Beruflich Dokumente

Kultur Dokumente

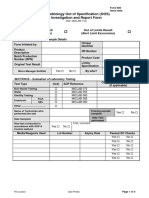

Format For MFR

Hochgeladen von

SUNILA DEVIOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Format For MFR

Hochgeladen von

SUNILA DEVICopyright:

Verfügbare Formate

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:1 of 13

MASTER FORMULA RECOED

PRODUCT NAME :

LIC. NO. :

PRODUCT CODE :

M.F.R. NO. :

EFFECTIVE DATE :

REVIEW DATE :

SUPERSEDES :

REVISION NO . :

INDEX

SR. PARTICULARS PAGE NO.

NO.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:2 of 13

1 Introduction

2 Manufacturing Plant

2.1 Warehouse

2.2 Manufacturing Facility

2.3 Raw material handling

3 Manufacturing Process

3.1 Process Flowchart

3.2 List of Equipments

4 BPR

5 Quality Control System

6 Stability Study

7 Utility

8 Effluent Treatment Plant

NICOTINAMIDE

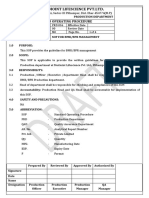

1. INTRODUCTION

Product : Nicotinamide

Physical Characteristics : A white, crystalline powder or colourless

crystals.

Solubility : Freely soluble in water and in ethanol.

Molecular Weight : 122.1

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:3 of 13

Molecular Formula : C6H6N2O

Molecular Structure :

CAS No : 98-92-0

Action & Use : Component of vitamin B.

Master Batch Size : 200kg

2. MANUFACTURING FACILITIES

The facilities available at plant are as following

2.1 Ware- house

2.2 Manufacturing plant

2.3 Raw material handling

2.1 Warehouse

Ware house facility consists of the following:

a. Solid raw material storage area: All solid raw materials used are stored in separate raw

material store building.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:4 of 13

b. Solvent storage area: All liquid solvents, which are stored into drums in separate solvent

storage area.

c. Packaging material storage area: packaging materials like fiber/HDPE drums/polythene

bags are stored in separate area of solid raw material storage building.

d. Dispensing area: This area is used for dispensing of solid raw materials. It is equipped

with weighing balance.

e. Engineering goods area: All engineering goods used are stored in separate engineering

goods area.

2.2 Manufacturing Plant

The production facility is divided in two main areas:

1.Chemical processing area

2.Powder processing area

Chemical processing area: All reactors, centrifuges and filters are located in this area plant no.2.

Powder processing area: This area is further divided into following separate areas

Dryer Room

Multimilling, pulverizing

Quarantine rooms, Finish Goods.

This area is also provides with Temp. & Humidity control.

Equipment maintenance & calibration: The manufacturing facilities are maintained by a

program of preventive and shut down maintenance procedures. Periodical maintenance of

equipment is done by the In –House maintenance department.

Calibration: Calibration of some measuring devices installed in bulk drug facility is performed by

outside.

2.3 Raw Material Handling

Incoming Procedure

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:5 of 13

Delivery of RM is taken by store in-charge who will check the challan, invoices.

Each consignment of material is sequentially entered in to a register.

The consignment received is checked for the number of containers damages labels batch no.

quantity manufacture/ supplier etc.

Batch Numbering System

Every consignment of RM received is segregated batch wise or lot wise. A goods receipt report is

prepared based on this number. This report will indicate all receipt details of RM.

Raw Material Sampling & Release

A good receipt report is prepared by store department and sent to quality control.

Material in quarantine is identified by under test label pasted on drums showing quarantined

status.As the status of material changes i,e. when the material is sampled by a sampled stamp.

Representative sample of each batch no./ lot is collected as per sample plan by formula √n+1.

Raw Material Release

After analysis results are entered in the protocol and QC reference no. are given in the numbering

register. A approved or rejected slips are prepared accordingly.

The original copy of report is retained for QC records. Copies of analytical reports are forwarded

to production and store department.

The sampling chemist will go to stores and change the status position of raw material by affixing

“APPROVED” or “REJECTED” stickers.

The stores personnel then enters of the raw material in their stock register .

Raw Materials Distribution

Stores department maintains the physical stock of the approved raw materials.

The material is issued against the issue indent received form plant.

The materials are issued batch/ lot wise. Quantities of each raw material required for each batch/

lot are checked as per the standard norms.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:6 of 13

The procedure whereby the oldest approved stock of the material is distributed first is followed.

Packing Material Specification

1. Common Name : Drum

2. Specific Name : Fiber drum for 25 Kg

3. Description : Brown colored, plain, Cylindrical Drum,

closed at one end and covered with a

detachable lid on other end.

4. Size : Tolerance

a. Height : 508.00 mm (508 mm to 510 mm)

b. Diameter : 406.00 mm (406 mm to 408 mm)

5. Weight with Cover : 4.25 Kg (+ 5.00 %)

6. Thickness of the wall : 3.8 mm (3.6 to 4.0)

SPECIMEN LABELS

It includes product name, batch number, manufacturing date, expiry date, manufacturing site address,

net weight, gross weight, storage conditions & special precautions.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:7 of 13

MANUFACTURING PROCESS

4.1. List of Raw Materials Required

S. No. Name of the Raw Materials Quantity Required

1 3-Cyano Pyridine 600 Kg

2 Purified Water 425ltr

3 Sodium Hydroxide 8.4 Kg

4 Activated Carbon 1.5Kg

5 Liquor Ammonia 2.0 ltr

Standard Batch Size 200kg

The following steps are followed in manufacturing of NICOTINAMIDE:-

Charge purified water in appropriate capacity reactor.

Charge 3-cynopyridine in reactor and maintain the required temperature.

After obtaining the required temperature add the sodium hydroxide solution for hydrolysis.

Maintain the reflex for defined period.

Add activated Charcoal.

Hydrolyzed mass is filtered through the suitable filter.

Hydrolyzed mass is basified with ammonia solution.

Basified material is centrifuged.

Centrifuged material is dried in a drier.

The dried material is grinded through multimill through appropriate mess.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:8 of 13

3.2 MANUFACTURING FLOW CHART :

PURIFIED WATER 3 CYANOPYRIDINE

SODIUM HYDROXIDE SOLUTION

ACTIVATED

CARBON

REACTOR

REFLUX

FILTER

REACTOR + Cooling

CENTRIFUSE

DRYING

MILLING

SHIFTING

PACKING

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:9 of 13

3.2 Major Production Equipments Required For Nicotinamide

S. No. Equipments Capacity Number

1 R-109, SS reactor, jacketed with agitator 2000L 1

2 R-109, SS-316 with agitator, 5HP flame proof motor & 2000L 1

gear box with variable speed

3 Multi mill 100kg/h 1

4 Pulverizer SS-316 50kg/h 1

5 Shifter SS-316 100kg/h 1

3. QUALITY CONTROL LABORATORY

Quality control laboratory worked independently and having all the testing facilities in the premises with SOP’s,

STP’s etc. We are having “Reference Standards” of all the products.

Wet Chemical laboratory, there is a well-equipped instrumental testing laboratory having KF titrator,

Polarimeter, pH meter, electronic weighing balance.

Instrument lab includes computerized analytical instruments such as High performance liquid

chromatograph, Gas Chromatographs etc.

Microbiological testing laboratory include state of art facilities involving AHU controlled room and

laminar bench to name a few. .

4.1 List of Laboratory Equipment

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:10 of 13

S. No. Name of Instrument Make Quantity

1. HPLC ( LC-10A VP) Shimadzu One

3. Gas Chromatography System (NUCON-5700) One

4. UV Spectrophotometer Beckman Model DU 40 One

5. Polarimeter Advance One

6. K.F. Titrator (Veego/MATIC–D) One

7. Auto K. F. Titrimeter N.S One

8. Electronic Balance Dhona (200-D) One

9. Electronic Balance Denver (APX-60) One

10. Melting Point Apparatus (APX-60) One

11. Digital pH Meter (Toshiba) NIG 333 One

12. Digital pH Meter (Toshiba) 152R One

13. Humidity Cabinet (Toshiba & Multitech) Two

14. Muffle Furnace N.S One

15 Hot Air Oven Ambassador One

16. TLC UV Cabinet Toshiba India (Delhi) One

17. Ultra sonicator bath 105 (H) One

18. Vacuum pump N.S One

19. Magnetic Stirrer with hot plate Toshiba India Ltd. One

20. Potentiometer Metrohm One

21. Heating mental 100watt Sunbeam India Ltd. Four

22. Vacuum pump PpI Pump One

23. Distillation apparatus Remimoters Two

4. STABILITY STUDIES

A documented ongoing testing program is designed to monitor the stability characteristics of the product

and the result is used to confirm appropriate storage condition and retest or expiry dates. The stability

testing is carried out using the following protocol.

Procedure

Selection batches and sample size:

- Three consecutive commercial production batches will be used for long term and accelerated

stability testing.One batch after every six months will be kept for the above testing.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:11 of 13

- 25 gm of the sample from each batch will be used for stability under the stability storage conditions.

Specification and Procedure

- Sample will be analyzed for the following test as per standard testing procedure.

- Description

- MeltingPoint

- pH

- LOD

- Sulphated Ash

- Assay

Storage Conditions

- Sample will be placed under the following conditions.

Testing Temp./ Humidity Period

Long term testing Temp. 250C ± 20C Up to expiry

RH 60% ± 5%

Accelerated Temp. 400C ± 20C 6 Months

RH 75% ± 5%

Packing

- Sample will be packed in double polybags with inner and outer packing of transparent polybags that

simulate the market containers.

Testing frequency

- The sample kept for long term testing are analyzed after zero, three, six, nine, twelve, eighteen,

twenty four, thirty six or up to expiry.

- The sample kept for accelerated study is analyzed after every month up to 6 months.

7. UTILITIES

Utility system support the manufacturing operation centralized utilities include:

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:12 of 13

Power receiving and distribution system.

Standing power generation station.

Motor treatment, storage and distribution system

Steam generation and distribution system.

Low temperature chilled brine system.

Compressed air system.

All utilities systems are operated and maintained as per the best engineering practices.

S. No Equipments Capacity

1 Generator (kirloskar cumins0 125 kva

2 Generator (kirloskar) 62.5 kva

3 Generator (kirloskar) 33 kva

4 Chilling plant with kirloskar Cumins compressor 25 ts 25 ts.

refrigeration cap. of brine -30 C

5 Chilling plant excel - 5 chilled water brine 10 Ts.

6 Boiler automatic oil fired makes energy machines, (hp 400 kg. /hr.

steam/lp steam both).

7 Water Softening Plant 1 each/gener.

8 Purified Water Plant 80 kl/gener.

9 SS Centrifugal Pump 3 kl/hr

10 MS Butterfly Pump 2kl/hr

11 Distillation unit with 1000 l distillation vessel with 24 feet 130l/hr

column. & SS 304 condenser of 5 sq. Meter.

8. EFFLUENTS TREATMENT PLANT

The gaseous effluents are scrubbed or condensed, eliminating any emissions.

Waste water generation is minimized by recovery and recycle as far as is practical liquid effluents is treated

chemically, followed by aerobic digesters in an effluent Treatment plant. The treated water is used for in

house land irrigation.

Solid waste is packed in poly bags & dump into the space provided by Municipal Corporation.

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

PHARMCHEM

Modern Industrial Estate, Bahadurgarh,- 124507 Haryana

Title: Master Formula Record

Format Number: QA/011/F1-00 Effective Date: Page No.:13 of 13

PREPARED BY CHECKED BY APPROVED BY

NAME

DESIGNATION

DEPARTMENT

SIGN./DATE

Format No.: QA/001/F2-00

Das könnte Ihnen auch gefallen

- Annual Product Quality Review APQR FormatDokument9 SeitenAnnual Product Quality Review APQR FormatDr.Sivakumar Selvaraj100% (1)

- Area Qualification ProtocolDokument19 SeitenArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- BMR PraperationDokument9 SeitenBMR PraperationwondwossengNoch keine Bewertungen

- Solitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyDokument7 SeitenSolitaire Pharmacia Pvt. LTD.: Restricted Circulation Authorised Persons OnlyNgoc Sang HuynhNoch keine Bewertungen

- Annual Product Quality Review (APQR) SOP - PharmaBDokument14 SeitenAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Temperature Mapping For FG StoreDokument19 SeitenTemperature Mapping For FG Storemehrdarou.qaNoch keine Bewertungen

- SOP For Drug Product Recall & Mock Recall - Pharma BeginnersDokument13 SeitenSOP For Drug Product Recall & Mock Recall - Pharma BeginnersFled NguyenNoch keine Bewertungen

- Aphrin 500 MG Capsule BPR 1Dokument12 SeitenAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- SOP of Glassware HandlingDokument1 SeiteSOP of Glassware HandlingPrince Moni100% (2)

- 05.SOP For Storage and Use of Reagents & ChemicalsDokument4 Seiten05.SOP For Storage and Use of Reagents & ChemicalsBejoy Karim75% (4)

- Reference Format No.: SOP/QA/001-F01-00Dokument4 SeitenReference Format No.: SOP/QA/001-F01-00Rahul67% (3)

- 01.collection, Storage and Control of Reserve Samples For Drug ProductsDokument4 Seiten01.collection, Storage and Control of Reserve Samples For Drug ProductsBejoy KarimNoch keine Bewertungen

- Ointment Process ValidationDokument25 SeitenOintment Process ValidationTrinh Huy CongNoch keine Bewertungen

- Interview Question Q.ADokument9 SeitenInterview Question Q.AHema KrishnaNoch keine Bewertungen

- QA005-04 Vendor Qualification-IM & PMKDokument9 SeitenQA005-04 Vendor Qualification-IM & PMKSagar ChavanNoch keine Bewertungen

- Prosses Validation Protocol For Albendazole SuspensionDokument25 SeitenProsses Validation Protocol For Albendazole Suspensionمحمد عطاNoch keine Bewertungen

- Sop For Annual Product ReviewDokument1 SeiteSop For Annual Product ReviewPrince Moni100% (1)

- Analyst Qualification (Modified)Dokument6 SeitenAnalyst Qualification (Modified)vasant ugale75% (4)

- List of QC SopDokument3 SeitenList of QC SopPrince MoniNoch keine Bewertungen

- Alarm Verification Protocol FOR Incubators (Microbiology, Q-Block)Dokument10 SeitenAlarm Verification Protocol FOR Incubators (Microbiology, Q-Block)cpkakope100% (1)

- BPR - FP025-1 V-1Azinil 35ml PFSDokument17 SeitenBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- 023-SOP For Conducting Hold Time StudyDokument3 Seiten023-SOP For Conducting Hold Time StudyAshok Lenka100% (2)

- 8.3 Operation Qualification Protocol For Dispensing BoothDokument4 Seiten8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Raw Material Requisition Slip - For MergeDokument1 SeiteRaw Material Requisition Slip - For Mergeasit_mNoch keine Bewertungen

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDokument3 SeitenVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- Protocol Jacketed MFG Tank LV02Dokument7 SeitenProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- 02.SOP of Retention Sample (Raw Material)Dokument5 Seiten02.SOP of Retention Sample (Raw Material)Bejoy Karim100% (2)

- SOP of Stability Study - 1Dokument5 SeitenSOP of Stability Study - 1YousifNoch keine Bewertungen

- Performance Qualification Protocol FOR Automatic Capsule Filling MachineDokument13 SeitenPerformance Qualification Protocol FOR Automatic Capsule Filling Machinemehrdarou.qaNoch keine Bewertungen

- Vatakulantka Rasa TabletDokument7 SeitenVatakulantka Rasa Tabletreflectprakash3610Noch keine Bewertungen

- Gmail - Offer Letter of ManpowerGroupDokument3 SeitenGmail - Offer Letter of ManpowerGroupankitkelkar2Noch keine Bewertungen

- 004 Handling of Deviation 2-1Dokument16 Seiten004 Handling of Deviation 2-1Sagar ChavanNoch keine Bewertungen

- Certificate of Analysis ProcedureDokument5 SeitenCertificate of Analysis ProcedureHaroon Rasheed100% (1)

- Hold Time Study 1Dokument3 SeitenHold Time Study 1aboemadaldeenNoch keine Bewertungen

- Microbiology Out of Specification (OOS) Investigation and Report FormDokument3 SeitenMicrobiology Out of Specification (OOS) Investigation and Report FormIra Nurjannah100% (1)

- Applicant's PartDokument114 SeitenApplicant's PartCesar RodriguezNoch keine Bewertungen

- Helix Pharma (Private) Limited: Validation ProtocolDokument4 SeitenHelix Pharma (Private) Limited: Validation Protocolziauddin bukhari0% (2)

- SOP of Instruction of Master Formula RecordDokument2 SeitenSOP of Instruction of Master Formula RecordYousif100% (1)

- Clean RoomDokument19 SeitenClean Roomhouas menasriaNoch keine Bewertungen

- SOP For Retest of Raw MaterialsDokument3 SeitenSOP For Retest of Raw MaterialsRainMan75Noch keine Bewertungen

- Process Validation Protocol (500 MG Tablet)Dokument6 SeitenProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- Purpose: Preventive & Breakdown Maintenance of Equipments and InstrumentsDokument3 SeitenPurpose: Preventive & Breakdown Maintenance of Equipments and InstrumentsMayson BaliNoch keine Bewertungen

- Site Master FileDokument18 SeitenSite Master FileAaron Chris GonzalesNoch keine Bewertungen

- Aphrin Pfs BPR p1 v-1Dokument13 SeitenAphrin Pfs BPR p1 v-1ShagorShagorNoch keine Bewertungen

- 43 02 Operation of Stabilty Chamber (I)Dokument17 Seiten43 02 Operation of Stabilty Chamber (I)systacare remediesNoch keine Bewertungen

- Issuing Date Doc No: Effective Date Department Next Review Date SectionDokument5 SeitenIssuing Date Doc No: Effective Date Department Next Review Date SectionAmer Abu RahmahNoch keine Bewertungen

- Cleaning Validation Report TEMPLATEDokument9 SeitenCleaning Validation Report TEMPLATEnatavceNoch keine Bewertungen

- Standard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationDokument3 SeitenStandard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationMajed HossainNoch keine Bewertungen

- Emiset - BPRDokument25 SeitenEmiset - BPRjordan7half7donNoch keine Bewertungen

- Equipment Cleaning Validation Protocol FOR Aceclofenac /etodolac TabletsDokument25 SeitenEquipment Cleaning Validation Protocol FOR Aceclofenac /etodolac TabletsQA PROTECH100% (1)

- Azithromycin 250mg TabletDokument12 SeitenAzithromycin 250mg TabletziadddNoch keine Bewertungen

- CV Protocol-Coated TabletsDokument22 SeitenCV Protocol-Coated Tabletsqaheadjml007Noch keine Bewertungen

- 025 SOP Self InspectionDokument6 Seiten025 SOP Self InspectionMhammad Naveed50% (2)

- Temperature Mapping Protocol: Lincoln Parenteral LTDDokument7 SeitenTemperature Mapping Protocol: Lincoln Parenteral LTDRajender SinghNoch keine Bewertungen

- Batch Release (VHS QA 027 R0)Dokument8 SeitenBatch Release (VHS QA 027 R0)Ajay patel Patel100% (1)

- DQ Report For BrineDokument12 SeitenDQ Report For BrineNishit SuvaNoch keine Bewertungen

- SOP For Change OverDokument6 SeitenSOP For Change OverJayesh Meharwal100% (3)

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDokument4 SeitenMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNoch keine Bewertungen

- PQ-Sample fIVEDokument13 SeitenPQ-Sample fIVEcpkakopeNoch keine Bewertungen

- Vendors Certification AnnexuresDokument16 SeitenVendors Certification Annexuresisrael afolayan mayomiNoch keine Bewertungen

- Cenpes: Index of Revisions REV Description And/Or Revised SheetsDokument30 SeitenCenpes: Index of Revisions REV Description And/Or Revised SheetsOrlando PWRNoch keine Bewertungen

- REACHDokument16 SeitenREACHTranVinhNoch keine Bewertungen

- Ammonia Waste WaterDokument19 SeitenAmmonia Waste WaterAnonymous GfPSYi4nNoch keine Bewertungen

- Paper - I - General: Previous Year Paper GPAT DIDokument20 SeitenPaper - I - General: Previous Year Paper GPAT DIVikash KushwahaNoch keine Bewertungen

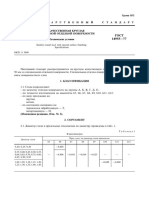

- Äèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12Dokument7 SeitenÄèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12TetianaNoch keine Bewertungen

- Plate and Frame Heat ExchangersDokument6 SeitenPlate and Frame Heat ExchangersAndrés Ramón Linares100% (1)

- Acids and Bases YMS X ALJDokument9 SeitenAcids and Bases YMS X ALJFaqihah Syahindah Mohammed FiroozNoch keine Bewertungen

- Structure Test 2Dokument3 SeitenStructure Test 2Seda Aydin100% (1)

- Certificate: Internal Teacher's SignDokument8 SeitenCertificate: Internal Teacher's SignVyomNoch keine Bewertungen

- Is: 11871-1986Dokument24 SeitenIs: 11871-1986Sumit LakhotiaNoch keine Bewertungen

- PO - Lapox P 62Dokument2 SeitenPO - Lapox P 62alpesh.samruddhigroupNoch keine Bewertungen

- DrillingDokument21 SeitenDrillingNabil RajNoch keine Bewertungen

- Hyundai HL780-3ADokument636 SeitenHyundai HL780-3AAnonymous yjK3peI740% (5)

- Lubrication SystemsDokument5 SeitenLubrication SystemssaiNoch keine Bewertungen

- IHSMarkit Fertecon The Worlds Top40 Ammonia Buyers MARKETINGDokument18 SeitenIHSMarkit Fertecon The Worlds Top40 Ammonia Buyers MARKETINGhzulqadadarNoch keine Bewertungen

- Student Lab 1 Intro Semiconductor LabvoltDokument5 SeitenStudent Lab 1 Intro Semiconductor LabvoltbishoyNoch keine Bewertungen

- Weekly Construction Report - 2011.10.15Dokument22 SeitenWeekly Construction Report - 2011.10.15Farouq SHah100% (5)

- 3 NsaidsDokument23 Seiten3 NsaidsHagai MagaiNoch keine Bewertungen

- Thurmalox 8200 Painting SpecificationDokument2 SeitenThurmalox 8200 Painting SpecificationFreddy Carl FredricksenNoch keine Bewertungen

- PGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresDokument10 SeitenPGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresGiovanni AlfieriNoch keine Bewertungen

- Metabolit SekunderDokument76 SeitenMetabolit SekunderCempaka Kusuma DewiNoch keine Bewertungen

- Refineries: Application Focus: HydroprocessingDokument4 SeitenRefineries: Application Focus: HydroprocessingmudrikaNoch keine Bewertungen

- Influence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabDokument18 SeitenInfluence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabShaker QaidiNoch keine Bewertungen

- ECV5701 Notes For Concrete Inspection and Assessment-1Dokument19 SeitenECV5701 Notes For Concrete Inspection and Assessment-1ahmed almhjani100% (1)

- Augmentation of Pulverized Coal Injection System of Blast FurnaceDokument28 SeitenAugmentation of Pulverized Coal Injection System of Blast FurnaceShubhajyoti SahaNoch keine Bewertungen

- Plumbing Piping For Building: NIOEC-SP-30-05Dokument9 SeitenPlumbing Piping For Building: NIOEC-SP-30-05masoud132Noch keine Bewertungen

- Soil PH and Soil Acidity PDFDokument16 SeitenSoil PH and Soil Acidity PDFManuel EscobarNoch keine Bewertungen

- 000 3DT 00005 000 - 2Dokument116 Seiten000 3DT 00005 000 - 2anbesivam87Noch keine Bewertungen

- Efinal Format AppendicesDokument13 SeitenEfinal Format AppendicesRRNoch keine Bewertungen

- Unt, in Moles, of Carbon Atoms Compound A Is Completely Oxidised To Carbon Dioxide and Water. Copper Is The Only Other Product of THDokument30 SeitenUnt, in Moles, of Carbon Atoms Compound A Is Completely Oxidised To Carbon Dioxide and Water. Copper Is The Only Other Product of THG M Ali KawsarNoch keine Bewertungen