Beruflich Dokumente

Kultur Dokumente

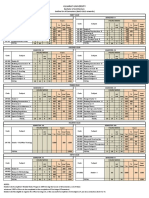

Gallons 6.5 Gallons Is The Average For Ordinary Jobs.: "AA" 1 X 1 X 3 12 9.5 0.5 1.0 "A" 1 X 2 X 4 9 7 0.5 1.0

Hochgeladen von

J. Vince0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten3 Seitenddfdf

Originaltitel

BT

Copyright

© © All Rights Reserved

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten3 SeitenGallons 6.5 Gallons Is The Average For Ordinary Jobs.: "AA" 1 X 1 X 3 12 9.5 0.5 1.0 "A" 1 X 2 X 4 9 7 0.5 1.0

Hochgeladen von

J. VinceSie sind auf Seite 1von 3

CONCRETE – mixture of cement, aggregates and water

CEMENT or PORTLAND CEMENT – AGGREGATES – WATER-

A powdery substance made with Particles that are durable Should be free from oil, acid,

calcined lime, silica, alumina and iron strong, clean, hard and alkali, vegetable matter, or

components. uncoated, and which are other deleterious substances.

free from injurious amount

of dusts, lumps, soft, and

other deleterious

substances.

Special Cements Type of Aggregates Water-cement ratio

a. White Portland Cement – pure a. Fine Aggregates – – is the amount of water used

white or non-staining cement which is smaller than 6mm (1/4”) in per bag of cement.

primarily used for architectural size which consist of sand, – Usually varies from 5 to 7

purposes. stone screenings or other gallons; 6.5 gallons is the

b. Masonry Cement – designed to inert materials. average for ordinary jobs.

produce better mortar with good b. Course Aggregates – – The less water used in mixing,

plasticity and workability, good larger than 6mm (1/4”) in the better quality of concrete

adhesion and bond. size which consists of – The ideal mix is one that is

c. Air-entraining Portland Cement crushed stones, gravel or plastic and workable.

– used for resistance to severe frost. other inert materials.

d. Oil Well Cement – used for c. Special Aggregates – WATER – CEMENT RATIO

sealing oil wells such as cinders, blast

Assumed 28- Maximum Pounds of

f. Waterproofed Portland Cement – furnace, slag, clay, perlite, day water- water per

Compressive cement ratio 100 lbs. of

produced by adding small amount of vermiculite, that may strength U.S. gallons cement

stearate. produce lightweight, nailable (lbs. per sq. of water per

inch) sack Cement

and thermal insulating of 94 lbs.

concrete. 2,000 7.00 62.0

d. Sand - found in 2,500 6.50 57.5

3,000 5.75 51.0

riverbeds, free of salt and 3,750 5.00 44.5

must be washed.

CONCRETE MIXTURE

Class Mixture 40 Kg 50 Kg Sand Gravel Usage

“AA” 1 x 1½ x 3 12 9.5 0.5 1.0 Concrete

underwater,

retaining wall

“A” 1x2x4 9 7 0.5 1.0 Footings,

columns,

beams, RC

slabs

“B” 1 x 2½ x 5 7.5 6 0.5 1.0 Slab on fill, non-

bearing wall

“C” 1x3x6 6 5 0.5 1.0 Concrete Plant

boxes, etc.

ADMIXTURE – Accelerates or retards concrete setting.

a. Accelerators – speed up the concrete

b. Retarders – delay or extend the concrete

c. Air-entraining Agents – contains surface active agents which reduce the surface tension of water for

better resistance to frost action.

d. Dispersal Agents – causes cement particles to separate by imparting electrostatic charges to them.

*Flocculate – cement particles tend to gather in clamps

e. Concrete Hardeners – used for surfaces which subjected to rolling live loads

f. Water-reducing Admixture – used to reduce the amount of water necessary to produce a concrete

of given consistency or to increase the slump for a given water content.

g. Waterproofing or Damproofing – it reduces the capillary attraction of the voids in the concrete or

mortar, but while it may decrease water absorption of the concrete or mortar, it does not render concrete

waterproof.

CONCRETE TEST

a. Slump Test – to ensure the specified slump is being attained consistently.

*Standard slump cone is ø8” (.20) x ø4” (.10) x 12” (.30)

b. Compressive Strength Test – common quality-control test of concrete.

*Specimens are usually cylinders with a length equal to twice the diameter.

*Compressive stresses are 2,000 Psi, 2,500 Psi, and 3,000 Psi.

MORTAR MIXTURE

Class Mixture 40 Kg 50Kg Sand (m3)

“A” 1:2 18 14.5 1.0

“B” 1:3 12 9.5 1.0

“C” 1:4 9 7 1.0

“D” 1:5 7.5 6 1.0

MIXING OF CONCRETE

COLUMN

Types of Column:

Tied Column - has

reinforcement consisting of

vertical or longitudinal bars held

Reinforced Concrete

in position by lateral

Column

Post – refers to a piece of timber of reinforcement called lateral ties.

either cylindrical, square or other

Short - when the

geometrical cross section placed Spiral Column - is the term

unsupported height is not

vertically to support a building. given where a circular concrete

greater than ten times the

Column – refers to vertical structure core in enclosed by spirals with

shortest lateral dimension of

use to support a building made of vertical or longitudinal bars.

the cross section.

stone, concrete, steel or combination

Long - when the

of the above materials. Composite Column - where

unsupported height is more

Storey – is the space in a building structural steel column is

than ten times the shortest

between floor levels or between a floor embedded into the concrete

lateral dimension of the

and a roof above. core of a spiral column.

cross section.

Combined Column - with

structural steel encased in

concrete of at least 7 cm thick

reinforced with wire mesh

surrounding the column at a

distance of 3 cm inside the outer

surface of the concrete covering.

Lally Column - is a fabricated

steel pipe provided with a flat

steel bars or plate which hold a

girder, girts or beam.

METAL REINFORCEMENTS

Reinforced Concrete – is a 4cm. – allowance protective covering

combination of concrete and steel. of steel bars from the outside of the

main reinforcement.

Concrete – is strong in supporting

compression load but weak in resisting *building code required that a balance

tension forces. beam shall provide, that the cross

sectional area of steel reinforcement

Steel – possesses the strength to resist shall be equal to .005 times the cross

both compression and tension. sectional product of the width and the

depth of the beam.

Balance Beam – when the area of the

concrete and steel are just enough to Common Used Lateral Ties:

carry the compression and tension 1. 10mm dia. If longitudinal

Kind of Stresses that forces simultaneously. bars 32mm smaller

may act on structure 2. 12mm dia. If longitudinal

Inflection Points – refer to the portion bars 36mm bigger

Compression

of a beam where bending moment

Tension

changes from positive to negative. Three Factors for Spacing of the

Shear

Lateral Ties:

Torsion No Bent Bars – when bars are not 1. should not be more than 16

bent, an additional straight reinforcing times the diameter of the

bars are placed on the top of the beam longitudinal or main

across the supports extended to the reinforcing bars.

required length.

2. should not be more than 48

Bent Reinforcing Bars – are bent up times the diameter of the

on or near the inflection point and are lateral ties.

extended at the top of the beam across

the support towards the adjacent span.

3. Should not more than the

*Bend Bar advantage; resist the shortest dimension of the

diagonal tension. column.

Das könnte Ihnen auch gefallen

- Splice Connection CHSDokument180 SeitenSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Arki Tabulated Reviewer Add 21525218249 PDFDokument108 SeitenArki Tabulated Reviewer Add 21525218249 PDFRafael Yap GNoch keine Bewertungen

- Project Organization and ManagementDokument12 SeitenProject Organization and ManagementJ. VinceNoch keine Bewertungen

- Gujarat University: Bachelor of Architecture Outline For All Semesters (Batch 2015 Onwards)Dokument12 SeitenGujarat University: Bachelor of Architecture Outline For All Semesters (Batch 2015 Onwards)KrutiGDesaiNoch keine Bewertungen

- Multi Storey Steel BuildingDokument24 SeitenMulti Storey Steel BuildingPrashant100% (1)

- Designs-Guide-to-en-1994-Part 2 Bridges-Eurocode-4 PDFDokument184 SeitenDesigns-Guide-to-en-1994-Part 2 Bridges-Eurocode-4 PDFErnie ErnieNoch keine Bewertungen

- AA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsDokument45 SeitenAA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsJakesNoch keine Bewertungen

- V & M DiagramsDokument26 SeitenV & M Diagramsengr_malabanan60% (5)

- Building Technology I ReviewerDokument20 SeitenBuilding Technology I ReviewerBabylyn MordenNoch keine Bewertungen

- Building Technology I ReviewerDokument20 SeitenBuilding Technology I ReviewerBabylyn MordenNoch keine Bewertungen

- Div 03Dokument19 SeitenDiv 03Laurence PunsalanNoch keine Bewertungen

- Concrete Mixture Proportion: Ultimate Compressive StrengthDokument14 SeitenConcrete Mixture Proportion: Ultimate Compressive StrengthAngel Mine AlcantaraNoch keine Bewertungen

- BT3 PrelimDokument19 SeitenBT3 PrelimEsquibel, Mary AngelaNoch keine Bewertungen

- Ale Reviewer All in OneDokument106 SeitenAle Reviewer All in OneNicolas BrownNoch keine Bewertungen

- REINFORCED CONCRETE STRUCTURES 1stDokument63 SeitenREINFORCED CONCRETE STRUCTURES 1styanot leiNoch keine Bewertungen

- Arki Tabulated Reviewer Add 21525218249 PDFDokument108 SeitenArki Tabulated Reviewer Add 21525218249 PDFRafael Yap GNoch keine Bewertungen

- Arki Tabulated Reviewer 200501143515Dokument155 SeitenArki Tabulated Reviewer 200501143515Charles Godwin CordialNoch keine Bewertungen

- Chapter 05Dokument20 SeitenChapter 05Bek AsratNoch keine Bewertungen

- Lecture 5 - Concrete 3Dokument64 SeitenLecture 5 - Concrete 3abdullaharoon458Noch keine Bewertungen

- Materials and Construction - I: Lecture No. 3 Dated: 27/02/2020Dokument22 SeitenMaterials and Construction - I: Lecture No. 3 Dated: 27/02/2020awais anjumNoch keine Bewertungen

- Lecture #9 PET ENG 4210 Cementing 1Dokument11 SeitenLecture #9 PET ENG 4210 Cementing 1حيدر بادي - Haider BadiNoch keine Bewertungen

- Building Tech 1 (Div 03 Concrete) ReviewerDokument4 SeitenBuilding Tech 1 (Div 03 Concrete) ReviewerKristin Josette RempilloNoch keine Bewertungen

- Building Tech Reviewer (Concrete)Dokument11 SeitenBuilding Tech Reviewer (Concrete)Melliah PlataNoch keine Bewertungen

- Arbt ReviewerDokument24 SeitenArbt Reviewerluismgnzls14Noch keine Bewertungen

- Topic 3-Part 1Dokument61 SeitenTopic 3-Part 1Nur ShazrinNoch keine Bewertungen

- All in One ALE ReviewerDokument53 SeitenAll in One ALE Reviewergulay yuo100% (1)

- Topic 1 CE 13 Materials EstimateDokument14 SeitenTopic 1 CE 13 Materials EstimateAngelo VilleroNoch keine Bewertungen

- 4 ConcreteDokument55 Seiten4 ConcreteMartin NavarrozaNoch keine Bewertungen

- BMC 100 Important Questions 71Dokument24 SeitenBMC 100 Important Questions 71Its WorldNoch keine Bewertungen

- Ce6506-Construction Techniques and Practice: Prepared by Er.N.NAGARAJANM.E.,M.B.A.Dokument38 SeitenCe6506-Construction Techniques and Practice: Prepared by Er.N.NAGARAJANM.E.,M.B.A.Nagarajan NarayanasamyNoch keine Bewertungen

- 01 Concrete PDFDokument103 Seiten01 Concrete PDFLyka Mendoza MojaresNoch keine Bewertungen

- BDS PPT Lecture 2Dokument59 SeitenBDS PPT Lecture 2Stephen Bulay-ogNoch keine Bewertungen

- Cement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDokument8 SeitenCement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDanish KhanNoch keine Bewertungen

- Formation of The Dam Body: For Concrete Gravity DamsDokument44 SeitenFormation of The Dam Body: For Concrete Gravity DamsOsmanNoch keine Bewertungen

- Mod 6 DRLG BasicsDokument17 SeitenMod 6 DRLG BasicsMin Thant MaungNoch keine Bewertungen

- 001 Concrete ConstructionDokument10 Seiten001 Concrete ConstructionKimMinJae26Noch keine Bewertungen

- As Ton Sun UmDokument44 SeitenAs Ton Sun Umwahyu budiharjoNoch keine Bewertungen

- Complete ReviewerDokument24 SeitenComplete Reviewergene2693Noch keine Bewertungen

- CONCRETE-How To Make Good Concrete-Jan 2012-slDokument31 SeitenCONCRETE-How To Make Good Concrete-Jan 2012-slTrisha van der MerweNoch keine Bewertungen

- CONCRETEDokument33 SeitenCONCRETEparth massandNoch keine Bewertungen

- CONCRETEDokument47 SeitenCONCRETEGourav SachdevaNoch keine Bewertungen

- Concrete Material and MixtureDokument51 SeitenConcrete Material and MixtureAina Aqilah100% (1)

- Building Technology 4 Week 3Dokument39 SeitenBuilding Technology 4 Week 3Xette FajardoNoch keine Bewertungen

- Workability and Durability of ConcreteDokument1 SeiteWorkability and Durability of ConcreteMiller GuizadoNoch keine Bewertungen

- Concrete: - Nilanjan MitraDokument16 SeitenConcrete: - Nilanjan MitrassriramiitNoch keine Bewertungen

- Concrete Construction Article PDF - Making Mortar For Glass BlockDokument2 SeitenConcrete Construction Article PDF - Making Mortar For Glass BlockSandip MNoch keine Bewertungen

- MASONRYDokument41 SeitenMASONRYArchie Denece GajardoNoch keine Bewertungen

- Best Construction PracticeDokument18 SeitenBest Construction Practiceahmed khanNoch keine Bewertungen

- Chapter 6 Brick WorkDokument17 SeitenChapter 6 Brick WorkFaisal KhanNoch keine Bewertungen

- On ConcreteDokument102 SeitenOn Concreteblg watersupplyNoch keine Bewertungen

- Concrete & Aggregates: Payad. Bantayan. Bucal. Hostallero. NazarenoDokument48 SeitenConcrete & Aggregates: Payad. Bantayan. Bucal. Hostallero. NazarenoShaira Jane De MesaNoch keine Bewertungen

- Plaster TestsDokument23 SeitenPlaster TestsRobin SNoch keine Bewertungen

- BDS Chapter 2 Construction MaterialsDokument24 SeitenBDS Chapter 2 Construction MaterialsStephen Bulay-ogNoch keine Bewertungen

- CONCRETEDokument4 SeitenCONCRETEAngelika Lei GaraoNoch keine Bewertungen

- AggregatesDokument30 SeitenAggregatesbenedict shivachiNoch keine Bewertungen

- Concreting Underwater - Compressed PDFDokument15 SeitenConcreting Underwater - Compressed PDFIndigo CupcakeNoch keine Bewertungen

- Nirman SahayakDokument32 SeitenNirman SahayakRoti100% (2)

- BT Concrete 2023Dokument8 SeitenBT Concrete 2023Ralph Juneal BlancaflorNoch keine Bewertungen

- Brickwork: Practical Restoration HandbookDokument26 SeitenBrickwork: Practical Restoration HandbookJailaneeNoch keine Bewertungen

- BDE Standard Specification of BuildingDokument50 SeitenBDE Standard Specification of BuildingFreedom Love NabalNoch keine Bewertungen

- Cement: C) Bogue's CompoundsDokument31 SeitenCement: C) Bogue's CompoundsSafikul HossainNoch keine Bewertungen

- Unit 5Dokument19 SeitenUnit 5Julius waruiruNoch keine Bewertungen

- Construction Materials and Testing Manual NewDokument89 SeitenConstruction Materials and Testing Manual NewJosiah AntoninoNoch keine Bewertungen

- Concrete RatioDokument1 SeiteConcrete RatioKiel BuenconsejoNoch keine Bewertungen

- 25 Pdfsam ConcDokument1 Seite25 Pdfsam ConcscrNoch keine Bewertungen

- Lecture Notes on Reinforced Concrete DesignVon EverandLecture Notes on Reinforced Concrete DesignNoch keine Bewertungen

- Methods of Compensation ComparisonDokument12 SeitenMethods of Compensation ComparisonJ. VinceNoch keine Bewertungen

- Arho 01Dokument3 SeitenArho 01J. VinceNoch keine Bewertungen

- EkajpptDokument24 SeitenEkajpptJ. VinceNoch keine Bewertungen

- Capitol TheaterDokument1 SeiteCapitol TheaterJ. VinceNoch keine Bewertungen

- Capitol TheaterDokument1 SeiteCapitol TheaterJ. VinceNoch keine Bewertungen

- Holy Week SchedDokument4 SeitenHoly Week SchedJ. VinceNoch keine Bewertungen

- Barangay 104 Zone 11 Pasay CityDokument3 SeitenBarangay 104 Zone 11 Pasay CityJ. VinceNoch keine Bewertungen

- Palm Sunday (Tag) - Mar24 SGBCDokument71 SeitenPalm Sunday (Tag) - Mar24 SGBCJ. VinceNoch keine Bewertungen

- Construction ManagementDokument21 SeitenConstruction ManagementJ. VinceNoch keine Bewertungen

- Written Report: A. National TaxesDokument6 SeitenWritten Report: A. National TaxesJ. VinceNoch keine Bewertungen

- Our Lady of The Most Blessed Sacrament ParishDokument4 SeitenOur Lady of The Most Blessed Sacrament ParishJ. VinceNoch keine Bewertungen

- Singing Heralds Choir Singing Heralds Choir: New Members New MembersDokument1 SeiteSinging Heralds Choir Singing Heralds Choir: New Members New MembersJ. VinceNoch keine Bewertungen

- Article IDokument10 SeitenArticle IJ. VinceNoch keine Bewertungen

- This Study For Socialized Housing Serves As A Concrete Basis On The Parameter in Designing and To Identify TheDokument1 SeiteThis Study For Socialized Housing Serves As A Concrete Basis On The Parameter in Designing and To Identify TheJ. VinceNoch keine Bewertungen

- Singing Heralds Application FormDokument2 SeitenSinging Heralds Application FormJ. VinceNoch keine Bewertungen

- Palm Sunday (Tag) - Mar24 SGBCDokument71 SeitenPalm Sunday (Tag) - Mar24 SGBCJ. VinceNoch keine Bewertungen

- Singing Heralds Choir: New MembersDokument1 SeiteSinging Heralds Choir: New MembersJ. VinceNoch keine Bewertungen

- Building ParticipantsDokument9 SeitenBuilding ParticipantsJ. VinceNoch keine Bewertungen

- Music BasicsDokument13 SeitenMusic BasicsJ. VinceNoch keine Bewertungen

- Construction ManagementDokument14 SeitenConstruction ManagementJ. VinceNoch keine Bewertungen

- BT OutlineDokument1 SeiteBT OutlineJ. VinceNoch keine Bewertungen

- Project InitiationDokument34 SeitenProject InitiationJ. VinceNoch keine Bewertungen

- Intelligent Buildings: Components and Its SystemDokument9 SeitenIntelligent Buildings: Components and Its SystemJ. VinceNoch keine Bewertungen

- REGALARIO - Intelligent BuildingsDokument61 SeitenREGALARIO - Intelligent BuildingsJ. VinceNoch keine Bewertungen

- Report On PP 02Dokument3 SeitenReport On PP 02J. VinceNoch keine Bewertungen

- Green Building SystemDokument3 SeitenGreen Building SystemJ. VinceNoch keine Bewertungen

- Report Components of IBDokument1 SeiteReport Components of IBJ. VinceNoch keine Bewertungen

- Intelligent BuildingDokument15 SeitenIntelligent BuildingJ. VinceNoch keine Bewertungen

- The EC3 Approach To The Design of Columns, Beams and Beam-ColumnsDokument23 SeitenThe EC3 Approach To The Design of Columns, Beams and Beam-ColumnsMatthew Mamek SanggatNoch keine Bewertungen

- ColumnDokument41 SeitenColumnFun JinNoch keine Bewertungen

- Optimum Design of Launching Nose During Incremental Launching Construction of Same Span Continuous BridgeDokument6 SeitenOptimum Design of Launching Nose During Incremental Launching Construction of Same Span Continuous BridgePenyair SufiNoch keine Bewertungen

- Stresses in Beams: JU. Dr. Ibrahim Abu-AlshaikhDokument20 SeitenStresses in Beams: JU. Dr. Ibrahim Abu-AlshaikhqusayNoch keine Bewertungen

- Raft Foundations - Design & Analysis With A Practical Approach PDFDokument140 SeitenRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- CE Review For Nov 2022 - Theory 3: Figure P-736Dokument1 SeiteCE Review For Nov 2022 - Theory 3: Figure P-736JuDeNoch keine Bewertungen

- Assign 1Dokument2 SeitenAssign 1TariqIntegratedNoch keine Bewertungen

- Strap Footing Design As Per Is 456Dokument4 SeitenStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- CompositeMegaColumns Full Report PDFDokument275 SeitenCompositeMegaColumns Full Report PDFWasin WaiyasusriNoch keine Bewertungen

- 7 Unrestrained BeamsDokument39 Seiten7 Unrestrained BeamsImran SaikatNoch keine Bewertungen

- Development Length of Bars - Daily CivilDokument5 SeitenDevelopment Length of Bars - Daily CivilfelixNoch keine Bewertungen

- ADS01 Robustness 2018-2019Dokument107 SeitenADS01 Robustness 2018-2019tdrnkNoch keine Bewertungen

- PSC TutorialDokument2 SeitenPSC TutorialRevaNoch keine Bewertungen

- Beam Shear Connection Working 2Dokument41 SeitenBeam Shear Connection Working 2rammohan100% (2)

- CHAPTER11 NMDOT Bridge Design Guide 12-08 PDFDokument12 SeitenCHAPTER11 NMDOT Bridge Design Guide 12-08 PDFAnonymous kBl0u3nNoch keine Bewertungen

- Alina Dawood - QS - Long AssignmentDokument11 SeitenAlina Dawood - QS - Long AssignmentK AndreNoch keine Bewertungen

- Bridge Deck FormworkDokument8 SeitenBridge Deck Formworkedgarabraham100% (1)

- 5 PSC 1Dokument32 Seiten5 PSC 1Satyajit Ghate100% (1)

- 74781-Civil Degree PDFDokument14 Seiten74781-Civil Degree PDFCgpscAspirantNoch keine Bewertungen

- Elevation Section: Roof BeamDokument1 SeiteElevation Section: Roof BeamCONFIANCE INFRATECH MANAGEMENT PVT LTDNoch keine Bewertungen

- Design and Analysis of Flyover Bridge Using SAPDokument7 SeitenDesign and Analysis of Flyover Bridge Using SAPInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- 5.3.conjugate Beam MethodDokument14 Seiten5.3.conjugate Beam MethodRemylin De GuzmanNoch keine Bewertungen

- Steel Connection Design ClassDokument32 SeitenSteel Connection Design ClassJohn HammerNoch keine Bewertungen

- Bro The Very Narrow Aisle WarehouseDokument70 SeitenBro The Very Narrow Aisle WarehouseSuvin NambiarNoch keine Bewertungen