Beruflich Dokumente

Kultur Dokumente

Itp - Eifs

Hochgeladen von

sathiyaprasathOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Itp - Eifs

Hochgeladen von

sathiyaprasathCopyright:

Verfügbare Formate

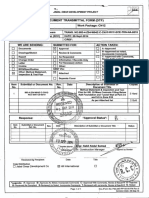

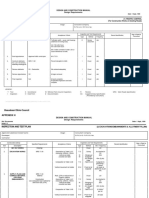

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 1 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 2 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 3 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 4 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 5 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 6 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 7 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 8 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 9 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 10 of 22 Form No. : MS-30-ITP R0

INSPECTION & TEST PLAN

Project Name :

Activity : EIFS Works ( MS-31 )

Acceptance Criteria /

Reference

Item Quality Control Point Type of Check Specification Clause /

Document

Manufacturer

Review of Specification

1 Approval of EIFS Material documents & MS Vendor List Material Submittal, Pre-Qualification

with RA MS with RA

Final Inspection for Block Work / Visual, Specification Free from Cracks and Hollowness and

2

Check Surface Preparation Measurement Method statement Surface should be Smooth and Flat

Fixing of EPS Board with Fiber

Visual, Specification As Per Specification, Manufacturer

3 Reinforced polymer& adhesive

Measurement Method statement Recommendations

material

Visual, Specification As Per Specification, Manufacturer

4 Application of CT 325 Mesh on EPS

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

5 Application of CT 16 Primer

Measurement Method statement Recommendations

Visual, Specification As Per Specification, Manufacturer

6 Application of CT 60 Platster

Measurement Method statement Recommendations

Page 11 of 22 Form No. : MS-30-ITP R0

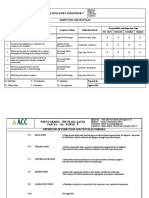

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 12 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 13 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 14 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 15 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 16 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 17 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 18 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 19 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 20 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 21 of 22 Form No. : MS-30-ITP R0

N & TEST PLAN

Surveillance Points

Verifying

Document

Contractor Consultant Client Comments

WIR,MIR & MS with RA

H A S

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I W S

Checklist MS-31-CL-01

WIR,

I H S

Checklist MS-31-CL-01

Page 22 of 22 Form No. : MS-30-ITP R0

Das könnte Ihnen auch gefallen

- MS 05Dokument21 SeitenMS 05unnicyriacNoch keine Bewertungen

- Al Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & WiresDokument5 SeitenAl Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & Wiresmidhun muraliNoch keine Bewertungen

- Standard Construction Specs for Roads and Pavement MarkingsDokument3 SeitenStandard Construction Specs for Roads and Pavement MarkingsRolando de GuzmanNoch keine Bewertungen

- TRN 0515 B PDFDokument15 SeitenTRN 0515 B PDFrayNoch keine Bewertungen

- SECTION 02 4116 Structure Demolition (Actual Requirements)Dokument2 SeitenSECTION 02 4116 Structure Demolition (Actual Requirements)Joice Chiø VelascoNoch keine Bewertungen

- A Qac Pro 000 38951Dokument30 SeitenA Qac Pro 000 38951Amin GNoch keine Bewertungen

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADokument48 SeitenM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNoch keine Bewertungen

- BMJV-QUA-F18.01 Excavation Checklist R00Dokument1 SeiteBMJV-QUA-F18.01 Excavation Checklist R00Taiwo OshinNoch keine Bewertungen

- Lesson 10 Project Quality PlanningDokument51 SeitenLesson 10 Project Quality PlanningDevjit MandalNoch keine Bewertungen

- Construction Supervising Site EngineerDokument76 SeitenConstruction Supervising Site Engineernashrul_izzuanNoch keine Bewertungen

- Lps 01 Hti MST El 005 Point WiringDokument22 SeitenLps 01 Hti MST El 005 Point WiringJomy JohnyNoch keine Bewertungen

- Div 03544 Cement Based ScreedDokument8 SeitenDiv 03544 Cement Based ScreedrayNoch keine Bewertungen

- PMPT Itp 010Dokument3 SeitenPMPT Itp 010hz135874Noch keine Bewertungen

- Underground UPVC Drainage Method StatementDokument50 SeitenUnderground UPVC Drainage Method StatementDiaa GobranNoch keine Bewertungen

- QM Plan ProcedureDokument13 SeitenQM Plan ProcedureHans JonesNoch keine Bewertungen

- Quality PlanDokument21 SeitenQuality PlanQianlei ZhuNoch keine Bewertungen

- Request For Information (Rfi) : Company (Contractor) Contract/ Purchase NoDokument2 SeitenRequest For Information (Rfi) : Company (Contractor) Contract/ Purchase NoResearcherNoch keine Bewertungen

- Appendix H: Design and Construction Manual Design RequirementsDokument17 SeitenAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNoch keine Bewertungen

- QA QC by FMIDokument2 SeitenQA QC by FMIfreddy.eerstaNoch keine Bewertungen

- Civil Quality Control Plan EarthworksDokument3 SeitenCivil Quality Control Plan Earthworksroekyat hendrawanNoch keine Bewertungen

- PQP Vs ISO 9001 Clauses List PDFDokument1 SeitePQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- Unops Daily ReportDokument2 SeitenUnops Daily ReportFeraydoon NasratzadaNoch keine Bewertungen

- Lavatex 2000...Dokument2 SeitenLavatex 2000...ArifNoch keine Bewertungen

- WQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers WorksDokument68 SeitenWQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers Worksmuhammad.younisNoch keine Bewertungen

- Contractor Monthly Quality Report SummaryDokument11 SeitenContractor Monthly Quality Report SummaryKarthik KumarNoch keine Bewertungen

- METHOD - STATEMENT - FOR D Wall and Guide WallDokument6 SeitenMETHOD - STATEMENT - FOR D Wall and Guide WalldhruvNoch keine Bewertungen

- Checklist For Excavation & Backfilling WorkDokument2 SeitenChecklist For Excavation & Backfilling WorkHimanshu ChaudharyNoch keine Bewertungen

- Method Statement of Mass Concrete Block Precast WorksDokument41 SeitenMethod Statement of Mass Concrete Block Precast WorksShams JogNoch keine Bewertungen

- METHOD OF STATEMENT - ALKHOMRA PROJECT - CarbstoneDokument7 SeitenMETHOD OF STATEMENT - ALKHOMRA PROJECT - Carbstoneahmed samirNoch keine Bewertungen

- AAA-Project Quality Plan (Rev.0-2015)Dokument8 SeitenAAA-Project Quality Plan (Rev.0-2015)Behroze ShabirNoch keine Bewertungen

- QC Check Sheet for Earthworks ExcavationDokument1 SeiteQC Check Sheet for Earthworks ExcavationPrasanna KumarNoch keine Bewertungen

- Quality Assurance Plan for ASARCO DemolitionDokument20 SeitenQuality Assurance Plan for ASARCO DemolitionRen SalazarNoch keine Bewertungen

- Drawing Register 01Dokument1 SeiteDrawing Register 01tidypainNoch keine Bewertungen

- METHOD STATEMENT DRAINAGE CONSTRUCTIONDokument9 SeitenMETHOD STATEMENT DRAINAGE CONSTRUCTIONAishah AliasNoch keine Bewertungen

- Itp Lime StabilizationDokument2 SeitenItp Lime StabilizationMikiRoniWijayaNoch keine Bewertungen

- Personal Data & Work Experience: Sameh ElsayedDokument4 SeitenPersonal Data & Work Experience: Sameh Elsayedshamim ahmadNoch keine Bewertungen

- Section 017700 - Closeout ProceduresDokument5 SeitenSection 017700 - Closeout ProceduresChase GietterNoch keine Bewertungen

- QAP Plan For Biratnagar AirportDokument20 SeitenQAP Plan For Biratnagar AirportNirmal bhandariNoch keine Bewertungen

- 01 ITP TemplateDokument6 Seiten01 ITP TemplateHelsy FuentesNoch keine Bewertungen

- DE-QC-IT-S01 (Inspection & Test Plan)Dokument8 SeitenDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNoch keine Bewertungen

- Check List For Backfilling WorksDokument2 SeitenCheck List For Backfilling WorksYash SharmaNoch keine Bewertungen

- Sp3-3 - Reinforced Concrete SpecDokument11 SeitenSp3-3 - Reinforced Concrete SpecJon WadsworthNoch keine Bewertungen

- REMOVING SHUTTERSDokument8 SeitenREMOVING SHUTTERSAhmet ÖzdenNoch keine Bewertungen

- Qualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesDokument7 SeitenQualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesRHOWELLE TIBAYNoch keine Bewertungen

- Summary of Construction Documentation for Riyadh Metro ProjectDokument103 SeitenSummary of Construction Documentation for Riyadh Metro ProjectZiaul HaqNoch keine Bewertungen

- QA/QC Guidelines Objectives & ScopeDokument20 SeitenQA/QC Guidelines Objectives & ScopeFurqanam196100% (2)

- Dashboard C-1101 MR 2013 Fox HillsDokument10 SeitenDashboard C-1101 MR 2013 Fox HillsrmdarisaNoch keine Bewertungen

- Epoxy Coating Method StatementDokument23 SeitenEpoxy Coating Method StatementbukhoriNoch keine Bewertungen

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDokument3 SeitenProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNoch keine Bewertungen

- QC MANUAL (Project Quality Plan) WisnuDokument10 SeitenQC MANUAL (Project Quality Plan) WisnuNovie DwiyantiNoch keine Bewertungen

- MS Site and FenceDokument11 SeitenMS Site and FenceSahabzada AamirNoch keine Bewertungen

- 5 Formwork ChecklistDokument81 Seiten5 Formwork ChecklistAlphaNoch keine Bewertungen

- Quality InductionDokument15 SeitenQuality InductionaleemmurtazaNoch keine Bewertungen

- Installation Method for Lift ProjectDokument22 SeitenInstallation Method for Lift ProjectFarisNoch keine Bewertungen

- Construction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineDokument5 SeitenConstruction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineIkhwan HishamNoch keine Bewertungen

- Hill Method StatementDokument2 SeitenHill Method StatementrayNoch keine Bewertungen

- 10.method Statement Piling WorkDokument6 Seiten10.method Statement Piling Workشاز إياسNoch keine Bewertungen

- Inspection In Manufacturing A Complete Guide - 2020 EditionVon EverandInspection In Manufacturing A Complete Guide - 2020 EditionNoch keine Bewertungen

- Proceduer of Pmi - Rev - 03 Dec 25-2019Dokument14 SeitenProceduer of Pmi - Rev - 03 Dec 25-2019Rajat TiwariNoch keine Bewertungen

- QA QC DEPT IntroductionDokument6 SeitenQA QC DEPT IntroductionsathiyaprasathNoch keine Bewertungen

- Green Code-Construction Materials BookDokument133 SeitenGreen Code-Construction Materials Bookscarlett3232100% (2)

- Noc CarDokument1 SeiteNoc CarsathiyaprasathNoch keine Bewertungen

- Dev and Lap Splice Lengths - ETN-D-1-15 PDFDokument9 SeitenDev and Lap Splice Lengths - ETN-D-1-15 PDFsathiyaprasathNoch keine Bewertungen

- Prevention & Repair of Cracks in Concrete StructuresDokument98 SeitenPrevention & Repair of Cracks in Concrete StructuresvinujohnpanickerNoch keine Bewertungen

- Green Code-Construction Materials BookDokument133 SeitenGreen Code-Construction Materials Bookscarlett3232100% (2)

- Finishes Schedule - Annexure 1: 43-4 External CirculationDokument1 SeiteFinishes Schedule - Annexure 1: 43-4 External CirculationsathiyaprasathNoch keine Bewertungen

- MS 03 - Responsibility MatrixDokument2 SeitenMS 03 - Responsibility MatrixsathiyaprasathNoch keine Bewertungen

- Quality ManagmentDokument97 SeitenQuality Managmentsathiyaprasath0% (1)

- NMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallDokument8 SeitenNMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallsathiyaprasathNoch keine Bewertungen

- Why The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Dokument4 SeitenWhy The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Vipin Kumar ParasharNoch keine Bewertungen

- Corporate SaamiyarkalDokument120 SeitenCorporate SaamiyarkalPrasanth KumarNoch keine Bewertungen

- HoneycombDokument14 SeitenHoneycombsathiyaprasath100% (1)

- Sodamco Comparison With BASFDokument3 SeitenSodamco Comparison With BASFsathiyaprasathNoch keine Bewertungen

- Construction Safety ManagementDokument45 SeitenConstruction Safety ManagementLalith RohanaNoch keine Bewertungen

- HoneycombDokument14 SeitenHoneycombsathiyaprasath100% (1)

- Install Chain Link FenceDokument11 SeitenInstall Chain Link Fencesathiyaprasath80% (10)

- Quality Management: It Costs A Lot To Produce A Bad ProductDokument62 SeitenQuality Management: It Costs A Lot To Produce A Bad ProductandrefkatoNoch keine Bewertungen

- Method Statement For Claustra Block Works.Dokument12 SeitenMethod Statement For Claustra Block Works.sathiyaprasath80% (5)

- 1.concentric Butterfly Valve in Various ApplicationDokument10 Seiten1.concentric Butterfly Valve in Various ApplicationMaciekNoch keine Bewertungen

- 713 00079 01 Acumer 4200 Water Treatment PolymerDokument2 Seiten713 00079 01 Acumer 4200 Water Treatment PolymermnasiroleslamiNoch keine Bewertungen

- Econ Ball Valves Carbon Steel Stainless SteelDokument1 SeiteEcon Ball Valves Carbon Steel Stainless SteelChristianGuerreroNoch keine Bewertungen

- Am 2Dokument38 SeitenAm 2Chandan KumarNoch keine Bewertungen

- Products of CombustionDokument5 SeitenProducts of CombustionAJ SiosonNoch keine Bewertungen

- FLOWTITE Jacking Pipe ID Series Type SE Joint Non Pressure ChartDokument2 SeitenFLOWTITE Jacking Pipe ID Series Type SE Joint Non Pressure ChartNADEEM AHMEDNoch keine Bewertungen

- Bamberger Bapolene ® 2035 High Density Polyethylene, Blow Molding GradeDokument1 SeiteBamberger Bapolene ® 2035 High Density Polyethylene, Blow Molding GradedianaNoch keine Bewertungen

- DSR 2002Dokument149 SeitenDSR 2002api-3823524100% (2)

- Topic 1 - Introduction Mechanical OperationsDokument82 SeitenTopic 1 - Introduction Mechanical OperationsAmeen HussainNoch keine Bewertungen

- Shallow Floors: Downstand Beams Distribution of ServicesDokument3 SeitenShallow Floors: Downstand Beams Distribution of ServicesAnurag PandeyNoch keine Bewertungen

- Developments in Insulating Paper For Pow PDFDokument30 SeitenDevelopments in Insulating Paper For Pow PDFDante FilhoNoch keine Bewertungen

- Iso 7203-1-2019Dokument50 SeitenIso 7203-1-2019alejandroNoch keine Bewertungen

- Construction Materials CanvassDokument14 SeitenConstruction Materials CanvassBhell MendiolaNoch keine Bewertungen

- Liquitint by Milliken FlyerDokument1 SeiteLiquitint by Milliken FlyerLaura GarcíaNoch keine Bewertungen

- Drills TheoryDokument56 SeitenDrills TheoryrohanNoch keine Bewertungen

- Temparature Sensor. CompleteDokument15 SeitenTemparature Sensor. CompleteMarvin BenedictoNoch keine Bewertungen

- CbsDokument3 SeitenCbsBharat ChatrathNoch keine Bewertungen

- Civil Module 1 NotesDokument36 SeitenCivil Module 1 NotesPrateek MalagundNoch keine Bewertungen

- Fiama Di WillsDokument4 SeitenFiama Di WillsDipti JainNoch keine Bewertungen

- Fasteners - How To Identify Stainless SteelDokument3 SeitenFasteners - How To Identify Stainless SteelMichael Lanfield Raw VeganNoch keine Bewertungen

- Fosroc Nitoflor Emeritop: Abrasion-Resistant Concrete Floor HardenerDokument4 SeitenFosroc Nitoflor Emeritop: Abrasion-Resistant Concrete Floor HardenerVincent JavateNoch keine Bewertungen

- Damp Proof Course: Building Construction & MaterialDokument11 SeitenDamp Proof Course: Building Construction & MaterialElsa kNoch keine Bewertungen

- The Role of Hardness in Jewelry AlloysDokument19 SeitenThe Role of Hardness in Jewelry AlloysAswin AntoniusNoch keine Bewertungen

- Precast Concrete ReportDokument28 SeitenPrecast Concrete ReportAchyutam Khajuria50% (2)

- LubricantsDokument21 SeitenLubricantsGourav KumarNoch keine Bewertungen

- Masteremaco N 202: Description PrimingDokument2 SeitenMasteremaco N 202: Description PrimingshahidNoch keine Bewertungen

- ISBN: 978-81-265-4475-2: Engineering Chemistry (Revised Edition)Dokument46 SeitenISBN: 978-81-265-4475-2: Engineering Chemistry (Revised Edition)srinivasNoch keine Bewertungen

- Chemical GroutingDokument34 SeitenChemical GroutingAndrew ReidNoch keine Bewertungen

- Nioec SP 90-51Dokument6 SeitenNioec SP 90-51masoud132Noch keine Bewertungen

- Electric and water requirements for concrete batch plantDokument8 SeitenElectric and water requirements for concrete batch plantWael WaelNoch keine Bewertungen