Beruflich Dokumente

Kultur Dokumente

Guide To Concrete Repair: Surface Preparation Standards

Hochgeladen von

mochammad yudyantoOriginaltitel

Copyright

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Guide To Concrete Repair: Surface Preparation Standards

Hochgeladen von

mochammad yudyantoCopyright:

Guide to

Concrete Repa ir

Surface Preparation Standards

In repair and restoration work it is recommended to

ICRI Guideline No. 03732 and the ACI 546 Concrete

first take care of the cause before repairing the effect.

Repair Guide provides an in depth description of

Many times a condition survey is needed to determine

various types of surface preps, substrate condition

the cause(s) and to plan the proper, most cost-

surveys, and selection & specifying methods of

effective approach to correct the problem.

surface preparation.

Surface preparation is very important. The best of ACI 546 Concrete Repair Guide

products with poor surface preparation is no better ICRI 310.1R-2008, “Guide for Surface

than the lesser product with the proper surface Preparation for the Repair of Deteriorated

preparation. Concrete Resulting from Reinforcing Steel

Corrosion”

What is Surface Preparation? ICRI 310.2R-2013 Surface Preparation

Standards

“The process whereby a method or combination of

CSP # (Concrete Surface Profile) Designed

methods is used to remove deteriorated or

to match equipment.

contaminated concrete and roughen and clean a

substrate to enhance bond of a repair material or

protective coating.”

Surface Preparation Methods

Water-blast

* In doing so, this will provide the desired cleanliness Sand-blast

and profile of the substrate in order for the repair

Scabbler

material or protective coating to achieve its full

potential. Scarifier

Grinder

*ICRI Concrete Repair Terminology. Needle gun

Hammer chisels

To restore Concrete, identify the “Cause” of the

Shot-blasting

condition 1st…Then properly address the “Effect”!

Procedures that should be followed

Examination of concrete for the purpose of

identifying and defining areas of distress. Provide a high profile substrate for a good

mechanical bond.

For a lasting repair, it is critical to determine Have a defined edge…saw cut or use a

the cause of any problem to ensure that the grinding wheel to create a clean defined edge

appropriate products and procedures are to which you will work the repair mortar.

specified. Mixing methods: drill & paddle, mortar mixer,

concrete mixer (when stone added), pump, by

hand.

4226 Kansas Ave, Kansas City, Kansas 66106 | 877-266-7732 | www.DaytonSuperior.com

1/18/2016 Page 1 of 4

Guide to Concrete

Repa ir Cont inued

Concrete substrate to be in a Saturated- Vertical/Overhead Repair

Surface-Dry condition (SSD) so that the

concrete will not absorb water from the repair Mortars:

mortar.

When mixing less than a full bag always first Architectural Finish™

mix the bag so that a representative sample Polymer modified

is obtained. Use for rubbing, smoothing, resurfacing

Add the powder to the water. repairing vertical surfaces

Water requirements stay the same regardless Colored blended to a light gray

if the material is used neat or if pea gravel is Featheredge to 1/8” application depth

used.

Perma Patch VO™

Application methods: by hand, form & pump,

form & pour, dry packing, pneumatic One component w/water or 2-component

(spraying), pneumatic (shotcrete). w/approved admixture

Min. thickness 1/4”, max. 2” neat

Formulated for vertical / overhead

General Use Repair Mortars: applications

Shrinkage compensated

ReCrete™ 5 Minute & ReCrete™ 20 Minute

Can be sprayed or pumped through small

Cost-effective repair mortar with no polymers volume pneumatic equipment

or fibers Rapid strength gain

Min. thickness 1/8”, max. 2”, neat

Can be extended with aggregate

Extend with clean washed stone for repairs for repairs > 2”

> 2” per Data Sheet

Water substitution with Acrylic Bonding Agent HD 25 VO

J40 1:1, recommended for enhanced Designed for vertical and overhead

performance applications

Polymer modified

Polyfast™ FS

Min. thickness 1/4”, max. 2” neat

Rapid setting vertical and overhead

applications

More rapid initial strength gain than Polyfast

Polymer modified Civil / Structural VO

Min. thickness 1/4”, max. 2”, neat

Vertical or overhead applications

Extend with clean washed stone for repairs Formulated for use in spray applications using

> 2” per Data Sheet the wet process

Easily shaped and finished

Can also be applied be hand or trowel

Contains a corrosion inhibitor

Very high compressive strengths

4226 Kansas Ave, Kansas City, Kansas 66106 | 877-266-7732 | www.DaytonSuperior.com

1/18/2016 Page 2 of 4

Guide to Concrete

Repa ir Cont inued

Form & Pour Repair Mortars:

Civil / Structural FPX HD 50

For form & pour or horizontal applications Pourable consistency

Extended with blended aggregate Very rapid setting

Contains a corrosion inhibitor Polymer modified, fiber reinforced

Long working time Min. thickness ½”, max. 2”, neat

Extend with clean washed stone for repairs

Perma Patch™ F/P > 2” per Data Sheet

Flowable/self-consolidating

Up to 40 minute working time Pave Patch 3000

Ideal for horizontal or formed Pourable consistency

vertical/overhead applications Very rapid setting

High early strength Min. thickness ½”, max. 2”, neat

Extend with clean washed stone for repairs

Horizontal Repair Mortars: > 2” per Data Sheet

Capable of being extended up to 60% (40#

Thin Resurfacer stone) per bag

Polymer modified Resists freeze-thaw cycles to extend the life

Min. thickness 1/16”, max. 1/2” and cannot be of the patch

extended

Substitute 1 qt. of water with J-40 for Resinous Based Repair Mortars

enhanced performance

Rapid Resin Repair

Special Patch 100% solids 3-component low modulus

Shrinkage compensated repair material

High early strength Chemically resistant

Rapid-hardening mortar that accepts foot Cures from -20°F to 130°F

traffic in1-2 hours and pneumatic Low odor

Good resistance to freeze-thaw and impact

Excellent abrasion resistance to heavy loads Sure Patch™

and traffic 100% solids 3-component low modulus repair

polymer-modified, cementitious, two material

component Trowelable

Rapid strength gain

Moisture insensitive

4226 Kansas Ave, Kansas City, Kansas 66106 | 877-266-7732 | www.DaytonSuperior.com

1/18/2016 Page 3 of 4

Guide to Concrete

Repa ir Cont inued

Epoxy/Cementitious Bonding Specialty Repairs:

Agent/Rebar Primer Snaplugs®

Perma Prime™ 3C High Strength cement compound

Bonding agent & rebar primer/protector Plugs for tie cone holes

Long open time Gray in color

Epoxy-modified with corrosion inhibitor Saves time and labor

Anchor All

Non-shrink

Pourable

Fast setting

Ideal for posts and dowels

Waterstop

Rapid setting hydraulic cement

For plugging & stopping water or fluid leaks

in concrete or CMU

Initial set 2½ min., final set 3½ min.

Non-corrosive, non-rusting

4226 Kansas Ave, Kansas City, Kansas 66106 | 877-266-7732 | www.DaytonSuperior.com

1/18/2016 Page 4 of 4

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- CSWIP 3 1 Homework PDFDokument201 SeitenCSWIP 3 1 Homework PDFjfdlksa67% (3)

- TL WW KD df12Dokument25 SeitenTL WW KD df12Vulebg VukoicNoch keine Bewertungen

- Concrete Pre-Placement Checklist BackupDokument1 SeiteConcrete Pre-Placement Checklist Backuphermano balbonNoch keine Bewertungen

- DLM Final Presentation NiteshDokument29 SeitenDLM Final Presentation NiteshVishal ChamariaNoch keine Bewertungen

- Non-Traditional Machining PDFDokument21 SeitenNon-Traditional Machining PDFSaurabh ManralNoch keine Bewertungen

- Efka PB 2010Dokument2 SeitenEfka PB 2010LyHienNoch keine Bewertungen

- Casting: Workshop Practice ME-105Dokument20 SeitenCasting: Workshop Practice ME-105Mazahir habib100% (1)

- Innovative Use of Paper Industry Waste (Hypo Sludge) in Pervious Concrete - DR - Jayeshkumar Pitroda - Academia - EduDokument12 SeitenInnovative Use of Paper Industry Waste (Hypo Sludge) in Pervious Concrete - DR - Jayeshkumar Pitroda - Academia - EduRahul Singh PariharNoch keine Bewertungen

- MaterialData 15030Dokument2 SeitenMaterialData 15030onesmileNoch keine Bewertungen

- SAILMA Grades Steel Plates & SheetsDokument2 SeitenSAILMA Grades Steel Plates & SheetsElumalai SrinivasanNoch keine Bewertungen

- Stove Testing For DurabilityDokument25 SeitenStove Testing For DurabilityJose Humberto BernillaNoch keine Bewertungen

- BPAS - 184 Logistics ManagementDokument60 SeitenBPAS - 184 Logistics ManagementSafwan PandikashalaNoch keine Bewertungen

- Part I - 12 Material HandlingDokument7 SeitenPart I - 12 Material Handlingsalah abddayemNoch keine Bewertungen

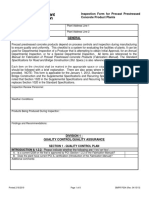

- Inspection Form For Precast Prestressed Concrete Product PlantsDokument8 SeitenInspection Form For Precast Prestressed Concrete Product PlantsAbdi Septia PutraNoch keine Bewertungen

- Yadav Khagendra K. M-Tech (AME) Hindustan UniversityDokument28 SeitenYadav Khagendra K. M-Tech (AME) Hindustan Universityمحمد قديشيNoch keine Bewertungen

- S275NLDokument1 SeiteS275NLMukesh ShettyNoch keine Bewertungen

- S4 - Shackles - V2 PDFDokument20 SeitenS4 - Shackles - V2 PDFlonewolf 3le7Noch keine Bewertungen

- Eindhoven Car Park Collapse PDFDokument5 SeitenEindhoven Car Park Collapse PDFBartosz ZaforemskiNoch keine Bewertungen

- Exam - 2Dokument12 SeitenExam - 2Stanley Alex100% (3)

- Super Alloys (Ni-Base) and Dislocations, An IntroductionDokument26 SeitenSuper Alloys (Ni-Base) and Dislocations, An IntroductionHassanNoch keine Bewertungen

- Brochure TIMREX Graphites and Cokes For Friction MaterialsDokument20 SeitenBrochure TIMREX Graphites and Cokes For Friction MaterialsVarun DodhiaNoch keine Bewertungen

- Strategies For Managing Plastic Waste From Construction and Manufacturing ProjectsDokument9 SeitenStrategies For Managing Plastic Waste From Construction and Manufacturing Projectsviktorija bezhovskaNoch keine Bewertungen

- Wheeled Coach2Dokument2 SeitenWheeled Coach2Rachelle Lim-Magtanggol67% (3)

- Ps-x01 Nls InputdataDokument100 SeitenPs-x01 Nls InputdatapckolNoch keine Bewertungen

- Kiln BuildingDokument245 SeitenKiln Buildingxpsal100% (4)

- Materials Management Is Defined As "The Groupings of Management FunctionsDokument15 SeitenMaterials Management Is Defined As "The Groupings of Management FunctionsAugusto Jr Rafael BasaNoch keine Bewertungen

- 2.4 FAC I L I TY Locat I ON: 1. Deciding On Domestic or International LocationDokument10 Seiten2.4 FAC I L I TY Locat I ON: 1. Deciding On Domestic or International Locationkapun kumar nayakNoch keine Bewertungen

- Jis G3112 - Sd295aDokument1 SeiteJis G3112 - Sd295aWin Than100% (1)

- 16BME0279 Digital Assignment 1 Aritra Guha Ray Welding Engineering MEE-2011Dokument3 Seiten16BME0279 Digital Assignment 1 Aritra Guha Ray Welding Engineering MEE-2011FileDownloderNoch keine Bewertungen