Beruflich Dokumente

Kultur Dokumente

Measuring Dust Concentration Wet Gases

Hochgeladen von

nobby52Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measuring Dust Concentration Wet Gases

Hochgeladen von

nobby52Copyright:

Verfügbare Formate

P r o d u c t i n f o r m at i o n

FWE200

Particulate Measurement in Wet Gas

Measurement of Dust Concentration

in Wet Gases

FWE200

Dust measuring system for highly precise

particle monitoring in many different applications

A r e a s o f a pp l i c at i o n

• Measurement of dust concentrations in wet flue gas • Plants that are subject to EPA PS-11 requirements or as

−− In saturated gas downstream of desulfurization plants part of PC MACT, Boiler MACT or Utility MACT

−− Downstream of wet scrubber, e.g. in waste incinerators

Re l i a b l e Ope r at i o n c o s t b e n ef i t s C o mp a c t DeS i g n

• Automatic test cycle with monitor • Minimal consumables • Extraction and feedback of sample

of zero point, reference and • Minimal operational costs - long gas in one probe: only one flange

contamination value maintenance intervals required

• Simple setting of parameters and • Long life cycle • Measuring and control units com-

controls with user friendly software pletely on one mounting plate

• Integrated system monitoring for • Optional: For even easier installa-

early recognition of maintenance tion and mounting work, the com-

requirements plete system can be fitted on a

frame

fe at u r e s

• Measures very low to medium dust concentration with • Display of operational value and system status on a LCD

scattered-light measurement using a scattered-light cell

• Flow control with integrated differential pressure measure-

with free jet flow

ment

• Extraction of part of the gas flow from the gas duct

• More than 35 years experience with over 35,000 dust and

• Drying and superheating of wet partial gas flow with a con- opacity monitors worldwide

trollable electric heater for a constant sample gas temper-

ature. This prevents measurement errors caused by drop-

lets.

2 FWE200 | Sick 2011-08

Subject to change without notice

F W E 2 0 0 S y s t em O v e r v i ew

A partial flow of gas is extracted from the

flue gas duct via a probe and heated Thermocyclone

above dewpoint in a thermocyclone

before it is supplied to a scattered-light Scattered

cell. The FWE200 then uses the sender/ light cell

receiver unit to measure the scattered- Sender/

light intensity in the test cell as a mea- receiver unit

sure of the dust concentration. Following Gas duct

this, the test gas is fed to the sample-gas Ejector

probe via an ejector and returned to the

duct. The sample gas is forwarded via Control

the ejector by means of a blower unit cabinet

that also supplies the sender/receiver

unit with purge air for keeping the optical

surfaces clean.

Signals Test gas

(sample)

probe

Power

supply

Blower

unit

s c at t e r e d l i g h t P r i n c i p l e

The FWE200 is based on the scat- The received signal is electrically ampli-

tered light principle (forward scatter- fied and supplied to the measuring chan-

ing). Smallest particle concentrations nel of a microprocessor as the central

can be recorded due to the extremely part of the measuring, control and evalu-

high sensitivity of this principle. ation electronics. The point of intersec-

tion between the transmitted beam and

A laser diode directs a beam of modu- the receiver aperture defines the mea-

lated light in the visible range (wave- suring volume in the gas duct.

length approximately 650 nm) at the Detector

dust particles in the gas flow. The light

scattered by the particles is recorded

by a highly sensitive detector which is Sender

positioned at an angle of approxi-

mately 15° to the beam axis.

2011-08 Sick | FWE200 3

Subject to change without notice

FWE200 PI/2011-08 ∙ DIV03 ∙ Printed in USA ∙ Subject to change without prior notice

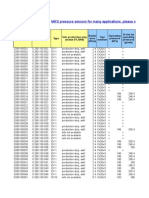

Technical data FWE200 Particulate Measurement

Measuring data

Measuring principle Scattered-light intensity, proportional to the dust concentration

Measuring ranges • 0...5 mg/m3

• 0...200 mg/m3

• Higher on request, in-between values freely configurable

Accuracy ±2% of full scale

Response time (t90) 0.1...600 s; freely selectable

Measuring conditions

Gas temperature • Maximum 248°F (120°C) for PVDF probes

• Maximum 392°F (200°C) for Hastelloy probes (higher on request)

Internal duct pressure ±20 hPa (8 inces water column) (±20 mbar)

Gas velocity 13...65.5 ft/sec (4...20 m/s), higher on request

Ambient Conditions

Ambient temperature -4...+120°F (–20...+50°C) (housing required for other temperature limits)

-4...+113°F (–20...+45°C) intake temperature for fan

Inputs, outputs, interfaces

Analog outputs Electrically isolated, 0/2/4...20 mA, max. load 750 Ω; 10 bit, resolution ± 1 %

Optional second analog output, electrically isolated, 0/2/4...20 mA, max. load 750 Ω, can be

set separately

Relay outputs 4 outputs: status signals operation/malfunction, warning, limit value, maintenance

Load carrying capacity: 48 V DC 0.5 A / 250 V, 1 A; floating

Interfaces RS232 for laptop/PC

Digital input Digital Input 1 = connection for maintenance switch with floating contact

General Information

System components • Extraction probe

• Measurement- and control unit

• Purge air unit

• Blower unit (weather proof cover required for outdoor installation)

Function check • Automatic control for zero and reference point

• Contamination measurement

Approvals

Compliances EPA PS-11

Electrical safety according to EN 61010-1

• Measuring and control unit and blower unit protection class I

• Sender/receiver unit protection class III

Protection class • System: IP 54

• Electronic housing: IP 65

SICK Process Automation Division

United States - Minneapolis, Minnesota | Houston, Texas | 281-436-5100

Canada - Calgary, Alberta | Toronto, Ontario | 905-771-1444 | 855-742-5583

e-mail: information@sick.com | www.sicknorthamerica.com

Das könnte Ihnen auch gefallen

- Bosch Injector Data SheetDokument124 SeitenBosch Injector Data SheetThibaut Lrt56% (9)

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsVon EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsBewertung: 4 von 5 Sternen4/5 (2)

- PotentiometryDokument27 SeitenPotentiometryShafique Ahmed100% (2)

- F0358 CMM 010Dokument164 SeitenF0358 CMM 010MJI EUWNoch keine Bewertungen

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentVon EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentBewertung: 4.5 von 5 Sternen4.5/5 (3)

- qualification-UV FTIR DSC HPLCDokument61 Seitenqualification-UV FTIR DSC HPLCRavi Kant100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Improving Power System Stability Through Integrated Power System Stabilizers - 100520Dokument25 SeitenImproving Power System Stability Through Integrated Power System Stabilizers - 100520soumyanitcNoch keine Bewertungen

- ESM Andersen BrochureDokument12 SeitenESM Andersen BrochureGezgin BiriNoch keine Bewertungen

- Feed Mill InfoDokument33 SeitenFeed Mill InfoSapelNoch keine Bewertungen

- How To Measure Gas Composition by Gas AnalyserDokument6 SeitenHow To Measure Gas Composition by Gas AnalyserSalah RomdaniNoch keine Bewertungen

- Basics of GCDokument52 SeitenBasics of GCBalaji SabanayagamNoch keine Bewertungen

- Types of Process AnalyzersDokument50 SeitenTypes of Process AnalyzersHARIS AHAMMED0% (1)

- NERC Reactive Support and Control WhitepaperDokument307 SeitenNERC Reactive Support and Control WhitepapersulemankhalidNoch keine Bewertungen

- 590p Trips and Fault Finding Sds Quick GuidesDokument19 Seiten590p Trips and Fault Finding Sds Quick GuidesHitesh Panigrahi100% (1)

- GS TDLS200 - Edition 3 FinalDokument12 SeitenGS TDLS200 - Edition 3 FinalApisitUsungnoenNoch keine Bewertungen

- Still Will: TestsDokument3 SeitenStill Will: TestsDanilo FortesNoch keine Bewertungen

- Ic m22 Inline Vortex Flow Meter 1Dokument8 SeitenIc m22 Inline Vortex Flow Meter 1syahril boonieNoch keine Bewertungen

- n65619 Solutionsheet Opacimeter E WebDokument2 Seitenn65619 Solutionsheet Opacimeter E WebRichardNoch keine Bewertungen

- Condition Monitoring of Electrical Components (EEL 426Dokument57 SeitenCondition Monitoring of Electrical Components (EEL 426Rohit Joshi100% (1)

- RASI 800 MCERTS Test KitDokument7 SeitenRASI 800 MCERTS Test KitAbderrahmaneAdaneNoch keine Bewertungen

- Simultaneous Measurement of Aggressive GasesDokument4 SeitenSimultaneous Measurement of Aggressive Gasesloli2323Noch keine Bewertungen

- Calibration Aruna AssignmentDokument30 SeitenCalibration Aruna AssignmentDr. Rajendra Singh ThakurNoch keine Bewertungen

- Qualification 1702203029Dokument61 SeitenQualification 1702203029Andrés PacompíaNoch keine Bewertungen

- Determination of Carbon in Fly-Ash: Roduct NformationDokument5 SeitenDetermination of Carbon in Fly-Ash: Roduct NformationandiNoch keine Bewertungen

- GM32 Sick Manual PDFDokument4 SeitenGM32 Sick Manual PDFMotorola AndroidNoch keine Bewertungen

- AGC NovaSTREAM 6000 O2Dokument4 SeitenAGC NovaSTREAM 6000 O2MiguelNoch keine Bewertungen

- Online Gas Analyser: Specialist of UV SpectrosDokument8 SeitenOnline Gas Analyser: Specialist of UV Spectroslaoying qdNoch keine Bewertungen

- Product Information Mercem300z en Im0040724Dokument12 SeitenProduct Information Mercem300z en Im0040724Supapol RangfakNoch keine Bewertungen

- Tender - GCMS SpecificationDokument5 SeitenTender - GCMS SpecificationMd AfzanNoch keine Bewertungen

- WDG-1210 現址式氧氣分析儀Dokument4 SeitenWDG-1210 現址式氧氣分析儀SeanKuoNoch keine Bewertungen

- pb3-06 510series Broc QX PDFDokument8 Seitenpb3-06 510series Broc QX PDFJaime LondoñoNoch keine Bewertungen

- Ultrasonic Gas Flow Measuring DevicesDokument216 SeitenUltrasonic Gas Flow Measuring DevicesGia BaoNoch keine Bewertungen

- Determination of Carbon in Fly AshDokument5 SeitenDetermination of Carbon in Fly AshTam Huynh ThanhNoch keine Bewertungen

- Wellwatcher Flux: Multizonal Reservoir Monitoring SystemDokument2 SeitenWellwatcher Flux: Multizonal Reservoir Monitoring Systemheqinghai heNoch keine Bewertungen

- Stackflow 200 Flow Monitor DatasheetDokument2 SeitenStackflow 200 Flow Monitor DatasheetAllen Bradley AyTNoch keine Bewertungen

- Leak Detection TechnologyDokument10 SeitenLeak Detection TechnologymasoudNoch keine Bewertungen

- COD & TOC AnalyserDokument24 SeitenCOD & TOC AnalyserSivakumar SelvarajNoch keine Bewertungen

- General Specifications: Measurement Solution: Truepeak TDLS500 Integrated Cavity Output Spectroscopy (ICOS)Dokument8 SeitenGeneral Specifications: Measurement Solution: Truepeak TDLS500 Integrated Cavity Output Spectroscopy (ICOS)ApisitUsungnoenNoch keine Bewertungen

- Product Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434Dokument12 SeitenProduct Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434cocot 666Noch keine Bewertungen

- FM CODEL GCEM40xx Ap12 PDFDokument6 SeitenFM CODEL GCEM40xx Ap12 PDFCandi.nntppNoch keine Bewertungen

- Continuous flow measurement for low solid/air ratiosDokument4 SeitenContinuous flow measurement for low solid/air ratiosDuc Duong TichNoch keine Bewertungen

- AAS 920 376G Telaire Ventostat T8041 T8042 Web 1485169Dokument5 SeitenAAS 920 376G Telaire Ventostat T8041 T8042 Web 1485169paola ochoa sanchezNoch keine Bewertungen

- GE Sample Systems WhitepaperDokument4 SeitenGE Sample Systems WhitepaperMateusz SynowieckiNoch keine Bewertungen

- 03 VESDA Pipes and Fittings TDS AQ IE LoresDokument4 Seiten03 VESDA Pipes and Fittings TDS AQ IE LoresLuiz BuenoNoch keine Bewertungen

- High Res Impeller FlowmeterDokument7 SeitenHigh Res Impeller FlowmeterFranciscaNoch keine Bewertungen

- Dust Concentration Measuring DeviceDokument2 SeitenDust Concentration Measuring DeviceTùng Hồ ThanhNoch keine Bewertungen

- Specification: Agilent 4890D Gas ChromatographDokument4 SeitenSpecification: Agilent 4890D Gas ChromatographRuiz ManuelNoch keine Bewertungen

- Flotation Process ControlDokument12 SeitenFlotation Process ControlJai Prakash PatelNoch keine Bewertungen

- Broc Pentair - Ffa 3019 LRDokument4 SeitenBroc Pentair - Ffa 3019 LRlauguicoNoch keine Bewertungen

- GS TDLS220 - Edition 2 - FinalDokument8 SeitenGS TDLS220 - Edition 2 - FinalApisitUsungnoenNoch keine Bewertungen

- PMT Hps Elster GasLabQ2 DatasheetDokument4 SeitenPMT Hps Elster GasLabQ2 DatasheetSharad GargNoch keine Bewertungen

- Burefenery - En-GbDokument8 SeitenBurefenery - En-GbnwhiteNoch keine Bewertungen

- AMETEK 910 AtexDokument2 SeitenAMETEK 910 AtexSaulius ŽilinskasNoch keine Bewertungen

- Endress Prowirl 73 SpecDokument20 SeitenEndress Prowirl 73 SpecMuhammad Fajar Bhayangkara PNoch keine Bewertungen

- ANALYTICS International: Hydrocarbon Analyser Thermo-FID PTDokument4 SeitenANALYTICS International: Hydrocarbon Analyser Thermo-FID PTSumeet Sisir SarkarNoch keine Bewertungen

- 【产品】LaserGas™ II HydrogenDokument2 Seiten【产品】LaserGas™ II Hydrogenlaoying qdNoch keine Bewertungen

- Feedback 37 100Dokument2 SeitenFeedback 37 100Ashik AhmedNoch keine Bewertungen

- Turbimax CUS31: Technical InformationDokument12 SeitenTurbimax CUS31: Technical InformationScridElGrandeNoch keine Bewertungen

- Bidirectional Sphere Type Prover: Smith Meter ProversDokument2 SeitenBidirectional Sphere Type Prover: Smith Meter Proversk ONoch keine Bewertungen

- Ammonit Wind Resource Assessment SystemsDokument4 SeitenAmmonit Wind Resource Assessment SystemsAbbas BahriNoch keine Bewertungen

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDokument4 Seiten5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNoch keine Bewertungen

- Calibration of Uv & IrDokument37 SeitenCalibration of Uv & IrDommaraju varunNoch keine Bewertungen

- CEMS SpecificationDokument10 SeitenCEMS SpecificationPriyabrat KumarNoch keine Bewertungen

- MEMBRANE-BASED GAS SENSING PROVIDES ROBUST PAY IDENTIFICATIONDokument6 SeitenMEMBRANE-BASED GAS SENSING PROVIDES ROBUST PAY IDENTIFICATIONprowednesNoch keine Bewertungen

- Brochure - Delta en WebDokument12 SeitenBrochure - Delta en WebcartarNoch keine Bewertungen

- Ocpf81d 82D-81 82 TiDokument15 SeitenOcpf81d 82D-81 82 TiHumbertoNoch keine Bewertungen

- PA Process Measurement EnglishDokument32 SeitenPA Process Measurement Englishnobby52Noch keine Bewertungen

- GHG Control MeasurementDokument8 SeitenGHG Control Measurementnobby52Noch keine Bewertungen

- SI EmissionMeasurement en V1!0!2012-03 WEBDokument32 SeitenSI EmissionMeasurement en V1!0!2012-03 WEBNicuVisanNoch keine Bewertungen

- Mercury Analyzer For Continuous Monitoring in Flue GasDokument8 SeitenMercury Analyzer For Continuous Monitoring in Flue Gasnobby52Noch keine Bewertungen

- Measuring Dust Concentration Wet GasesDokument4 SeitenMeasuring Dust Concentration Wet Gasesnobby52Noch keine Bewertungen

- BIRA-WAT Symposium 20060316 Final PDFDokument33 SeitenBIRA-WAT Symposium 20060316 Final PDFnobby52Noch keine Bewertungen

- SI EmissionMeasurement en V1!0!2012-03 WEBDokument32 SeitenSI EmissionMeasurement en V1!0!2012-03 WEBNicuVisanNoch keine Bewertungen

- PA Process Measurement EnglishDokument32 SeitenPA Process Measurement Englishnobby52Noch keine Bewertungen

- Sick Insight Pa 2014-01 en WebDokument2 SeitenSick Insight Pa 2014-01 en Webnobby52Noch keine Bewertungen

- PA Process Measurement EnglishDokument32 SeitenPA Process Measurement Englishnobby52Noch keine Bewertungen

- SI EmissionMeasurement en V1!0!2012-03 WEBDokument32 SeitenSI EmissionMeasurement en V1!0!2012-03 WEBNicuVisanNoch keine Bewertungen

- Sick Insight Pa 2014-01 en WebDokument2 SeitenSick Insight Pa 2014-01 en Webnobby52Noch keine Bewertungen

- BIRA-WAT Symposium 20060316 FinalDokument33 SeitenBIRA-WAT Symposium 20060316 Finalnobby52Noch keine Bewertungen

- Pest of PelDokument7 SeitenPest of PelSaqib AkhtarNoch keine Bewertungen

- ασκήσεις υδραυλικων λαδιουDokument160 Seitenασκήσεις υδραυλικων λαδιουchristodoulos charalambousNoch keine Bewertungen

- Automatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFDokument29 SeitenAutomatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFEi Po Po AungNoch keine Bewertungen

- Radiography Sai KripaDokument4 SeitenRadiography Sai KripaSarthak EnterprisesNoch keine Bewertungen

- Apd NG150Dokument5 SeitenApd NG150Magaly PeraltaNoch keine Bewertungen

- Profile ForgingDokument17 SeitenProfile ForgingMahipal ChandanNoch keine Bewertungen

- Condensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minDokument5 SeitenCondensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minBui Hoang DucNoch keine Bewertungen

- Solar GeometryDokument34 SeitenSolar GeometryPatricia Franchette AmoraNoch keine Bewertungen

- ATSDokument8 SeitenATSserban_elNoch keine Bewertungen

- EV Technology QPDokument3 SeitenEV Technology QPvcetnaac c6Noch keine Bewertungen

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesDokument6 SeitenJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanNoch keine Bewertungen

- Biofuel For Sri LankaDokument0 SeitenBiofuel For Sri LankaJaanu SanthiranNoch keine Bewertungen

- Closer #1Dokument32 SeitenCloser #1Mike SmallNoch keine Bewertungen

- Water Supply Sanitary Eng PDFDokument5 SeitenWater Supply Sanitary Eng PDFReddy NaveenNoch keine Bewertungen

- Is SP 72 2010Dokument25 SeitenIs SP 72 2010mkannanofficialNoch keine Bewertungen

- Curved Data KEW PUMP KSSE 3 1Dokument1 SeiteCurved Data KEW PUMP KSSE 3 1Haryono SyalimNoch keine Bewertungen

- Bel Ray BrochureDokument20 SeitenBel Ray BrochureaditNoch keine Bewertungen

- ACME AHX Water-Cooled Condenser - 06.10 PDFDokument3 SeitenACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002Noch keine Bewertungen

- UNIVERSITY QUIZDokument4 SeitenUNIVERSITY QUIZJericko Lian Del RosarioNoch keine Bewertungen

- Label Odner BantexDokument4 SeitenLabel Odner Bantexdana setiawanNoch keine Bewertungen

- Mx37y Technical DescriptionDokument38 SeitenMx37y Technical DescriptionVladimir PeshicNoch keine Bewertungen

- Generate Electricity From Park Revolving DoorDokument39 SeitenGenerate Electricity From Park Revolving Doortariq7660% (5)

- Xenon Short Arc Lamps: Light Source XE150 (650-0091)Dokument2 SeitenXenon Short Arc Lamps: Light Source XE150 (650-0091)Abhishek GuddadNoch keine Bewertungen