Beruflich Dokumente

Kultur Dokumente

API 1104 Spec. Summary

Hochgeladen von

johnson0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten1 Seiteapi 1104 summary

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenapi 1104 summary

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten1 SeiteAPI 1104 Spec. Summary

Hochgeladen von

johnsonapi 1104 summary

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

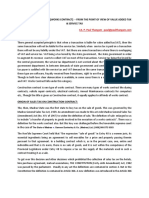

API 1104

ACCEPTANCE STANDARDS FOR NON-DESTRUCTIVE TESTING (SECTION 9)

SECTION DESCRIPTIONS UNACCEPTABLE WHEN

9.3.1 Inadequate Penetration (IP) a. Length of individual indication > 1” (25mm)

b. Aggregate length > 1” (25mm) per 12” (300mm) weld

c. Aggregate length > 8% for weld < 12” (300mm) in length

9.3.2 Inadequate Penetration Due a. Length of individual indication > 2” (50mm)

to High-Low (IPD) b. Aggregate length > 3” (75mm) per 12” (300mm) weld

9.3.3 Inadequate Cross a. Length of individual indication > 2” (50mm)

Penetration (ICP) b. Aggregate length > 2” (50mm) per 12” (300mm) weld

9.3.4 Incomplete Fusion – Open a. Length of individual indication > 1” (25mm)

to Surface (IF) b. Aggregate length > 1” (25mm) per 12” (300mm) weld

c. Aggregate length > 8% for weld < 12” (300mm) in length

9.3.5 Incomplete Fusion Due to a. Length of each indication > 2” (50mm)

Cold Lap – Not Open to b. Aggregate length > 2” (50mm) per 12” (300mm) weld

Surface (IFD) c. Aggregate length > 8% of weld length

9.3.6 Internal Concavity (IC) a. Density exceed base metal; refer to Burn Through for acceptance

9.3.7 Burn Through (BT) For Pipe O/D 2.375” (60.3mm)

9.3.7.2 a. Density > Base metal; ¼” (6mm) maximum dimension

b. Density > Base metal; Dimension > thinner wall thickness

c. Density > Base metal; Aggregate length > ½” (13mm) per 12” (300mm) weld or

total weld

9.3.7.3 For Pipe O/D < 2.375” (60.3mm)

a. Density > Base metal; ¼” (6mm) maximum dimension

b. Density > Base metal; Dimension > thinner wall thickness

c. Density > Base metal; > 1 indication

9.3.8 Slag Indication (ISI/ESI) For Pipe O/D 2.375” (60.3mm)

9.3.8.2 a. ESI > 2” (50mm) - Wagon Tracks; width > 1/32” (0.8mm) is considered as

separate indications

b. Aggregate length > 2” (50mm) per 12” (300mm) weld

c. Width of ESI > 1/16” (1.6mm)

d. Aggregate length ISI > ½” (13mm) per 12” (300mm) weld

e. Width of ISI > 1/8” (3mm)

f. > 4 ISI with maximum width 1/8” (3mm) per 12” (300mm) weld

g. Aggregate length of ESI and ISI > 8% of weld length

9.3.8.3 For Pipe O/D < 2.375” (60.3mm)

a. ESI > 3X thinnest wall thickness

b. Width of ESI > 1/16” (1.6mm)

c. Aggregate length ISI > 2X thinnest wall thickness and width ½ thinnest wall

thickness

d. Aggregate length of ESI and ISI > 8% of weld length

9.3.9 Porosity

9.3.9.2 Individual or Scattered (P) a. Individual pore > 1/8” (3mm)

b. Individual pore > 25% of thinner wall thickness

c. Distribution > Figure 19 or 20

9.3.9.3 Cluster Porosity (CP) As 9.3.9.2 except for finish pass

a. Diameter of cluster > ½” (13mm)

b. Aggregate length > ½” (13mm) per 12” (300mm) weld

c. Individual pore within cluster > 1/16” (2mm)

9.3.9.4 Hollow Bead (HB) a. Length of individual indication > ½” (13mm)

b. Aggregate length > 2” (50mm) per 12” (300mm) weld

c. Individual HB > ¼” (6mm) length and < 2” (50mm) separation

d. Aggregate Length > 8% of weld length

9.3.10 Cracks (C) a. Is not a shallow crater or star crack

b. Shallow crater or star crack > 5/32” (4mm)

9.3.11 Undercutting (EU/IU) a. Aggregate length of EU & IU combination > 2” (50mm) per 12” (300mm) weld

b. Aggregate length of EU & IU combination > 1/6 of weld length

9.3.12 Accumulation of Excluding Incomplete Penetration due to High-Low and Undercutting

Discontinuities a. Aggregate length > 2” (50mm) per 12” (300mm) weld length

b. Aggregate length > 8% of weld length

9.3.13 Pipe or Fitting Arc burn, long seam discontinuities and other discontinuities detected by

Discontinuities radiographic testing shall be reported to the client

Prepared by :OPI

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Valve InspectionDokument6 SeitenValve Inspectionrosid_alhusnaNoch keine Bewertungen

- Inspection of Storage Tank API - 650Dokument4 SeitenInspection of Storage Tank API - 650Michael Albuquerque0% (1)

- Construction Contracts Works Contract From The Point of View of Value Added Tax Service TaxDokument6 SeitenConstruction Contracts Works Contract From The Point of View of Value Added Tax Service TaxjohnsonNoch keine Bewertungen

- CSWIP 3.1 Question and AnswerDokument31 SeitenCSWIP 3.1 Question and AnswerDevendran Marappan92% (52)

- SISGuide WPS & PQTDokument11 SeitenSISGuide WPS & PQTjohnsonNoch keine Bewertungen

- LIFTING GearsDokument1 SeiteLIFTING GearsjohnsonNoch keine Bewertungen

- PiggingDokument47 SeitenPiggingMohamed Adam100% (6)

- Whom So Ever It May ConcernDokument1 SeiteWhom So Ever It May ConcernjohnsonNoch keine Bewertungen

- Partnership Deed FormatDokument4 SeitenPartnership Deed FormatPranathi DivakarNoch keine Bewertungen

- Partnership Deed FormatDokument4 SeitenPartnership Deed FormatPranathi DivakarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 510 Closed Exam ADokument24 Seiten510 Closed Exam AAPINoch keine Bewertungen

- Integrity of Structural Steel After Exposure To Fire PDFDokument13 SeitenIntegrity of Structural Steel After Exposure To Fire PDFSevrinNoch keine Bewertungen

- Chem 136-LAB CDokument3 SeitenChem 136-LAB Csidro12371% (7)

- Abs Approved Steel Mills PDFDokument129 SeitenAbs Approved Steel Mills PDFravmansion100% (1)

- Presentation Asme Sec-Ix Wps PQR Wpq..Dokument176 SeitenPresentation Asme Sec-Ix Wps PQR Wpq..Utkarsh GautamNoch keine Bewertungen

- A1020A1020M-02 (2012) Standard Specification For SteeDokument4 SeitenA1020A1020M-02 (2012) Standard Specification For SteeRony YudaNoch keine Bewertungen

- Bhushan Traders - Delhi - Steel & Stainless Steel Manufacturers and SuppliersDokument3 SeitenBhushan Traders - Delhi - Steel & Stainless Steel Manufacturers and Suppliersbiswasdipankar05Noch keine Bewertungen

- Cathodic Protection Explained - CathwellDokument4 SeitenCathodic Protection Explained - Cathwellreninbabaski100% (1)

- Chemistry and Industrial RevolutionDokument4 SeitenChemistry and Industrial Revolutioncantutr50% (2)

- Master AlloysDokument8 SeitenMaster AlloysAsif AliNoch keine Bewertungen

- Akasison Siphonic Drainage: About ComponentsDokument1 SeiteAkasison Siphonic Drainage: About ComponentsebsboliviaNoch keine Bewertungen

- s355j2 Typical DefectsDokument19 Seitens355j2 Typical DefectsMada Teto100% (1)

- E 307-15Dokument2 SeitenE 307-15Ahmed Abdel NabiNoch keine Bewertungen

- Hydro FormingDokument17 SeitenHydro FormingvengadeshNoch keine Bewertungen

- Manufacturing Technology (ME361) - Lecture 5: Instructor: Shantanu BhattacharyaDokument22 SeitenManufacturing Technology (ME361) - Lecture 5: Instructor: Shantanu BhattacharyaSahil SundaNoch keine Bewertungen

- DV462S1 5-EnDokument1 SeiteDV462S1 5-EnchemibermudezNoch keine Bewertungen

- A Guide To Surface Engineering TerminologyDokument195 SeitenA Guide To Surface Engineering Terminologyhaptooor100% (1)

- Hexagon Head Plug: Length of Thread Screwed Into FittingDokument1 SeiteHexagon Head Plug: Length of Thread Screwed Into FittingEdward Jr ChapetonNoch keine Bewertungen

- Production RangeDokument20 SeitenProduction RangeSharad ShahNoch keine Bewertungen

- Understanding Magnesium Heat TreatmentDokument2 SeitenUnderstanding Magnesium Heat Treatmentmp87_ingNoch keine Bewertungen

- Astm G 67 - 04 - Rzy3Dokument3 SeitenAstm G 67 - 04 - Rzy3Samuel EduardoNoch keine Bewertungen

- AReviewof Cylindrical Grinding ProcessDokument12 SeitenAReviewof Cylindrical Grinding ProcessSardar HamzaNoch keine Bewertungen

- Toilet and Bath Accessories - MSTDokument7 SeitenToilet and Bath Accessories - MSTwafikmh4Noch keine Bewertungen

- Common Fastener Related Abbreviations: Abbreviation MeaningDokument3 SeitenCommon Fastener Related Abbreviations: Abbreviation MeaningezhiljananiNoch keine Bewertungen

- TDW C-Pro Series White PaperDokument8 SeitenTDW C-Pro Series White PaperSujay SarkarNoch keine Bewertungen

- THERMIT-Presentasi Lengkap Thermit-Oxy LanceDokument14 SeitenTHERMIT-Presentasi Lengkap Thermit-Oxy LanceFirdaus AdenNoch keine Bewertungen

- Detecting Transformation From Delta Ferrite To Sigma Phase in SsDokument9 SeitenDetecting Transformation From Delta Ferrite To Sigma Phase in SsAndrea CalderaNoch keine Bewertungen

- © Ncert Not To Be Republished: A I E, A N M MDokument10 Seiten© Ncert Not To Be Republished: A I E, A N M MbnkjayaNoch keine Bewertungen

- Welding Consumables Product Catalogue 09 10Dokument698 SeitenWelding Consumables Product Catalogue 09 10stkm100% (2)

- Cable Tray Catalogue Web PDFDokument64 SeitenCable Tray Catalogue Web PDFimranNoch keine Bewertungen