Beruflich Dokumente

Kultur Dokumente

Guide To Inspecting and Maintaining Cranes

Hochgeladen von

Berk TekinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guide To Inspecting and Maintaining Cranes

Hochgeladen von

Berk TekinCopyright:

Verfügbare Formate

GUIDE TO INSPECTING

AND MAINTAINING CRANES

This Guide provides information on inspecting, testing, maintaining and repairing cranes in the workplace

and supports the General guide for cranes.

This Guide forms part of a series of guides and information sheets for cranes that includes information on:

mobile cranes

tower cranes

bridge and gantry cranes

vehicle loading cranes

vessel-mounted cranes

crane-lifted workboxes

using other powered mobile plant as a crane, and

quick-hitches for earth moving machinery.

Maintaining a safe work environment

As a person conducting a business or undertaking you have obligations under the Work Health and

Safety (WHS) Regulations to ensure, so far as is reasonably practicable, workers and other people are

not exposed to health and safety risks arising from the business or undertaking. This includes making

sure cranes at your workplaces are inspected and maintained.

A preventative inspection, maintenance and testing program will help ensure a crane is safe to use.

Inspections and maintenance should be done in accordance with the manufacturer’s instructions or,

if these are not available, a competent person’s specifications or according to relevant technical

standards and engineering principles.

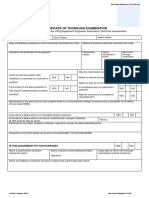

Checklists for the inspection and testing of tower and mobile cranes including for major inspections and

tower crane pre-erection and commissioning inspections are at Appendix A.

Pre-operational checks

Before operating a crane a pre-operational check should be completed by a competent person.

An appropriate log book should be used to record the condition of the crane.

Routine inspection and maintenance

Regular inspection, maintenance and repair are to be carried out in accordance with the manufacturer’s

instructions or those of a competent person. For inspections, if this is not practicable, they must be

completed at least annually.

Cranes should be routinely inspected and tested even if they are not operated regularly. This is because

the crane may have deteriorated through corrosion or be damaged.

Routine inspections can take place weekly, monthly or quarterly and should include an inspection of:

crane functions and the controls for speed, smoothness of operation and limits of motion

emergency and safety switches and interlocks including limiting and indicating devices

lubrication of moving parts

verify accuracy of any load moment indicator (LMI) and rated capacity indicator (RCI) devices with a test

lift using a certified test weight

filters and fluid levels and leaks

visual inspection and measurements as necessary of structural components and critical parts including

brakes, gears, fasteners, pins, shafts, wire ropes, sheaves, locking devices and electrical contactors

signage including warning signs and control markings

wear on wheels and tyres, and

978-1-76028-492-3 [Multi-Vol. Set] 978-1-76028-476-3 [PDF]

978-1-76028-477-0 [DOCX]

extra items nominated in the crane manufacturer’s instructions.

A written report should be prepared when the inspection is finished. If replacement parts are needed as

a result of the inspection, these parts should meet the original part’s specification.

If a crane has been damaged and there are risks to health and safety, it should be immediately taken

out of service and people prevented from operating the crane. If the crane needs to be operating during

maintenance or cleaning, risk control measures must enable this to occur without risk to health and

safety.

Annual inspection

Regular inspections must be carried out in accordance with the manufacturer’s instructions or those of a

competent person or, if this is not reasonably practicable, annually.

An annual inspection may be less comprehensive than a major inspection. It should include every item

specified by the crane manufacturer for annual inspection and every item included in the routine

inspection and maintenance programs.

Annual inspections should include a detailed check of:

functioning and calibration of limiting and indicating devices

structural and wear components

tolerances for wear limit

evidence of corrosion

critical areas for evidence of cracking, and

for tower cranes, relevant items in the pre-erection inspection and tests that can be safely completed

while the crane is erected.

Where a tower crane owner is aware a crane will be erected when the scheduled annual inspection falls

due, the owner can choose to carry out an annual inspection before erecting the crane or during the

pre-erection inspection.

Major inspections

A major inspection must be completed for registered mobile and tower cranes. Non-registrable mobile

cranes and bridge and gantry cranes should have a regular ‘major’ inspection completed so that they

continue to be safe to operate.

Major inspections must be carried out at the end of the crane’s design life, as determined by the

manufacturer’s instructions, or if these are not available, as determined by a competent person to meet

the same minimum requirements established by relevant technical standards.

If it is not reasonably practicable to inspect a crane according to either of these, you should inspect the

crane at least every 10 years from the date the crane was first commissioned or registered, whichever

was first. This must include inspection of the structure as well as mechanical components.

Major inspections must be carried out by, or under the supervision of, a competent person who:

has acquired through training, qualifications or experience the knowledge and skills to carry out a major

inspection of the plant and is registered under a law that provides for the registration of professional

engineers, or

is determined by the regulator to be a competent person.

Appendix A lists some items to be inspected during a major inspection for tower and mobile cranes.

Some of the items may not apply, for example where the item does not exist on the crane. The full list

of items to be inspected must be determined by a competent person.

Completion of a major inspection does not indicate that the components inspected will have a further

10 year life. It should not be assumed that the items included in the list only require inspection at

10 yearly intervals. Items will require some type of inspection and maintenance at more frequent intervals,

for example at annual and other inspection intervals, according to the crane manufacturer’s instructions.

Where there is documented evidence that inspection and testing has been carried out on certain items,

for example slew ring bolts, drive systems and braking systems, within a reasonable preceding period

(as determined by a competent person) the item may not have to be stripped down in the major

Guide to inspecting and maintaining cranes December 2015 Page 2 of 7

inspection. The competent person should still inspect the safe operation of the item to certify it is

operating safely and document the reasons for the decision.

Record keeping

Crane records including maintenance logbooks of the significant events concerning the safety and

operation of the crane must be kept and readily available. Records should be kept in a suitable format

and must be transferred with ownership of the crane. Entries in the maintenance logbook should:

clearly describe the work carried out and parts replaced

be dated

note the name of the person carrying out the work, and

be signed by the person carrying out the work.

The checks, adjustments, replacement of parts, repairs, inspections performed and irregularities

or damage concerning the unit’s safe use must be recorded.

Inspection records should include a statement from a competent person confirming the item of plant has

been inspected and is safe to operate.

Inspection records should include:

What was looked at – component specification or areas of the plant inspected.

What was looked for – signs of wear, damage, cracking or corrosion.

What criteria were used – rejection criteria.

How was it looked for – techniques used.

What was found – test results, photographs or measurements.

What was recommended – repairs required before continued use.

What recommendations were actioned – recommendations acted upon and date tasks were completed.

Tower cranes

Pre-erection inspection and tests—on ground inspection

Tower crane components should be inspected and tested by a competent person according to the

manufacturer’s instructions before being delivered to the workplace and before being erected.

Where a tower crane owner is aware a crane will be erected when the scheduled annual inspection is

due, the owner may consider carrying out an annual inspection during the pre-erection inspection.

Crane owners should develop their own pre-erection inspection and test report that satisfies the

requirements of the WHS Regulations and the manufacturer’s instructions. The report should also reflect

the specific type and model of crane and reference relevant design drawings and test certificates.

Commissioning inspection and tests

Commissioning inspections and test should be carried out by a competent person according to the

manufacturer’s instructions before a tower crane is put into service.

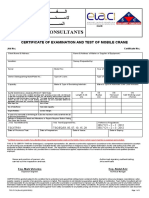

Non-destructive testing of tower crane components

Non-destructive testing (NDT) is the testing of materials to detect internal, surface and concealed defects,

cracks, breaks or gaps using methods which do not damage or destroy the material being tested.

NDT must be carried out by a competent person having suitable knowledge and experience in NDT

methods and being able to determine the appropriate NDT method for the component being tested.

When using magnetic particle NDT to detect cracks in metals remove the paint from the metal surface.

This is not required for Eddy current NDT.

NDT of specific tower crane components should take place according to the manufacturer’s instructions

and at set intervals, for example pre-erection tests and major inspection. Table 1 indicates some common

minimum frequencies of NDT for particular crane components.

Guide to inspecting and maintaining cranes December 2015 Page 3 of 7

Table 1 Minimum frequency of NDT for particular crane components

Component tested NDT description NDT frequency

Boom clevises Crack test Pre-erection

Counterweight sheave bracket welds – Crack test Pre-erection

moving counterweights only

Cruciform welds – luffing cranes only Crack test Pre-erection

Butt heal bosses – luffing cranes only Crack test Pre-erection

Band brake welds Crack test Pre-erection

Slew ring bolts – where slew ring has to Crack test minimum 10% bolts Pre-erection

be split at disassembly

Tower bolts (where applicable) Crack test minimum 10% bolts Pre-erection

Boom lacing welds Crack test minimum 10% Pre-erection

Tower sections Crack test minimum 10% Pre-erection

Aluminium sheaves Crack test Pre-erection

Slew ring bolts – slew rings Crack test bolts 5 years

Boom chord thickness Material thickness testing 10 years

Slew ring Crack test 10 years

Hydraulic luffing cylinder gland nut Crack test 10 years

Hydraulic luffing cylinder and ram-rod Crack test 10 years

ends and caps

A-frame – connector welds on primary Crack test 10 years

chords

A-frame lacing welds Crack test minimum 10% 10 years

Hook Crack test 10 years

Welds on hook trolley Crack test 10 years

Crack testing of booms and counterweight sheave bracket welds

Booms on non-self-erecting tower cranes are connected by pins passing through male and female

clevises on the ends of each boom section. Every weld on male and female clevises on the ends of every

boom section should undergo NDT before each crane erection for non-self-erecting cranes. Magnetic

particle testing is the usual method used for performing these tests.

Counterweight sheave bracket welds, butt heal bosses and welds in cruciform area on luffing crane

booms are known to crack and should also be crack tested by NDT before each crane erection.

Crack testing of band brakes

Older designs of luffing tower cranes use band brakes. On some of these cranes the steel band is welded

to an end fitting that has a pin passing through it. These welds have been known to crack.

You should crack test the weld between the band and the end fitting by NDT before each time a luffing

tower crane fitted with band brakes is erected, keeping in mind there may not be a weld on some brake

bands.

Crack testing of slew ring bolts

The integrity of slew ring bolts is critical for making sure both the machine deck and boom remain

attached to the tower. Once removed, slew ring bolts should be replaced unless the manufacturer’s

instructions state they can be reused. If bolts can be reused they should be tested.

Guide to inspecting and maintaining cranes December 2015 Page 4 of 7

For tower cranes where the slew ring needs to be split each time the crane is moved, NDT 10 per cent

of slew ring bolts is suggested. Bolts to be tested should be selected from the slew ring by a competent

person. Complete removal of the bolts from the slew ring and use of magnetic particle testing is

recommended. If cracks are detected, bolts should be discarded and replaced with new bolts.

Crack testing of tower bolts or pins

Tower bolts or pins are a critical part of the crane and permit the effective transfer of load from the crane

boom to the crane base. Tower bolts or pins can become damaged and their effective life can be reduced

if the bolts are either under or over-torqued. Some tower bolts are made from extremely high grade steel

and can be more susceptible to cracking.

Unless the manufacturer’s instructions state tower bolts can be reused, they should be replaced. If bolts

can be reused, crack test a minimum of 10 per cent of tower bolts by NDT before each crane erection.

If cracks are found, tower bolts should be discarded and replaced with new bolts.

A system that makes sure tower bolts or pins are tested over time is preferred. However a random

system of testing can also be used. The tested bolts should be identified by a method that does not

damage the bolt.

Chord thickness testing

Steel lattice-type tower crane booms can be prone to internal and external corrosion affecting the

thickness of the boom. The thickness of the chord wall can be reduced through abrasive blasting of the

boom.

Main chord sections on tower crane booms should undergo thickness testing at intervals not exceeding

10 years. Ultrasonic thickness testing is one method of verifying the strength in the chords

of the boom.

Review chord sections for structural adequacy when the thickness is shown by testing to be 90 per cent

or less than 90 per cent of the original thickness.

Further information

The following technical standards provide further information on inspecting and maintaining cranes:

AS 2550.1-2011: Cranes, hoists and winches—Safe use Part 1: General requirements

AS 2550.3-2002: Cranes, hoists and winches—Safe use Part 3: Bridge, gantry, portal (including

container cranes) jib and monorail cranes

AS 2550.4-2004: Cranes, hoists and winches—Safe use Part 4: Tower cranes

AS 2550.5-2002: Cranes, hoists and winches—Safe use Part 5: Mobile cranes

AS 2550.11-2004: Cranes, hoists and winches—Safe use Part 11: Vehicle-loading cranes, and

AS 2550.20-2005: Cranes, hoists and winches—Safe use Part 20: Self-erecting tower cranes.

Guide to inspecting and maintaining cranes December 2015 Page 5 of 7

Appendix A - inspection / testing for tower cranes

Commissioning

Pre-erection inspections / tests Major inspection

inspections / tests

NDT of welds on vital components Crane electricity supply— Slew Ring

including boom clevises, butt heel bosses where used Hydraulic motors

and counterweight rope sheave brackets Crane base weights or Hydraulic pumps

NDT of tower crane bolts ballast—where used Valve blocks

NDT of slew ring bolts Tower section identification (bodies)

NDT of aluminium sheaves and entry Hoist and luff

The condition of the power supply cable— Tower bolts to correct drums

where used tension Braking systems

The condition of motor brakes Pins and fastenings Rope sheaves

The condition of the slew ring gear and Climbing frame and Hydraulic luffing

pinions connection cylinder

Air controls and associated valves Jib connection pins and Gear boxes and

The condition of ropes and sheaves e.g. retainers drive shafts

erecting, hoisting, counterweight and A-frame connections and Boom

trolley, correct rope tracking and no signs retainers—where applicable

A-frame

of damage or excess wear Jib and deck pendant pins

Pins with moving

The condition of limit switches and limiting and retainers—where used

parts for

devices Machinery guarding example, boom

The condition of counterweights Leakage in lines, tanks, heel pins and

The condition and fitment of machinery valves, pumps and other ram pins

guarding parts of air or hydraulic Static pins

Brake systems can be dismantled and systems

Steel wire ropes

inspected for wear and damage: The condition of the ropes

and sheaves e.g. erecting,

o dry brakes—before each erection or

hoisting, trolley and

more frequently if directed by the

counterweight, and correct

manufacturer

rope tracking

o wet brakes—before each erection or

Isolating switches

after 5000 hours of crane operation or

as directed by the manufacturer The condition and phase of

the power supply cable

Normal service items including items Verification the crane wiring

supplied by the crane manufacturer e.g. complies with AS/NZS

temperature control units and seating being 3000:2007: Electrical

maintained in a serviceable condition installations

according to the crane manufacturer’s

Effective operation of

instructions, and

controls including interlocks

Other tests as specified by the

Effective operation of

manufacturer.

indicating devices

Once the tower crane components have been

Effective operation of travel

delivered to the workplace they should be

deceleration switches

inspected by a competent person for possible

damage and wear that may have occurred Effective operation of hoist

during transport. Inspections should include: upper and lower—where

needed—working limit

The crane base design and engineer’s

switches

report

Effective operation of

Crane ties and structure to support them

warning devices

where used

Effective operation of

The power supply and earthing.

weather-vaning

Effective operation of the

hoist and travel brakes when

the crane is laden to the

Guide to inspecting and maintaining cranes December 2015 Page 6 of 7

Commissioning

Pre-erection inspections / tests Major inspection

inspections / tests

maximum rated capacity

Effective operation of the

rescue controlled descent

device

Other tests specified by the

crane manufacturer.

Appendix A - inspection / testing for mobile cranes

Major inspection

Chassis including outriggers and boxes

Drive train and suspension components

Slew ring

Slew ring bolts

Hook rollers

Drive systems including winches, hydraulic motors, gearboxes and drive-shafts

Control systems

Braking systems

Electrical systems

Hydraulic systems—cylinders including outrigger cylinders

Booms

Safety devices including rated capacity limiters and load indicators

Outriggers

Steel wire ropes, and

Rope sheaves.

Electrical systems—hazardous voltage

Control systems—non-hazardous voltage

Electric motors

Hook assembly

Guide to inspecting and maintaining cranes December 2015 Page 7 of 7

Das könnte Ihnen auch gefallen

- Fact Sheet Rocket StovesDokument2 SeitenFact Sheet Rocket StovesMorana100% (1)

- OECP Crane Operator Candidate ManualDokument66 SeitenOECP Crane Operator Candidate ManualkhalidNoch keine Bewertungen

- Lift Director SummaryDokument4 SeitenLift Director SummarysamNoch keine Bewertungen

- Crane Supervisor Course (A62Dokument3 SeitenCrane Supervisor Course (A62Niel Brian VillarazoNoch keine Bewertungen

- General Crane SafetyDokument4 SeitenGeneral Crane SafetyEhab Mostafa AliNoch keine Bewertungen

- EMMARDokument5 SeitenEMMARNisar DeenNoch keine Bewertungen

- Suspended personnel platform checklistDokument1 SeiteSuspended personnel platform checklistmark lester caluzaNoch keine Bewertungen

- Integrity ManagementDokument8 SeitenIntegrity Managementgurdeepsarora8738Noch keine Bewertungen

- Derrick-Mast Inspection ProcedureDokument3 SeitenDerrick-Mast Inspection ProcedureChandrasekhar Sonar100% (3)

- Coupling in AnsysDokument19 SeitenCoupling in AnsysBalaji ModepalliNoch keine Bewertungen

- Fall Protection ANSIDokument5 SeitenFall Protection ANSIsejudavisNoch keine Bewertungen

- (Jf613e) CVT Renault-Nissan PDFDokument4 Seiten(Jf613e) CVT Renault-Nissan PDFJhoanny RodríguezNoch keine Bewertungen

- 2016 04 1420161336unit3Dokument8 Seiten2016 04 1420161336unit3Matías E. PhilippNoch keine Bewertungen

- Business Advantage Pers Study Book Intermediate PDFDokument98 SeitenBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- Mobile Crane Inspection FormDokument6 SeitenMobile Crane Inspection FormSham AranNoch keine Bewertungen

- Guide To Inspecting and Maintaining CranesDokument8 SeitenGuide To Inspecting and Maintaining CranesMohammed MujahidNoch keine Bewertungen

- Regulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Dokument18 SeitenRegulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Revankar B R ShetNoch keine Bewertungen

- Mobile Crane Logbook Permanent Record: (OHS) ActDokument20 SeitenMobile Crane Logbook Permanent Record: (OHS) ActAltayeb YassinNoch keine Bewertungen

- Alert: Preventing Worker Injuries and Deaths From Mobile Crane Tip-Over, Boom Collapse, and Uncontrolled Hoisted LoadsDokument26 SeitenAlert: Preventing Worker Injuries and Deaths From Mobile Crane Tip-Over, Boom Collapse, and Uncontrolled Hoisted LoadsAnonymous LFgO4WbID100% (1)

- Contractor Lift Plan Sep 1509Dokument9 SeitenContractor Lift Plan Sep 1509Saju JosephNoch keine Bewertungen

- Basic Rigging Work BookDokument45 SeitenBasic Rigging Work BookJohn Henry Sinurat100% (1)

- Inspection & Maintenance of SlingsDokument58 SeitenInspection & Maintenance of SlingsMohammad Abubakar Siddiq100% (1)

- Slings Standards RequirementsDokument15 SeitenSlings Standards RequirementsBinoy GopinathanNoch keine Bewertungen

- SAFETY TRAINING CRANES AND HOISTS (38Dokument89 SeitenSAFETY TRAINING CRANES AND HOISTS (38Jose Antonio García Ruíz100% (3)

- OverheadDokument58 SeitenOverheaddaveNoch keine Bewertungen

- 2009 Crane Start Up Inspection FormDokument3 Seiten2009 Crane Start Up Inspection Formsaeed ghafooriNoch keine Bewertungen

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Dokument2 SeitenUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengNoch keine Bewertungen

- LIFTING AND MOBILE EQUIPMENT AWARENESSDokument100 SeitenLIFTING AND MOBILE EQUIPMENT AWARENESSPhilip AdewunmiNoch keine Bewertungen

- Offshore Crane OperationsDokument1 SeiteOffshore Crane OperationsAnonymous cekPJylABoNoch keine Bewertungen

- Cranes & ComponentsDokument13 SeitenCranes & ComponentsdenyNoch keine Bewertungen

- Document Reference LEEA-030.2a2Dokument1 SeiteDocument Reference LEEA-030.2a2engmuhmud100% (1)

- Liebherr LR1350 1 PDFDokument54 SeitenLiebherr LR1350 1 PDFRazat RanaNoch keine Bewertungen

- February 2012 Wire Rope ExchangeDokument80 SeitenFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNoch keine Bewertungen

- Inspection Plan For Crane PDFDokument3 SeitenInspection Plan For Crane PDFalinor_tnNoch keine Bewertungen

- Cranes Hoists Truck CranesDokument26 SeitenCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Powered Industrial Trucks: ForkliftsDokument25 SeitenPowered Industrial Trucks: ForkliftsHamdiMallouliNoch keine Bewertungen

- Instructions For The Safe Use Of: Wire Rope SlingsDokument2 SeitenInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNoch keine Bewertungen

- Tower Crane Inspection ItemsDokument3 SeitenTower Crane Inspection ItemsLuffy11Noch keine Bewertungen

- Drilling Machine Inpection Checklist - 1Dokument1 SeiteDrilling Machine Inpection Checklist - 1Subbu AbuNoch keine Bewertungen

- Products - Monthly Checklist MCDokument2 SeitenProducts - Monthly Checklist MCDiegoCaicedo1982Noch keine Bewertungen

- Crane Maintenance and Check PointDokument12 SeitenCrane Maintenance and Check Pointspsl5100% (4)

- Tips For Heavy Lifting AND Rigging Engineering: Inspection: 1Dokument25 SeitenTips For Heavy Lifting AND Rigging Engineering: Inspection: 1pablodugalNoch keine Bewertungen

- 2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteDokument23 Seiten2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteSudiatmoko Supangkat100% (1)

- Crane Safety: 38 Hazards and ProtectionsDokument38 SeitenCrane Safety: 38 Hazards and ProtectionsunbridledsuccessNoch keine Bewertungen

- Mobile CraneDokument2 SeitenMobile CraneSHARAFUDHEEN TKNoch keine Bewertungen

- Course Material For Rigger-Latest - Final CHVR 2010Dokument138 SeitenCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Mobile CraneDokument84 SeitenMobile CraneFar Away100% (1)

- Safety in Maintenance of EOT CranesDokument31 SeitenSafety in Maintenance of EOT CranesSwapnil pupulwadNoch keine Bewertungen

- Pedestal Mounted Crane Training SampleDokument84 SeitenPedestal Mounted Crane Training SampleCesar Augusto Vera JaimesNoch keine Bewertungen

- Mobile Crane Load TestDokument4 SeitenMobile Crane Load TestMeritorious KhanNoch keine Bewertungen

- Instructions For Safe Use ShacklesDokument2 SeitenInstructions For Safe Use ShacklesNickNoch keine Bewertungen

- Alaska Petroleum Crane Operator TestDokument23 SeitenAlaska Petroleum Crane Operator TestvasucristalNoch keine Bewertungen

- Rigging and Slinging TechniquesDokument15 SeitenRigging and Slinging TechniquesShiraz Najat100% (1)

- Mobile Crane Certification and Inspection ReportDokument2 SeitenMobile Crane Certification and Inspection ReportRafael LecuNoch keine Bewertungen

- Crane Proof Testing & LAG Revisions 2020 PDFDokument26 SeitenCrane Proof Testing & LAG Revisions 2020 PDF朱峰Noch keine Bewertungen

- Yale PE2 Lever Hoist - 40192 ADokument16 SeitenYale PE2 Lever Hoist - 40192 AAthox QhurienNoch keine Bewertungen

- Maintenance Check List of HydraulicDokument7 SeitenMaintenance Check List of HydraulicShubham SinghNoch keine Bewertungen

- Slinger Signaller Study GuideDokument40 SeitenSlinger Signaller Study GuidePrimelift Safety Resources Limited100% (1)

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDokument1 SeiteEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNoch keine Bewertungen

- EOT Crane Safety Inspection Checklist Global EHSDokument1 SeiteEOT Crane Safety Inspection Checklist Global EHSSafety MohiniNoch keine Bewertungen

- Guide To Inspecting and Maintaining CranesDokument8 SeitenGuide To Inspecting and Maintaining CranesEEPNoch keine Bewertungen

- Self Erecting Tower CraneDokument16 SeitenSelf Erecting Tower CraneVinoth MalaikaniNoch keine Bewertungen

- 64-Crane Operator Program NcmscurrentDokument5 Seiten64-Crane Operator Program NcmscurrentJojo Betanio AkajoknoNoch keine Bewertungen

- Accreditation Requirements for Inspection BodiesDokument52 SeitenAccreditation Requirements for Inspection BodiesFarrukh AhmedNoch keine Bewertungen

- OSHA Crane Inspection GuidelinesDokument11 SeitenOSHA Crane Inspection Guidelinesmisu110382100% (1)

- API Recommended Practice 4G - Exceprt Section 6Dokument4 SeitenAPI Recommended Practice 4G - Exceprt Section 6ANTONI RamNoch keine Bewertungen

- NORSOK R-002 Lifting EquipmentDokument40 SeitenNORSOK R-002 Lifting Equipmentgrimaldi_8350% (2)

- Nuts and Bolts Stress LinearizationDokument17 SeitenNuts and Bolts Stress LinearizationcutefrenzyNoch keine Bewertungen

- Balancing Reaction ForcesDokument17 SeitenBalancing Reaction ForcesajimonNoch keine Bewertungen

- Mak El 1-Pres ProjesiDokument13 SeitenMak El 1-Pres ProjesiBerk TekinNoch keine Bewertungen

- Structural Modeling and Static Mechanical AnalysisDokument8 SeitenStructural Modeling and Static Mechanical AnalysisBerk TekinNoch keine Bewertungen

- LiteratureDokument2 SeitenLiteratureBerk TekinNoch keine Bewertungen

- Tekniktanitimpart2 PDFDokument31 SeitenTekniktanitimpart2 PDFBerk TekinNoch keine Bewertungen

- Boxer eDokument16 SeitenBoxer eIvan ErmolaevNoch keine Bewertungen

- Folleto PortainerDokument1 SeiteFolleto Portaineramra_26721Noch keine Bewertungen

- Chapter 7 Management of SubordinatesDokument16 SeitenChapter 7 Management of SubordinatesBerk TekinNoch keine Bewertungen

- Digicharger D4: Operating Instructions Warranty ServiceDokument2 SeitenDigicharger D4: Operating Instructions Warranty ServiceBerk TekinNoch keine Bewertungen

- Fluid Mech QuestionsDokument1 SeiteFluid Mech QuestionsBerk TekinNoch keine Bewertungen

- Fluid Mech QuestionDokument5 SeitenFluid Mech QuestionBerk TekinNoch keine Bewertungen

- Pages From 101 LopezClaros MataDokument13 SeitenPages From 101 LopezClaros MataBerk TekinNoch keine Bewertungen

- Me353 HW2Dokument3 SeitenMe353 HW2Berk TekinNoch keine Bewertungen

- STS 481 Special Topics: Innovation Management"Dokument17 SeitenSTS 481 Special Topics: Innovation Management"Berk TekinNoch keine Bewertungen

- MessiDokument12 SeitenMessiBerk TekinNoch keine Bewertungen

- Teamwork and DevelopmentDokument17 SeitenTeamwork and DevelopmentBerk TekinNoch keine Bewertungen

- Chapter 2 Decision MakingDokument13 SeitenChapter 2 Decision MakingBerk TekinNoch keine Bewertungen

- Chapter 4 Delegation of AuthorityDokument9 SeitenChapter 4 Delegation of AuthorityBerk TekinNoch keine Bewertungen

- Chapter 5 Communication PDFDokument9 SeitenChapter 5 Communication PDFBerk TekinNoch keine Bewertungen

- Italian 101 - FALL 2012-13 SYLLABUS: Presenting Myself and Giving Some Personal Information. Producing A Short EssayDokument2 SeitenItalian 101 - FALL 2012-13 SYLLABUS: Presenting Myself and Giving Some Personal Information. Producing A Short EssayBerk TekinNoch keine Bewertungen

- Presentation SkillsDokument38 SeitenPresentation SkillsBerk TekinNoch keine Bewertungen

- Chapter 7 Management of SubordinatesDokument16 SeitenChapter 7 Management of SubordinatesBerk TekinNoch keine Bewertungen

- Fluid MechanicsDokument4 SeitenFluid MechanicsBerk TekinNoch keine Bewertungen

- Materials Selection For DesignDokument26 SeitenMaterials Selection For DesignBerk TekinNoch keine Bewertungen

- Chapter 4 Delegation of AuthorityDokument9 SeitenChapter 4 Delegation of AuthorityBerk TekinNoch keine Bewertungen

- WB-Mech 121 Ch07 Buckling PDFDokument18 SeitenWB-Mech 121 Ch07 Buckling PDFflorinelvvNoch keine Bewertungen

- WB-Mech 121 Ch06 ThermalDokument26 SeitenWB-Mech 121 Ch06 ThermalBerk TekinNoch keine Bewertungen

- Hindustan Coca ColaDokument63 SeitenHindustan Coca ColaAksMastNoch keine Bewertungen

- Difference Between Knowledge and SkillDokument2 SeitenDifference Between Knowledge and SkilljmNoch keine Bewertungen

- Entrepreneurship and EconomicDokument2 SeitenEntrepreneurship and EconomicSukruti BajajNoch keine Bewertungen

- Fleck 3150 Downflow: Service ManualDokument40 SeitenFleck 3150 Downflow: Service ManualLund2016Noch keine Bewertungen

- Personal InsuranceDokument11 SeitenPersonal InsuranceSumit Kumar SharmaNoch keine Bewertungen

- FOMRHI Quarterly: Ekna Dal CortivoDokument52 SeitenFOMRHI Quarterly: Ekna Dal CortivoGaetano PreviteraNoch keine Bewertungen

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDokument122 SeitenExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganNoch keine Bewertungen

- Memento Mori: March/April 2020Dokument109 SeitenMemento Mori: March/April 2020ICCFA StaffNoch keine Bewertungen

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDokument7 SeitenUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataNoch keine Bewertungen

- Rust Experimental v2017 DevBlog 179 x64 #KnightsTableDokument2 SeitenRust Experimental v2017 DevBlog 179 x64 #KnightsTableIngrutinNoch keine Bewertungen

- A CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHDokument9 SeitenA CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHprajakta shindeNoch keine Bewertungen

- Superior University: 5Mwp Solar Power Plant ProjectDokument3 SeitenSuperior University: 5Mwp Solar Power Plant ProjectdaniyalNoch keine Bewertungen

- Tambunting Pawnshop Vs CIR Re VATDokument7 SeitenTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNoch keine Bewertungen

- Converting An XML File With Many Hierarchy Levels To ABAP FormatDokument8 SeitenConverting An XML File With Many Hierarchy Levels To ABAP FormatGisele Cristina Betencourt de OliveiraNoch keine Bewertungen

- Statement of PurposeDokument2 SeitenStatement of Purposearmaan kaurNoch keine Bewertungen

- Organization Structure GuideDokument6 SeitenOrganization Structure GuideJobeth BedayoNoch keine Bewertungen

- EDP/LRP Well Intervention System OverviewDokument22 SeitenEDP/LRP Well Intervention System OverviewJerome LIKIBINoch keine Bewertungen

- Automatizari Complexe - Laborator Nr. 4: Wind (M/S)Dokument1 SeiteAutomatizari Complexe - Laborator Nr. 4: Wind (M/S)Alexandru AichimoaieNoch keine Bewertungen

- Introduction to Human Resource Management Functions and Their ImportanceDokument23 SeitenIntroduction to Human Resource Management Functions and Their ImportancedhrupaNoch keine Bewertungen

- Human Resource Management: Chapter One-An Overview of Advanced HRMDokument45 SeitenHuman Resource Management: Chapter One-An Overview of Advanced HRMbaba lakeNoch keine Bewertungen

- PB Engine Kappa EngDokument20 SeitenPB Engine Kappa EngOscar AraqueNoch keine Bewertungen

- Method StatementDokument11 SeitenMethod StatementMohammad Fazal Khan100% (1)

- PDS-1st PageDokument1 SeitePDS-1st PageElmer LucreciaNoch keine Bewertungen

- Model Paper 1Dokument4 SeitenModel Paper 1Benjamin RohitNoch keine Bewertungen

- Sierra Wireless AirPrimeDokument2 SeitenSierra Wireless AirPrimeAminullah -Noch keine Bewertungen