Beruflich Dokumente

Kultur Dokumente

ME8451 MT-II Syllabus

Hochgeladen von

pragashOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME8451 MT-II Syllabus

Hochgeladen von

pragashCopyright:

Verfügbare Formate

ME8451 MANUFACTURING TECHNOLOGY – II LTPC3003

OBJECTIVES:

To understand the concept and basic mechanics of metal cutting, working of standard machine tools such as

lathe, shaping and allied machines, milling, drilling and allied machines, grinding and allied machines and

broaching.

To understand the basic concepts of Computer Numerical Control (CNC) of machine tools and CNC

Programming.

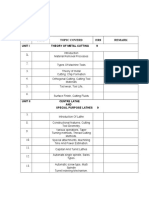

UNIT I THEORY OF METAL CUTTING 9

Mechanics of chip formation, single point cutting tool, forces in machining, Types of chip, cutting tools–

nomenclature, orthogonal metal cutting, thermal aspects, cutting tool materials, tool wear, tool life, surface

finish, cutting fluids and Machinability.

UNIT II TURNING MACHINES 9

Centre lathe, constructional features, specification, operations – taper turning methods, thread cutting

methods, special attachments, machining time and power estimation. Capstan and turret lathes- tool layout –

automatic lathes: semi automatic – single spindle: Swiss type, automatic screw type – multi spindle:

UNIT III SHAPER, MILLING AND GEAR CUTTING MACHINES 9

Shaper – Types of operations. Drilling, reaming, boring, Tapping. Milling operations - types of milling

cutter. Gear cutting – forming and generation principle and construction of gear milling ,hobbing and gear

shaping processes –finishing of gears.

UNIT IV ABRASIVE PROCESS AND BROACHING 9

Abrasive processes: grinding wheel – specifications and selection, types of grinding process– cylindrical

grinding, surface grinding, centreless grinding and internal grinding- Typical applications – concepts of

surface integrity, broaching machines: broach construction – push, pull, surface and continuous broaching

machines

UNIT V CNC MACHINING 9

Numerical Control (NC) machine tools – CNC types, constructional details, special features, machining

centre, part programming fundamentals CNC – manual part programming – micromachining – wafer

machining. TOTAL : 45 PERIODS

OUTCOMES:

CO 1 Explain the mechanism of material removal process.

CO 2 Describe the constructional and operational features of centre lathe and other special purpose lathes.

CO 3 Describe the constructional and operational features of shaper, planner, milling, drilling, sawing and

broaching machines.

CO 4 Explain the types of grinding and other super finishing processes apart from gear manufacturing processes.

CO 5 Summarize numerical control of machine tools and write a part program.

TEXT BOOKS:

1. Hajra Choudhury, “Elements of Workshop Technology”, Vol.II., Media Promoters 2014

2. Rao. P.N “Manufacturing Technology – Metal Cutting and Machine Tools”, 3rd Edition, Tata McGraw-

Hill, New Delhi, 2013.

REFERENCES:

1. Richerd R Kibbe, John E. Neely, Roland O. Merges and Warren J.White “Machine Tool Practices”,

Prentice Hall of India, 1998

2. Geofrey Boothroyd, “Fundamentals of Metal Machining and Machine Tools”, Mc Graw Hill, 1984

3. HMT, “Production Technology”, Tata McGraw Hill, 1998.

4. Roy. A.Lindberg, “Process and Materials of Manufacture,” Fourth Edition, PHI/Pearson Education 2006

Das könnte Ihnen auch gefallen

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingVon EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingBewertung: 5 von 5 Sternen5/5 (2)

- Construction Method Statement: Fabrication & Erection of Piping SystemDokument24 SeitenConstruction Method Statement: Fabrication & Erection of Piping SystemHarun Akkaya100% (2)

- Wagi ValvesDokument2 SeitenWagi ValvesAlex VarHer100% (1)

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- Tutorial 2 HandoutDokument13 SeitenTutorial 2 HandoutedsaregNoch keine Bewertungen

- Standards and Specifications For GRCDokument2 SeitenStandards and Specifications For GRCHani NemrawiNoch keine Bewertungen

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Von EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Bewertung: 5 von 5 Sternen5/5 (1)

- Manufacturing ProcessDokument1 SeiteManufacturing ProcessRonald Reagon20% (5)

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDokument4 SeitenWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNoch keine Bewertungen

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsVon EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsBewertung: 5 von 5 Sternen5/5 (1)

- 01CS1B01Dokument4 Seiten01CS1B01Muhammad Farukh ManzoorNoch keine Bewertungen

- Manual Bombas SandPiper S20Dokument24 SeitenManual Bombas SandPiper S20Rodrigo F MNoch keine Bewertungen

- Me8451 Manufacturing Technology - Ii ObjectivesDokument2 SeitenMe8451 Manufacturing Technology - Ii ObjectivesravivpsNoch keine Bewertungen

- Me2252 Manufacturing Technology SyllabusDokument1 SeiteMe2252 Manufacturing Technology Syllabusrgopi_83Noch keine Bewertungen

- Manufacturing Technology 2Dokument2 SeitenManufacturing Technology 2msloveindia0% (2)

- SyllabusDokument2 SeitenSyllabuselavarasansivaNoch keine Bewertungen

- Machine ToolsDokument238 SeitenMachine ToolsSeban AugustineNoch keine Bewertungen

- Me6402 Manufacturing Technology - Ii Unit I Theory of Metal CuttingDokument1 SeiteMe6402 Manufacturing Technology - Ii Unit I Theory of Metal CuttingsureshNoch keine Bewertungen

- MCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Dokument91 SeitenMCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Pilla SireeshaNoch keine Bewertungen

- MC&MT r13 SyllabusDokument2 SeitenMC&MT r13 Syllabussanyasirao1Noch keine Bewertungen

- SYLLABUSDokument2 SeitenSYLLABUSJohn BrinkyNoch keine Bewertungen

- Manufacturing Technology II SyllabusDokument1 SeiteManufacturing Technology II Syllabussmg26thmay100% (1)

- Metal Cutting & Machine ToolsDokument1 SeiteMetal Cutting & Machine Toolskela nNoch keine Bewertungen

- Metal CuttingDokument1 SeiteMetal Cuttingkela nNoch keine Bewertungen

- SyllabusDokument2 SeitenSyllabusDhana MuruganNoch keine Bewertungen

- SyllabusDokument2 SeitenSyllabusDhana MuruganNoch keine Bewertungen

- ME6402 MT II by WWW - Learnengineering.inDokument102 SeitenME6402 MT II by WWW - Learnengineering.inVikram C KNoch keine Bewertungen

- ME6402 SCAD MSM by EasyEngineering - Net 2Dokument101 SeitenME6402 SCAD MSM by EasyEngineering - Net 2Akash PrasanthNoch keine Bewertungen

- Machining Process SyllabusDokument2 SeitenMachining Process SyllabusRahul PatilNoch keine Bewertungen

- Lesson Plan mp2Dokument2 SeitenLesson Plan mp2Saravanan RajendranNoch keine Bewertungen

- Metal Cuuting SyllabusDokument1 SeiteMetal Cuuting SyllabusAnonymous wrSPc7Bh05Noch keine Bewertungen

- Manufacturing Processes SyllabusDokument14 SeitenManufacturing Processes SyllabusdeekamittalNoch keine Bewertungen

- MFT-2 .Two Marks With KeyDokument13 SeitenMFT-2 .Two Marks With KeySujith KumarNoch keine Bewertungen

- Syllabus-Manufacturing Technology - IIDokument1 SeiteSyllabus-Manufacturing Technology - IIMoney vasagamNoch keine Bewertungen

- Manufacturing Process SyllabusDokument3 SeitenManufacturing Process SyllabusRohit KumarNoch keine Bewertungen

- Manufacturing ProcessesDokument2 SeitenManufacturing ProcessespmagrawalNoch keine Bewertungen

- ME8451-MT-II - by WWW - LearnEngineering.inDokument102 SeitenME8451-MT-II - by WWW - LearnEngineering.inSundar GaneshNoch keine Bewertungen

- MCMT SyllabusDokument3 SeitenMCMT SyllabusshahazadNoch keine Bewertungen

- Works T-IIIDokument3 SeitenWorks T-IIITki NeweNoch keine Bewertungen

- MF6505 CNC SyllabusDokument2 SeitenMF6505 CNC SyllabusSenthil KumarNoch keine Bewertungen

- Manufacturing Process Lab IiiDokument5 SeitenManufacturing Process Lab IiiMuhammad Bilal SahiNoch keine Bewertungen

- Syllabus PtamDokument1 SeiteSyllabus PtamDhana MuruganNoch keine Bewertungen

- Me 2252 Manufacturing TechnologyDokument3 SeitenMe 2252 Manufacturing TechnologyRamarajan YogeeswaranNoch keine Bewertungen

- MEF 112 Course HandoutDokument4 SeitenMEF 112 Course HandoutAR7 StudioNoch keine Bewertungen

- Manufacturing Processes PDFDokument6 SeitenManufacturing Processes PDFAbhi GalandeNoch keine Bewertungen

- Machine Tools Week 01 2021Dokument39 SeitenMachine Tools Week 01 2021Anıl ŞenyurtNoch keine Bewertungen

- Advanced Manufacturing ProcessesDokument2 SeitenAdvanced Manufacturing ProcessesROOSSVELT PRABHU K A VNoch keine Bewertungen

- Machining Processes SyllabusDokument2 SeitenMachining Processes SyllabusshailkhanNoch keine Bewertungen

- Advanced Manufacturing ProcessesDokument5 SeitenAdvanced Manufacturing Processessagar mhetreNoch keine Bewertungen

- S.No Date Topic Coverd HRS Remark: Unit I Theory of Metal Cutting 9Dokument4 SeitenS.No Date Topic Coverd HRS Remark: Unit I Theory of Metal Cutting 9srivijaiNoch keine Bewertungen

- Production Technology PDFDokument2 SeitenProduction Technology PDFRamana Kumar NarsipuramNoch keine Bewertungen

- Syllabus: Manufacturing Processes IiDokument1 SeiteSyllabus: Manufacturing Processes IiAbhishek MishraNoch keine Bewertungen

- Production TechnologyDokument1 SeiteProduction TechnologyBhavesh PipaliyaNoch keine Bewertungen

- Junior Instructor in Draftsman Mechanic in Industrial TDokument6 SeitenJunior Instructor in Draftsman Mechanic in Industrial ThariNoch keine Bewertungen

- 23 Certificate Course in CNC TechnologyDokument2 Seiten23 Certificate Course in CNC TechnologyDeepak RajNoch keine Bewertungen

- Materials and MachiningDokument116 SeitenMaterials and MachiningGian RemundiniNoch keine Bewertungen

- B.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsDokument11 SeitenB.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsAnkesh KapilNoch keine Bewertungen

- Name of Faculty: Kumel Nagori, Jalpesh Chaudhary: Ubject Subject Code Class ECH UTO R O O OF ECTDokument3 SeitenName of Faculty: Kumel Nagori, Jalpesh Chaudhary: Ubject Subject Code Class ECH UTO R O O OF ECT113314Noch keine Bewertungen

- Manufacturing Processes - IDokument2 SeitenManufacturing Processes - Isameer_m_daniNoch keine Bewertungen

- Production Processes and MetrologyDokument3 SeitenProduction Processes and MetrologymaheshNoch keine Bewertungen

- Course Syllabus Manufacturing Processes (1) Metal CuttingDokument4 SeitenCourse Syllabus Manufacturing Processes (1) Metal CuttingG. Dancer GhNoch keine Bewertungen

- Syllabus Man Pro IIDokument1 SeiteSyllabus Man Pro IISukhamMichaelNoch keine Bewertungen

- Syllabus Man Pro IIDokument1 SeiteSyllabus Man Pro IIVishwas DivseNoch keine Bewertungen

- Me 6702 MechatronicsDokument4 SeitenMe 6702 MechatronicsRAJANoch keine Bewertungen

- Grinding Overview: Machinist Grinder Interview Questions and AnswersVon EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNoch keine Bewertungen

- Autos Rejection Formate NazakatDokument4 SeitenAutos Rejection Formate NazakatM ALI RajaNoch keine Bewertungen

- Flammability Testing Servicefor Building MaterialsDokument1 SeiteFlammability Testing Servicefor Building MaterialsHendri WaeNoch keine Bewertungen

- Masonry: Building Weather-Resistant Masonry WallsDokument4 SeitenMasonry: Building Weather-Resistant Masonry WallsghchgNoch keine Bewertungen

- Cathelco: Anode Length 100 8Dokument1 SeiteCathelco: Anode Length 100 8hakkıNoch keine Bewertungen

- Preheating ObjectiveDokument2 SeitenPreheating Objectivehafiz zahariNoch keine Bewertungen

- Ac 800 Series BrochureDokument12 SeitenAc 800 Series BrochureAnung PriyantoNoch keine Bewertungen

- Hugh Donovan, Eight-Year Review of The Full Depth Reclamation Process in The City of EdmontonDokument40 SeitenHugh Donovan, Eight-Year Review of The Full Depth Reclamation Process in The City of Edmontoneye2iNoch keine Bewertungen

- 1Dokument14 Seiten1bk100% (2)

- The Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyDokument6 SeitenThe Behaviour of Concrete by Partial Replacement of Fine Aggregate With Copper Slag and Cement With GGBS - An Experimental StudyIOSRjournalNoch keine Bewertungen

- 97 724Dokument2 Seiten97 724Syawaluddin Fitri AwangNoch keine Bewertungen

- Apec Steel Structures CatalogDokument24 SeitenApec Steel Structures CatalogJohn TreffNoch keine Bewertungen

- Ayvaz EN 14800 Dogalgaz Baglanti Hortumlari ENGDokument4 SeitenAyvaz EN 14800 Dogalgaz Baglanti Hortumlari ENGandy131078Noch keine Bewertungen

- Astm A394Dokument6 SeitenAstm A394MaxNoch keine Bewertungen

- Chemrite - 520Dokument2 SeitenChemrite - 520ICPL-RWPNoch keine Bewertungen

- Is 6051 1970Dokument15 SeitenIs 6051 1970harshal161987100% (1)

- W Stacbond Metallic Colors STB TMC 102Dokument2 SeitenW Stacbond Metallic Colors STB TMC 102Reona VulpeNoch keine Bewertungen

- Electrical Symbols: General Notes and SpecificationsDokument1 SeiteElectrical Symbols: General Notes and SpecificationsRolly Marc G. SoteloNoch keine Bewertungen

- Facade GuidenceDokument83 SeitenFacade GuidencebrunoNoch keine Bewertungen

- 8 SemDokument22 Seiten8 SemHarsh ShahNoch keine Bewertungen

- Classification of Cracks - Nature Wise, Width Wise & Shape WiseDokument13 SeitenClassification of Cracks - Nature Wise, Width Wise & Shape WiseYolanda Leah UrbanoNoch keine Bewertungen

- Pulley Lagging PDFDokument2 SeitenPulley Lagging PDFSanatha AgungNoch keine Bewertungen

- Sika Carbodur S Pds enDokument5 SeitenSika Carbodur S Pds enHarnawan Satya W ArsitekNoch keine Bewertungen

- DS-EN 1996-1-1 DK NA-2013 Part 1-1 General Rules For Reinforced and Unreinforced Masonry StructuresDokument15 SeitenDS-EN 1996-1-1 DK NA-2013 Part 1-1 General Rules For Reinforced and Unreinforced Masonry StructuresPatrik AlfredssonNoch keine Bewertungen