Beruflich Dokumente

Kultur Dokumente

Calculating Tension Forces of Belt Conveyors

Hochgeladen von

PoyaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calculating Tension Forces of Belt Conveyors

Hochgeladen von

PoyaCopyright:

Verfügbare Formate

Ismet Ibishi et al.

/ International Journal of Engineering Science and Technology (IJEST)

CALCULATION OF TENSION FORCE

OF BELT CONVEYOR

Ismet Ibishi1

Department of Mining Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

ismetibishi609@hotmail.com

Ahmet Latifi2

Department of Mechanical Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

ahmetnlatifi@hotmail.com

Gzim Ibishi3

Department of Mining Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

Gzim-Ibishi@hotmail.com

Kadri Sejdiu4

Department of Mechanical Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

kadrimsejdiu@live.com

Melihate Shala-Galica5

Department of Mechanical Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

Bekim Latifi6

Department of Mechanical Engineering, University of Prishtina

Mitrovice, Republic of Kosovo

bekimlatifi123@hotmail.com

Abstract:

In this paper is done the explanation on tension fashion of the belt conveyor which is employed in Kosovo

Energy Corporation – KEK, for coal transportation to provide electric power plant. The aim of the paper enables

to recognize tension forces not to pass with deformation of belt so that this problem will damage the working

process. Work principle is based on initial tension and tension during working process. The fact is known that

the tension starts from the carriage on the way to tension mechanization, so forces on the rope passing through

pulley there has to dominate the friction coefficient. All this process is related to economy of transportation

mechanism.

Key words: belt conveyor, tension force, carriage, friction coefficient, mechanism, pulley.

1. Introduction

Belt conveyors can be used for hoisting rock up surface slopes, drifts for inclinations not greater than 18°.

Raghvendra, Arvind, Pratesh [2012], a typical conveyor installation has the following principle components

such as; belt which carries the material, idler which support the carrying, pulleys which support and move the

belt and control its tension as well as change directions, and drive which transmits the motive power to one or

more pulleys to move the belt and its carrying load. Ramlu [1996], as belt conveyors consists of several

components, their careful selection and design have decisive influence on the capital and operating costs and

hence the economy of conveyor transportation as a whole. Lech, Robert, Jędrzej [2011] stated that a good belt

conveyor design is based on

Calculations while a theory is based on experiments, which are an exhaustible source of knowledge. A theory

and calculations are inseparably bound. Without a verified theory taking all the factors into account one cannot

make accurate calculations and so one cannot optimally design a belt conveyor. Tension force is calculated

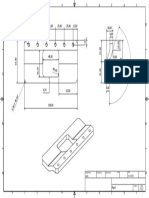

according to principle scheme of the belt conveyor during the coal transportation which is presented in figure 1.

Peripheral force in the driving drums, which stimulate operating power, is;

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4886

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

Fig 1 Principle scheme of conveyor

Todd, Larry, Andrew [2002], Baldin, Furlanetto, Turco [1982] Belt conveyors have shown the ability to

transport materials that vary from large, heavy, sharp-edged lumps to fine particles; from wet, sticky slurry to

dry, dusty powders; from foundry sand to potato chips; and from tree-length logs to wood chips. Of all the

material handling systems, belt conveyors typically operate with the lowest transport cost per ton, the lowest

maintenance cost per ton, the lowest power cost per ton, and the lowest labor cost per ton. From the illustrating

above we gain;

(1)

(2)

Whereas the tension force [Ft] that secure the normal work during the movement of belt conveyor is;

(3)

So that if we have . Then;

2 (4)

Substituting the force [F2] in function of [Fp] the tension force is;

(5)

Where are;

µ - Coefficient of sliding friction between the belt and pulley

- Angle of contact or angle of wrap of the belt around the pulley in radians

Table 1 Friction coefficient

µ - Coefficient of sliding friction between the belt and pulley

Surface of drum Steel Rubber layer Ceramic layer

Dry surface 0.35-0.4 0.4-0.45 0.4-0.45

Wet clean surface 0.1 0.35 0.35-0.4

Wet lubricated surface 0.05-0.1 0.25-0.3 0.35

For our study problem we have [µ = 0.35] and [ = 2000] in table 1 shown friction coefficient [µ] so whether we

substitute in equation 5 we get tension force 0.83332 . Values of tension force [Ft] are given in table 3

whereas in table 2 are presented values of [ .

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4887

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

Table 2 Values of

Contact Friction coefficients of drive pulley

Angle 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60

170 2.895 1.784 1.234 0.909 0.697 0.548 0.439 0.357 0.293 0.243 0.203

180 2.709 1.661 1.144 0.838 0.638 0.499 0.398 0.321 0.262 0.216 0.179

190 2.543 1.552 1.063 0.775 0.587 0.456 0.361 0.290 0.235 0.192 0.158

200 2.394 1.453 0.990 0.718 0.541 0.418 0.329 0.262 0.212 0.172 0.140

210 2.259 1.364 0.925 0.667 0.499 0.384 0.300 0.238 0.190 0.154 0.125

220 2.136 1.284 0.866 0.621 0.462 0.353 0.274 0.216 0.172 0.138 0.111

230 2.024 1.211 0.812 0.579 0.428 0.325 0.251 0.197 0.155 0.124 0.099

240 1.922 1.144 0.763 0.541 0.398 0.300 0.230 0.179 0.140 0.111 0.088

250 1.828 1.082 0.718 0.506 0.370 0.277 0.212 0.163 0.127 0.100 0.079

360 1.144 0.638 0.398 0.262 0.179 0.125 0.088 0.063 0.045 0.033 0.024

370 1.102 0.612 0.379 0.248 0.168 0.116 0.082 0.058 0.041 0.030 0.021

380 1.063 0.587 0.361 0.235 0.158 0.109 0.076 0.053 0.038 0.027 0.019

390 1.025 0.563 0.345 0.223 0.149 0.102 0.070 0.049 0.034 0.024 0.017

400 0.990 0.541 0.329 0.212 0.140 0.095 0.065 0.045 0.031 0.022 0.015

410 0.957 0.519 0.314 0.201 0.132 0.089 0.061 0.042 0.029 0.020 0.014

430 0.894 0.480 0.287 0.181 0.118 0.078 0.052 0.035 0.024 0.016 0.011

450 0.838 0.445 0.262 0.163 0.105 0.068 0.045 0.030 0.020 0.013 0.009

Table 3 Values of tension force [Ft]

Floor Conveyor

V-1 Z-1 ZTU-1 KTU-1 KTU-2 ITU-1 ITU-2 STU-1 STU-2

15386.72 69479.7 36939.7 33243.66 23593.43 249653. 106408.0 18116.24 46132.52

8 9 8 9 8 6 3 9

Main Conveyor

GTU-1 XIII-a XIII GTU-3 GTU-4 XII XIII-a XIV XV

71241.32 6980.62 2037.52 42395.7 81134.92 72444.9 39318.92 89977.35 83434.13

6 5 2 9

2. Materials and Methods

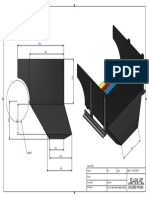

According to principle scheme of mechanism for tension of belt which is shown in figure 2, is consisted by

driving drum, weight, infinite rope, carriage for tension, moveable pulley, and unmovable pulley. The working

principle is done into two steps, first one is initial tension and the second step is tension during work. During

initial tension the weight is placed on the floor whereas belt conveyor is loose. When the mechanism of driving

drum activates, the rope is wrapped on drum whereas the tension carriage starts gradually to move, when the

tension force in tension carriage is based on weight, then the weight start to lift up. If the weight is lift up until to

an unexpected height, then the driving mechanism is determined and the brakes will activate so that the drum

cannot move further. After the initial tension is done, then the conveyor may start working. During the working

process the loads may change on belt conveyor and also the tension force will change which is necessary to

secure normal work. The balance of these loads makes it possible to lift up and down different weights

according to how loads vary respectively how the length of the belt varies.

3. Results and Discussion

3.1 Calculation of loads for tension with two- pulley

From the principle scheme 2, for the initial tension we have;

, , (6)

Whether we substitute by [Gt] we have;

(7)

In the same fashion for tension force [Ft] we have;

2 (8)

If we substitute previous equation by [Gt];

(9)

For [ = 0.95] we have 0.464819 . Number of rings is; /

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4888

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

From the principle scheme 2, for tension during the working we have;

, , , (10)

If we substitute [Fz] we have;

(11)

If we substitute [F], in the same fashion for weight we get;

(12)

For [ = 0.95] we have 0.3014153 . Number of disks is; / . Results of the calculation of

loads for tension with two pulleys are presented in table 4;

Fig 2 Principle work with two-pulley

Table 4 Results of tension with two pulleys

Conveyor ZTU-I KTU-I KTU-2 STU-I STU-2

Fp (N) 44328.35 35898.04 28318.5 21739.84 57759.96

Initial 0.4648 20603.817 18543.04 13160.2 10510.09 26847.92

tension

/ 3.4339 3.09 2.1933 1.68418 4.4747

Tension 0.2511 11133.907 10019.89 7111.35 5460.373 14507.51

during / 1.8556 1.6699 1.1852 0.691 2.4179

work

No of rings 5 5 5 5 7

Avg. no of /2 2.6447 2.3799 1.689 1.297 3.4459

rings

3.2 Calculation of loads for tension with four-pulley

According to principle scheme of tension we have tension force [Ft] and weight [G].

2 (13)

(14)

Initial tension has to dominate friction resistances of pulley from driving drum up to carriage tension. The

friction has to be considered through utilization scale [ = 0.95].

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4889

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

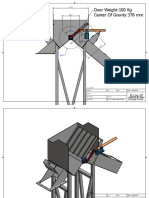

Fig 3 Principle work with four-pulley

From the principle scheme in figure 3, the initial tension is;

, , (15)

If [Gt] is substituted we have;

(16)

The force in the drum is given;

(17)

If we substitute in [Gt];

(18)

For [ = 0.95] we have 1.242448 . If we substitute [Fsh] into [Gt] we have 1.035 , its

weight makes safety work without slipping in the beginning. The number of rings is given;

(19)

We understand that the tension during the work starts from the carriage tension towards to tension mechanism.

During this time forces which come up on the rope while they pass through pulleys have to dominate the friction

coefficient. This friction factor we consider through utilization coefficient [ = 0.95]. From the principle scheme

in figure 3 we gain formulations of tension during working;

, , , , (20)

From the above expressions we gain;

, , (21)

If we substitute into [Ft] we gain;

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4890

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

(22)

Whereas the weight is given as;

(23)

If we substitute [F] we gain;

(24)

For [ = 0.95] we have 0.5195 . If we substitute [Ft] into [Gt] we have 0.43295

This is the minimal force of tension during the work, when the forces are in balance. If the loads are smaller

then it cannot secure the normal work of driving mechanism. The weights are composed of rings, and their total

weight is 600 . The number of rings is given;

Results of the calculation of loads for tension with four pulleys are presented in table 5;

Table 5 Results of tension with four pulleys

ITU-1 ITU-2 GTU-1 XII XIII-a XIII GTU-3 XIV XV GTU-1

127981.72

107975.57

100170.57

29589.37

85490.84

86933.79

67021.32

50875.12

97362.37

47812.9

30624.997

132160.99

88483.019

89976.472

103676.53

100770.05

69367.06

52655.74

111574.4

Initial Tightening

48834.3

0.4648

22.026

14.747

17.279

16.795

5.104

14.99

11.56

8.775

18.62

8.13

12809.238

55277.745

37008.884

36733.637

20425.477

29013.529

46742.494

43363.838

42148.169

Tightening during

22023.83

0.4648

7.227

work

2.13

6.27

4.83

3.67

7.79

7.03

9.2

6.2

3.4

Numb

er of

10

10

11

12

11

13

11

11

12

12

measures of

Number of

10.457

13.205

12.253

3.617

15.62

10.63

5.765

5.198

6.222

11.9

After the calculation we have concluded the final scheme of the conveyor system in Bellaçeva Open pit mine.

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4891

Ismet Ibishi et al. / International Journal of Engineering Science and Technology (IJEST)

Fig 4 Coal System in BELLAÇEVA

3. Conclusion

In this paper are realized calculations of weights of loads in rubber belt of conveyor which at the same time are

done according to tension force of belt that relates with the force of rope of pulleys. We have done the

calculations of forces during the tension of system with tow and four pulleys, these calculations have its

technical and economical importance because is know the duration of belt and tension rope and enable to know

the time of replacement of belts and their maintenance.

References

[1] Baldin, A., Furlanetto, L., Turco, F. (1982). Priručnik za održavanje industrijskih postrojenja, OMO Beograd

[2] Lech G., Robert K., Jędrzej B. (2011). Tests of belt conveyor resistance to motion; Eksploatacja i Niezawodność - Maintenance and

Reliability, 3: 17-25.

[3] Raghvendra, S.G., Arvind, Y., Pratesh, J. (2012). Failure analysis of belt conveyor system in a thermal power plant, IJATER, 2(3)

pp.204-210.

[4] R. Todd Swinderman., Larry J. Goldbeck., Andrew D. Marti. (2002). Foundations 3: The Practical Resource for Total Dust & Material

Control, Neponset, Illinois, USA.

[5] Ramlu, M.A. (1996). Mine Hoisting, 1st ed. A.A. Balkema, USA

ISSN : 0975-5462 Vol. 4 No.12 December 2012 4892

Das könnte Ihnen auch gefallen

- Study of Mechanical Behavior of Structures Welded With Friction Spot Stir ProcessDokument5 SeitenStudy of Mechanical Behavior of Structures Welded With Friction Spot Stir ProcessZahi DrawNoch keine Bewertungen

- Bola Tash Vili 2009Dokument4 SeitenBola Tash Vili 2009Vikyath PopuriNoch keine Bewertungen

- Lecture 2 - ME460 Renewable Energy ResourcesDokument125 SeitenLecture 2 - ME460 Renewable Energy ResourcessaadNoch keine Bewertungen

- Minimum Weight Optimization of Materials and High Strength For Spur Gear DesignDokument14 SeitenMinimum Weight Optimization of Materials and High Strength For Spur Gear DesignTJPRC PublicationsNoch keine Bewertungen

- Design, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeDokument7 SeitenDesign, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeIJRASETPublicationsNoch keine Bewertungen

- Study of The Principles For Ensuring The AccuracyDokument9 SeitenStudy of The Principles For Ensuring The AccuracyNobNoch keine Bewertungen

- Design and Analysis of Two Wheeler Alloy Wheel Rim Using Two Different MaterialsDokument6 SeitenDesign and Analysis of Two Wheeler Alloy Wheel Rim Using Two Different MaterialsIJRASETPublicationsNoch keine Bewertungen

- National Institute of Technology, Rourkela-769008Dokument2 SeitenNational Institute of Technology, Rourkela-769008Abhii SahaNoch keine Bewertungen

- CH31007 Mechanical Operations MA 2016Dokument2 SeitenCH31007 Mechanical Operations MA 2016Nitin MauryaNoch keine Bewertungen

- Mens Underwear Knitted Material Properties Test ADokument6 SeitenMens Underwear Knitted Material Properties Test ADibyendu DattaNoch keine Bewertungen

- Mukhammadiev 2021 J. Phys. Conf. Ser. 1889 042042Dokument10 SeitenMukhammadiev 2021 J. Phys. Conf. Ser. 1889 042042Mễro ĢANoch keine Bewertungen

- Week10 - Explicit Dynamic ContactDokument9 SeitenWeek10 - Explicit Dynamic ContactjshanakaNoch keine Bewertungen

- Design of Piezoresistive Microcantilever For Mass Sensing: V. Jyothi, B. Rajesh Kumar, V. Suresh, Ch. IndraniDokument7 SeitenDesign of Piezoresistive Microcantilever For Mass Sensing: V. Jyothi, B. Rajesh Kumar, V. Suresh, Ch. Indraniijieee ijieeeNoch keine Bewertungen

- Tension TestDokument7 SeitenTension Testabdulla abdulkhaliqNoch keine Bewertungen

- Tensile TestDokument5 SeitenTensile TestNabeel J. AwadNoch keine Bewertungen

- Department of Chemical Engineering: Particle TechnologyDokument2 SeitenDepartment of Chemical Engineering: Particle TechnologyKhan AaghaNoch keine Bewertungen

- Numerical Analysis of Stress Causing Fracture FailDokument9 SeitenNumerical Analysis of Stress Causing Fracture FailAvinash YadavNoch keine Bewertungen

- IJCRT2009174Dokument8 SeitenIJCRT2009174Shubham kumarNoch keine Bewertungen

- Mech 343 Lab 1 ReportDokument18 SeitenMech 343 Lab 1 ReportYousef Meguid0% (1)

- Mech 343 Lab Report 1Dokument22 SeitenMech 343 Lab Report 1Yousef MeguidNoch keine Bewertungen

- Comfort properties of polyester-viscose suiting fabricsDokument5 SeitenComfort properties of polyester-viscose suiting fabricsAditya ShrivastavaNoch keine Bewertungen

- Analysis of Combination Tool For End Mill and ReamerDokument6 SeitenAnalysis of Combination Tool For End Mill and ReamerIJRASETPublicationsNoch keine Bewertungen

- Investigation on Material Removal Rate of Al + 6% B4C MMC in WEDMDokument7 SeitenInvestigation on Material Removal Rate of Al + 6% B4C MMC in WEDMshanjuneo17Noch keine Bewertungen

- Investigation On Material Removal Rate of Al + 6% B C MMC in Wire Electrical Discharge Machining ProcessDokument7 SeitenInvestigation On Material Removal Rate of Al + 6% B C MMC in Wire Electrical Discharge Machining Processshanjuneo17Noch keine Bewertungen

- The Influence of Carbon Nanotube Addition On The Properties of Shear Thickening FluidDokument4 SeitenThe Influence of Carbon Nanotube Addition On The Properties of Shear Thickening FluidJufri ArdiNoch keine Bewertungen

- The Evaluation of Grinding Process Using MODSIM©: January 2012Dokument15 SeitenThe Evaluation of Grinding Process Using MODSIM©: January 2012saadabderrahmane064Noch keine Bewertungen

- Be Winter 2016Dokument3 SeitenBe Winter 2016babaf79912Noch keine Bewertungen

- 2 - Experimental characterization of the tridimensional gradient of microstructure induced by RCF in the rolling band of railsDokument9 Seiten2 - Experimental characterization of the tridimensional gradient of microstructure induced by RCF in the rolling band of railsanime MAVCNoch keine Bewertungen

- Deflection of A Simply Supported BeamDokument15 SeitenDeflection of A Simply Supported Beamshuqing heongNoch keine Bewertungen

- 022 P5500 UnistrutDokument2 Seiten022 P5500 UnistrutEsteban CurliNoch keine Bewertungen

- Flexible Road Overlay Design by FWDDokument9 SeitenFlexible Road Overlay Design by FWDafifa kausar100% (1)

- HW1 ReportDokument3 SeitenHW1 ReportAbdul Ahad100% (1)

- Shear of Rubber TestDokument11 SeitenShear of Rubber TestTahseen QashouNoch keine Bewertungen

- Air PropertyDokument1 SeiteAir PropertyDawit WaleNoch keine Bewertungen

- Modeling and Optimization of Machining Parameters For Minimizing Surface Roughness and Tool Wear For EN100Cr6 Steel Dry TurningDokument10 SeitenModeling and Optimization of Machining Parameters For Minimizing Surface Roughness and Tool Wear For EN100Cr6 Steel Dry TurningEditor IJTSRDNoch keine Bewertungen

- Influence of Rolling Force and Roll Gap On Thickness of StripDokument5 SeitenInfluence of Rolling Force and Roll Gap On Thickness of StripYashWant DonGe ThaKurNoch keine Bewertungen

- Tensile Test Lab ReportDokument5 SeitenTensile Test Lab ReportLudik CarvalhoNoch keine Bewertungen

- EMSE ReportDokument30 SeitenEMSE ReportRohan BhagatNoch keine Bewertungen

- Prediction of Compressive Strength of Self-Compacting Concrete Using Intelligent Computational ModelingDokument18 SeitenPrediction of Compressive Strength of Self-Compacting Concrete Using Intelligent Computational ModelingAfaq AhmedNoch keine Bewertungen

- Determination of Shear Modulus of A Material: Institute of Space Technology, IslamabadDokument5 SeitenDetermination of Shear Modulus of A Material: Institute of Space Technology, IslamabadMohsin JalilNoch keine Bewertungen

- MB08G2SEC3Dokument26 SeitenMB08G2SEC3Azfariena SyafiqahNoch keine Bewertungen

- Claw Tooth of Mole CricketsDokument5 SeitenClaw Tooth of Mole CricketsAmeer BA-faiadhNoch keine Bewertungen

- BITS Pilani Machine Tool Design Exam QuestionsDokument3 SeitenBITS Pilani Machine Tool Design Exam QuestionsSharad ShrivastavaNoch keine Bewertungen

- Cornering Fatigue Test and Radial Fatigue Test On A Rim With Steps For A Mono-Tyre E-Vehicle Using Finite Element AnalysisDokument8 SeitenCornering Fatigue Test and Radial Fatigue Test On A Rim With Steps For A Mono-Tyre E-Vehicle Using Finite Element AnalysisGowtham KumarNoch keine Bewertungen

- Applying The Taguchi Method On An EDM MachineDokument5 SeitenApplying The Taguchi Method On An EDM Machinechirag kolambeNoch keine Bewertungen

- Non Structural PropertiesDokument1 SeiteNon Structural PropertiesLJ ClimacoNoch keine Bewertungen

- Influence of Electromagnetic Stirring Position On Liquid Level Fluctuation in Billet MoldDokument6 SeitenInfluence of Electromagnetic Stirring Position On Liquid Level Fluctuation in Billet MoldJJNoch keine Bewertungen

- S3 - Deflection of Straight BeamDokument15 SeitenS3 - Deflection of Straight BeamAfif HaziqNoch keine Bewertungen

- Mechanical PrinciplesDokument46 SeitenMechanical PrinciplesHarshini Premachandra0% (1)

- Static and modal analysis of a deep soil loosening machineDokument11 SeitenStatic and modal analysis of a deep soil loosening machineevelin6891Noch keine Bewertungen

- Seismic Mitigation Performance-5649Dokument5 SeitenSeismic Mitigation Performance-5649greeshma cNoch keine Bewertungen

- Design and Analysis of Telescopic Boom FDokument5 SeitenDesign and Analysis of Telescopic Boom FEduardo RateikeNoch keine Bewertungen

- Wind Load Example - CylinderDokument18 SeitenWind Load Example - CylinderAnonymous f3uZJugqvNoch keine Bewertungen

- Torsion Test MOM Lab 2Dokument12 SeitenTorsion Test MOM Lab 2TejkumarigurungNoch keine Bewertungen

- Materials Science Tutorial 2Dokument2 SeitenMaterials Science Tutorial 2steve gateriNoch keine Bewertungen

- Base Plate & Anchor Bolt - BP1Dokument20 SeitenBase Plate & Anchor Bolt - BP1munishant1Noch keine Bewertungen

- Design and Pre Manufacturing Analysis of PDFDokument7 SeitenDesign and Pre Manufacturing Analysis of PDFLihas AirohalNoch keine Bewertungen

- 17Chute-New Version02Dokument3 Seiten17Chute-New Version02PoyaNoch keine Bewertungen

- User 2/12/2020: Designed by Checked by Approved by Date DateDokument1 SeiteUser 2/12/2020: Designed by Checked by Approved by Date DatePoyaNoch keine Bewertungen

- Crusher Hopper Chute Assembly DetailsDokument1 SeiteCrusher Hopper Chute Assembly DetailsPoyaNoch keine Bewertungen

- BearingDokument34 SeitenBearingIrwan SattuNoch keine Bewertungen

- Door Weight:100 KG Center of Gravity:376 MM: Crusher PayamDokument2 SeitenDoor Weight:100 KG Center of Gravity:376 MM: Crusher PayamPoyaNoch keine Bewertungen

- JackDokument1 SeiteJackPoyaNoch keine Bewertungen

- Heavy Duty Electro-Mechanical Linear ActuatorsDokument7 SeitenHeavy Duty Electro-Mechanical Linear ActuatorsPoyaNoch keine Bewertungen

- Screen Upper Chute JackDokument1 SeiteScreen Upper Chute JackPoyaNoch keine Bewertungen

- Warman AH Pump BrochureDokument4 SeitenWarman AH Pump BrochureLodyNoch keine Bewertungen

- Maximum Water Flow CapacitiesDokument5 SeitenMaximum Water Flow CapacitiesPoyaNoch keine Bewertungen

- DIMER E - Catalogue O Rings - EN PDFDokument43 SeitenDIMER E - Catalogue O Rings - EN PDFPoyaNoch keine Bewertungen

- GWPD8Dokument12 SeitenGWPD8PoyaNoch keine Bewertungen

- Daido Chain CatalogDokument147 SeitenDaido Chain CatalogAmanda Rezende100% (1)

- DIMER E - Catalogue O Rings - EN PDFDokument43 SeitenDIMER E - Catalogue O Rings - EN PDFPoyaNoch keine Bewertungen

- Progressive Cavity Pump F Series - Model N: Technical CharacteristicsDokument4 SeitenProgressive Cavity Pump F Series - Model N: Technical CharacteristicsPoyaNoch keine Bewertungen

- Pump Iran Kafkesh 2Dokument20 SeitenPump Iran Kafkesh 2PoyaNoch keine Bewertungen

- Electrical Main Cabin Panel SchematicDokument1 SeiteElectrical Main Cabin Panel SchematicPoyaNoch keine Bewertungen

- Control circuit diagram analysisDokument1 SeiteControl circuit diagram analysisPoyaNoch keine Bewertungen

- لیست آماده تراشDokument1 Seiteلیست آماده تراشPoyaNoch keine Bewertungen

- فرمول تولید خامDokument1 Seiteفرمول تولید خامPoyaNoch keine Bewertungen

- Wagon Frequency Inverter 1FI: IN Reduce SpeedDokument1 SeiteWagon Frequency Inverter 1FI: IN Reduce SpeedPoyaNoch keine Bewertungen

- Evo TestDokument1 SeiteEvo TestPoyaNoch keine Bewertungen

- اولیهDokument1 SeiteاولیهPoyaNoch keine Bewertungen

- Pump IranDokument108 SeitenPump IranPoyaNoch keine Bewertungen

- گزارش ریخته گریDokument1 Seiteگزارش ریخته گریPoyaNoch keine Bewertungen

- Burner 1 Burner 2 Burner 3 Burner 4: 27 28 N PE 29 27 30 N PE 31 27 32 N PE 33 27 34 N PE 35Dokument1 SeiteBurner 1 Burner 2 Burner 3 Burner 4: 27 28 N PE 29 27 30 N PE 31 27 32 N PE 33 27 34 N PE 35PoyaNoch keine Bewertungen

- 2 Project Description 4 CustomerDokument1 Seite2 Project Description 4 CustomerPoyaNoch keine Bewertungen

- Wagon Out Wagon in Wagon in Reduce SpeedDokument1 SeiteWagon Out Wagon in Wagon in Reduce SpeedPoyaNoch keine Bewertungen

- PCodesDokument1 SeitePCodesPoyaNoch keine Bewertungen

- Project Description 2 Customer: Combustion Air Fan 3PH / 380V / 11KW Wagon Motor 3PH / 380V /3KWDokument1 SeiteProject Description 2 Customer: Combustion Air Fan 3PH / 380V / 11KW Wagon Motor 3PH / 380V /3KWPoyaNoch keine Bewertungen

- Astm D2041-11 GMMDokument4 SeitenAstm D2041-11 GMMAbbasi HussainNoch keine Bewertungen

- ATP Synthesis and Oxidative Phosphorylation ExplainedDokument5 SeitenATP Synthesis and Oxidative Phosphorylation Explainedkman0722Noch keine Bewertungen

- D473 - Sedimetnos Por ExtracciónDokument6 SeitenD473 - Sedimetnos Por ExtracciónCarito LopezNoch keine Bewertungen

- Slide Gate Indian CodeDokument26 SeitenSlide Gate Indian CodeRolando Alvarado100% (1)

- Caterpillar Service Welding GuideDokument77 SeitenCaterpillar Service Welding GuideGaston Gingarelli100% (1)

- Mil DTF 5541fDokument12 SeitenMil DTF 5541fMarcos PerezNoch keine Bewertungen

- Rep19 MaseDokument66 SeitenRep19 Mase3utiaNoch keine Bewertungen

- Class X Physics Heat and Optics DocumentDokument111 SeitenClass X Physics Heat and Optics DocumentsugothaaaNoch keine Bewertungen

- Physica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungDokument8 SeitenPhysica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungMilton David SernaNoch keine Bewertungen

- Mec 224 Properties of Mat TheoryDokument73 SeitenMec 224 Properties of Mat TheoryNoreliana Md Sharif100% (5)

- Important Notes On Ana Chem Lecture 1Dokument3 SeitenImportant Notes On Ana Chem Lecture 1Eliza Loren PalleraNoch keine Bewertungen

- Astm D5322 92 97Dokument6 SeitenAstm D5322 92 97Ahmed AbidNoch keine Bewertungen

- Lab Exercise 6 SIMPLE STAININGDokument5 SeitenLab Exercise 6 SIMPLE STAININGArianne Jans MunarNoch keine Bewertungen

- BS en Iso 12944-1-2017Dokument41 SeitenBS en Iso 12944-1-2017Dwarakanathan Makkada YuvarajNoch keine Bewertungen

- FNL Flanged Housings Provide Simple, Reliable Bearing SupportDokument22 SeitenFNL Flanged Housings Provide Simple, Reliable Bearing Supportsaeed shirvaniNoch keine Bewertungen

- Is 6396 - 2000 De-CarburisationDokument10 SeitenIs 6396 - 2000 De-CarburisationDheeraj Chavan100% (1)

- Sikaflex 256Dokument2 SeitenSikaflex 256aboali8686Noch keine Bewertungen

- 5-30-2012emerson Weighs in On Rootless CornDokument3 Seiten5-30-2012emerson Weighs in On Rootless CornRaka Nttu Iqbal GejeyerzNoch keine Bewertungen

- Dapust 21Dokument5 SeitenDapust 21Dewo BontangNoch keine Bewertungen

- Fire Retardant Finishes ExplainedDokument26 SeitenFire Retardant Finishes Explainedrahul raj100% (1)

- NOV Bolt Torque ValuesDokument14 SeitenNOV Bolt Torque ValuesandreyengNoch keine Bewertungen

- DSSC PresentationDokument50 SeitenDSSC PresentationWisaruth MaethasithNoch keine Bewertungen

- Bio FermentationDokument8 SeitenBio FermentationCecil ClaveriaNoch keine Bewertungen

- Irc 45 - 1972Dokument36 SeitenIrc 45 - 1972kapinjal_Noch keine Bewertungen

- Dual LockDokument6 SeitenDual Lockcvazquez999Noch keine Bewertungen

- GGR240L Use and Care ManualDokument2 SeitenGGR240L Use and Care ManualBobDewilleNoch keine Bewertungen

- Remediation of Contaminated Soil and GroundwaterDokument3 SeitenRemediation of Contaminated Soil and GroundwaterTamires NassarNoch keine Bewertungen

- Factor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoDokument3 SeitenFactor Determination of Cerium Sulphate vs. Hydroquinone: Mettler ToledoBhupesh MulikNoch keine Bewertungen

- Thermodynamics in The News... : Airborne Soot Adds To Weather Woes, Some SayDokument13 SeitenThermodynamics in The News... : Airborne Soot Adds To Weather Woes, Some SayJames Patrick TorresNoch keine Bewertungen

- E-NTU Heat Transfer: LibraryDokument7 SeitenE-NTU Heat Transfer: LibrarySergio AymiNoch keine Bewertungen