Beruflich Dokumente

Kultur Dokumente

Macro Boilers

Hochgeladen von

FUCKUCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Macro Boilers

Hochgeladen von

FUCKUCopyright:

Verfügbare Formate

ECOBOILER COUNTERTOP WATER BOILERS/TAP ECOBOILER COUNTERTOP WATER BOILERS/TAP

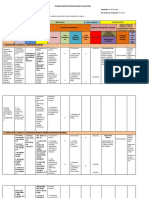

ECOBOILER T5 ECOBOILER T10 ECOBOILER T20 ECOBOILER T30 DIMENSIONS ECOBOILER T5, T10, T20, T30

1000660 1000661 1000662 1000663

ECOBOILER T5 ECOBOILER T10

PRODUCT DIMENSIONS

SEE TABLE FOR

CABINET CLEARANCE 1000660 1000661

4.1”/105.5mm 2.5”/64mm Hole Saw

2”/50mm

2”/50mm

4.1”/105.5mm 2.5”/64mm Hole Saw

4.1”/105.5mm 2.5”/64mm Hole Saw 14.3”/363mm 13.8”/350mm

13.8”/350mm

2”/50mm

2”/50mm

13.8”/350mm

2”/50mm

2”/50mm 14.3”/363mm

** **

Power Water

14.3”/363mm

Power Water

23.2”/589mm

3.5"/91mm 3.5"/91mm

18.3”/465mm

**

12.2”/309mm

7.2”/185mm

7.2”/185mm

8.3”/212mm

12.2”/309mm

8.3”/212mm

11.1”/283mm

11.1”/283mm

D Power Water

3.5"/91mm

W

18.3”/465mm

20”/509mm 20.3”/515mm

2”/50mm* 2”/50mm

Plan View

2”/50mm* 2”/50mm

* Required for ventilation if the machine

• 5, 10, 20 or 30 litre options • Made from 95% recyclable materials

is installed in an enclosed cabinet. Plan View * Required for ventilation if the machine

is installed in an enclosed cabinet.

**Ecoboiler T5 8.3”/212mm

** See page 33

Ecoboiler T10 8.3”/212mm

ECOBOILER T20 ECOBOILER T30

Ecoboiler T20 9.5”/242mm

7.2”/185mm

Ecoboiler T30 11.8”/302mm

• Easy to descale • Energy-efficient with precise temperature

12.2”/309mm

8.3”/212mm

1000662 1000663

11.1”/283mm

• Removeable drip tray

13.8”/350mm 13.8”/350mm

16.5”/420mm 16.7”/424mm

4.1”/105.5mm 2.5”/64mm Hole Saw 4.1”/105.5mm 2.5”/64mm Hole Saw

2”/50mm

2”/50mm

2”/50mm 2”/50mm

ECOBOILER WALL MOUNT DIMENSIONS 20”/509mm

1000671

27.1”/690mm

27.1”/690mm

** 8.3”/211mm

2”/50mm

Power Water Power Water

2”/50mm* 4.1"/106mm 4.1"/106mm

Plan View * Required for ventilation if the machine

is installed in an enclosed cabinet.

8.3”/212mm

7.2”/185mm

8.3”/212mm

7.2”/185mm

12.2”/309mm

12.2”/309mm

**Ecoboiler T5 8.3”/212mm

11.1”/283mm

11.1”/283mm

Ecoboiler T10 8.3”/212mm

Ecoboiler T20 9.5”/242mm

Ecoboiler T30 11.8”/302mm

22.2”/566mm 22.2”/570mm

2”/50mm* 2”/50mm 2”/50mm* 2”/50mm

447 Plan View * Required for ventilation if the machine

is installed in an enclosed cabinet.

Plan View * Required for ventilation if the machine

is installed in an enclosed cabinet.

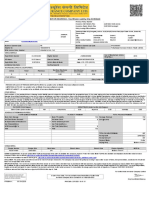

ELECTRICAL INSTALLATION PROCEDURE OPERATING BOILER FOR THE FIRST TIME

When installing the machine, always observe the local • Check that all installation procedures have been

regulations and standards. The standard machine is carried out.

222 supplied with a UK 3-pin plug. For EU models a 2-pin CEE-7 • Ensure water valve is on.

plug will be supplied. US models will be supplied with the

325 suitable plug. A suitable mains power supply socket should • Plug boiler into a suitable socket and press power

be available within easy access of the appliance so that it button on the front of the machine marked ‘Power’.

NOTE: On the T5 the ‘Power’ button light also acts as

• 133 cups (180ml) per hour • Wall mounted to take up minimal space can be disconnected easily after install.

the“Ready/Status” indicator.

PLUMBING INSTALLATION PROCEDURE • The “power on” light will glow green and the machine will

fill to a safe level, above the elements, before heating.

• Ensure that the equipment is installed according to local

TAP BOILERS IN A RANGE OF VOLUMES FOR CATERING LOCATIONS SUCH AS CAFÉS, HOTELS, • The “Ready/Status” light will cycle two red flashes while

plumbing & water regulations.

RESTAURANTS AND CANTEENS. the machine is filling to the safe level.

• Mains water pressure required (limits): 14.5 - 145psi

(100 - 1000kPa, 0.1 - 1MPa). • Whilst the machine is above the safe level and filling,

the “Ready/Status” light will glow orange.

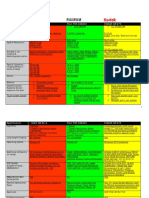

NAME POWER IMMEDIATE OUTPUT CUPS (180ml) DIMENSIONS TAP TO TRAY PLUMBING • Requires inline water filter within your water

ORDER CODE @ 230V DRAW OFF PER HOUR PER HOUR (D x W x H mm) (T mm) REQS specifications. • The “Ready/Status” light will glow green when the

machine is both full and up to normal operating

• The machine is supplied with a 3/4“ BSP connection.

Ecoboiler T5 505 x 212 temperature, allow approx 15 minutes.

2.8kW 5L 28 L 156 185 3/4“ BSP • Connect straight tailpiece of the hose to the stop valve

1000660 x 465 • The boiler is now ready for use.

fitting. Make sure that the pre-attached sealing washer

Ecoboiler T10 505 x 212 is fitted. NOTE: Because the boiler is electronically controlled no

2.8kW 10 L 28 L 156 185 3/4“ BSP

1000661 x 590 priming is necessary. The element cannot switch on until

• Turn on the water to flush any impurities, dust etc

Ecoboiler T20 566 x 242 from the inlet hose and water pipe. Allow several litres a safe level of water is reached.

2.8kW 20 L 28 L 156 185 3/4“ BSP

1000662 x 690 through, especially for new installations.

Ecoboiler T30 570 x 302 • Connect the hose to the inlet valve of the boiler. Make

5.6kW 30 L 56 L 311 185 3/4“ BSP sure a sealing washer is fitted.

1000663 x 690

Ecoboiler WMT 5 222 x 325 • Turn on water and check for leaks.

2.4kW 5L 24 L 133 — 3/4“ BSP

1000671 x 447

For spare parts, customer care and service visit www.marcobeveragesystems.com

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- MDM Motor Planning Kit PDFDokument24 SeitenMDM Motor Planning Kit PDFFUCKUNoch keine Bewertungen

- 2017 PHD Cowan PDFDokument230 Seiten2017 PHD Cowan PDFFUCKUNoch keine Bewertungen

- Hearnshaw TSBE Conference Paper 2012Dokument8 SeitenHearnshaw TSBE Conference Paper 2012FUCKUNoch keine Bewertungen

- ESight 2019.1 Release NotesDokument6 SeitenESight 2019.1 Release NotesFUCKUNoch keine Bewertungen

- Red RingDokument24 SeitenRed RingFUCKUNoch keine Bewertungen

- RXS L3V1B - Technical Data PDFDokument43 SeitenRXS L3V1B - Technical Data PDFFUCKUNoch keine Bewertungen

- Bsria-Blue-Book-2019 (Sample) PDFDokument24 SeitenBsria-Blue-Book-2019 (Sample) PDFFUCKUNoch keine Bewertungen

- The Zip GuideDokument72 SeitenThe Zip GuideFUCKUNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- JAZEL Resume-2-1-2-1-3-1Dokument2 SeitenJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoNoch keine Bewertungen

- Avalon LF GB CTP MachineDokument2 SeitenAvalon LF GB CTP Machinekojo0% (1)

- Cs8792 Cns Unit 1Dokument35 SeitenCs8792 Cns Unit 1Manikandan JNoch keine Bewertungen

- Historical Development of AccountingDokument25 SeitenHistorical Development of AccountingstrifehartNoch keine Bewertungen

- Aisladores 34.5 KV Marca Gamma PDFDokument8 SeitenAisladores 34.5 KV Marca Gamma PDFRicardo MotiñoNoch keine Bewertungen

- Cancellation of Deed of Conditional SalDokument5 SeitenCancellation of Deed of Conditional SalJohn RositoNoch keine Bewertungen

- Convention On The Rights of Persons With Disabilities: United NationsDokument13 SeitenConvention On The Rights of Persons With Disabilities: United NationssofiabloemNoch keine Bewertungen

- Delta AFC1212D-SP19Dokument9 SeitenDelta AFC1212D-SP19Brent SmithNoch keine Bewertungen

- Online Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Dokument16 SeitenOnline Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Maulana Adhi Setyo NugrohoNoch keine Bewertungen

- Check Fraud Running Rampant in 2023 Insights ArticleDokument4 SeitenCheck Fraud Running Rampant in 2023 Insights ArticleJames Brown bitchNoch keine Bewertungen

- CHAPTER 3 Social Responsibility and EthicsDokument54 SeitenCHAPTER 3 Social Responsibility and EthicsSantiya Subramaniam100% (4)

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Dokument3 SeitenAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNoch keine Bewertungen

- Hexoskin - Information For Researchers - 01 February 2023Dokument48 SeitenHexoskin - Information For Researchers - 01 February 2023emrecan cincanNoch keine Bewertungen

- 1.1. Evolution of Cloud ComputingDokument31 Seiten1.1. Evolution of Cloud Computing19epci022 Prem Kumaar RNoch keine Bewertungen

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDokument1 SeiteMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNoch keine Bewertungen

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDokument58 SeitenSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiNoch keine Bewertungen

- Process States in Operating SystemDokument4 SeitenProcess States in Operating SystemKushal Roy ChowdhuryNoch keine Bewertungen

- Rating SheetDokument3 SeitenRating SheetShirwin OliverioNoch keine Bewertungen

- CV Ovais MushtaqDokument4 SeitenCV Ovais MushtaqiftiniaziNoch keine Bewertungen

- Cabling and Connection System PDFDokument16 SeitenCabling and Connection System PDFLyndryl ProvidoNoch keine Bewertungen

- Food and Beverage Department Job DescriptionDokument21 SeitenFood and Beverage Department Job DescriptionShergie Rivera71% (7)

- Squirrel Cage Induction Motor Preventive MaintenaceDokument6 SeitenSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekNoch keine Bewertungen

- Fidp ResearchDokument3 SeitenFidp ResearchIn SanityNoch keine Bewertungen

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDokument7 SeitenPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiNoch keine Bewertungen

- 30 Creative Activities For KidsDokument4 Seiten30 Creative Activities For KidsLaloGomezNoch keine Bewertungen

- Are Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceDokument6 SeitenAre Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceNely Noer SofwatiNoch keine Bewertungen

- Aircraftdesigngroup PDFDokument1 SeiteAircraftdesigngroup PDFsugiNoch keine Bewertungen

- Methodical Pointing For Work of Students On Practical EmploymentDokument32 SeitenMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNoch keine Bewertungen

- Agricultural Economics 1916Dokument932 SeitenAgricultural Economics 1916OceanNoch keine Bewertungen

- Schmidt Family Sales Flyer English HighDokument6 SeitenSchmidt Family Sales Flyer English HighmdeenkNoch keine Bewertungen