Beruflich Dokumente

Kultur Dokumente

Tee L NT Ere Han G E: Steel Interchange Modern Steel Construction One East Wacker DR., Suite 3100 Chicago, IL 60601-2001

Hochgeladen von

David HoffmanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tee L NT Ere Han G E: Steel Interchange Modern Steel Construction One East Wacker DR., Suite 3100 Chicago, IL 60601-2001

Hochgeladen von

David HoffmanCopyright:

Verfügbare Formate

S TEE L N T ERe HAN G E

Steel Interchange is an open forum for Modern Steel Con- Answers and/or questions should be typewritten and double-

struction readers to exchange useful and practical professional spaced. Submittals that have been prepared by word-processing

ideas and information on all phases of steel building and bridge are appreciated on computer diskette (either as a Word file or in

construction. Opinions and suggestions are welcome on any sub- ASCII format).

ject covered in this magazine. If you have a question or problem The opinions expressed in Steel Interchange do not necessar-

that your fellow readers might help you to solve, please forward ily represent an official position of the American Institute of

it to Modern Steel Construction. At the same time, feel free to Steel Construction, Inc. and have not been reviewed. It is recog-

respond to any of the questions that you have read here. Please nized that the design of structures is within the scope and

send them to: expertise of a competent licensed structural engineer, architect

Steel Interchange or other licensed professional for the application of principles to

Modern Steel Construction a particular structure.

One East Wacker Dr., Suite 3100 Information on ordering AISC publications mentioned in

Chicago, IL 60601-2001 this article can be obtained by calling AISC at 800/644-2400.

**** Questions and answers can now be e-mailedto:rokach@aiscmail.com ****

The following responses from previous Steel election of the composite beam is based on satis-

Interchange columns have been received: S fying the maximum moment requirement and

the moment along the opening. If the maximum

(From the May 1998 issue) moment occurs at the opening, the design is gov-

erned by the reduced "flange" width. Otherwise,

How is a composite beam designed when the beam size considered should also be checked

there is an opening in the concrete "flange" for the reduced capacity at the opening.

adjacent to the steel beam? Does the length of In view of the above, the length of the opening is

the opening affect the design, if the opening irrelevant except for the deflection factor.

length is small relative to the beam length In the case shown in the sketch, with the appar-

can it be neglected? Does the location of the ent proximity of the opening to the point of maxi-

opening, relative to the maximum moment, mum moment, the reduced "flange" width will con-

affect the design? trol the design.

For example: If designing beams "B2" and Isaac Gordon, P.E.

"B3" (see sketch) as composite beams, is it too Ang Associates, Inc.

conservative to treat the beams as edge Philadelphia

beams for the total span (only accounting for

the concrete "flange" on the opposite side of (Another Answer)

the opening the full length of the beam)?

his subject has been covered by Kenneth B.

T Wresner in his paper, "Composite Beams with

Slab Openings," in the Proceedings, 1996 National

Steel Construction Conference .

. .---~/'j., ------ - ~

. SI

.---- James Rongoe

Rongoe Engineers

Darien, CT

'I"I . '1.' -'-V

'M

t

-z 1C

r-::::. -...- (From the May 1998 issue)

~ 6 . ~"3' I ____ - --

1 -- o]'E>J

- - ----

-

---

' '')

In my work, I often have to design reinforc-

ing for existing steel beams that have cast-in-

\l place concrete arches between the beam

'il+

webs. The bottom flanges are usually exposed

and if the concrete covers the top flange it is

not enough to provide adequate cover for

shear studs. Many times the top flange is

below cinder fill and roofing which is not to

be disturbed.

The procedure I use for design of the rein-

..

1' ·

~ forcement for increasing the midspan

moment capacity is as follows: First I calcu-

late the existing stress in the beam top flange

due to dead load only. I then size an inverted

WT shape to be welded to the bottom flange

of the existing beam. The WT is sized to limit

the sum of the existing compressive stress in

Modern Steel Construction / ./ 9

S TEE L N T ERe HAN G E

the unreinforced beam top flange and the diagram acting as a lateral support from

additional top flange stress due to new dead beam lateral-torsional buckling)?

and live loads on the composite section to

less than the allowable compressive stress. rofessor Joseph A. Yura of the University of

The beam is also checked for the increased

shear stress and the higher end reactions.

P Texas at Austin, and probably others, have

demonstrated analytically and through the use of

Is this method overly conservative? Are finite element analysis that the use of inflection

there any references on reinforcement of points as braced points in solid web I beams is not

non-composite beams? This method has its appropriate. An open web beam is probably suffi-

limitations when the existing dead load is ciently analogous to a solid web beam to support

close to the allowable. the assumption that this practice would not be pru-

dent in either.

n the 2nd Quarter 1996 Engineering Journal , Steven J. Thomas, P.E., S.E.

I"Strengthening

John Miller, P.E. , presents an article entitled

of Existing Composite Beams

Manager, Product Design

VP-Buildings, Inc.

Using LRFD Procedures." This method can also be

used for non-composite beams. A non-composite

beam can be thought of as a composite beam in

which the concrete has a thickness of zero. Mr.

Miller also uses an inverted WT section which is New Question

welded to the bottom flange.

I wrote a discussion of Mr. Miller's paper (3rd

Quarter 1997 Engineering Journal) in which I pre- Listed below is a question that we would like the

sented another method of strengthening the same readers to answer or discuss.

beam Mr. Miller had used. The method I used is If you have an answer or suggestion please send

post-tensioning by the use of cables applied below it to the Steel Interchange Editor, Modern Steel

the composite sections, and is very easy to use. The Construction, One East Wacker Dr. , Suite 3100,

simplest case is the non-composite. In my example, Chicago, IL 60601·2001 . Questions can also be sent

the cables are applied to the web, but they can be via e-mail tonewman@aiscmail.com.

applied to the bottom flange if there is sufficient Questions and responses will be printed in future

headroom. editions of Steel Interchange. Also, if you have a

In my discussion, there is a printing error. The question or problem that readers might help solve,

length of weld required is: send these to the Steel Interchange Editor.

39/(2x2.39) = 8.2 inches on each side.

The expression for T prime did not print clearly: In the Manual of Steel Construction, ASD,

The additional tension is T' (T prime) 9th Edition, Commentary, Chapter F, Section

T'=NUMIDEN F3 "Allowable Stress: Bending of Box Mem-

Peter Kocsis, S.E., P.E. bers, Rectangular Tubes and Circular Mem-

Barrington, IL bers" page 5-147, Equation (C-F3-1) is given

as:

For a specific load combination, some bottom

chord members of a continuous steel truss

are in tension and others are in compression. (rl) equiu. = VfITJK

JJT;

The manual then states "It can be shown

that, when d<10b and lIb>2500Fy, the allow-

able compression flange stress indicated by

the above equation will approximate O.60Fy'"

How does one show when lIb>2500/Fy that

the compression flange stress will approxi-

mate O.60Fy?

Dale H. Curtis, P.E.

Curtis Engineering Corporation

Is it possible to consider that the node, locat- San Diego, CA

ed between a tension and compression mem-

ber, can behave like a lateral support to eval-

uate the compression strength with respect

to the weak-axis of this member (by analogy

to the inflection point of a bending moment

10 / Modern Steel Construction /

Das könnte Ihnen auch gefallen

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Dokument2 SeitenSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNoch keine Bewertungen

- Modern Steel Construction's MonthlyDokument2 SeitenModern Steel Construction's MonthlyircivilcivilNoch keine Bewertungen

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDokument11 SeitenBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- CRSI-Designers Responsibility For Rebar Design PDFDokument16 SeitenCRSI-Designers Responsibility For Rebar Design PDFk_maheswari3397Noch keine Bewertungen

- CRSI The Designer's ResponsibilityDokument16 SeitenCRSI The Designer's ResponsibilityAdam Jones100% (1)

- Designer ResponsibilityDokument16 SeitenDesigner ResponsibilityCamilo AlvarezNoch keine Bewertungen

- PDH Torsion Concrete Design PDFDokument8 SeitenPDH Torsion Concrete Design PDFTaanzNoch keine Bewertungen

- RC Beam Torsion Design To PCA Comment PDFDokument8 SeitenRC Beam Torsion Design To PCA Comment PDFEngChuan LimNoch keine Bewertungen

- Torsion Aci DesignDokument8 SeitenTorsion Aci Designabbasshaikh21682Noch keine Bewertungen

- Si 7 2014 PDFDokument2 SeitenSi 7 2014 PDFhector diazNoch keine Bewertungen

- 97 2.0f AboutDokument12 Seiten97 2.0f AboutAndrea GibsonNoch keine Bewertungen

- Dss PDFDokument141 SeitenDss PDFBoxer BharathNoch keine Bewertungen

- Reinforcing SteelDokument8 SeitenReinforcing SteelPrittam Kumar JenaNoch keine Bewertungen

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 2: Beam DesignDokument4 SeitenDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 2: Beam DesignΤε ΧνηNoch keine Bewertungen

- Penetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Dokument2 SeitenPenetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Ganesh AdityaNoch keine Bewertungen

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- San Antionio OralDokument15 SeitenSan Antionio OralMercedez BenzNoch keine Bewertungen

- 98 Tips: For DesigningDokument6 Seiten98 Tips: For DesigningKarthikeyan KrishNoch keine Bewertungen

- SteelWise Tolerances IllustratedDokument6 SeitenSteelWise Tolerances IllustratedkenetjNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Dokument2 SeitenSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNoch keine Bewertungen

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Von EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Noch keine Bewertungen

- Composite and Steel Construction CompendiumDokument3 SeitenComposite and Steel Construction CompendiumΤε ΧνηNoch keine Bewertungen

- Structural Behavior of Concrete Encased Steel BeamDokument14 SeitenStructural Behavior of Concrete Encased Steel BeamChee Soon LeeNoch keine Bewertungen

- 2010v09 98 TipsDokument6 Seiten2010v09 98 Tipsvenkatesh19701Noch keine Bewertungen

- Transverse Design of Adjacent Precast Prestressed Concrete Box Girder BridgesDokument18 SeitenTransverse Design of Adjacent Precast Prestressed Concrete Box Girder BridgesMarek100% (1)

- An in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsDokument7 SeitenAn in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsvipinNoch keine Bewertungen

- Astm ManualDokument2 SeitenAstm ManualAashifCairoNoch keine Bewertungen

- What Are The Mechanical Properties of Structural Steel?: Resistence To Deformation Based UponDokument5 SeitenWhat Are The Mechanical Properties of Structural Steel?: Resistence To Deformation Based UponEni VinoNoch keine Bewertungen

- Prestressed Steel BeamDokument17 SeitenPrestressed Steel Beamvarun sainiNoch keine Bewertungen

- Structural Behavior of Concrete Encased Steel BeamDokument14 SeitenStructural Behavior of Concrete Encased Steel BeamDave WeiNoch keine Bewertungen

- 2003v04 Si WebDokument2 Seiten2003v04 Si WebMohanNoch keine Bewertungen

- Presentation On Reinforcing Detailing of R.CDokument16 SeitenPresentation On Reinforcing Detailing of R.CbertazcorpNoch keine Bewertungen

- Designing With Composite Deck: AuthorDokument17 SeitenDesigning With Composite Deck: AuthorBang SuccessNoch keine Bewertungen

- Rebar - Sizes PDFDokument8 SeitenRebar - Sizes PDFharold_bhieNoch keine Bewertungen

- Chapter 1: Overview and Literature ReviewDokument19 SeitenChapter 1: Overview and Literature Reviewloox600Noch keine Bewertungen

- Discussion - Mill Building Design ProcedureDokument4 SeitenDiscussion - Mill Building Design ProcedurejoseherreramogollonNoch keine Bewertungen

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDokument6 Seiten1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosNoch keine Bewertungen

- Design of Steel Structure: 5. Snow LoadDokument7 SeitenDesign of Steel Structure: 5. Snow Loadsuraj kumarNoch keine Bewertungen

- ASIC Steel Interchange - Shear Flow in Plastic DesignDokument2 SeitenASIC Steel Interchange - Shear Flow in Plastic DesignMikeNoch keine Bewertungen

- Steelwise Plank WebDokument2 SeitenSteelwise Plank Webalberto rosadoNoch keine Bewertungen

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDokument2 SeitenSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNoch keine Bewertungen

- Steel Interchange: Cold Weather Welding Plate Girder StiffenersDokument2 SeitenSteel Interchange: Cold Weather Welding Plate Girder Stiffenershector diazNoch keine Bewertungen

- Structural Behavior of Concrete Encased Steel Beams: Ain Shams Engineering Journal January 2005Dokument14 SeitenStructural Behavior of Concrete Encased Steel Beams: Ain Shams Engineering Journal January 2005LeonardoMadeira11Noch keine Bewertungen

- Step by StepDokument20 SeitenStep by StepJimboyNoch keine Bewertungen

- Compendium of Design Office Problems-Volume IIIDokument10 SeitenCompendium of Design Office Problems-Volume IIIsaber javidNoch keine Bewertungen

- Modern Steel Construction's MonthlyDokument2 SeitenModern Steel Construction's MonthlyapirakqNoch keine Bewertungen

- Form Deck - A Versatile Family of Products: AuthorDokument19 SeitenForm Deck - A Versatile Family of Products: AuthormuathNoch keine Bewertungen

- Retrofitting Design Guidelines Using Steel Plates and Shear BoltsDokument11 SeitenRetrofitting Design Guidelines Using Steel Plates and Shear BoltsLuis Ariel MorilloNoch keine Bewertungen

- Presentation On Reinforcing Detailing of R.CDokument19 SeitenPresentation On Reinforcing Detailing of R.CMC LeongNoch keine Bewertungen

- Atkins On TaylorDokument55 SeitenAtkins On Taylorbogdanostin0% (1)

- Dog Bone Connection PDFDokument9 SeitenDog Bone Connection PDFChinnaraja GandhiNoch keine Bewertungen

- 98 Tips For Designing Structural SteelDokument5 Seiten98 Tips For Designing Structural Steelklynchelle100% (2)

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Dokument2 SeitenSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNoch keine Bewertungen

- Why Steel Reinforcement Is Needed in Concrete SlabsDokument2 SeitenWhy Steel Reinforcement Is Needed in Concrete SlabsAuYongTheanSengNoch keine Bewertungen

- Cold-Formed Steel Design by Spreadsheet Program: Scholars' MineDokument19 SeitenCold-Formed Steel Design by Spreadsheet Program: Scholars' MineRaineir PabiranNoch keine Bewertungen

- Box Tube Connections Choices of Joint Details and Their Influence On CostDokument25 SeitenBox Tube Connections Choices of Joint Details and Their Influence On CostjorgeNoch keine Bewertungen

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkVon EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkNoch keine Bewertungen

- An Introduction to Metal-Working (Illustrated)Von EverandAn Introduction to Metal-Working (Illustrated)Bewertung: 2.5 von 5 Sternen2.5/5 (2)

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionVon EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNoch keine Bewertungen

- Welcome The Highroad Media Presentation of The Secret Law of Attraction As Explained by Napoleon Hill Compiled From Material Exerted and Adapted From Napoleon HillDokument4 SeitenWelcome The Highroad Media Presentation of The Secret Law of Attraction As Explained by Napoleon Hill Compiled From Material Exerted and Adapted From Napoleon HillDavid HoffmanNoch keine Bewertungen

- Reinforcing The PointDokument3 SeitenReinforcing The PointJuan Gutier CcNoch keine Bewertungen

- Shear Improvement To Shear DesignDokument4 SeitenShear Improvement To Shear DesignJuan Gutier CcNoch keine Bewertungen

- Shear Improvement To Shear DesignDokument4 SeitenShear Improvement To Shear DesignJuan Gutier CcNoch keine Bewertungen

- Steel ErectSteelDokument62 SeitenSteel ErectSteelgerryfmarrNoch keine Bewertungen

- Specwise: Structural Integrity-And ReorganizationDokument4 SeitenSpecwise: Structural Integrity-And ReorganizationJuan Gutier CcNoch keine Bewertungen

- The Meditations of The Emperor Marcus Aurelius AntoninusDokument248 SeitenThe Meditations of The Emperor Marcus Aurelius AntoninusMMMMM99999Noch keine Bewertungen

- Es Iso 12944-4 - 2002, Paints and Varnishes - Correction Prote PDFDokument24 SeitenEs Iso 12944-4 - 2002, Paints and Varnishes - Correction Prote PDFSheiss100% (1)

- Steel ErectSteelDokument62 SeitenSteel ErectSteelgerryfmarrNoch keine Bewertungen

- Job Description SupervisorDokument2 SeitenJob Description SupervisorDavid HoffmanNoch keine Bewertungen

- Performing Under PressureDokument33 SeitenPerforming Under PressureLee LaiHaaNoch keine Bewertungen

- Din en 15085 2Dokument24 SeitenDin en 15085 2David Hoffman100% (1)

- Elizabeth Laird - The House On The HillDokument14 SeitenElizabeth Laird - The House On The HillIskra100% (1)

- Thinketh PDFDokument22 SeitenThinketh PDFDavid HoffmanNoch keine Bewertungen

- Leak Test Procedure of BoilerDokument3 SeitenLeak Test Procedure of BoilerDavid Hoffman100% (3)

- Supervision Manual As Guidance For Supervisory StaffDokument20 SeitenSupervision Manual As Guidance For Supervisory StaffAxelNoch keine Bewertungen

- Img 0001Dokument1 SeiteImg 0001David HoffmanNoch keine Bewertungen

- LOLER RegulationsDokument72 SeitenLOLER Regulationsnageshkole100% (2)

- Walkdown Hazard Identification For Process PlantDokument12 SeitenWalkdown Hazard Identification For Process PlantDavid HoffmanNoch keine Bewertungen

- Guidesteelworkssupervision PDFDokument78 SeitenGuidesteelworkssupervision PDFPhạm Văn ĐảngNoch keine Bewertungen

- Hempadur Mastic 45880-45881Dokument3 SeitenHempadur Mastic 45880-45881David HoffmanNoch keine Bewertungen

- Jauflex Ingles J 106 IDokument1 SeiteJauflex Ingles J 106 IDavid HoffmanNoch keine Bewertungen

- Loler PDFDokument84 SeitenLoler PDFErcan AkkayaNoch keine Bewertungen

- Steel Work Inspection ReportDokument3 SeitenSteel Work Inspection ReportAhmad Hasnan100% (1)

- 첨부 #2 - ITB - Annex a - Technical SpecificationsDokument1 Seite첨부 #2 - ITB - Annex a - Technical SpecificationsDavid HoffmanNoch keine Bewertungen

- Checklist For Splicing - EnglishDokument2 SeitenChecklist For Splicing - EnglishDavid HoffmanNoch keine Bewertungen

- 첨부 #2 - ITB - Annex a - Technical SpecificationsDokument1 Seite첨부 #2 - ITB - Annex a - Technical SpecificationsDavid HoffmanNoch keine Bewertungen

- AkzoNobel SMCA MSDS 0909 Tcm18-10237Dokument0 SeitenAkzoNobel SMCA MSDS 0909 Tcm18-10237David HoffmanNoch keine Bewertungen

- MET 51 4 441 444 MatesaDokument4 SeitenMET 51 4 441 444 MatesaDavid HoffmanNoch keine Bewertungen

- Product Recommendation Hyundai County County D4AF (2004 and After)Dokument3 SeitenProduct Recommendation Hyundai County County D4AF (2004 and After)Jose CachipatoNoch keine Bewertungen

- Terex RT 100 PDFDokument22 SeitenTerex RT 100 PDFRAFA SOTONoch keine Bewertungen

- First Law Applied To Engineering SystemsDokument8 SeitenFirst Law Applied To Engineering Systemsguy100% (1)

- Risers Introduction: Charles A. MillerDokument11 SeitenRisers Introduction: Charles A. MillerSayan Manna100% (1)

- B SafeunitDokument2 SeitenB SafeunitvealealNoch keine Bewertungen

- ECS416 Ammar Aiman (2020461314)Dokument1 SeiteECS416 Ammar Aiman (2020461314)Aniqah RushdaNoch keine Bewertungen

- Chapter 10: Simple Machines (f2)Dokument24 SeitenChapter 10: Simple Machines (f2)ummubalqis27Noch keine Bewertungen

- Ferco Doors-Fire Shutter Installation Insulated Manual Rev 01Dokument13 SeitenFerco Doors-Fire Shutter Installation Insulated Manual Rev 01Ziaul HaqNoch keine Bewertungen

- Flexural-Torsional BucklingDokument25 SeitenFlexural-Torsional BucklingMohamed GamalNoch keine Bewertungen

- Sar Nba Etc partIIDokument231 SeitenSar Nba Etc partIISantosh WagajNoch keine Bewertungen

- CARRARO Axle Repair Ca130070Dokument104 SeitenCARRARO Axle Repair Ca130070Sunthron Somchai100% (3)

- Proiect Lemn - Facultatea de Constructii IasiDokument24 SeitenProiect Lemn - Facultatea de Constructii IasiIordana-Paula ManoleNoch keine Bewertungen

- Direct Inj L9707 Nissan PatrolDokument36 SeitenDirect Inj L9707 Nissan PatrolRouba YounesNoch keine Bewertungen

- 05 MPV R 01 eDokument35 Seiten05 MPV R 01 eJoao SilvaNoch keine Bewertungen

- F56449 and F56450 Recommended Parts Per Maintenance IntervalDokument31 SeitenF56449 and F56450 Recommended Parts Per Maintenance Intervalanwar sadatNoch keine Bewertungen

- Manual Tecnico Nissan Sentra 2008Dokument9 SeitenManual Tecnico Nissan Sentra 2008Anderson Luiz Manfredini Mendes0% (2)

- AC100 Training Manual Ver 2 0 PDFDokument382 SeitenAC100 Training Manual Ver 2 0 PDFما ضاقت الا لتفرج80% (5)

- TRANSPORT PHENOMENA - Unit 1 NotesDokument150 SeitenTRANSPORT PHENOMENA - Unit 1 NotesRathi ManiNoch keine Bewertungen

- Tensile & Elongation PVC Compound VC 8500 BKR VC 8751 BKI VC 8751 GRI - 15102019Dokument1 SeiteTensile & Elongation PVC Compound VC 8500 BKR VC 8751 BKI VC 8751 GRI - 15102019Vinh DuongvanNoch keine Bewertungen

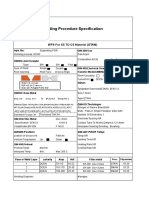

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Dokument1 SeiteWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNoch keine Bewertungen

- CablesDokument9 SeitenCablesanon_749279665Noch keine Bewertungen

- Causes of CarryoverDokument3 SeitenCauses of CarryoverRajesh SarkarNoch keine Bewertungen

- FDB Torsion2aDokument3 SeitenFDB Torsion2aVon Oliver RosarioNoch keine Bewertungen

- T Bolt Specs PDFDokument2 SeitenT Bolt Specs PDFrefaeNoch keine Bewertungen

- Peng 305: Drilling Engineering 1 Lecture NotesDokument30 SeitenPeng 305: Drilling Engineering 1 Lecture Noteskwesimark100% (1)

- Medium & High Voltage and High Speed Motors PDFDokument16 SeitenMedium & High Voltage and High Speed Motors PDFSandeep SinghNoch keine Bewertungen

- 72 Olympique (Owners Manual)Dokument40 Seiten72 Olympique (Owners Manual)JacobnMarie LaaksoNoch keine Bewertungen

- Ecu Remap and Why DRD DIESEL TUTORIALDokument13 SeitenEcu Remap and Why DRD DIESEL TUTORIALPetrus Van Schalkwyk100% (1)

- Work Sheet 2-1Dokument3 SeitenWork Sheet 2-1gudinabelayi6Noch keine Bewertungen

- Gas Laws Pre-AssessmentDokument3 SeitenGas Laws Pre-Assessmentapi-573214664Noch keine Bewertungen