Beruflich Dokumente

Kultur Dokumente

Cloud Point

Hochgeladen von

Ravi ShankarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cloud Point

Hochgeladen von

Ravi ShankarCopyright:

Verfügbare Formate

CLEARLY CLOUDY –

FINDING A CLOUDING GLYCOL

SYSTEM FOR FORMATE BRINES

L. Kaminski, Cabot Specialty Fluids; J.D. Downs, Formate Brine Ltd.; S.K. Howard, Cabot Specialty Fluids

Towards the perfect shale drilling fluid

Glycols or diols are a family of water-soluble alcohols containing 2 hydroxyl (-OH) Cabot and Formate Brine Ltd. have been developing a formate-based TAME fluid,

groups. The simplest industrial diol is ethylene glycol, which is widely used as a coolant, seeking suitable clouding glycols that meet the following performance criteria.

heat transfer agent and anti-freeze fluid. A distinctive feature of glycols is that they • Low viscosity liquids at 25°C

become less water-soluble at higher temperatures and may eventually phase-separate • High flash points, i.e. > 70°C

from water as a very fine emulsion. The temperature at which this phase separation or • Thermally stable to 200°C

‘clouding’ occurs in aqueous glycol solution is known as the cloud-point temperature • Soluble to at least 5% v/v in potassium and cesium formate brines at 25°C

(CPT). This is determined by the amount of glycol in solution, the glycol’s molecular • Clouds-out in formate brines at temperatures of between 30°C and 200°C

weight and the concentration and type of salt in solution with the glycol. A change in • Non-toxic to humans and all other life forms that it might encounter

any of these parameters changes CPT. • Readily biodegradable

The addition of low concentrations (e.g. 1 – 5% v/v) of water-soluble glycols to water-

based drilling fluids can improve drilling economics by: Experimental

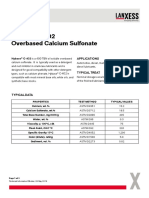

• Maintaining wellbore integrity in shale sections – glycols slow down fluid invasion Initial screening identified polyethylene glycols (PEGs) in the molecular weight range

and pore pressure penetration in shale. 200 – 600 as good candidates for more detailed testing. The properties of PEG 200,

• Maintaining drilled cuttings integrity – glycols displace water from clay cuttings, 400 and 600 liquids are shown in Table 1.

reducing swelling pressure and maintaining cuttings integrity during their journey

Table 1 Cloud-point measurements were made on 1 – 5% v/v solutions of these PEG liquids in

up the annulus. Polyethylene glycols (PEGs) are particularly good at intercalating potassium formate brines of 4 – 13 mol/litre and cesium formate brines of 2 – 11 mol/litre molarity.

within the clay matrix. Keeping cuttings firm and intact reduces mud maintenance

costs and waste volumes. Property PEG 200 PEG 400 PEG 600

Viscosity @ 100°C (CSt) 4.3 7.3 10.8

• Lubricating contact surfaces – clouding glycols coat onto solid surfaces in their

Flash point, closed cup (°C) 185 227 185

clouded state, providing good metal-to-metal and metal-to-rock lubrication in

Solubility at 5% in water @ 25°C Complete Complete Complete

the wellbore.

Freezing point (°C) -65 4–8 15 – 25

• Reducing bit balling – glycols reduce bit balling and are widely used in water-based Density (g/cm3 @ 20°C) 1.124 1.125 1.126

muds as ROP enhancement additives. Toxicity – human hazard Non-hazardous Non-hazardous Non-Hazardous

• Improving efficiency of filter cakes – glycols reduce drilling fluid loss rates and Toxicity-environmental hazard Low toxicity Low toxicity Low toxicity

eliminate differential sticking at high overbalance. Biodegradability Readily biodegradable Readily biodegradable Readily biodegradable

• Slowing thermal degradation of polymer additives – glycols appear to reduce Figure 2 Cloud point of 5% PEG in potassium formate brine

depolymerisation rates of fluid viscosifiers and fluid loss control polymers at high

temperatures. 225

200

• Defoaming and demulsification – some glycols act as defoamers and demulsifiers,

Cloud-point temperature of PEG (ºC)

175

especially in their clouded state.

150

125 PEG 400

100 PEG 600

PEG 200 400 blend

75

PEG 200

50

25

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Molar concentration of potassium formate in brine (mol/L)

Figures 2 and 3 show cloud-point lines of the three PEGs and a PEG blend at 5% v/v

concentration in potassium and cesium formate as a function of brine molarity. The

lines are best fits of experimental data. These results indicate that selected PEGs in

the molecular weight range 200 – 600 should be capable of creating active TAME-

clouding glycol systems at any temperature between 25°C and 200°C in either cesium

or potassium formate brines of 2 – 13 molarity (1.18 – 2.30 g/cm3 density).

Figure 3 Cloud point of 5% PEG in cesium formate brine

275

250

225

Cloud-point temperature of PEG (ºC)

Figure 1 1.85 g/cm cesium formate with 5% PEG 400 at room temperature (left) and heated to 60°C (right)

3

200

175

Shell first tested clouding glycol drilling fluids, which are known as TAME (Thermally 150 PEG 400

Activated Mud Emulsions) in 1992 by drilling over 30,000 feet of 17.5", 12.25", 8.5" and 6" 125 PEG 600

PEG 200 400 blend

holes in five deviated development wells and one exploration well in the UK North Sea. 100

PEG 200

75

Shell’s conclusion from its field evaluation of TAME (see SPE paper 26699) is:

50

25

“The overall conclusion from this test campaign is that the TAME system is superior to 0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

conventional muds by virtue of its better borehole stabilising qualities, higher rates Molar concentration of cesium formate in brine (mol/L)

of penetration, significant waste reduction and lower mud time rates (i.e. the total

time spent drilling on bottom, tripping, conditioning the hole or mud and circulating

the mud).” This preliminary work demonstrates that benign low-molecular-weight polyethylene

glycols are effective clouding agents in high-density single-salt potassium and

cesium formate brines. Further study is required to check PEG behaviour in mixed

potassium/cesium formate brine blends with common drilling fluid additives.

The 20th SPE Bergen One Day Seminar

April 10th 2013 | Bergen, Norway

Das könnte Ihnen auch gefallen

- PegDokument24 SeitenPegAkhmad Rafi'iNoch keine Bewertungen

- Table 1. Synthetic Polymer Acid Gelling AgentsDokument4 SeitenTable 1. Synthetic Polymer Acid Gelling AgentsLeo Rojas DomNoch keine Bewertungen

- BWA Belcor 575 Replaces Molybdate USA - WF 0Dokument2 SeitenBWA Belcor 575 Replaces Molybdate USA - WF 0mnasiroleslami100% (2)

- Peg Chemical GradeDokument3 SeitenPeg Chemical GradeelsitaelisNoch keine Bewertungen

- Rheological Properties of Polyethylene Glycol Solutions and Gels 2469 9764 1000102Dokument5 SeitenRheological Properties of Polyethylene Glycol Solutions and Gels 2469 9764 1000102Elena DoniciNoch keine Bewertungen

- Rheological Properties of Polyethylene Glycol Solutions and GelsDokument3 SeitenRheological Properties of Polyethylene Glycol Solutions and Gelsromulo feitosa navarroNoch keine Bewertungen

- TDS - Glenium Ace 415Dokument3 SeitenTDS - Glenium Ace 415Alexi ALfred H. TagoNoch keine Bewertungen

- New - Coladet LD-150Dokument2 SeitenNew - Coladet LD-150mndmattNoch keine Bewertungen

- Poly BD Resins in Construction ApplicationsDokument6 SeitenPoly BD Resins in Construction ApplicationsJOSEANTONIO2001Noch keine Bewertungen

- Coatosil MP 200 Crosslinker WB Systems m8 PDFDokument8 SeitenCoatosil MP 200 Crosslinker WB Systems m8 PDFjoseNoch keine Bewertungen

- Property (Unit) Typical Value Test MethodDokument2 SeitenProperty (Unit) Typical Value Test MethodAlejandro MartinezNoch keine Bewertungen

- Ez Mud Plus Product Data SheetDokument2 SeitenEz Mud Plus Product Data SheetSudkate BoonthawornNoch keine Bewertungen

- AFE Reak: Product BulletinDokument2 SeitenAFE Reak: Product BulletinyfcozNoch keine Bewertungen

- Redicote C-450: High Reactive Aggregates: CationicDokument1 SeiteRedicote C-450: High Reactive Aggregates: CationicRabin BeraNoch keine Bewertungen

- Redicote E-7000: Versatile Emulsifier: Provides Both AniDokument1 SeiteRedicote E-7000: Versatile Emulsifier: Provides Both AniRabin Bera0% (1)

- TDS-187 Carbopol ETD 2020 Personal Care ApplicationsDokument2 SeitenTDS-187 Carbopol ETD 2020 Personal Care ApplicationsMagister Veneficae Antonius Endrilius100% (1)

- Poly Gly KoleDokument8 SeitenPoly Gly KoleArianna Sánchez GonzálezNoch keine Bewertungen

- CH CH CH - CH CL CL N N: PolymerizationDokument34 SeitenCH CH CH - CH CL CL N N: PolymerizationBagoes Rebel CrewNoch keine Bewertungen

- CH CH CH - CH CL CL N N: PolymerizationDokument40 SeitenCH CH CH - CH CL CL N N: PolymerizationAkash YadavNoch keine Bewertungen

- Sulphite Data SheetDokument1 SeiteSulphite Data SheetMohammad Al-TamimiNoch keine Bewertungen

- Water Gel: Product Data Sheet (PDS)Dokument1 SeiteWater Gel: Product Data Sheet (PDS)Iqbal batchaNoch keine Bewertungen

- TDS - Glenium Ace 340Dokument3 SeitenTDS - Glenium Ace 340Alexi ALfred H. TagoNoch keine Bewertungen

- KH-819 TDSDokument1 SeiteKH-819 TDSNganNoch keine Bewertungen

- Products Presentation 1060Dokument6 SeitenProducts Presentation 1060atharv swaroopNoch keine Bewertungen

- Phenoline 1205: Selection & Specification DataDokument4 SeitenPhenoline 1205: Selection & Specification DataKris WilliamsNoch keine Bewertungen

- Ocpol 800 VE TdsDokument2 SeitenOcpol 800 VE Tdshussainamir786Noch keine Bewertungen

- Uqon 50-HB 5100Dokument17 SeitenUqon 50-HB 5100wjawich100% (1)

- BR Og Mid Gasdehydration 200624 - 17507514458507Dokument8 SeitenBR Og Mid Gasdehydration 200624 - 17507514458507KarthikNoch keine Bewertungen

- Confi-Gel Product Data SheetDokument1 SeiteConfi-Gel Product Data SheetpaimanNoch keine Bewertungen

- Kelco-Crete DG-FDokument3 SeitenKelco-Crete DG-FPelleNoch keine Bewertungen

- Selvol - Polyvinyl AlcoholDokument12 SeitenSelvol - Polyvinyl AlcoholJuanNoch keine Bewertungen

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDokument10 SeitenAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFSumanta RoyNoch keine Bewertungen

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDokument10 SeitenAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFraahul_nNoch keine Bewertungen

- Carbonates Acidizing PPTDokument61 SeitenCarbonates Acidizing PPTBolsec14Noch keine Bewertungen

- Pekasol L Datenblatt GB 4S 11 2015Dokument4 SeitenPekasol L Datenblatt GB 4S 11 2015tungxuanbrNoch keine Bewertungen

- RedicoteEM 44ADokument1 SeiteRedicoteEM 44ARicardoNoch keine Bewertungen

- Carboguard 60 LH PDSDokument4 SeitenCarboguard 60 LH PDSRicardo SantosNoch keine Bewertungen

- Gel Formation in HDPEDokument4 SeitenGel Formation in HDPESubhasish Mitra100% (3)

- Personal Care: Dow CorningDokument4 SeitenPersonal Care: Dow CorningMay Wulan DewiNoch keine Bewertungen

- Testing Fluid BRDokument1 SeiteTesting Fluid BRRonak VaghaniNoch keine Bewertungen

- 0901 B 803808 EbffdDokument7 Seiten0901 B 803808 EbffdForeverNoch keine Bewertungen

- Daelim LicensorsDokument17 SeitenDaelim LicensorsSunny Ooi Jian ZhenNoch keine Bewertungen

- High Running Solid Solvent-Based Laminating AdhesiveDokument2 SeitenHigh Running Solid Solvent-Based Laminating AdhesivealfredoNoch keine Bewertungen

- PRIMAL™ HG-1000 Binder: Technical Data SheetDokument9 SeitenPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoNoch keine Bewertungen

- Core Range - Industrial Formulators PDFDokument18 SeitenCore Range - Industrial Formulators PDFAniket Patel100% (1)

- Customer HYDRO-GEN1 SystemDokument23 SeitenCustomer HYDRO-GEN1 SystemLong Nhật PhanNoch keine Bewertungen

- Rheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDokument3 SeitenRheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteFrancois-Noch keine Bewertungen

- Aspiro - EOR PolymersDokument12 SeitenAspiro - EOR PolymersDarmawanSaputraNoch keine Bewertungen

- Reactive Polyglycol EthersDokument2 SeitenReactive Polyglycol EthersJayNoch keine Bewertungen

- Chempart SC 100 2016 PDFDokument1 SeiteChempart SC 100 2016 PDFDeepak WalhekarNoch keine Bewertungen

- Poly WaxDokument4 SeitenPoly WaxBharathi RajaNoch keine Bewertungen

- F04.5 200s Oxhydryl Data SheetDokument2 SeitenF04.5 200s Oxhydryl Data SheetAnonymous C0lBgO24iNoch keine Bewertungen

- Calcium Bromide Liquid Product Data SheetDokument1 SeiteCalcium Bromide Liquid Product Data SheetpaimanNoch keine Bewertungen

- Laropal Grades: Technical InformationDokument6 SeitenLaropal Grades: Technical InformationTOPS SYNERGIST CO.,LTDNoch keine Bewertungen

- Versagel C: A Better Way To FormulateDokument3 SeitenVersagel C: A Better Way To Formulateيوميات صيدلانية pharmacist diariesNoch keine Bewertungen

- Easy Pol PdsDokument1 SeiteEasy Pol Pdssultanbona99Noch keine Bewertungen

- Catalogue Water Conformance Water Shutoff Rev02 SKRDokument7 SeitenCatalogue Water Conformance Water Shutoff Rev02 SKRMehrez AssidyNoch keine Bewertungen

- A Review of Thermally Stable Gels For Fluid Diversion in Petroleum ProductionDokument10 SeitenA Review of Thermally Stable Gels For Fluid Diversion in Petroleum ProductionElif AlyamacNoch keine Bewertungen

- Polyamide Resin: General Description PackagingDokument1 SeitePolyamide Resin: General Description PackagingManuel ChireNoch keine Bewertungen

- 100ML Dimidium Bromide Disulfine Extra Pure Blue Indicator Stock Solution SLR PDFDokument10 Seiten100ML Dimidium Bromide Disulfine Extra Pure Blue Indicator Stock Solution SLR PDFRavi ShankarNoch keine Bewertungen

- B329 Standard Test For Apparent Density by Scott VolumeterDokument3 SeitenB329 Standard Test For Apparent Density by Scott Volumeterakjeevanantham100% (1)

- SP-042 Specification of DVS4U066 PDFDokument1 SeiteSP-042 Specification of DVS4U066 PDFRavi ShankarNoch keine Bewertungen

- Potassium Cocoate Liquid SDS VivaDokument5 SeitenPotassium Cocoate Liquid SDS VivaRavi ShankarNoch keine Bewertungen

- Soft Water SpecificationDokument1 SeiteSoft Water SpecificationRavi ShankarNoch keine Bewertungen

- Safety Data Sheet R-54477: Section: 1. Product and Company IdentificationDokument7 SeitenSafety Data Sheet R-54477: Section: 1. Product and Company IdentificationRavi ShankarNoch keine Bewertungen

- Preparation of Ammonium Acetate PDFDokument1 SeitePreparation of Ammonium Acetate PDFRavi ShankarNoch keine Bewertungen

- Astm d5453Dokument3 SeitenAstm d5453Ravi ShankarNoch keine Bewertungen

- Buffer Preparation and Capacity: Buffer Systems Available in LabDokument5 SeitenBuffer Preparation and Capacity: Buffer Systems Available in LabRavi ShankarNoch keine Bewertungen

- Astm d5453Dokument3 SeitenAstm d5453Ravi ShankarNoch keine Bewertungen

- Hybase C 402Dokument16 SeitenHybase C 402Ravi ShankarNoch keine Bewertungen

- ASTM StandardsDokument29 SeitenASTM StandardsRavi Shankar0% (1)

- Astm D5453 PDFDokument3 SeitenAstm D5453 PDFRavi Shankar100% (2)

- HCL Testing Procedure PDFDokument22 SeitenHCL Testing Procedure PDFRavi ShankarNoch keine Bewertungen

- EMDCSS DatasheetDokument5 SeitenEMDCSS DatasheetHoracio UlloaNoch keine Bewertungen

- Open Mapping Theorem (Functional Analysis)Dokument3 SeitenOpen Mapping Theorem (Functional Analysis)Silambu SilambarasanNoch keine Bewertungen

- Shaw, Milton C. Metal Cutting PrinciplesDokument759 SeitenShaw, Milton C. Metal Cutting PrinciplesJuan Sebastian Quinche Velandia75% (4)

- Calibration Procedure On ML-D5, D6 (ZERO-SPAN Adjustment)Dokument2 SeitenCalibration Procedure On ML-D5, D6 (ZERO-SPAN Adjustment)Haytham RedaNoch keine Bewertungen

- Model 793.00 System SoftwareDokument750 SeitenModel 793.00 System SoftwareMichel Zarzosa RojasNoch keine Bewertungen

- Punching Shear PDFDokument13 SeitenPunching Shear PDFmohamedadel100Noch keine Bewertungen

- Maquinaria Forestal..Dokument14 SeitenMaquinaria Forestal..Juan G ContrerasNoch keine Bewertungen

- Laplace TransformDokument2 SeitenLaplace TransformumangNoch keine Bewertungen

- 2210 w18 Ms 12Dokument12 Seiten2210 w18 Ms 12Fiyazul HaqueNoch keine Bewertungen

- Bread and Pastry ProductionDokument9 SeitenBread and Pastry Productionwhite newgatesNoch keine Bewertungen

- Calculate Quantities of Materials For Concrete - Cement, Sand, AggregatesDokument7 SeitenCalculate Quantities of Materials For Concrete - Cement, Sand, Aggregatesvenkateswara rao pothinaNoch keine Bewertungen

- 3D-ICONS Guidelines PDFDokument53 Seiten3D-ICONS Guidelines PDFAna Paula Ribeiro de AraujoNoch keine Bewertungen

- SampleDokument43 SeitenSampleSri E.Maheswar Reddy Assistant ProfessorNoch keine Bewertungen

- HKV-8 Valve Catalog SPLRDokument128 SeitenHKV-8 Valve Catalog SPLRCabrera RodriguezNoch keine Bewertungen

- Creating Interfaces For The SAP Application Interface Framework With Service Implementation WorkbenchDokument12 SeitenCreating Interfaces For The SAP Application Interface Framework With Service Implementation WorkbenchKrishanu DuttaNoch keine Bewertungen

- SeqP&D GPL Met enDokument52 SeitenSeqP&D GPL Met enSriram ChNoch keine Bewertungen

- Subjects Revised Curriculum BS ELECTRICAL ENGINEERINGDokument18 SeitenSubjects Revised Curriculum BS ELECTRICAL ENGINEERINGData StatsNoch keine Bewertungen

- An Ecient Uniform-Cost Normalized Edit Distance AlgorithmDokument12 SeitenAn Ecient Uniform-Cost Normalized Edit Distance Algorithmanon-75650Noch keine Bewertungen

- Economics Solution Book PDFDokument368 SeitenEconomics Solution Book PDFgoutam1235100% (3)

- Entity Framework Interview Questions With AnswersDokument16 SeitenEntity Framework Interview Questions With AnswersShivprasad Koirala100% (5)

- Hana Table PartitioningDokument12 SeitenHana Table PartitioningGowri Prasanth Chaduvula0% (1)

- Properties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistDokument4 SeitenProperties of Solutions: Electrolytes and Non-Electrolytes by Dan HolmquistPaul Schumann50% (2)

- SPE15010Dokument11 SeitenSPE15010Leandro NavarroNoch keine Bewertungen

- Practical - 1: 1.1 CommitDokument8 SeitenPractical - 1: 1.1 CommitRoy BokhiriyaNoch keine Bewertungen

- Probability H Venn Diagrams v2 SOLUTIONS v2 2 PDFDokument7 SeitenProbability H Venn Diagrams v2 SOLUTIONS v2 2 PDFEcho BaguinonNoch keine Bewertungen

- Reflection and ShearDokument7 SeitenReflection and ShearsamNoch keine Bewertungen

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDokument3 SeitenFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Programming in C - CPU Scheduling - Round RobinDokument3 SeitenProgramming in C - CPU Scheduling - Round RobinGenus SumNoch keine Bewertungen

- Ferrofluids (Introduction, Future Horizons and Applications)Dokument21 SeitenFerrofluids (Introduction, Future Horizons and Applications)Makhdoom Luqman HashmiNoch keine Bewertungen

- Game TheoryDokument13 SeitenGame TheoryPriyanka ChaurasiyaNoch keine Bewertungen