Beruflich Dokumente

Kultur Dokumente

Modeling and Optimization of Brazing For Aa 6061/ Aisi 304lusing Grey Relational Analysis

Hochgeladen von

IAEME PUBLICATIONOriginaltitel

Copyright

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Modeling and Optimization of Brazing For Aa 6061/ Aisi 304lusing Grey Relational Analysis

Hochgeladen von

IAEME PUBLICATIONCopyright:

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 01, January 2019, pp. 107–118, Article ID: IJMET_10_01_011

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=1

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

MODELING AND OPTIMIZATION OF BRAZING

FOR AA 6061/ AISI 304LUSING GREY

RELATIONAL ANALYSIS

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M.

College of Materials Engineering, Babylon University

ABSTRACT

In this paper, joining of aluminum alloy 6061 as annealed and austenitic stainless

steel AISI 304L was carried out by furnace brazing at (620 and under protection of

argon gas. Lap joints of AA 6061/AISI 304L were investigated with AlSi12, and

AlSi10Cu4 filler alloys in form of paste using different brazing times (5, 10, 15, and 20

min). The optimum shear strength of the joint reached to (3.36 KN) at (10 min) using

AlSi12 filler alloy. While, the maximum shear strength of the joint with AlSi10Cu4

filler alloy reached to (2.59 KN) at (15 min). In addition, microhardness of the

interfacial layer of the joint with filler AlSi10Cu4 was higher than the microhardness

value of the interfacial layer of the joint with AlSi12 filler alloy at the same brazing

conditions. For each filler, at brazing time (5 min), lap joints were weak with

minimum shear strength. Finally, the corrosion behavior of brazing joints in 3.5%

NaCl was studied to evaluate the rate of corrosion for brazing joints. The minimum

corrosion rate is achieved (0.005209mpy) (1.68 by (10 min) using AlSi12 filler

alloy. Grey relational analysis (GRA) based on Taguchi method was applied using

two factors, brazing time (T) and filler type (F) with four levels. The results showed

that the variation of brazing time is the most affective parameter on the shear force,

corrosion rate, and microhardness of the interfacial reaction layer. While, the type of

filler alloy is slightly affective on the output response. In addition, these results

manifested that the Taguchi based grey relational approach improves the properties

of the output response of the joined AA 6061 and AISI 304L.

Key words: AA6061, AISI 304L, Filler alloys, brazing, Taguchi method, GRA,

Interfacial reaction layer, Corrosion rate.

Cite this Article: Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad

M, Modeling and Optimization of Brazing for AA 6061/ AISI 304Lusing Grey

Relational Analysis, International Journal of Mechanical Engineering and

Technology 10(1), 2019, pp. 107–118.

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=10&IType=1

1. INTRODUCTION

The need for joints of aluminum alloy and stainless steel has highly increased in a wide range

of industrial applications due to weight reduction and energy saving. The difficulties of

http://www.iaeme.com/IJMET/index.asp 107 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

dissimilar metals joining return into the high differences in thermophysical properties between

them as well the easy formation of intermetallic compound at high temperature, which effects

on the mechanical properties of the joints. L. Peng et al. [1]. reported that the brazing metal

consists of (Al, Fe, Si), -Al (Si) and Al of the joint AA1060/AISI 304 by vacuum brazing

technology method using Al-Si filler alloy. J. Yang et al. [2] found that the interface between

the braze seam and the stainless steel contains Fe4Al13 IMC layer of the joint

AA6061/AISI304 using filler alloy of Zn-15Al-xZr.

To achieve a highly qualified joint between aluminum and stainless steel, various welding

processes were investigated. R. Qiu et al. [3] conducted resistance spot welding with a cover

plate of AA5052 to austenitic stainless steel, where reaction products of the joint contain

Fe2Al5 and FeAl3. E. Taban et. al. [4] successfully joined aluminum alloy 6061 to AISI 1018

steel that was investigated with friction stir welding. Intermetallic compounds (IMC s)

appeared, including FeAl and Fe2Al5 in the interfacial reaction layer. C. Dharmendra et al. [5]

suggested the laser welding- brazing process to join zinc coated steel (DP600) with aluminum

alloy (AA6061) using filler wire Zn85-Al15 and various thicknesses of IMC with a difference

in heat input.

S. H. Al- shafaie and S. B. Al-ghazaly [6] investigated improving properties of output

response (elongation, yield stress, and ultimate tensile strength) of welded Al 6061 and Al

7075 aluminum alloy by friction stir welding. K. D. Dwivedi and A. Srivastava [7] found that

Taguchis parameters design approach allows for improving the quality for the joint stainless

steel 304 and C-25 carbon steel using a metal inert gas welding. By Taguchi design, it was

found that the wire feed rate is the first parameter that has the highest effect on the hardness

then current and voltage parameters.

In this paper, a Taguchi method is applied to conduct the experiments and a Grey

Relational Analysis approach is used for development of a second–order polynomial model

and optimize of corrosion rate, shear force and hardness of layer with the time and filler as

input parameters.

2. EXPERIMENTAL WORK

AA 6061 and AISI 304L sheets with dimensions (60x18x1mm) are chosen to produce

dissimilar joints by the brazing process. Two filler alloys AlSi12 and AlSi10Cu4 are applied

as a paste form. The chemical compositions of base alloys and filler alloys are listed in

Table1.

Table 1 Chemical composition of alloys (wt %) [8][9][10]

Alloy % C Cr Si Mn P Mo Ni Al Cu Fe Mg Ti Zn

0.02 ˗ ˗ ˗

AISI304L 18.93 0.41 1.42 0.055 0.053 7.85 0.001 0.164 Bal

5

AISI304L ≤

18-20 ≤ 1.00 ≤ 2.00 ≤ 0.045 - 8-11 - - Bal

(Standard)[8] 0.03

AA6061 ˗ 0.11 0.91 0.23 ˗ ˗ 0.06 96.78 0.14 0.57 0.99 0.12 0.08

AA 6061 0.04- 0.15%

0.4-0.8 96 0.15-0.4 0.7 0.8-1.2 0.15 0.25

(Standard)[9] 0.35

AlSi12 ˗ ˗ 11.9 0.01 ˗ ˗ ˗ Bal. <0.01 o.14 0.01 <0.01 <0.01

AlSi12

11-13 0.15 Bal. 0.30 0.8 0.01 0.20 0.2

Standard[10]

AlSi10Cu4 ˗ ˗ 10 0.02 ˗ ˗ ˗ Bal. 4 0.7 0.02 0.03 0.05

AlSi10Cu4 9.3-

0.15 Bal. 3.3-4.7 0.8 0.01 0.1-0.2 0.20

Standard[10] 10.7

http://www.iaeme.com/IJMET/index.asp 108 editor@iaeme.com

Modeling and Optimization of Brazing for AA 6061/ AISI 304L using Grey Relational Analysis

Before brazing, the workpieces were cleaned by silicon carbide abrasive paper and

acetone to remove grease or oil. Then, all joints were fixed using a simple fixture of stainless

steel to hold the assembly the pieces as shown Fig. (1). The pieces were produced by furnace

using quartz tube in an argon atmosphere at rate 5 L/min. After the samples preparation was

finished, samples with added fillers were heated to 620 for a variable holding times and

finally cooled by furnace.

Figure 1 Fixtures for the joints: (a) for a lap joint: (b) for a small joint.

Based on initial experiments, the independent factors affecting the responses were

identified as: holding time (T) and filler type (F) therefore, the influenced factors and their

levels are tabulated in Table 2.

Table 2 Process parameters and their levels.

Coded/Actual level

parameters Unit

1 2 3 4

Holding time (T) min. 5 10 15 20

Filler type (F) - AlSi12 AlSi10Cu4 ---- ----

After brazing, a typical cross- section of the joint was cut and mounted in self –setting

epoxy resin. Then, course grinding was conducted on the mounted samples starting with

sandpaper up to 2000. After that, polishing was done using diamond solution (0.1-0.3 micron)

for (15 min) and etched with Kellerʼs reagent (5HNO3, 3HCl, 2HF, 200H2O) for 5-7 sec.

The distribution of the microhardness along the cross section of the joint was obtained by

Vickers-microhardness test. Tensile shear test was applied for a joint with (102 mm) in

length. Finally, Tafel test was applied for each joint to determine the current density and

corrosion rate in NaCl solution with different brazing conditions.

3. RESULT AND DISCUSSION

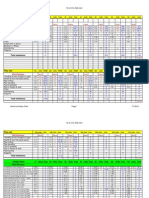

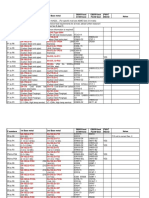

The selected design metrics according to a Taguchi design orthogonal array (OA) are shown

in Table 3. It was the two factor different levels containing 8 sets of actual conditions run

which allowed the assessment of the effects the factors on the Corrosion Rate (CR), Shear

Force (FS), and Hardness of layer (HoL). The value of the output is organized in Table 3.

Table 3 Observed values for performance characteristics.

Exp. T F CR FS HoL

No mpy KN HV

1 1 1 0.0190400 0.9186 98.70

2 1 2 0.0187800 0.8574 113.30

3 2 1 0.0052090 3.3600 262.40

4 2 2 0.0056103 2.2000 297.10

5 3 1 0.0103200 3.0700 360.10

6 3 2 0.0123780 2.5902 372.50

7 4 1 0.0143890 2.3992 393.25

8 4 2 0.0154480 2.0464 401.10

http://www.iaeme.com/IJMET/index.asp 109 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

3.1. Parametric Analysis of Responses

Parametric analysis of each variable on CR, FS and HoL are shown in Fig. 2. It is seen that as

T increases above 5 min the CR of the joint decreases until 10 min, after that the CR of the

joint increases. The minimum CR is achieved (0.005209mpy) (1.68 by (10 min) due to

consider the suitable time to make a good wetting of the filler alloy at the substrate surface by

the capillary reaction. That assists to produce a good joint with the fewest defects and less

thickness of interfacial layer with phases a good corrosion resistance (AlNi3) see fig 3.

While, the T increase to (15, 20 min) led to raise the corrosion resistance rate to (0.01032

and 0.014389 mpy) (3.33 , 4.64 , respectively. This increasing of corrosion rate is due

to the change in the microstructure of the interfacial joint; crack appearance and thickness

growth of the interfacial layer which contains (IMCs) see fig. 4.

A Main Effects Plot for CR B Main Effects Plot for Fs C Main Effects Plot for HoL

Data Means Data Means Data Means

T F T F T F

0.0200 3.0 400

0.0175 350

2.5

0.0150 300

Mean of HoL

Mean of CR

Mean of Fs

2.0

0.0125 250

0.0100 1.5 200

0.0075 150

1.0

0.0050 100

1 2 3 4 1 2 1 2 3 4 1 2 1 2 3 4 1 2

Figure 2 Main Effect Plots for A: CR, B: Fs and C: HoL.

Figure 3 Microstructure of AA 6061/AISI 304L

Figure 4 Microstructure for the joint with different filler alloys at different times

In addition, with 5 min T, for both filler alloys AlSi12 and AlSi10Cu4, the CR raised to

(0.01904 mpy) (6.14 and (0.01878 mpy) (11.52 due to the brazing lack time that

isn’t enough to wet on the substrate by the filler alloy. That leads to crack formation and

porosity. These defects at the joint lead to a galvanic corrosion because of the variation in the

concentration of elements at the interfacial layer, see fig5 .

http://www.iaeme.com/IJMET/index.asp 110 editor@iaeme.com

Modeling and Optimization of Brazing for AA 6061/ AISI 304L using Grey Relational Analysis

Figure 5 The microstructure for the interfacial joint at 5 min (SEM)

Type of the filler (F) affected on the rate of corrosion through using AlSi12 that improved

the resistance of corrosion due to the presence of (4%Cu) in filler alloy that leads to the

growth of the reaction layer [11].

In addition it is seen that as T increases above 5 min the Fs and HoL of brazing AA6061

and 304L increases. While as T increases above 10 min the Fs decreases but the HoL

increases of the joint.

For both filler alloy, when the time of brazing joint increases above 10 min , the Fs of

brazing joint AA6061/ 304L decreases due to the growth of the interfacial layer thickness,

which consists of the intermetallic compounds, Roulin et. al. (1999) found the maximum of

the shear strength joint is (21 MPa) after (10min) brazing time at the brazing temperature

(600 during brazing of aluminum /stainless steel joints using eutectic brazing alloy Al-Si

with different brazing times (5, 10, 20, 40, 60 min )by furnace process [12].

For each brazing time, the Fs of the joint tends to decrease with the filler alloy AlSi10Cu4

due to the 4%Cu in the filler alloy leads to the growth occurrence in the interfacial layer, this

agreement with the present study, Dong et.al. (2012) obtained that the thickness of the

interfacial layer for a joint with AlSi12 less than the thickness of it for the joint with

AlSi10Cu4 [11], see fig. 6.

Figure 6 The effect of brazing time on the thickness of interfacial layer of the joint for both filler

alloys (SEM)

For less than (10 min), at (5 min), the Fs value for the brazing joint reduced due to the

lack of time that is required for a complete wetting between the braze alloy and the base alloy

that led to the deboned of contact area between the faying surfaces.

When the time increases above 10 min, the average hardness of the interfacial layer

increases due to the growth of the interfacial layer with IMCs hardened layer by increasing the

diffusion rate, see fig7.

http://www.iaeme.com/IJMET/index.asp 111 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

Figure 7 Microstructure of AA 6061/AISI 304L with the different brazing times (SEM) using AlSi12

filler alloy

At the brazing time (5 min), the hardness of the interfacial reaction of the joint is

minimum due to the lack of time that is required for a complete wetting between the braze

alloy and the base that led to to the occurrence deboned.

Besides that, the use of AlSi12 filler alloy led to a fall in the hardness compared with the

using AlSi10Cu4 due to the presence Cu may be distributed in the grain boundaries to form

Al2Cu a brittle intermetallic compound [13,14].

Equations 1 -3 shown below are the predicted regression models for calculating output

(corrosion rate, shear force and hardness of layer). Equations of output are developed with

95% confidence levels.

CR = 0.036376 ˗ 0.022783 T ˗ 0.000589 F + 0.004267 T2 + 0.000561 T×F.…......... (1)

2

Fs = ˗ 1.26032 + 3.55876 T ˗ 0.46480 F ˗ 0.62482 T ˗ 0.01946 T×F......................... (2)

2

HoL= -173.344 + 280.984 T + 28.025 F -35.719 T -4.255 T×F................................. (3)

3.2. Checking the sufficiency of the model

The adequacy of the models so developed is then tested by using the analysis of variance

technique (ANOVA). Using this technique, it can be noted that, as illustrated in Table 4, all

the quadratic regression models significant (0 < p-value < 0.05), except F for all outputs (p-

value > 0.05) and thus all the models adequately represent the experimental data.

Table 4 ANOVA Table for output.

Source DF Seq SS Adj SS Adj MS F P

For CR

T 3 0.000197 0.000197 0.000066 134.34 0.001

F 1 0.000001 0.000001 0.000001 2.72 0.198

Residual Error 3 0.000001 0.000001 0.000000

Total 7 0.000200

For Fs

T 3 4.9075 4.9075 1.6358 15.11 0.026

F 1 0.5273 0.5273 0.5273 4.87 0.114

Residual Error 3 0.3247 0.3247 0.1082

Total 7 5.7595

For HoL

T 3 92174 92779 92174.4 43.82 0.001

F 1 605 605 604.7 0.29 0.615

Residual Error 3 10518 10518 2103.5

Total 7 103297

Another criterion that is commonly used to illustrate the adequacy of a predicted

regression model is the coefficient of determination (R2). For the models, the calculated R2

values is 94.40%, 99.3% and 89.82 % for Cr, Fs and HoL respectively as shown in Table 5.

These values indicate that the regression models are quite adequate. The validity of regression

http://www.iaeme.com/IJMET/index.asp 112 editor@iaeme.com

Modeling and Optimization of Brazing for AA 6061/ AISI 304L using Grey Relational Analysis

models developed is further tested by drawing scatter diagrams. Typical scatter diagrams for

all the models are presented in fig.8. The observed values and predicted values of the

responses are scattered close to the 45° line, indicating an almost perfect fit of the developed

empirical models.

Table 5 R2 Test for CR, Fs and HoL regression model.

Response R2 value Remarks

CR 94.40 % Adequate

Fs 99.30 % Adequate

HoL 89.82 % Adequate

A Scatterplot of Estimated1 vs Corrosion Rate. B Scatterplot of Estimated vs Shear Force. C Scatterplot of Estimated vs Hardness (HV)

3.5

0.018 400

Predicted value of corrosion Rate (mpy)

Predicted value of shear Force (KN)

Predicted value of Hardness (HV)

3.0 350

0.016

0.014 2.5 300

250

0.012 2.0

200

0.010 1.5

150

0.008 1.0

100

0.006

0.0050 0.0075 0.0100 0.0125 0.0150 0.0175 0.0200 1.0 1.5 2.0 2.5 3.0 3.5 100 150 200 250 300 350 400

Estimated value of corrosion Rate (mpy) Estimated value of shear Force (KN) Estimated value of Hardness (HV)

Figure 8 Scatter diagram of the A: CR, B: Fs and C: HoL.

3.3. Determination of Optimal Process Parameters in Grey Relation Analysis

GRA

In this section, the use of the Taguchi design orthogonal array (OA) with the grey relation

analysis (GRA) for determining the optimal process parameters is reported step by step.

3.3.1. Data Pre-Processing

In GRA, data pre-processing is required since the range and unit in one data sequence may

differ from the others. Data pre-processing is also necessary when the sequence scatter range

is too large, or when the directions of the target in the sequence are different. Data pre-

processing is a process of transferring the original sequence to a comparable sequence. For

this purpose, the experimental results are normalized in the range between zero and one.

Depending on the characteristics of data sequence, there are various methodologies of data

pre-processing available for the GRA.

Response or output can be converted into the comparative series ( according to

equations 4 to 6 for “the larger, the better”, “the smaller, the better” and “values closer to the

optimal value of response are better” characteristics respectively.

( (

( (

( (

( (

( (

( (

| ( ( |

( (

( (

where, ( and xi (k) are the sequence after the data preprocessing and comparability

sequence respectively, min xi (k) is the smallest value of xi (k) for the kth response, and max

Xi(k) is the largest value of Xi(k) for the kth response, k=1 and 2 for corrosion rate, shear force

and hardness of layer; i=1, 2, 3…, 8 for experiment numbers 1 to 8.

http://www.iaeme.com/IJMET/index.asp 113 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

Table 6 shows the normalized results for corrosion rate, shear force and hardness of layer,

where corrosion rate for the smaller the better, shear force for the larger the better, and

hardness of layer for values closer to the optimal value of response are better.

All the sequences of each performance characteristic after data preprocessing using

Equation 4-6 are presented in Table 6.

Table 6 The sequences of each performance characteristic after data processing.

Exp. No CR Fs HoL

Reference 1.000000 1.000000 1.000000

sequence

1 0.000000 0.024455 1.657290

2 0.018798 0.000000 1.529000

3 1.000000 1.000000 0.218800

4 0.970985 0.536482 0.086116

5 0.630468 0.884121 0.639719

6 0.481672 0.692400 0.748682

7 0.336274 0.616079 0.931019

8 0.259706 0.475106 1.000000

Now, ∆0i(k) is the deviation sequence of the reference sequence ( and the

comparability sequence ( , i.e.

( | ( ( | (

Using Eq. 7 the deviation sequence ∆0i can be computed and the results are clear in Table 7.

Table 7 The deviation sequences

Deviation

∆0i (1) ∆0i (2) ∆0i (3)

sequences

Expt. No. 01 1.000000 0.975545 0.657290

Expt. No. 02 0.981202 1.000000 0.529000

Expt. No. 03 0.000000 0.000000 0.781200

Expt. No. 04 0.029015 0.463518 0.913884

Expt. No. 05 0.369532 0.115879 0.360281

Expt. No. 06 0.518328 0.307600 0.251318

Expt. No. 07 0.663726 0.383921 0.068981

Expt. No. 08 0.740294 0.524894 0.000000

3.3.2. The Grey Relational Coefficient and the Grey Relational Grade

After data pre-processing is performed, GRC is computed from the normalized data to

establish a relationship between the preferred and actual data. The GRC is known as follows:

( (

(

The distinguishing or identification coefficient ,ξ, has been used to compensate for the

effect of the data series and is defined between zero to one. The value of ξ has been taken

equal to 0.5. The GRC for each experiment OA is shown in Table 8.

Table 8 Grey relational grade and its order in the optimization. After get the GRC, the

GRG is calculated by averaging the GRC corresponding to every response. The overall

evaluation of the multiple responses (output) is based on the GRG, that is:

http://www.iaeme.com/IJMET/index.asp 114 editor@iaeme.com

Modeling and Optimization of Brazing for AA 6061/ AISI 304L using Grey Relational Analysis

∑ ( (

Where γi the GRG for the ith experiment and n is the number of output or responses. Table

8 shows the grey relational grade for each experiment using L8 OA. The higher grey

relational grade represents that the corresponding experimental result is closer to the ideally

normalized value. Experiment 3 has the best multiple performance characteristics among

eight experiments because it has the highest grey relational grade. It can be seen that in the

present study, the optimization of the complicated multiple performance characteristics of

brazing of AISI 304L and AA 6061 has been converted into optimization of a grey relational

grade.

Since the experimental design is orthogonal, it is then possible to separate out the effect of

each process parameter on the grey relational grade at different levels. For example, the mean

of the grey relational grade for the time at levels 1 and 2 can be calculated by averaging the

grey relational grade for the experiments (1 and 2) and (3 and 4) and (5 and 6) and (7 and 8)

respectively as shown in Table 8.

Table 8 Response table for the grey relational grade.

Grey relational coefficient Grey relational grade

Expt. ξi (1) ξi (2) ξi (3) Rank

γi = (ξ i (1) +ξ i (2) +ξ i (3))

No. CR Fs HoL

01 0.338858 0.333333 0.410096 0.360762 8

02 0.333333 0.337564 0.463457 0.378118 7

03 1 1 0.369055 0.789685 1

04 0.518932 0.945153 0.333333 0.599139 5

05 0.811848 0.575022 0.55914 0.64867 2

06 0.619118 0.491001 0.645161 0.585093 6

07 0.565661 0.429654 0.868838 0.621384 4

08 0.487855 0.403130 1 0.630328 3

The mean of the grey relational grade for each level of the other process parameters,

namely, filler can be computed in the same manner. The mean of the grey relational grade for

each level of the process parameters is summarized and shown in Table 9. In addition, the

total mean of the grey relational grade for the eight experiments is also calculated and

presented in Table 9.

Table 9 Response table for the grey relational grade.

Process Grey relational grade

Main effect

Symbol parameter Level 4 Rank

Level 1 Level 2 Level 3 (max-min)

s

A T 0.36944 0.694412* 0.616882 0.625856 0.324972 1

*

B F 0.605125 0.54817 ----- ----- 0.056955 2

The total mean value of the grey relational grade γm= 0.576647

* Levels for optimum grey relational grade

Fig.9 shows the grey relational grade obtained for different process parameters. The mean

of grey relational grade for each parameter is shown by horizontal line. Basically, the larger

the grey relation grade is, the closer will be the product quality to the ideal value. Thus, larger

grey relational grade is desired for optimum performance. Therefore, the optimal parameters

setting for lesser corrosion rate, better shear force and nominal hardness of layer are (A2B1) as

http://www.iaeme.com/IJMET/index.asp 115 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

presented in Table 9. Optimal level of the process parameters is the level with the highest grey

relational grade.

Main Effects Plot for Means

Data Means

T (min.) F

0.70

0.65

0.60

Mean of Means

0.55

0.50

0.45

0.40

0.35

1 2 3 4 1 2

Figure 9 Effect of process parameters on the multi-performance characteristics.

Furthermore, ANOVA has been performed on grey relational grade to obtain contribution

of each process parameter affecting the process characteristics jointly and is discussed in the

forthcoming section.

3.3.3. Analysis of Variance for GRG

ANOVA for grey relational grade is presented in Table10. Percentage contributions for each

term affecting grey relational grade are shown in fig.10. The figure clearly shows that time is

the dominant parameter that affects grey relational grade and hence contributes in reducing

corrosion rate improving shear force nominal hardness of layer.

Table 10: ANOVA of grey relational grade.

Percentage

Source DF Seq SS MS F

contribution()

T 3 0.121687 0.040562 8.77 85.6631

F 1 0.006488 0.006488 1.40 4.567309

Error 3 0.013878 0.004626 - 9.769593

Total 7 0.142053 - 100.00000

Figure 10 Percentage contributions of factors on the grey relational grade.

Based on the above discussion, the optimal process parameters are time at level 2, and

filler at level 1 It can be seen from fig.10 that time is the most significant factor that affects

the grey relational grade followed by filler.

3.3.4. Confirmation test

Confirmation test has been carried out to verify the improvement of performance

characteristics in brazing of AA 6061/AISI 304L. The optimum parameters are selected for

the confirmation test as presented in Table 11. The estimated grey relational grade ̂ using the

optimal level of the process parameters can be calculated using following equation.

̂ ∑( (

http://www.iaeme.com/IJMET/index.asp 116 editor@iaeme.com

Modeling and Optimization of Brazing for AA 6061/ AISI 304L using Grey Relational Analysis

where is the total mean of the grey relational grade is the mean of the grey relational

grade at the optimal level, and q is the number of the process parameters that significantly

affect multiple-performance characteristics.

The obtained process parameters, which give higher grey relational grade, are presented in

Table 11. The predicted CR, Fs, HoL and GRG for the optimal process parameters are

obtained using Equation 10 and also presented in Table 11 which shows the comparison of

the experimental results using the initial (A2B1) and optimal (grey theory prediction design,

A2B1) process parameters. Based on Table 11, the CR decreased from 0.0052090 to

0.0043070 mpy, Fs is accelerated from 3.3600 to 4.1400 KN and the HoL remain

approximately constant at (262.40 ≈ 261.94) HV. The corresponding improvements in CR and

Fs are 17.31%, 18.84 %, respectively. It is clearly shown that the multiple performance

characteristics in the process are greatly improved through this study.

Table 11 Improvements in grey relational grade with optimized process parameters.

Optimal process parameters

Condition

Initial process Grey theory

description

parameters Prediction design

Level A2B1 A2B1

CR (mpy) 0.0043070 0.0052090

Fs (KN) 4.1400 3.3600

HoL (HV) 261.94 262.40

GRG 0.710672 0.789685

Improvement in grey relational grade = 0.079013

4. CONCLUSIONS

The shear force of the joint registered an optimum value 3.36KN with AlSi12 at 10 min.

While the maximum shear force of the joint with AlSi10Cu4 reached to 2.59 KN at 15 min.

For the lap joint at (10 min) using AlSi12, the minimum corrosion rate is 0.0052090 mpy.

According to microhardness test, the interfacial layer of the joint with AlSi12 has less

hardness than the hardness of the interfacial layer of joint using AlSi10Cu4.

The optimum value for brazing time 10 min, filler alloy type AlSi12 respectively.

The experiment exhibits the best factors combination and the predicted values were closer to

the observed values.

This approach easily converts the multiple performance characteristics into the GRG, thus

simplifying the analysis.

The results showed that the optimal condition based on the method can offer a better overall

quality.

REFERENCES

[1] Peng Liu, Li Yajiang, Wang Juan, and Guo Jishi (2003) “ Vacuum brazing technology and

microstructure near the interface of Al/18-8 stainless steel”, Materials Research Bulletin,

pp.1493-1499.

[2] Yang Jinlong, Songbai Xue, Peng Xue, Zhaoping Lv, Weimin Long, Guanxing Zhang,

Qingke Zhang, and Peng He (2016) “ Development of Zn-15Al-xZr filler metals for

Brazing 6061 aluminum alloy to stainless steel”, Materials Science and Engineering A,

pp. 425-434.

http://www.iaeme.com/IJMET/index.asp 117 editor@iaeme.com

Ahmed O. Al- Roubaiy, Saad Hameed Al-Shafaie, Wurood Asaad M

[3] Qiu Ranfeng, Chihiro Iwamoto, and Shinobu Satonaka (2008) “ Interfacial microstructure

and strength of steel/aluminum alloy joints welded by resistance spot welding with cover

plate”, Journal of Mterials Processing Technology, pp. 4186-4193.

[4] Taban Emel, Jerry E.Gould, and John C. Lippold (2010) “ Dissimilar friction welding of

606-T6 aluminum and AISI1018 steel: Properties and microstructural characterization”,

Materials and Design, pp. 2305-2311.

[5] Dharmendra C., K.P.Rao, J.Wilden, S.Reich (2011) “ Study on laser welding- brazing of

Zinc coated steel aluminum alloy with a zinc based filler”, Materials Science and

Engineering A, 1497-1503.

[6] Saad Hameed Al-shafaie and Sara bahjet Al-ghazaly (2018) “Optimization of friction stir

welding parameters of Al 6061 and Al 7075 using GRA”,

[7] Kamaleshwar Dhar Dwivedi and Anurag Srivastava ( 2017) “ Parametric Optimization of

MIG Welding for Dissimilar Metals Using Taguchi Design Method” Department of

Mechanical Engineering, S. R. Institute of Management and Technology, A. K. T. U.

Lucknow, Inia, Volume 3.

[8] ASTM Handbook (1989) “Iron and metal products”,vol. 01.01.

[9] ASM Handbook (1990) Properties and Selection: Nonferrous Alloys and Special-Purpose

Materials, American society for Metals, Vol. 2.

[10] Lejeune Road (2007) Specification for Induction Brazing, American Welding Society (

AWS), 2nd ed.

[11] Dong Honggang, Wenjin Hu, Yuping Duan, Xudong Wang, and Chuang Dong (2012) “

Dissimilar metal joining of aluminum alloy to galvanized steel with Al-Si, Al- Cu, Al-Si-

Cu and Zn-Al filler wires”, Journal of Materials Processing Technology, pp. 458-464.

[12] Roulin M., J.W. Luster, G.Karadeniz and A. Mortensen (1999) “Strength and Structure of

Furnace- Brazed Joints between Aluminum and Stainless Steel”, Welding Research

Supplement.

[13] Kadhim Naief Kadhim and Ahmed H. ( Experimental Study Of Magnetization Effect On

Ground Water Properties).Jordan Journal of Civil Engineering, Volume 12, No. 2, 2018

[14] Lin S. B., J.L.Song, C.L. Yang, C.L. Fan, D. W. Zhang (2010) “ Brazability of dissimilar

metals tungsten inert gas butt welding- brazing between aluminum alloy and stainless steel

with Al-Cu filler alloy”, Materials and Design, pp. 2637-2642.

http://www.iaeme.com/IJMET/index.asp 118 editor@iaeme.com

Das könnte Ihnen auch gefallen

- CS Pipe Fab & Erect CostsDokument6 SeitenCS Pipe Fab & Erect Costswally55bear69% (16)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Metallurgy and Corrosion Control in Oil and Gas ProductionVon EverandMetallurgy and Corrosion Control in Oil and Gas ProductionNoch keine Bewertungen

- Dissimilar Metal WeldingDokument37 SeitenDissimilar Metal WeldingAlbar33% (3)

- Gsce ChemistryDokument2 SeitenGsce ChemistryAaravNoch keine Bewertungen

- Microstructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessDokument8 SeitenMicrostructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessretrogradesNoch keine Bewertungen

- A36 PropertiesDokument2 SeitenA36 PropertiesFernando RomeroNoch keine Bewertungen

- Training 1 LF IntroductionDokument14 SeitenTraining 1 LF IntroductionprasenjitsayantanNoch keine Bewertungen

- Davies (1935) - Roman MinesDokument3 SeitenDavies (1935) - Roman MinesGeorge TNoch keine Bewertungen

- P1 To P8Dokument9 SeitenP1 To P8Pat AuffretNoch keine Bewertungen

- Microstructure, Mechanical Properties and Non-Destructive Test On Dissimilar AA5083-AA7075 Aluminium Alloys Using GTAWDokument14 SeitenMicrostructure, Mechanical Properties and Non-Destructive Test On Dissimilar AA5083-AA7075 Aluminium Alloys Using GTAWKalamchety Ravikumar SrinivasaNoch keine Bewertungen

- Comparative Study of Hardfacing of AISI 1020 Steel by Gas Welding and Tig Welding ProcessesDokument5 SeitenComparative Study of Hardfacing of AISI 1020 Steel by Gas Welding and Tig Welding ProcessesRela FaradinaNoch keine Bewertungen

- Hassan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1105 012047Dokument11 SeitenHassan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1105 012047AHMED SAMIR ALEMDARNoch keine Bewertungen

- Influence of Copper and Brass On Tensile Properties of Aluminium Alloy AA6351 Friction Stir WeldsDokument13 SeitenInfluence of Copper and Brass On Tensile Properties of Aluminium Alloy AA6351 Friction Stir WeldsSreeharan Nagamani BNoch keine Bewertungen

- Effect of Tool Pin Profile On FrictDokument6 SeitenEffect of Tool Pin Profile On FrictmanishcguptaNoch keine Bewertungen

- Ultrasonic Welding of Dissimilar Metals, AA6061 and Ti6Al4VDokument6 SeitenUltrasonic Welding of Dissimilar Metals, AA6061 and Ti6Al4Vkaliappan45490Noch keine Bewertungen

- Experimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFDokument7 SeitenExperimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFfaisalNoch keine Bewertungen

- 01-The Effects of Gas Tungsten Arch Welding On The Corrosion and Mechanical Properties of AA 6061 T6Dokument12 Seiten01-The Effects of Gas Tungsten Arch Welding On The Corrosion and Mechanical Properties of AA 6061 T6hamidouNoch keine Bewertungen

- Metals 06 00056Dokument11 SeitenMetals 06 00056THANADOL KAMSRINoch keine Bewertungen

- Experimental Evaluation of Coated Carbide Insert On Alloy of Steel Materials During High Speed Turning ProcessDokument11 SeitenExperimental Evaluation of Coated Carbide Insert On Alloy of Steel Materials During High Speed Turning ProcessAZOJETENoch keine Bewertungen

- Pea - Vol. 14, No 1 - 01. 2017Dokument4 SeitenPea - Vol. 14, No 1 - 01. 2017Lily Camila GalárragaNoch keine Bewertungen

- Qualitative and Quantitative Analysis of Friction Stir Welding of 6111-T4 Alloy Joint With PreheatingDokument12 SeitenQualitative and Quantitative Analysis of Friction Stir Welding of 6111-T4 Alloy Joint With PreheatingTJPRC PublicationsNoch keine Bewertungen

- FATIGA BUENOsivaraj2014Dokument9 SeitenFATIGA BUENOsivaraj2014Taguis VelascoNoch keine Bewertungen

- On Welding Gray Cast Iron Using SMAW and GTAW Process: Articles You May Be Interested inDokument11 SeitenOn Welding Gray Cast Iron Using SMAW and GTAW Process: Articles You May Be Interested inDoty RisantiNoch keine Bewertungen

- SPE-176488-MS Corrosion Assessment of Different Production Casings and Material Selection in Sour Gas WellsDokument9 SeitenSPE-176488-MS Corrosion Assessment of Different Production Casings and Material Selection in Sour Gas WellsLuis David Concha CastilloNoch keine Bewertungen

- Welding Stainless SteelDokument4 SeitenWelding Stainless SteelJohan ZraghozNoch keine Bewertungen

- Alloy 6moDokument2 SeitenAlloy 6moqshaath100% (1)

- Dissimilar Welding of Aa7075 and Aa6063Dokument7 SeitenDissimilar Welding of Aa7075 and Aa6063192016006.sseNoch keine Bewertungen

- 2019 June IJRARDokument8 Seiten2019 June IJRARtarasasankaNoch keine Bewertungen

- Austempered Materials For Powertrain App PDFDokument9 SeitenAustempered Materials For Powertrain App PDFangel expositoNoch keine Bewertungen

- The Effect of Joint Design and Volume Fraction On Friction Welding Properties of A360/Sic (P) CompositesDokument9 SeitenThe Effect of Joint Design and Volume Fraction On Friction Welding Properties of A360/Sic (P) CompositesGaddipati MohankrishnaNoch keine Bewertungen

- Processing and Mechanical Testings of 7075 Al Matrix Composite Reinforced With Al2O3 Nano-Particles Fabricated by Stir Casting RouteDokument12 SeitenProcessing and Mechanical Testings of 7075 Al Matrix Composite Reinforced With Al2O3 Nano-Particles Fabricated by Stir Casting RouteTJPRC PublicationsNoch keine Bewertungen

- 860 876 Ramanchandran - Paper New PDFDokument17 Seiten860 876 Ramanchandran - Paper New PDFSurendar Aravindhan0% (1)

- Fracture Toughness of Recycled AISI 1040 Steel Chip ReinforcedDokument8 SeitenFracture Toughness of Recycled AISI 1040 Steel Chip ReinforcedSharan AnnapuraNoch keine Bewertungen

- Yazid HelalDokument7 SeitenYazid HelalYazid HelalNoch keine Bewertungen

- Microstructure and Residual Stress Distributions in Friction Stir Welding ofDokument9 SeitenMicrostructure and Residual Stress Distributions in Friction Stir Welding ofRaul VelascoNoch keine Bewertungen

- Astm A 29 (1030)Dokument10 SeitenAstm A 29 (1030)Rizki FebriyantoNoch keine Bewertungen

- Investigation of Corrosion Behavior of Low CarbonDokument18 SeitenInvestigation of Corrosion Behavior of Low CarbonHazimNoch keine Bewertungen

- Effect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC CastingsDokument24 SeitenEffect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC Castingskt rajaNoch keine Bewertungen

- 7075 Extrusion PDFDokument6 Seiten7075 Extrusion PDFJoselo HRNoch keine Bewertungen

- Analysis of Stainless Steel Welded JointsDokument4 SeitenAnalysis of Stainless Steel Welded JointsadriansinisaNoch keine Bewertungen

- MgO Based Inclusions in Aluminum Killed SteelsDokument19 SeitenMgO Based Inclusions in Aluminum Killed SteelsEstéfano Aparecido VieiraNoch keine Bewertungen

- Shoebs ProjectDokument20 SeitenShoebs ProjectMehdiNoch keine Bewertungen

- 2nd Review Paper (1111,2222,3333)Dokument8 Seiten2nd Review Paper (1111,2222,3333)SHAIKJAFARNoch keine Bewertungen

- Microstructural and Mechanical Properties of Gravity-Die-Cast A356 Alloy Inoculated With Yttrium and Al-Ti-B Grain Refiner SimultaneouslyDokument6 SeitenMicrostructural and Mechanical Properties of Gravity-Die-Cast A356 Alloy Inoculated With Yttrium and Al-Ti-B Grain Refiner SimultaneouslyNarasimha Murthy InampudiNoch keine Bewertungen

- Prediction of Heat Affected Zone and Effect of Heat Input in GTA Welded Al Alloy 6061Dokument8 SeitenPrediction of Heat Affected Zone and Effect of Heat Input in GTA Welded Al Alloy 6061Bassam AbdelazeemNoch keine Bewertungen

- Mill Scale 2Dokument7 SeitenMill Scale 2viswaprasad005Noch keine Bewertungen

- Examining The Mechanical Properties of High-Strength Steel Weld MetalsDokument7 SeitenExamining The Mechanical Properties of High-Strength Steel Weld MetalszhangjlNoch keine Bewertungen

- Data SAF2205 04Dokument8 SeitenData SAF2205 04il_yoo_1Noch keine Bewertungen

- SUJDokument11 SeitenSUJamit2688Noch keine Bewertungen

- Pei 2020Dokument6 SeitenPei 2020Marco A. R. JimenesNoch keine Bewertungen

- Parametric Analysis and Effect of Tool On FSW Joint of 6082 Al Alloy by Taguchi MethodDokument6 SeitenParametric Analysis and Effect of Tool On FSW Joint of 6082 Al Alloy by Taguchi MethodTJPRC PublicationsNoch keine Bewertungen

- Improving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat TreatmentDokument11 SeitenImproving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat Treatmentפּואַ פּוגאַNoch keine Bewertungen

- Ensaio de CorrosãoDokument9 SeitenEnsaio de CorrosãoLeonardo MartinsNoch keine Bewertungen

- Mechanical Properties and Reinforced Mechanism ofDokument9 SeitenMechanical Properties and Reinforced Mechanism ofnguyentbilienNoch keine Bewertungen

- Stainless Steel AISI Grades For PM ApplicationsDokument16 SeitenStainless Steel AISI Grades For PM ApplicationsAxtronNoch keine Bewertungen

- ISF Aachen Welding Technology Part II PDFDokument140 SeitenISF Aachen Welding Technology Part II PDFscott2355Noch keine Bewertungen

- The Improvement of The Mechanical Properties of AA 6063 Aluminum Alloys Produced by Changing The Continuous Casting ParametersDokument9 SeitenThe Improvement of The Mechanical Properties of AA 6063 Aluminum Alloys Produced by Changing The Continuous Casting Parameterschandika herathNoch keine Bewertungen

- AlSi12Fe MS, Props Under VacuumDokument14 SeitenAlSi12Fe MS, Props Under VacuumRishabh MenonNoch keine Bewertungen

- The Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelDokument8 SeitenThe Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelAnonymous Qha8B2Noch keine Bewertungen

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dokument6 SeitenDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNoch keine Bewertungen

- Evaluation of MechanicalDokument5 SeitenEvaluation of MechanicalPatil HemantNoch keine Bewertungen

- Ijmet 10 01 062Dokument14 SeitenIjmet 10 01 062IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 064Dokument10 SeitenIjmet 10 01 064IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 054Dokument7 SeitenIjmet 10 01 054IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 047Dokument10 SeitenIjmet 10 01 047IAEME PUBLICATION100% (1)

- Ijmet 10 01 050Dokument11 SeitenIjmet 10 01 050IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 039Dokument10 SeitenIjmet 10 01 039IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 034Dokument9 SeitenIjmet 10 01 034IAEME PUBLICATIONNoch keine Bewertungen

- Optimisation of 3D Printing Parameter For Improving Mechanical Strength of Abs Printed PartsDokument6 SeitenOptimisation of 3D Printing Parameter For Improving Mechanical Strength of Abs Printed PartsIAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 031Dokument10 SeitenIjmet 10 01 031IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 041Dokument4 SeitenIjmet 10 01 041IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 013Dokument9 SeitenIjmet 10 01 013IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 018Dokument7 SeitenIjmet 10 01 018IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 001Dokument7 SeitenIjmet 10 01 001IAEME PUBLICATIONNoch keine Bewertungen

- Order Management System With Enterprise Service Bus in Telecommunication IndustryDokument7 SeitenOrder Management System With Enterprise Service Bus in Telecommunication IndustryIAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 008Dokument15 SeitenIjmet 10 01 008IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 009Dokument8 SeitenIjmet 10 01 009IAEME PUBLICATIONNoch keine Bewertungen

- Ijmet 10 01 005Dokument10 SeitenIjmet 10 01 005IAEME PUBLICATIONNoch keine Bewertungen

- SIW Product CatalogDokument88 SeitenSIW Product CatalogSagar GavaneNoch keine Bewertungen

- Lecture 5 Non Ferrous Metals PropertiesDokument20 SeitenLecture 5 Non Ferrous Metals PropertiesAmrit DangNoch keine Bewertungen

- Mild Steel Product Guide 25Dokument25 SeitenMild Steel Product Guide 25shani5573Noch keine Bewertungen

- Aisi A6Dokument1 SeiteAisi A6123vigenNoch keine Bewertungen

- INSTAGDokument3 SeitenINSTAGJeeva Z FedricoNoch keine Bewertungen

- Astm A234 PDFDokument8 SeitenAstm A234 PDFhans30Noch keine Bewertungen

- WPQTDokument10 SeitenWPQTnike_y2kNoch keine Bewertungen

- IPS d-SIGN 98Dokument2 SeitenIPS d-SIGN 98Toma IoanaNoch keine Bewertungen

- Hydrogen Trapping in Heat Treated and Deformed Armco Iron: March 2019Dokument13 SeitenHydrogen Trapping in Heat Treated and Deformed Armco Iron: March 2019PeterJonasNoch keine Bewertungen

- Pre Dispatch ChecklistDokument2 SeitenPre Dispatch ChecklistBhawna100% (1)

- GALVOTEC Aluminium Catalogue (Draft 2020)Dokument18 SeitenGALVOTEC Aluminium Catalogue (Draft 2020)bello imamNoch keine Bewertungen

- Electrode Types: DC Copperclad Pointed ElectrodesDokument1 SeiteElectrode Types: DC Copperclad Pointed Electrodesshah jehan hanifNoch keine Bewertungen

- Sheet Metal Working JournalDokument12 SeitenSheet Metal Working JournalNazif MisnanNoch keine Bewertungen

- Material Selection - SMSDokument38 SeitenMaterial Selection - SMSKong LingweiNoch keine Bewertungen

- Asme Section II A Sa-352 Sa-352mDokument8 SeitenAsme Section II A Sa-352 Sa-352mAnonymous GhPzn1xNoch keine Bewertungen

- Materials Used at NCPLDokument28 SeitenMaterials Used at NCPLkeyur1109Noch keine Bewertungen

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Dokument1 SeiteJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNoch keine Bewertungen

- Tool SteelsDokument31 SeitenTool SteelsMaheswaran MuthuNoch keine Bewertungen

- B253 PDFDokument8 SeitenB253 PDFSky LeeNoch keine Bewertungen

- Gonzalez 21399Dokument11 SeitenGonzalez 21399Yogesh S Yogi SNoch keine Bewertungen

- Welding Electrodes SelectionDokument19 SeitenWelding Electrodes SelectionjerickNoch keine Bewertungen

- 11 (1) 1Dokument24 Seiten11 (1) 1অর্ঘ্য রায়Noch keine Bewertungen

- 5-Hot Tear PDFDokument9 Seiten5-Hot Tear PDFPeeka Prabhakara RaoNoch keine Bewertungen

- Metals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDokument7 SeitenMetals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDianna LambertNoch keine Bewertungen

- Cast Iron Vs Wrought IronDokument7 SeitenCast Iron Vs Wrought IronLahiru Prabhatha AmarasenaNoch keine Bewertungen