse Management Page 39

User

Guide

Transfer Order Processing

If the entries are fine, save to confirm the TO.

When the TO is displayed only the selected item will appear as confirmed:

UN Umoja Training Umoja Warehouse Management Page 40

User

Guide Transfer Order Processing

Partial confirmation using LT12

It is possible to confirm selected TO items also using the T-code LT12. The TO with multiple

items (red traffic light) for confirmation is displayed below:

Perform the same initial steps described in the section “Confirm Transfer Order – LT12”.

In the selection screen indicate the TO number and press Enter. The below screen with the

items to be confirmed is displayed:

UN Umoja Training Umoja Warehouse Management Page 41

User

Guide

Transfer Order Processing

If, in the example below, only line item 3 is to be confirmed; select line items 2 and 4 by

highlighting them:

Click on the “Inactive” push button. The items will appear under the “Inactive items” tab.

UN Umoja Training Umoja Warehouse Management Page 42

User

Guide Transfer Order Processing

Only line item 3 will be processed.

Select Confirm Internally from the Menu. The system will display the confirmed item under the

“Confirmed” tab:

Save. The system will display the TO number confirmed:

UN Umoja Training Umoja Warehouse Management Page 43

User

Guide

Transfer Order Processing

When displaying the TO we will see the the confirmed items (green traffic light) and the

remaining ones still to be confirmed (red traffic light).

UN Umoja Training Umoja Warehouse Management Page 44

User

Guide Transfer Order Processing

Manage quantity change during TO confirmation – LT12

Quantity differences may be identified during the put-away. Here below it is described a sample

scenario. The TO for put-away includes the following line items:

Execute T-code LT12 to confirm the TO.

In this example only the first 3 line items of the TO will be confirmed. The other line items will

be confirmed at a later stage. To do so, highlight the lines that will be processed later and click

on the “Inactive” push button.

UN Umoja Training Umoja Warehouse Management Page 45

User

Guide

Transfer Order Processing

The quantity of the items put away is in this scenario less than the original TO quantity. Upon

confirmation, it is possible to update the quantity.

The system will populate the Dest. Diff. Qty column with the difference between the TO original

quantity and the put-away quantity. In this case, for each line item, the difference is 1.

Click Confirm Internally. The system will display a confirmation pop-up box for each one of the

lines with differences.

UN Umoja Training Umoja Warehouse Management Page 46

User

Guide Transfer Order Processing

Click on Confirm Difference to accept it.The system will display the final put-away screen with

the quantity specified during the confirmation.

Save to confirm the TO. Display the TO using transaction code LT21 (refer to the Display

Transfer order – LT21 in this User Guide).

UN Umoja Training Umoja Warehouse Management Page 47

User

Guide

Transfer Order Processing

The system displays the TO with:

o 3 confirmed line items with the green traffic light and a red icon to indicate that the

confirmation was performed with differences.

o 4 not yet confirmed line items with the red traffic light. These are the lines that have been

de-activated for later processing at the beginning of this scenario.

The system shows the difference quantity in the storage type “999”, in an interim storage bin

that the system created with the same number as the TO.

In this scenario, the reasons for the difference will have to be investigated, depending on the

predecessor document type. If, for example, the TO was following a goods receipt, it could be

that the GR quantity was wrong, or that there have been losses during internal warehouse

movements. The corrective action will depend on the cause determined through the

investigation.

UN Umoja Training Umoja Warehouse Management Page 48

User

Guide Transfer Order Processing

Display Transfer Order – LT21

Step-by-Step Instructions

The steps to display a Transfer Order are as follows:

1. Enter LT21 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

TO No: This is the Transfer Order number created in previous steps

4. Click the Enter icon

Cancel not confirmed Transfer Orders – LT15

Step-by-Step Instructions

The steps to cancel not confirmed Transfer Orders are as follows:

1. Enter LT15 in the Command field

2. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 49

User

Guide

Transfer Order Processing

3. Populate the following fields in the Basic Data tab:

TO Number

Warehouse No

4. Click the Execute button. The system will display the Overview of Transfer Order

Items screen

UN Umoja Training Umoja Warehouse Management Page 50

User

Guide Transfer Order Processing

5. Click the Save icon

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 51

User

Guide

Goods Transfers in the Warehouse

Goods Transfers in the Warehouse

Create Transfer Order – LT01

Step-by-Step Instructions

The steps to create a Transfer Order to move goods in the warehouse are as follows:

1. Enter LT01 in the Command field

2. Click the Enter icon

3. Populate the following fields:

Warehouse No

Movement Type = 999

Material Number

Quantity

Quantity Unit (will default from Material Master)

Plant

Storage Location

Batch (if applicable)

UN Umoja Training Umoja Warehouse Management Page 52

User

Guide Goods Transfer in the Warehouse

4. Click the Enter icon

5. The system will take you to the Transfer Order data entry screen. Enter the following

input data:

Source and Destination storage type

Source and Destination storage section

Source and Destination storage bin

Quant (optional)

6. Click the Enter icon

7. Click the Save/Posting button

Note: Storage Types "DSP"(for goods to be disposed) and "TRN" (for in-transit goods) allow for

dynamic bin creation: to do so, enter the storage types code in the storage type field, and press

enter; the system will populate the storage section field automatically; now specify a storage bin

name; the system will automatically create a bin with the name specified.

UN Umoja Training Umoja Warehouse Management Page 53

User

Guide

Goods Transfers in the Warehouse

Stock Transfer Bin to Bin from a list – LT10

Step-by-Step Instructions

The steps to create the transfer order from a list are as follows:

1. Enter LT10 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No

Storage Type

Storage Bin (if needed)

4. Click the Execute button

UN Umoja Training Umoja Warehouse Management Page 54

User

Guide Goods Transfer in the Warehouse

5. Select the Storage Bin that you want to transfer the material from

6. Click the Stock transfer Foreground icon

7. Enter the following information in the Specify destination data window:

Storage Type

Storage Bin

Storage Section

Print Code (optional)

Printer (optional)

Movement Type (optional): 999

Confirm Immediately Check Box: if you want to confirm the TO immediately

UN Umoja Training Umoja Warehouse Management Page 55

User

Guide

Goods Transfers in the Warehouse

8. After completing the input, click the Copy button

Will turn green if the storage bin / material has no blocks.

9. Repeat steps above for other quants to be moved

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 56

User

Guide Outbound Delivery Processing

Outbound Delivery Processing

Create Transfer Order for Outbound Delivery – LT03

Step-by-Step Instructions

1. Enter LT03 in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

Plant

Delivery No: Delivery number (inbound or outbound)

4. Press Enter

Click the Generate and Next Material button

UN Umoja Training Umoja Warehouse Management Page 57

User

Guide

Outbound Delivery Processing

5. Populate the Destination Information in the fields:

Destination storage type

Destination storage section (optional)

Destination storage bin

Quant (optional)

6. Click the Enter icon

7. Click the Save button

Goods Reversal from Delivery – LT0G

Step-by-Step Instructions

The steps to return goods to stock from delivery are as follows:

1. Enter LT0G in the Command field

2. Click the Enter icon

3. Populate the following fields in the Basic Data tab:

Warehouse No: The number of the warehouse

Delivery No: Delivery number (inbound or outbound)

Movement Type: Use the system default type

4. There are 2 option buttons to choose from and choose one button to click

Delivery view: This option will show the delivery to be reversed at the Header

Level; if you choose this option, the picking for all line items will be reversed

TO item view: This option will show the delivery to be reversed at the Line item

level; if you choose this option you will be able to reverse selected line items

UN Umoja Training Umoja Warehouse Management Page 58

User

Guide Outbound Delivery Processing

5. Click the Enter icon

6. A list displayed with the delivery line items for reversal. Select a specific line item for

reversing and check the box

7. There are 3 options to put away the material back into the warehouse:

Putaway Foreground: this option will allow to return the stock in a bin different from

the one from which it was picked

Putaway Background: same as above, but the transaction will be performed in

background mode

Return to Stock: this option will return the stock in the same bin from which it was

picked

8. For the option of Putaway Foreground, select the line item you would like to move back

into warehouse and click the Putaway Foreground button

9. Populate the following fields in the Basic Data tab:

Storage Type

Storage Bin

Storage Selection

10. Click on the Adopt button

11. For the option of Return to Stock, only need to click the Return to Stock button

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 59

User

Warehouse Internal Maintenance Guide

Warehouse Internal Maintenance

Create Storage Bin Manually – LS01N

The steps to create a storage bin are as follows:

1. Enter LS01N in the Command field

2. Click the Enter icon

The Create Storage Bin screen is displayed.

3. Populate the following fields:

Warehouse No.

Storage type

Storage bin (To be created)

4. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 60

User

Guide Warehouse Internal Maintenance

5. Populate the following fields:

Storage section

Storage bin type

6. Click the Save icon

Storage bin has been created. Note the storage bin for future reference.

UN Umoja Training Umoja Warehouse Management Page 61

User

Guide

Warehouse Internal Maintenance

Change Storage Bin Manually – LS02N

The steps to change a storage bin are as follows:

7. Enter LS02N in the Command field

8. Click the Enter icon

The Change Storage Bin screen is displayed.

9. Populate the following fields:

Warehouse No.

Storage type

Storage bin (To be changed)

Note: if not known, the storage bin can be selected by clicking on the drop down icon on

the right side of the Storage Bin field.

10. Click the Enter icon

11. The Change Storage Bin screen is displayed. You can change, for example:

Storage section

Or, if the Storage Bin is empty, you can delete it clicking on the icon .

UN Umoja Training Umoja Warehouse Management Page 62

User

Guide Warehouse Internal Maintenance

The system will prompt a message; answer Yes if you want to delete the Storage Bin.

The system will issue a confirmation message “Storage Bin has been deleted”.

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

UN Umoja Training Umoja Warehouse Management Page 63

User

Guide

Physical Count

Physical Count

Create System Inventory Record – LI01N

Step-by-Step Instructions

The steps to create a system inventory record are as follows:

1. Enter LI01N in the Command field

2. Click the Enter icon

The Create System Inventory Record screen is displayed.

3. Populate the following fields:

Warehouse No.

Storage type

Planned count date

4. Click the Enter icon

5. The next screen is displayed. Populate the following fields:

UN Umoja Training Umoja Warehouse Management Page 64

User

Guide Physical Count

List of Stor. Bin

Name of Counter

6. Click the Activate icon

The Inventory Record Number XXXXXXXX activated.

Note the inventory record number as a reference.

Print Inventory List – LI04

Step-by-Step Instructions

The steps to print inventory list are as follows:

1. Enter LI04 in the Command field

2. Click the Enter icon

Note: The system will pre-populate the fields if this transaction is executed immediately after

creation of the system inventory record (previous step).

UN Umoja Training Umoja Warehouse Management Page 65

User

Guide

Physical Count

3. Populate the following fields:

Warehouse Number

Inventory record

Recount version: Populate this field if it is a recount

Printer: LOCL

List name: ZRLLI0400 (default)

Print report: ZRLLI0400 (default)

4. Select the following check boxes:

Print list

Print immediately

UN Umoja Training Umoja Warehouse Management Page 66

User

Guide Physical Count

The Inventory List is printed.

Enter Inventory Count – LI11N

Step-by-Step Instructions

The steps to enter inventory count are as follows:

1. Enter LI11N in the Command field

2. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 67

User

Guide

Physical Count

Note: The system will pre-populate the fields if this transaction is executed immediately

after creation of the system inventory record (previous step).

3. Populate the following fields:

Warehouse Number

Inventory record

Recount version: Populate this field if it is a recount

Count date: Populate the date when the test was performed

Name of counter: This is an optional field. It will be automatically populated with

the user id of the user entering the count

4. Click the Enter icon

5. The Enter Inventory Count: Overview screen is displayed

6. Enter the count results in the Counted quantity field for each storage bin

7. Select the Zero check box for the storage bin where the count was zero

8. Click the Enter icon

Note: If there are differences, the system will display a new screen with details and a

message to notify the % variance: click on the green tick to confirm. The system will do

UN Umoja Training Umoja Warehouse Management Page 68

User

Guide Physical Count

this for each line item of the count with differences; please cleck on the green tick until

you get to the last item of the count with differences.

At the end the system will take you back to the overview screen.

9. Click on Save to save your count results.

Note: System message: Inventory count is added for inventory XXXX.

Start Recount – LI14

Step-by-Step Instructions

The steps to start recount are as follows:

1. Enter LI14 in the Command field

10. Click the Enter icon

11. Populate the following fields:

Warehouse Number

Inventory record

12. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 69

User

Guide

Physical Count

The Start Recount: Initial Screen is displayed. It displays a recount overview report

reflecting the recount variances and the total US$ value difference.

13. Select the check boxes on the left side of the line items (storage bins) which are to be

recounted from the list of various bins in that inventory record

14. Click the Initiate Recount button

UN Umoja Training Umoja Warehouse Management Page 70

User

Guide Physical Count

Note: To perform the recount, please refer to the steps followed for the Enter Inventory

Count and enter the recount version in LI11N transaction.

Clear Differences in WM – LI20

Step-by-Step Instructions

The steps to clear differences in WM are as follows:

1. Enter LI20 in the Command field

15. Click the Enter icon

16. Populate the following fields:

Warehouse Number

UN Umoja Training Umoja Warehouse Management Page 71

User

Guide

Physical Count

Inventory record

17. Click the Enter icon

The next screen is displayed.

18. Select the check boxes on the left side of all the storage bins for which you would like to

clear the differences, if any

19. Click the Write Off button

The system will display a message with number of bins cleared.

Clearing of Differences in IM (Serialized Materials) – ZLE_LI21

Step-by-Step Instructions

The steps to clear differences in IM are as follows:

1. Enter ZLE_LI21 in the Command field

2. Click the Enter icon

3. Populate the following fields:

UN Umoja Training Umoja Warehouse Management Page 72

User

Guide Physical Count

Warehouse Number

Storage type: 999 (this is a pre-definite value)

Storage bin: (blank)

4. Click the Execute button

Note:

If there are materials to be written off, the application takes you to the next screen

If there are no material to be written off , this step is not required

5. The system displays the warehouse physical count differences that are still to be cleared

in the Inventory Management

6. Select the check boxes on the left side of the line items that display the differences that

are to be written off

7. Click the List from the top menu

8. Select the Clear Online Frgrnd check box

The list of inventory with outstanding physical count differences is displayed.

9. The list shows the physical count document number in the Storage Bin field

Note:

The quantity with a negative sign is an addition to stock – this difference is

determined when the stock counted is more than the quantity in the system

The quantity has no sign – this difference is determined when the stock counted is

less than the quantity in the system

UN Umoja Training Umoja Warehouse Management Page 73

User

Guide

Physical Count

If the count included serialized materials for which there are differences, it is required to perform

the steps described below.

The steps for serialized materials are as follows:

The next screen is displayed.

10. Enter the serial number in the Serial Number field for the physical count difference that

is to be cleared

Note: If the serial number is not known, you can search for it by clicking the Matchcode

icon in the XXX (entry) field. The system will display a list where additional search

criteria can be entered to find the relevant serial number. An example of the relevant

criteria is the Batch, that is used also to identify the valuation class (e.g.,

OLD_SPARES, NEW_SPARES).

11. Click the Execute icon

Note: If, as a result of the physical count, a positive difference is detected (the counted

quantity of the material is higher than the quantity in the system), a serial number may

need to be created. To do so, just select the create serial number automatically

check box.

A pop up screen is displayed that specifies the Serial Number.

If you know the serial number, you can specify, else you can search it in the serial number list.

You can generate it for addition to stock (physical count results into a quantity higher than the

quantity in the system).

The Material document is created.

UN Umoja Training Umoja Warehouse Management Page 74

User

Guide Physical Count

The steps for non serialized materials are as follows:

12. Click the Write off button

Note: The transaction either removes the extra material from the inventory or adds

material to the inventory.

A message is displayed by the system indicating that the quant is cleared

In the background, a set of material and accounting documents are created

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

All

screenshots

will be left

aligned

UN Umoja Training Umoja Warehouse Management Page 75

User

Guide

Reports

Reports

Stock Overview WM – LS26

Step-by-Step Instructions

The steps to view the Stock Overview WM Report are as follows:

1. Enter LS26 in the Command field

2. Click the Enter icon

3. Populate the following fields:

Warehouse Number

Material

Plant: It is an optional field

Storage Location: It is an optional field

Storage Type: It is an optional field

Note: You can enter as many fields so as to narrow down the search.

UN Umoja Training Umoja Warehouse Management Page 76

User

Guide Reports

4. Click the Enter icon

The Stock Overview WM report is displayed.

This report can be executed only for one material at the time. Repeat the steps for

the other materials

The Stock Overview WM report displays a report of how the material is placed in the

various locations in the warehouse

If the report is executed after a goods receipt, before the items have been put away

in the warehouse, the items will appear in the goods receipt area and the quantity will

be the total received quantity by material / storage location / warehouse

5. Double-click the line item in the displayed list to view the details on the warehouse

locations. Further details are displayed, such as the storage bin and the quantity in the

bin

UN Umoja Training Umoja Warehouse Management Page 77

User

Guide

Reports

Bin Status Report – LX03

Step-by-Step Instructions

The steps to view the Bin Status Report are as follows:

1. Enter LX03 in the Command field

2. Click the Enter icon

3. Populate the following fields:

Warehouse No

Storage type

4. Click the Execute icon

Note: To search for a specific material, you can add it in the search selection criteria.

a. Click the Rainbow icon

b. A window is displayed where you can select the group of additional selection

criteria

UN Umoja Training Umoja Warehouse Management Page 78

User

Guide Reports

c. Click Quant

d. The list of available dynamic selections is displayed

e. Double-click the Material field

f. Enter value in the Material field

5. Click the Execute icon OR Press F8 to run the report

The Bin Status Report is displayed. It displays a list of bins with their stock figures etc.

It also displays the empty bins.

UN Umoja Training Umoja Warehouse Management Page 79

User

Guide

Reports

6. You can note down the following information for various purposes:

For all Picking processes, note down the bins where the material is available and in

stock

If the picking refers to serialized materials, please verify the serial numbers in the

selected bin by physically checking in the content / serial numbers; note down the

available serial numbers for future use

For Putaway processes, identify the bin for put-away: this can be an empty bin or a

bin where the material already exists, depending on the storing requirements

To create a manual TO, note down the Storage Type, Bin, Quant, etc.

Further column may be added to the standard layout. The steps to display additional

information, such as stock, batch, etc. are as follows:

7. Click the icon Current Layout on the top part of the screen. The system displays

the a pop up box with the columns currently displayed (on the left) and the available

columns for display in the right side. You can select the required columns from the right

side (multiple columns may be selected at the same time) and moved to the left side in

the required position using the arrow icons: The desired layout can be saved and

retrieved any time the report is executed

UN Umoja Training Umoja Warehouse Management Page 80

User

Guide Reports

List of Empty Bins Report – LX01

Step-by-Step Instructions

The steps to view the List of Empty Bins Report are as follows:

1. Enter LX01 in the Command field

2. Click the Enter icon

3. Populate the following fields:

Warehouse No.

Storage Type

UN Umoja Training Umoja Warehouse Management Page 81

User

Guide

Reports

4. Click the Execute icon

A List of Empty Bins Report is displayed. It displays a list of all the empty bins in that

warehouse/storage type depending on the search criteria mentioned.

You can note down the available bins. For putaway processes, you can note bin

number, storage section, and storage type.

UN Umoja Training Umoja Warehouse Management Page 82

User

Guide Reports

Stock per Material WM – LS24

Step-by-Step Instructions

The steps to view Stock Per Material WM Report are as follows:

1. Enter LS24 in the Command field

2. Click the Enter icon

3. Populate the following fields:

Warehouse No.

Material

Plant

Storage Location

Note: Depending on how much you would like to narrow down the report additional

selection criteria are available.

4. Click the Enter icon

UN Umoja Training Umoja Warehouse Management Page 83

User

Guide

Reports

A report with stock quantity and warehouse location is displayed.

Stock for All Material WM – LX02

Step-by-Step Instructions

The steps to view the Stock Per All Material WM report i.e., warehouse stock for multiple

materials are as follows:

1. Enter LX02 in the Command field

2. Click the Enter icon

The system displays the initial report screen where it is possible to indicate the selection

criteria.