Beruflich Dokumente

Kultur Dokumente

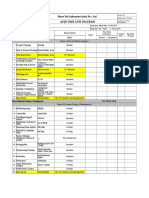

Supplier Change Request Form 8 DB 34 B 1 Ba

Hochgeladen von

HusseinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Supplier Change Request Form 8 DB 34 B 1 Ba

Hochgeladen von

HusseinCopyright:

Verfügbare Formate

Tracking #

SUPPLIER CHANGE REQUEST / REVIEW

Part Name

Part No./Chg. Level

Shown on chart #

Product Application Supplier Name Supplier Manufacturing Location & SAP ID

SECTION 1: CHANGE DESCRIPTION

Detailed Description of Change Proposal: Affects:

Yes No

(ANYONE CAN INITIATE)

Appearance

Cost/ Capacity

Drawing/ Dims.

Function

Key Prod. Char.

Mass

Material

Packaging

Process

Quality

Safety

Timing

Reason For Change: Reference PPR # (if applicable):

(THIS SECTION MUST BE COMPLETED FOR ALL ITEMS MARKED 'YES' IN ITEM #9. ATTACH DETAIL AS NECESSARY (See Instructions)

SECTION 2: CHANGE IMPACT

Impact change will have:

(SUPPLIER ONLY)

** ATTACH IMPLEMENTATION TIMELINE, CONTINGENCY PLAN, SKETCHES, DRAWINGS, ENG. PERMITS, etc. **

Signature: Submitted to:

(Supplier) Date:

For Further Details Firm PPAP

Supplier Contact: Phone: Submission Date:

Plants impacted

Krosno Cheb Luton Chihuahua Fangshan Shanghai Other

Signatures & Date of Decision

FUNCTION NAME & PHONE # APPROVED CR Number

Change Review Board Leader:

** If Approved: (one box must be checked)

Proceed with preparation of PPAP Submission as defined below (include copy of this form with PPAP submission)

NOTE - - This does not authorize production shipment incorporating change; authorization will be contingent on PPAP approval or

engineering permit.

- Subsequent ship requirements will be communicated through PC&L

PPAP Submission Not Required - Proceed with Change as defined below

SECTION 3: DISPOSITION

NOTE - Supplier must still update and maintain appropriate documents at their location

(BWI ONLY)

** If Rejected: (Reason for rejection)

Information to be Submitted / Actions Required: PPAP LEVEL -

PPAP Requirements: Implementation Requirements:

Part Submission Warrant Process Control Plan Pending Design/Process Validation

New Part Number Early Production Containment Pending Customer Approval

Print and Inspection Results Process Capability Studies Pending Production Trial Run

Appearance Approval Report Checking Aides On Site Audit

Sample Parts Gage Studies Early Production Containment

DFMEA Laboratory/Test Results/Specs Appropriate Packaging Forms

PFMEA Material Certification(s) Run at Rate Date

Process Flow Diagram Tier II Approval (Documentation Req'd) BWI Monitord Supp. Montitored

Engineering Permits Other Breakpoint Tag Required for Shipment

COMMENTS / CONDITIONS: by

CHANGE AUTHORIZATION SENT TO: Date:

(Supplier contact)

Rev 17-Mar-2016 BWI Supplier Change Request 310f1

Date of Contact for

Rev # / Revision Description Tab Revised Revision Questions

0 / Initial Issue - Was previously maintained outside of CPP All 17-Mar-2016 DM Hudson

Rev 17-Mar-2016 Revisions 310f1

Das könnte Ihnen auch gefallen

- Supplier Deviataion Request Form RevBDokument2 SeitenSupplier Deviataion Request Form RevBwdavid81100% (1)

- Product Qualification Requirements 2.0Dokument3 SeitenProduct Qualification Requirements 2.0Amit SinghNoch keine Bewertungen

- Jipl CL Pur 10 Testing Lab AuditDokument8 SeitenJipl CL Pur 10 Testing Lab AuditMeghna SharmaNoch keine Bewertungen

- Validation PlanDokument2 SeitenValidation PlanCHARMINGNoch keine Bewertungen

- Design Validation TipsDokument2 SeitenDesign Validation Tipsanilsamuel0077418Noch keine Bewertungen

- Aqpaxi Phase 2.rev13Dokument7 SeitenAqpaxi Phase 2.rev13Isabel SierraNoch keine Bewertungen

- Building An Effective Supplier Control Program:: A Review of Key Program Elements & Their ImplementationDokument37 SeitenBuilding An Effective Supplier Control Program:: A Review of Key Program Elements & Their Implementationmulyana-Noch keine Bewertungen

- CLAUSE 8.5 Production and Service ProvisionDokument10 SeitenCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNoch keine Bewertungen

- Control of Monitoring & Measuring DevicesDokument10 SeitenControl of Monitoring & Measuring DevicesRamesh mudunuriNoch keine Bewertungen

- Part Inspection Standard (May 2013)Dokument9 SeitenPart Inspection Standard (May 2013)san moedano100% (1)

- Template - Management Review ReportDokument2 SeitenTemplate - Management Review ReportIslam WayNoch keine Bewertungen

- Annual Product Quality Review (APQR) SOP - PharmaBDokument14 SeitenAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- PPAP Process Checklist / Sign Off Sheet InstructionsDokument7 SeitenPPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhaneNoch keine Bewertungen

- Form - Scar LogDokument18 SeitenForm - Scar LogHarie BongkyNoch keine Bewertungen

- Sop 003 For Analysis of Rinse SampleDokument3 SeitenSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- Change Management ProcedureDokument4 SeitenChange Management ProcedureCarlos Cueva GallegosNoch keine Bewertungen

- Change Control Alaxan FR Capsule 2020Dokument6 SeitenChange Control Alaxan FR Capsule 2020Rio FebriansyahNoch keine Bewertungen

- Procedure For ApqpDokument19 SeitenProcedure For ApqpRaja RehaNoch keine Bewertungen

- 9001 Audit Checklist - Quality Planning and DesignDokument14 Seiten9001 Audit Checklist - Quality Planning and DesignAmer RahmahNoch keine Bewertungen

- Excerpt From Table of Contents For Quality Manual of Aerospace CompanyDokument1 SeiteExcerpt From Table of Contents For Quality Manual of Aerospace CompanyluzmindaNoch keine Bewertungen

- QP Nonconforming Product Sample 2014Dokument2 SeitenQP Nonconforming Product Sample 2014Anna Maree100% (1)

- SOP-RD-7.1-001 Advanced Product Quality PlanningDokument13 SeitenSOP-RD-7.1-001 Advanced Product Quality PlanningXionNoch keine Bewertungen

- PPAPDokument16 SeitenPPAPRohit JanardananNoch keine Bewertungen

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDokument2 SeitenShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNoch keine Bewertungen

- SOP 20-005 Sampling InspectionDokument9 SeitenSOP 20-005 Sampling InspectionsushmaxNoch keine Bewertungen

- Review Meeting SOPDokument2 SeitenReview Meeting SOPMuneeb Hussaini0% (1)

- Training Needs IdentificationDokument1 SeiteTraining Needs IdentificationSachin RamdurgNoch keine Bewertungen

- OBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Dokument4 SeitenOBJECT 188 QOP-82-04 (01) Final Acceptance Inspection A 1Andy RojasNoch keine Bewertungen

- TMT Procedure - Analysis of Data & Continuous Improvement P2Dokument1 SeiteTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNoch keine Bewertungen

- Management Review Meeting ChecklistDokument1 SeiteManagement Review Meeting ChecklistGaruda84Noch keine Bewertungen

- SOPCQAQA006 Handling of Market ComplaintDokument7 SeitenSOPCQAQA006 Handling of Market ComplaintSagar ChavanNoch keine Bewertungen

- Quality Control PlanDokument1 SeiteQuality Control PlanScha Affin100% (1)

- QMS 060 SampleDokument4 SeitenQMS 060 SamplebaluchakpNoch keine Bewertungen

- PUR-PM-06 Initial Flow Control For PCS SupplierDokument4 SeitenPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNoch keine Bewertungen

- Supplier Audit FormatDokument4 SeitenSupplier Audit FormatPratik KarekarNoch keine Bewertungen

- Guide-Mqa-024-004 AprDokument9 SeitenGuide-Mqa-024-004 Aprdrs_mdu48Noch keine Bewertungen

- Change Request FormDokument6 SeitenChange Request FormVamsi aravetiNoch keine Bewertungen

- Cream & Ointment Process ValidationDokument3 SeitenCream & Ointment Process Validationtajmir haqueNoch keine Bewertungen

- SOP Change Control 2015 09 043Dokument16 SeitenSOP Change Control 2015 09 043kim_jamjungNoch keine Bewertungen

- Change Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-XxxDokument7 SeitenChange Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-Xxxrouss1906Noch keine Bewertungen

- Sample Process DefinitionDokument4 SeitenSample Process DefinitionAnkur Dhir0% (1)

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Dokument5 SeitenQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNoch keine Bewertungen

- APQP Checklist Design PDFDokument3 SeitenAPQP Checklist Design PDFShiva SNoch keine Bewertungen

- Form - Supplier Quality Survey - Rev 0Dokument3 SeitenForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNoch keine Bewertungen

- QAD Procedure - Lab Management P1Dokument1 SeiteQAD Procedure - Lab Management P1sumanNoch keine Bewertungen

- Blank CapaDokument2 SeitenBlank Capasahajapatel29Noch keine Bewertungen

- Control of Noncomformitiy and Corrective Action PDFDokument7 SeitenControl of Noncomformitiy and Corrective Action PDFNixNoch keine Bewertungen

- QSV 2 Product Release Procedure EN 01Dokument6 SeitenQSV 2 Product Release Procedure EN 01prashanthNoch keine Bewertungen

- Supplier Performance Evaluation Data SheetDokument13 SeitenSupplier Performance Evaluation Data SheetJohn StoltzNoch keine Bewertungen

- Control Plan FormatDokument6 SeitenControl Plan Formatazadsingh1Noch keine Bewertungen

- Asq What Is A Quality PlanDokument3 SeitenAsq What Is A Quality PlanCloud RedfieldNoch keine Bewertungen

- Why Perform Production Part Approval Process (PPAP)Dokument6 SeitenWhy Perform Production Part Approval Process (PPAP)Sourabh Patil100% (1)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDokument9 SeitenGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNoch keine Bewertungen

- ISO 9001 Conformity MatrixDokument3 SeitenISO 9001 Conformity Matrixkashifbutty2kNoch keine Bewertungen

- Quality Assurance Requirements For Licensees-07162010Dokument4 SeitenQuality Assurance Requirements For Licensees-07162010Norma GarciaNoch keine Bewertungen

- CSR - Audit ChecklistDokument2 SeitenCSR - Audit Checklistmahesk_dmNoch keine Bewertungen

- Critical Parameters Affecting Process ValidationDokument4 SeitenCritical Parameters Affecting Process ValidationruydeanzNoch keine Bewertungen

- VMP Proses Rev.13 2018Dokument19 SeitenVMP Proses Rev.13 2018fajarRS69Noch keine Bewertungen

- Change Control Request FormDokument3 SeitenChange Control Request FormSuleman FaizNoch keine Bewertungen

- NameDokument1 SeiteNameIrfan SiswantoNoch keine Bewertungen

- FebruaryDokument1 SeiteFebruaryAna Cristina SteffenNoch keine Bewertungen

- FebruaryDokument1 SeiteFebruaryAna Cristina SteffenNoch keine Bewertungen

- FebruaryDokument1 SeiteFebruaryAna Cristina SteffenNoch keine Bewertungen

- FebruaryDokument2 SeitenFebruaryHusseinNoch keine Bewertungen

- Total Quality Management: PCTI Limited - A Unique Name For Quality EducationDokument296 SeitenTotal Quality Management: PCTI Limited - A Unique Name For Quality Educationrajesh_vuNoch keine Bewertungen

- R & S Gratings CatalogueDokument48 SeitenR & S Gratings CatalogueBarrasons Engineers TeamNoch keine Bewertungen

- For Information Only, Will Not Be Exchanged When Altered!: Spare Part ListDokument12 SeitenFor Information Only, Will Not Be Exchanged When Altered!: Spare Part ListIrving Jose Vazquez QuezadaNoch keine Bewertungen

- Preguntas Al Comite API 1104Dokument12 SeitenPreguntas Al Comite API 1104alefeli26Noch keine Bewertungen

- RCA2600 User Manual Rev C PDFDokument9 SeitenRCA2600 User Manual Rev C PDFMarcus DragoNoch keine Bewertungen

- IJ GIS en - CompressedDokument24 SeitenIJ GIS en - CompressedpopaminoNoch keine Bewertungen

- Maruti Bba Project For MarketingDokument92 SeitenMaruti Bba Project For Marketingkaushal244256% (9)

- Mian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and SoDokument17 SeitenMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and SoWaseem WaseemNoch keine Bewertungen

- Access Hardware Architectural CatalogueDokument87 SeitenAccess Hardware Architectural CatalogueAccess HardwareNoch keine Bewertungen

- RDokument59 SeitenRChristopher AndersonNoch keine Bewertungen

- Double Layer Tile PressDokument6 SeitenDouble Layer Tile PressHaile Kebede100% (1)

- Irshad Ansari: Al Raha Village Mafraq Abu Dhabi UAEDokument2 SeitenIrshad Ansari: Al Raha Village Mafraq Abu Dhabi UAEirshadNoch keine Bewertungen

- Billypugh Practice1Dokument9 SeitenBillypugh Practice1Bernie SimcsNoch keine Bewertungen

- PRC Standards System, Standards Used in ChinaDokument3 SeitenPRC Standards System, Standards Used in ChinaFelix RanillaNoch keine Bewertungen

- Apple 7S ModelDokument2 SeitenApple 7S Modeljyothishwetha50% (4)

- 1 - Training PDS Interface - Generate PCD and PDS RDB FilesDokument25 Seiten1 - Training PDS Interface - Generate PCD and PDS RDB Filesno1139Noch keine Bewertungen

- Rt7015 Automatic Ticket Gates at Stations PDFDokument14 SeitenRt7015 Automatic Ticket Gates at Stations PDFCezary P.Noch keine Bewertungen

- SB805-10800-203 (Sky497)Dokument4 SeitenSB805-10800-203 (Sky497)Gerhard MNoch keine Bewertungen

- Risk Assessment Mwanza Oct 2014Dokument2 SeitenRisk Assessment Mwanza Oct 2014Rashid BumarwaNoch keine Bewertungen

- Annual Report2015-2016 HCL PDFDokument204 SeitenAnnual Report2015-2016 HCL PDFbhupendraNoch keine Bewertungen

- Pioneer4patrol PDFDokument17 SeitenPioneer4patrol PDFNelio CostaNoch keine Bewertungen

- Manual de Servicio Desarme Unidad de Imagen Tde Bizhub 350Dokument8 SeitenManual de Servicio Desarme Unidad de Imagen Tde Bizhub 350ruyNoch keine Bewertungen

- CSR 7th Edition FinalDokument9 SeitenCSR 7th Edition FinalLa Esencia De Lo FragilNoch keine Bewertungen

- SGL Carbon - Graphite HeDokument28 SeitenSGL Carbon - Graphite HevenkateaNoch keine Bewertungen

- Jindal Steel Product Catalogue PDFDokument32 SeitenJindal Steel Product Catalogue PDFkalaiNoch keine Bewertungen

- Essen Industries PVT - Ltd. AddressDokument4 SeitenEssen Industries PVT - Ltd. AddressChava RaviNoch keine Bewertungen

- Laporan Luaran Prosiding Internasional - SUPIYANDI - Tomuan HolbungDokument83 SeitenLaporan Luaran Prosiding Internasional - SUPIYANDI - Tomuan HolbungIka Devi PerwitasariNoch keine Bewertungen

- Minimum Equipment List/Permissible Unserviceability Procedures Manual 2. MEL Approval/Amendment Procedures 2.1 Introduction To The MEL Approval/Amendment ProcessDokument26 SeitenMinimum Equipment List/Permissible Unserviceability Procedures Manual 2. MEL Approval/Amendment Procedures 2.1 Introduction To The MEL Approval/Amendment ProcesspedatiNoch keine Bewertungen

- IRITS-0617-034 HLA Heatless Desiccant Air DryerDokument2 SeitenIRITS-0617-034 HLA Heatless Desiccant Air DryerEddie SantillánNoch keine Bewertungen

- CONSULTANT SELECTIONS 20202005 With NotesDokument27 SeitenCONSULTANT SELECTIONS 20202005 With NotesTimothy CruseNoch keine Bewertungen