Beruflich Dokumente

Kultur Dokumente

Jams, Jellies and Marmalades: Raw Materials

Hochgeladen von

Hafiz Abu BakarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Jams, Jellies and Marmalades: Raw Materials

Hochgeladen von

Hafiz Abu BakarCopyright:

Verfügbare Formate

Jams,

Jellies and Marmalades

CONTENT

G E N E R A L I N F O R M AT I O N 4

R A W M AT E R I A L S 5

G E L AT I O N O F H & F P E C T I N S 11

Pectin 11

Gelling Mechanisms 12

High Methylester Pectins – Gelling Behaviour 17

Low Methylester Pectins – Gelling Behaviour 23

Low Methylester, Amidated Pectins – Gelling Behaviour 28

S Y N E R E S I S B E H AV I O U R 38

T H E S TA N D A R D I Z AT I O N O F H & F P E C T I N S 42

C L A S S I C , C O M B I A N D A M I D P E C T I N S A N D T H E I R A P P L I C AT I O N 50

PRODUCTION METHODS OF JAMS, JELLIES AND MARMALADES 60

G E N E R A L C A L C U L AT I O N S A N D D E S I G N O F F O R M U L AT I O N S 64

F O O D L E G I S L AT I O N 69

2 Low-Calorie Products

Dietetic Products

71

73

3

INDIVIDUALITY IS OUR STRENGTH 74

Jams, Jellies and Marmalades

General Raw

Information Materials

Cooking jams, jellies and marmalades using The quality criteria for jams and marmalades Fresh fruits, for cost as well as seasonal reasons,

fruits, sugar, pectin and edible acids is one of are decisively determined by the flavour, co- are only used in smaller quantities for the

the oldest food preserving processes known to lour and consistency as well as state of preser- manufacture of finished products. Thus, the

mankind and presents a way of making food vation and distribution of fruits. These proper- largest amount of fruits for production purpo-

stable by increasing the content in soluble ties depend to a high degree on the raw mate- ses are either frozen, heated (canned) or pre-

solids. The shelf-life of the products gained by rials used, with special importance given to the served with sulphur dioxide.

this method depends on the following criteria proper selection of suitable fruits. The

as regards their stability to microbial spoilage: characteristic nature of the finished product is The most important quality criteria for fruits

● Perfect hygienic operating conditions, such further determined by the addition of sugars, used are:

as production units, filling and production pectin and edible acids. ● optimal state of ripeness

system. ● full fruity flavour

● Perfect hygienic raw materials and packa- The German Fruit Jams Regulation gives the ● variety-specific colour

ging materials. following definition for the required condition ● no blemishes (no spots, no bruises)

● A high sugar content (min. 60% soluble of the raw materials: ● sufficient consistency (solidity of form)

solids in jams, jellies and marmalades), ● soluble solids content in agreement with

which causes a lowering of the free water Fruits: quality standards

by hydration. Fresh, sound, not spoiled fruit, containing all ● perfect hygienic condition of raw materials

● Sufficient pasteurization or chemical preser- its essential constituents, after cleaning and and packaging

vation of low-calorie fruit spreads, jams, removal of blemishes and sufficiently ripe.

jellies and marmalades (less than 60% solu- Chestnut for the purpose of the regulation is

ble solids). the fruit of the sweet chestnut tree (Castanca Fruit Pulp (pulp):

● A low pH-range (pH 2.6-3.2) when using ● Cooking temperature: sativa). The term ”fruits” is extended for the The edible part of the whole fruit, peeled or

4 high methylester pectins.

● Sufficient cooking time to achieve an inver-

sion and exchange of sugar between the

open system: 90-105°C (194-221°F)

vacuum cooker: 65-80°C (149-176°F).

● Head space sterilization of the glass jar

purpose of the regulation also to:

The edible parts of rhubarb stalks, ginger, e.g.

cored if necessary, which may be whole, sliced

or chopped. 5

medium and fruits (otherwise the forma- after filling. parts of the ginger plant, tomatoes, cucumbers, Fruit Purée (purée):

tion of low-sugar concentration zones may ● Turn the closed glass upside down. melons, water melons, pumpkins, carrots and The edible part of the whole peeled or cored

incur the risk of crystal formation or water ● Capping under vacuum. sweet potatoes. fruit, which has been reduced to purée by

exudation). straining or a similar process.

Stone fruits and kernel fruits are generally pro-

cessed without stones, pits and cores and in

unpeeled condition, citrus fruits are generally

peeled when processed, part of the peels is

requently added.

Jams, Jellies and Marmalades

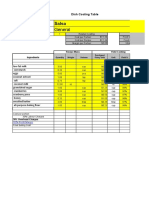

The following table gives a summary of the

average pectin contents as well as contents in

Fruit Juice: ● pH-value and titratable acid: titratable acids and calcium ions and the mean

Products complying with the German Fruit pH and titratable acid are indicators for the pH-range of the most important fruits in jam

Juice Regulation. quantity of organic acids and its salts con- manufacture.

tained in a fruit. Both factors affect gela-

Aqueous Extracts of Fruits: tion. In the production of jams with high

Aqueous extracts of fruits which contain all methylester pectins, the pH-range is usually

Type of fruit 1) 1) + 2) 2) 2)

water-soluble constituents of the fruits except set at about 2.8-3.2 with citric acid, since mgCa2+/100g pectin [%] pH titratable acid [%]

technically unavoidable losses. this pH-range is very favourable in view to apples 7 0.70 3.2-3.5 0.52 (M)

gelation, flavour and shelf-life; sweet cherries 17 0.36 3.4-3.7 1.36 (M)

Citrus Peels (peels): plums 14 0.76 3.1-3.4 2.21 (M)

Cleaned citrus peels with or without endocarp. ● Calcium content: peaches 8 0.54 3.4-3.8 0.62 (M)

Low methylester and amidated pectins gel apricots 16 0.96 3.6-3.8 1.13 (M)

Fruit Constituents: in combination with calcium ions. Thus the strawberries 26 0.81 3.2-3.5 1.11 (C)

In fresh condition, fleshy-juicy fruits consist, as fruit-owned calcium content is of great im- raspberries 40 0.40 3.1-3.6 1.35 (C)

a rule, of 80-85% water. The main constituents, portance. Generally speaking, the insoluble blackberries 44 0.48 3.3-3.6 1.09 (C)

besides water, are carbohydrates, furthermore parts of fruits are especially rich in calcium. red currants 29 0.93 3.0-3.1 2.14 (C)

gooseberries 29 0.62 2.7-3.1 2.37 (C)

organic acids, polymer carbohydrates such as However, the total calcium amount is not

pectins and starches, nitrogenous compounds, available to pectin, but only part of it, the Table 1: 1) Souci-Fachmann-Kraut: Die Zusammensetzung der

M: calculated as malic acid Lebensmittel, Nährwert-Tabellen 1989/1990, Wissen-

minerals, vegetable phenols, flavours and so-called ”free calcium”. The remaining

C: calculated as citric acid schaftliche Verlagsgesellschaft mbH Stuttgart 1989

vitamins. calcium ions, or ”bound calcium”, are solidly 2) K. Herrmann: Obst, Obstdauerwaren und Obster-

fixed to complexing agents. zeugnisse, Verlag Paul Parey 1966

The composition of the fruits underlies great

deviations in dependence on type of fruit,

degree of ripeness, conditions of cultivation

and climate.

Types of sugar:

6 Fruit varieties used in the production of jams,

jellies and marmalades have to be especially

All sugars listed in the ”German Regulation on

Certain Sugars Destined for Human Consump-

tion” (Zuckerarten-Verordnung vom 23.10.2003

For jam production, mostly refined sugar or

white sugar (sucrose) is used.

During cooking, sucrose is partially inverted.

7

selected for their: [BGBl. I.S. 2096] in the actual edition) may also This intended chemical reaction (splitting of

be used in solution and in any mixing ratio. sucrose into glucose and fructose by binding

● fruit owned pectin content: water) is influenced by

The fruit owned pectin content is off less Sugars are one of the main constituents of

importance. Usually the cooking time does jams, jellies and marmalades and influence the ● the pH-value

not suffice to let the pectin become soluble shelf-life of these products decisively through ● the temperature

and with that be able to gel; the soluble solids content. At the same time ● the time

they provide taste, flavour, consistency and

colouring.

Jams, Jellies and Marmalades

The formation of invert sugar prevents the generated by the fructose. Sweet taste, flavour Sugar Substitutes:

crystallization of the sucrose in the finished and aw-value in the finished product may be Sugar substitutes form a group of substances When high dosages (more than 20g per person

product. On the other hand, a complete inver- influenced by suitable combinations with other which may be used to substitute sucrose in and day) are consumed, polyols may sometimes

sion of sucrose may lead to crystallization of sugars. food products. Similar to sugars they provide

the glucose in the product. food with ”bulk” or ”body” and a physiological

Starch-Saccharification Products: calorific value. Their sweetening power is com-

Comparison of the sweetening power of

Jams and marmalades produced on vacuum Glucose Syrup, Dextrose: parable to sucrose or less. sugar substitutes in relation to sucrose

cookers are, as a rule, only slightly inverted. fructose 1.10-1.30 *

Glucose syrup is a starch degradation product The following sugar substitutes are of impor-

sorbitol 0.63 *

Liquid Sugar, Invert Liquid Sugar, Invert Sugar and contains glucose, maltose, dextrine and tance:

mannitol 0.50-0.60 *

Syrup: fructose. Glucose syrup is less sweet than Fructose (fruit sugar) is a monosaccharide

sucrose and inhibits crystallization of glucose which is naturally present in practically all fru- isomalt 0.45 *

Liquid sugar is an aqueous solution of sucrose and sucrose in the finished product. Its addi- its. Its relevance as a sugar substitute consists maltitol 0.65-0.68 *

with a minimum of 62% soluble solids and a tion improves the texture (smoother consisten- in its insulin independent metabolism and di- lactitol 0.30-0.35 *

maximum amount of 3% invert sugar related cy of the finished product). Dried glucose syrup gestion, which makes it suitable for dietetic

xylitol 0.00 *

to soluble solids (ss). may also be used instead of glucose syrup. food products for diabetics. The calorific value

of fructose is determined at 17KJ/g (or Table 2:

* the figures indicate the factor by which the sugar

Invert liquid sugar is an aqueous solution of Glucose syrups may be of different composition 4kcal/g), equal to sucrose or glucose. The

substitute in question tastes sweeter than sucrose.

sucrose, partially inverted in hydrolysis, in depending on the various possible methods sweetening power of fructose is higher than from: Süßungsmittel im Überblick (a summary of swee-

which the amount of invert sugar does not employed in large-scale productions. The pro- that of sucrose. Fruit sugar is normally traded teners), Gordian 88/4, p. 72ff.

preponderate and the following criteria are duction, however, always starts with a partial as fruit sugar have a laxative effect.

given: a minimum of 62% soluble solids and no starch hydrolysis. The application of the enzyme syrup with 70% ss. Sweeteners:

less than 3% but no more than 50% invert glucose isomerase has greatly extended the Sweeteners are natural or synthetic compounds

sugar related to soluble solids. range of available glucose syrups. This enzyme Polyols or sugar alcohols form the main group which have no or, compared to their sweete-

causes the conversion of part of the glucose of sugar substitutes. The physiological benefit ning power, only a negligible calorific value.

Invert sugar syrup is an aqueous solution of into fructose. The glucose syrups produced in of these sugar substitutes is their suitability for Their sweetening power is by far greater than

sucrose partially inverted in hydrolysis, which this way have higher fructose volumes and thus diabetics (insulin independent metabolism) as that of sucrose.

is dominated in its composition by the amount greater sweetening power as starter syrups. well as their partially anti-cariogenic effect and

of invert sugar present and which meets the Depending on the fructose share, these syrups lower calorific value. Comparison of the sweetening power of

sweeteners in relation to sucrose

8 following criteria: a minimum of 62% soluble

solids and more than 50% invert sugar related

to soluble solids.

are called glucose-fructose-syrup resp. fructose-

glucose-syrup. Thus high fructose-glucose-

syrups with approx. 42% fructose and 52%

For all sugar alcohols a uniform physiological

calorific value of 10kJ/7g is fixed.

acesulfame-k

aspartame

130-200 *

200-250 *

9

glucose related to soluble solids are, for exam- cyclamate 30-40 *

These sugar solutions are characteristic for ple, used in production.

saccharine 450-500 *

their relatively low viscosity, temperature tole-

sucralose approx. 600 *

rance and the fact, that they do not crystallize Dextrose is made by starch hydrolysis. It is of

even at a low temperature. They affect the practically no importance in jam manufacture, Table 3:

* the figures indicate the factor by which the sugar

microbiological stability of the product positi- since dextrose tends to crystallize and lends a

replacer in question tastes sweeter than sucrose.

vely owing to the higher osmotic pressures dull and mat appearance to the products. from: Süßungsmittel im Überblick (a summary of swee-

teners), Gordian 88/4, p. 72ff. resp. Handbuch Süßungs-

mittel, Behr’s Verlag

Jams, Jellies and Marmalades

Gelation

of H&F Pectins

In multi component systems like jams, jellies cially high concentration, the cell walls. This

Sweeteners are not insulin dependent in their Herbasweet apple extract is a high-quality and marmalades, pectin is a texture provider. explains why the press residues from the pro-

metabolism and thus suitable for diabetics. sweetener with a soluble solids content of The optimal formation of a gel is directly linked duction of apple and citrus juice are so valuable

Since they are generally used in small amounts, 70-72°Bx resp. 78°Bx, which is produced from to the volume ratio in which the ingredients for large-scale extraction of high-quality pectins.

they neither influence texture nor body of the the fruit extract of juice-extracted and carefully fruits, sugars, water, acid and pectin are pre-

sweetened food product. dried apples. sent. The addition of pectin, which is produced In the plant cell, pectin molecules are so tightly

from fruits, must be considered as naturally linked to the other molecules in the cellular

The various sweeteners differ in their characte- By state-of-the-art technologies minerals, fruit enhancing the inherent pectin content of the wall that they cannot be extracted by water.

ristics, such as profile in taste, stability in acidi- acids and natural colours are extracted from fruits used for the jam production. Additionnaly This water-insoluble form is called protopectin.

fied food and during heating. In composition the concentrated fruit extract. What remains is there are the acid resistance of pectin and the

they may sometimes yield a positive synergistic the concentrated sweetness of the apple, which fact, that it has no specific odour or flavour, Protopectin becomes soluble by acid hydrolysis

effect. may be universally used to sweeten food pro- that it is an excellent flavour carrier as well as and is then extracted with hot water. The pectin-

ducts instead of sugar or starch-saccharification the possibility to control consistency and set- rich extract is mechanically cleaned and care-

Sweeteners: products. ting rate. fully concentrated. Pectin is then precipitated

De-ionized fruit juice concentrates and fruit with alcohol from the liquid extract.

extracts are increasingly used as natural According to the German Fruit Jams Regulation, Pectin:

sweeteners. these sweeteners (different sugars gained from The gelling agent pectin, a constituent of the Alcohol-insoluble pectin substances in pure

fruits) are allowed. They are of great interest vegetable cell structure, strengthens and sup- form are obtained by this alcohol precipitation.

for the so-called ”all fruit products”, which con- ports as ”bonding substance” the structure of They are subsequently dried and ground to

sist only of ingredients from fruits. the plant tissue. powder. The gel strength of pectin as a natural

substance differs due to the raw material used

Any vegetable raw material with a high pectin and is standardized by blending with dextrose

content is suitable for the production of pectins. or other sugar types.

Different amounts of pectin may be extracted The molecular structure of pectins is composed

from various raw materials: of D-galacturonic acid molecules, which are

10 Pomace 10-15%

Sugar beet chips 10-20%

Citrus peels 20-35%

linked to each other in alpha-1-4-glycosidic

formation to polygalacturonic acid. Part of the

carboxyl groups is methoxylated with methanol.

11

Apples and citrus fruits have always been of Neutral sugars like arabinose, galactose and

superior importance for the production of pectin xylose, which are linked as side chains to the

No sugar is added to these products, they only destined for the manufacture of jams, jellies pectin macromolecule, as well as the interrup-

contain the sugar from the fruits they are ma- and marmalades. The highly valuable pectin tion of the main chain by rhamnose make

de from. substances are present in the pulp and, in espe- pectin a heteropolysaccharide.

Jams, Jellies and Marmalades

Therefore often neutral polysaccharides like Gelling Mechanisms:

galactane, arabane and also starch are conco- The association of pectin chains leads to the

mitant substances of isolated pectin. However, formation of three-dimensional networks, that

the specific composition depends on the raw means to gel formation. Two or more chain

material. The gelling power of pectin is mainly segments bond together and start to interact.

based on its molecular weight, i.e. the number These are longer segments of regular sequence, Fig. 2: Gel net

of chain links a pectin molecule boasts, which which are ruptured by the incorporation of

is kept intact by extremely sensitive production rhamnose or by the branching of the chain.

process. COOCH3 OH

Different types of chain associations exist which O

O O

If all carboxyl groups of the polygalacturonic are determined by the degree of esterification.

OH OH

acid are free, i.e. not methoxylated, one gets For high methylester pectins, two decisive fac- O O

pectic acid, its salts are called pectates. tors initiate gel formation:

H+

OH C

Pectic acid in nature is methoxylated (or esteri- 1. The addition of sucrose or other sugars has O O–

fied) in different degrees with methanol and a dehydrating effect on the pectin molecules, COOCH3 OH

O

thus becomes pectin. If the degree of esterifi- which facilitates the approach of the polymer O O

cation is higher than 50%, it is called high chains and enables a cross linkage of the OH

OH O

methylester pectin, with less than 50% it is hydrogen bridges. O

called low methylester pectin.

OH C

Fig. 3: Dissociation of carboxyl groups O OH

2. A lowering of the pH in the medium sup- Methylester groups are the hydrophobic part

12 13

Fig. 1: Section of a pectin molecule presses the dissociation of free carboxyl groups of a pectin molecule. Hydrophobic forces push

and thus reduces the electrostatic repulsion them into aggregate formations, while they

between the chains. The mechanism described are constantly striving to keep the contact sur-

above is referred to in literature as ”sugar-acid- face with water as small as possible. Moreover,

gelling mechanism”. hydrogen bridges are formed, e.g. between

non-esterified carboxyl groups, at a sufficiently

Recent studies, however, have shown that high low pH-value in the gel and the dissociation of

methylester pectins are stabilized in the gel by the carboxyl groups is largely suppressed.

a combination of hydrophobic interactions and

hydrogen bridge bondings, which means that

the term ”sugar-acid-gelling mechanism” requi-

res a closer definition.

Jams, Jellies and Marmalades

Ca2+ Ca2+ Ca2+ Ca2+ Ca2+ Ca2+ Ca2+ Ca2+

HO HO

O O

O O O O

–

HO –

HO

HO O COO HO

– O COO

–

O O O O O

OH OH

Ca2+ Ca2+

HO HO

O O O

O O

–

OOC –

O OH –OOC –

O OH

O OH O OH

O O

O OH O OH

Fig. 5: Arranged sequences in the pectin-calcium-gel ”egg box” model

soluble

solids

Fig. 4: Structure of [ºBrix]

connecting zones of 80

HM pectins

75

14 According to Oakenfull and Scott (1984), the over free, non-methoxylated carboxyl groups

70

pre-gelled 15

hydrogen bridge bondings are the responsible decreases and if the pH is too high, the number gelled

factor in the stabilization of a pectin network, of interfering factors (-COO-) decreases as well 65

but without the hydrophobic interaction of the (in case of a too high product pH, dissociated

liquid

methylester groups, gelation would not occur carboxyl groups interfere with the network

60

for energetic reasons. formation). This affects the gelling-pH-range. If

the degree of esterification is extremely high,

55

The higher the degree of esterification, the the suppression of dissociation does not matter

3.6 3.4 3.2 3.0 2.8 2.6 pH

greater the impact of hydrophobic forces in the anymore.

gelation. The number of hydrogen bridges Fig. 6: Setting range of high esterified pectins

Jams, Jellies and Marmalades

The higher the degree of esterification, the For low methylester, amidated pectins, the High Methylester Pectins – Gelling Behaviour:

higher also the pH-value is, at which gelation clustering of the pectin chains happens more

sets in. Completely methoxylated pectins controlled than for low methylester, non ami- Soluble Solids and pH-Value:

(100% degree of esterification) thus do not re- dated pectins, as the formation of the gel net- The chart on page 15 (setting range of high The lower limit for proper gelation of high

quire any acid for gelation (Deuel et al., 1950). work is, due to the hydrogen bonds between methylester pectins, mod., Pilnik, 1980) in prin- methylester pectins is a soluble solids content

the amid groups, more slow than the reaction cipal shows the setting ranges of sugar-acid-gels of about 55%. With 58-55% soluble solids,

The required high sugar concentration for the of low methylester pectins with calcium ions is. with high methylester pectins. Certain solids/ high methylester pectins with a very high

gelation of high methylester pectins could be pH areas are identified in which pre-gelling or degree of esterification (above 75%) show the

explained, according to Oakenfull, by the fact no gelling (liquid) occurs. Pre-gelling means best results. High methylester pectins do not

that certain sugars have an additionally stabi- that at the given filling temperature, the pro- gel at very low soluble solids contents, for this

lizing effect on the hydrophobic interactions. ducts have already started setting. Pumping, application low methylester and amidated

stirring or depositing during filling destroys pectins and calcium salts are used instead.

Low methylester pectins also gel according to this incipient gel structure, the formation of a

the mechanism described above. However, homogeneous gel is not more possible. There- Substituting sucrose by other sugars or polyols

they may form a gel even in relative indepen- fore the texture of a pre-gelled product is has an influence on the gelling characteristics

dence from soluble solids content and pH-value mushy with a reduced gel strength. of pectins and the texture of gels. The reasons

if multivalent cations, e.g. calcium ions, are for these phenomena are not yet sufficiently

present. The following model has been used to The chart also explains that sugar and acid may studied. It is assumed that this is due to the

describe this gelling mechanism: substitute each other within certain limits in different water activities of the sweeteners at

their contributions to the gel strength. A lower similar solids contents or substance specific

Pectins chains cluster during the gelation pro- sugar content requires for proper gelation a differences in the stabilizing effect (Oakenfull

cess. Due to their bent shape they create cavi- lower pH-value. Higher pH-values are feasible et al., 1984).

ties between them, which become occupied by with a higher sugar content. If the sugar con-

carboxyl and hydroxyl groups. Both the forma- tent remains constant, gels with lower pH-

tion of cavities and the carboxyl and hydroxyl values will be firmer and more brittle, the same

16 groups favour the association of pectin chains

by calcium gelation.

applies if the pH stays the same and the

amount of sugar increases. 17

As regards low methylester, amidated pectins, The optimal soluble solids content for jams is References:

Fig. 7: The three binding mechanisms for connecting

Oakenfull, D. and Scott, A. (1984): Hydrophobic Interac-

additional links by hydrogen bonds are created pectin chains 60-65%. Replacing part of the sucrose with

tion in the Gelation of High Methoxyl Pectins, J. Food

due to the presence of amid groups. The more glucose syrup or the use of the optimal type of Sci., 49 (4): 1093-1098.

amid groups are present, that means the more pectin may prevent the formation of brittle Deuel, H., Huber, G., Leuenberger, R. (1950): Über das

Geliervermögen von Polygalakturonsäuremethylester,

links are possible, the firmer the resulting gels gels and the crystallization of sugar and dex-

Helvetica Chimica Acta, Vol. 33, p. 1266ff.

will be. trose. Rees, D.A., and Welsh, E.J. (1977): Sekundär- und Tertiär-

struktur von Polysacchariden in Lösungen und Gelen,

Angewandte Chemie, Band 89, S. 228-239.

Pilnik, W. (1980): Pektine, in ”Gelier- und Verdickungs-

mittel in Lebensmitteln”, Forster Pub., Zurich

Jams, Jellies and Marmalades

Setting Time and Setting Temperature: ● Medium Rapid Set with a medium setting Rapid set pectins differ in their optimal pH-value Filling Temperature:

High methylester pectins are commercially temperature from slow set ones. While slow set pectins In this case, the criterion for selecting a suitable

available within a range of 50 to approx. 80% (Pectin Classic AF 401, Pectin Classic CF 301) achieve their greatest gel strength at a pH of pectin is that the manufactured product’s set-

degree of esterification. This group of pectins 3.0 and less, the optimal pH-value for rapid set ting temperature is lower than the filling tem-

shows a quite specific gelling behaviour. Under ● Slow Set with a medium setting pectins is raised to higher pH-values. For extra perature. This prevents pre-gelling, which

the virtually same conditions, higher methyl- temperature rapid set pectins, a pH-value of under 3.0 may would weaken the gel and exert a negative

ester pectins set faster and at higher tempera- (Pectin Classic AF 501, Pectin Classic CF 401) even be unfavourable, especially if the soluble influence on the texture. The height of the fil-

tures than pectins with lower degrees of esteri- solids content is clearly above 60%. Gelation ling temperature is determined by the machines

fication. This explains the importance of setting The setting temperature depends, beside the may then set in during the cooling process, and systems applied in the process as well as

time and setting temperature for the evaluation raw material, the production technology and with the very real risk of pre-gelling. the size of the packing containers used.

of high methylester pectins. the pectin’s degree of esterification, also on

the sugar content and the product’s pH-value Another look at chart 6 on page 15 makes clear Containers which cool more quickly allow a fil-

The setting temperature is the temperature at as well as the amount of buffer salts added why soluble solids of around 60% and a pH- ling at high temperatures of 85°C and 95°C

which gelation starts subsequent to gel manu- and the cooling rate. The faster the products value of about 3.0 are suitable for rapid set as (185°F and 203°F). Rapid set pectins in this tem-

facture in the following cooling period. There are cooled, the lower the setting temperature well as slow set pectins. The differences are perature range provide good gelation as well

is no setting above this temperature, even required. due to the setting temperature, setting time as an even distribution of the fruits in the jelly.

though all criteria for gel formation are met. and gel texture. Containers which pass through a long cooling

Gelation of extremely high methylester pectins, Therefore, to be able to compare setting tem- phase, on the other hand, require low filling

as was shown in test gels, may, for example, peratures, pectin gels are usually produced With high soluble solids contents and at low temperatures of e.g. 70°C to 75°C (158°F to

start already at 90°C (194°F), that of less high under reproducible, defined conditions and pH-values, slow set pectins must be used since 167°F), since otherwise the consistency of the

methylester pectins at 60°C (140°F). one subsequently observes at what tempera- otherwise pre-gelling may occur; with high product might suffer by heat-related damage

ture gelation sets in. soluble solids and at high pH-values, on the affecting the center. For this purpose, slow set

other hand, rapid set pectin are indicated since pectins are used that do not tend to pre-gel in

Based on these differences in setting tempera- The setting time is defined as the period in otherwise gelation is not possible. the temperature range in which they are

ture and setting time, the following types of which a fruit preparation starts to gel at a defi- applied. Furthermore, the setting rate may be

18 pectins are supplied as:

● Very Rapid Set with a very high setting

ned, constant temperature after terminating

the cooking process. The definition for rapid

set pectins might be that under defined condi-

In selecting the suitable type of high methyl-

ester pectins – rapid, medium or slow set ones –

the following criteria are of great importance:

controlled by adding suitable buffer salts

(retarders). Such gelling retardation is usually

practiced in the confectionery industry where

19

temperature tions gelation requires 10 minutes at 90°C processing with very high soluble solids is usual.

(Pectin Classic AF 101, Pectin Classic CF 101) (194°F) and slow set pectins need 20 minutes at

65°C (149°F).

● Rapid Set with a high setting temperature

(Pectin Classic AF 201, Pectin Classic CF 201)

Jams, Jellies and Marmalades

Fruits:

Fruits used in the manufacture also generate The edible acid originally present in the fruits

an influence on the gelling process, depending or added to the product tends to suppress the

on variety, state of ripeness and storage condi- dissociation of free carboxyl groups in pectin.

tions. The most important factors are the fruit- While the dissociated carboxyl groups repel

own pectin content, the sugar and acid content each other because of their similar negative

as well as the amount of minerals and other charges, the undissociated carboxyl groups

fruit-specific constituents. form a network structure in which water is

bound.

With increasing ripeness, enzymes within the

fruit degrade the fruit-inherent pectin and the Lactic acid:

pulp becomes softer. The fruit-own acid amount Lactic acid is commercially available as a 50%,

decreases and the sugar amount increases. 80% and 90% aqueous lactic acid solution. Its

specific acid value is lower than that of tartaric

Acid content: or citric acid.

The adjusting of the optimal pH-value for the

gelling process during jam production is achie- For reaching a defined pH-value the dosage of

ved by adding edible acids and their salts. lactic acid must be higher than for tartaric or

Together with the physical-chemical effect of citric acid.

the acids, the flavour enhancing factors are also

Texture: of great importance in this respect. However, Tartaric acid:

Texture is a very important parameter for For the purpose of spreading jam on slices of legal regulations need also to be considered. To Tartaric acid is a crystalline product which dis-

sensory acceptance and depends largely on the bread or sweet rolls, it should be noted that control the pH-value, the German Fruit Jams solves well in water. It has the highest specific

composition of raw materials such as the type jellies with a lower elastic phase are more diffi- Regulation permits the following additives: acid value of all the acids used for this purpose.

of fruit, fruit quantity and sugars used, but also cult to spread. In the extreme case, this implies Tartaric acid can be added in the smallest

on the selected type of pectin. that jellies spread on with a knife will just ● Lactic acid E 270 dosage. It is either directly added during the

break up from a large lump into many smaller ● Citric acid E 330 cooking process or in a 50% aqueous solution.

Pectins with a very high degree of esterification pieces. Gels with a higher viscous share, on the ● Tartaric acid E 334 However, this type of acid is used relatively un-

result in firm gels which are characterized by other hand, will spread on easily and form a ● Sodium lactate E 325 frequently in the production of jams due to its

20 the rheological parameter ”highly elastic with

a very low viscous phase”.

coherent jelly layer on the bread.

The proper selection of the suitable type of

● Calcium lactate E 327

● Sodium citrate E 331

● Calcium citrate E 333

characteristic taste profile.

21

Pectins with a medium degree of esterification pectin will thus be a great help in controlling ● Sodium tartrate E 335

result in firm gels which are characterized by the desired rheological parameters of these

the rheological parameter ”highly elastic with products. The use of a pH-meter in production control to

an important viscous phase”. guarantee uniform gelation in jams, jellies and

marmalades is an absolute necessity.

Apple pectins form gels with definitely higher

viscous share than citrus pectins with the same

degree of esterification do.

Jams, Jellies and Marmalades

lactic acid tartaric acid citric acid

EEC number E 270 E 334 E 330

Structural formula C3H6O3 C4H6O6 C6H8O7

Mol wt. 90 150 192

Ionization constant

pka 1 3.86 2.93 3.08

pka 2 4.23 4.74

pka 3 5.4

pH-value (0.1 n solution) 2.8 2.2 2.2

Table 4: Important data on lactic acid, tartaric acid and citric acid

From: Genußsäuren und Salze (edible acis and salts); Anwendung und Wirkung in Lebens-

mitteln (application and effect in food)/Publ. Fachgruppe Lebensmittelchemie und Gerichtl.

Chemie i.d. GDCh. (Editor: G. Wieder) – Hamburg, Behr, 1989

(Lebensmittelchemie, Lebensmittelqualität, Vol. 14).

Citric acid: Low Methylester Pectins – Gelling Behaviour: Concentration of Soluble Solids:

Citric acid is naturally present in a great num- On the other hand, if the pH-value in fruits is The gel formation of low methylester pectins Chart 8 on page 24 shows how the breaking

ber of fruits. It is crystalline and dissolves well too low, it can be increased in order to prevent must be seen as follows: strength of a gel changes with increasing cal-

in water. Citric acid as a weaker acid than tar- pre-gelation. cium dosage as a function of the different solu-

taric acid, but stronger than lactic acid. The When small amounts of calcium ions are added, ble solids contents. At a soluble solids content

flavour of the citric acid is naturally sour and If the aim is a stabilization of the pH-value the pectin chains start to bond over calcium of 60%, hardly no calcium ions are required to

harmonious. This acid, too, is preferred to be within strict limits, as is the case for jams, one bridges. With increasing calcium ion concentra- form a firm gel, while at 20-30% of soluble

added as 50% aqueous solution. profits from the specific properties of fruit tion, gelation sets in. In case of an exceeded solids major amounts of calcium become neces-

acids to form excellent buffer systems with dosage of calcium ions, calcium pectinate will sary. The lower the soluble solids content in a

If the acid value is too high (pH-value under their salts, e.g. in the combination citric acid precipitate under the given gel forming condi- gel, the higher the calcium requirement in order

2.8) the gel elasticity will be increased and the and sodium citrate. tions, which is referred to as ”pre-gelling”. to achieve proper gelation is. The gel strength

gels become firm and brittle. If the acid value is in these samples has been determined with the

low (pH-value above 3.3) the gel structures be- As a rule, fruit acids are added to the cooking The gel texture will then lose its elasticity, be- Herbstreith Pektinometer by testing the

come very soft. When exceeding a certain pH batch towards the end of the cooking process. comes more pasty and shows a lower breaking breaking strength.

limit, gelation is no longer possible. This prevents pre-gelling, which might occur if strength. The precipitation of calcium pectinate

22 The presence of buffer salts in fruits, e.g. salts

of citric and malic acid, suppresses the impact

the temperature of the cooking batch drops

below the setting temperature due to the blen-

ding in of the sugar or the pectin solution.

is reversible if the gel is heated again above

the setting temperature and cooled down in a

destruction free process.

With increasing calcium dosage, gels become

firmer until an optimal point is reached, from

which on they become more and more elastic

23

of pH modification by added fruit acids, part of and brittle. Reaching a certain soluble solids

the effective acid value is compensated. To get Even if all parameters are adjusted in an opti- The amount of calcium ions required for proper dependent calcium dosage, the gel strength

into the desired pH-value, the acid dosage mal way and the temperature is higher than gelation largely depends on the concentration will drop rapidly and no gels but pre-gelled

must be raised. the setting temperature, a processing time, of soluble solids, the sugar, the pH-value of the products are formed.

which is too long, can lead to pre-gelation product and the buffer substances.

after the addition of acid.

Jams, Jellies and Marmalades

Effect of Buffer Ions:

Type and concentration of buffer ions present The amount of calcium required for gelation is

2400

60% ss

in the gels, which originate largely from the not only, as already described, influenced by

2200

50% ss fruits used and may differ according to the the formulation parameters, but also by the

2000 variety of fruit, have a decisive impact on the production technology, especially the height of

40% ss

Breaking strength [HPU]

1800 30% ss calcium ion requirement in order to achieve the filling temperature. The higher the filling

20% ss

1600 sufficiently firm gels. temperature, the more calcium ions can be in-

corporated in the gel network without causing

1400

An increased concentration of buffer substan- pre-gelation.

1200

ces, especially with a strong binding effect on The amount of the calcium dosage does not

1000 calcium as e.g. exists for the salts of citric acid, only control the firmness of the gel, but also its

800 will, similar to a raise in the pH, require a si- rheological and sensory properties.

600 multaneous increase of the calcium dosage.

400

200

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 Pectin chains

Calcium-concentration [mgCa2+/g pectin] in solution

Fig. 8: Sucrose gel with increasing ss content (low methylester pectin,

Ca2+

DE° 40%, 0.1m citric acid/potassium citrate buffer solution, pH-value 3.0)

Chain

Effect of the type of sugar: association

Not only the concentration, but also the type The rise in pH will lead to an increased number

of sugar or sugar substitute used will affect of charged particles in the gel which dissociate

gelation. Thus, the calcium requirement to the pectin molecules even more strongly. The

Ca2+

24 achieve an optimal gelation is, for example,

usually much greater with a sugar substitute

than with sucrose. Fructose gels also require

reaction between the calcium ions and the other

charged buffer substances will be enhanced,

which in turn reduces the number of calcium

Gel

25

more calcium ions. ions available for reactions with pectin.

Ca2+

Effect of the Product’s pH: An increased concentration of calcium ions pro- Ca-pectinate

The increase of the pH-value in a gel must be vides more bonding points between the pectin precipitation Fig. 9: Gelation of low

methylester pectins in

followed by an increase of the amount of cal- molecules and will thus keep the gel strength dependence on calcium

cium ions required within the gel to achieve intact. ion concentration

comparable gel strength.

Jams, Jellies and Marmalades

Breaking strength

Gels of section II show in their majority viscous pumped but still hot and liquid, they have an

influences, they are spreadable, stable gels unlimited high viscosity and behave like solids.

with a high regeneration potential after mecha- Owing to this, fruit pieces will neither rise nor

nical stressing and show very little tendency to settle, but remain ”cast” in position in the gel.

syneresis. In the sensory respect as well, viscous This is understood by ”good fruit distribution”.

I II III IV components influence the flavour. These are

mgCa2+/g Pectin gels that will melt in the mouth and have a Fruit pieces regularly distributed in the gel are

fruity, sweet taste which is very pronounced. considered a quality feature of jams.

Fig. 10: Breaking strength of pectin gels in dependence on

added calcium ions (Section I-IV)

The reaction of pectins with calcium ions in- The yield point cannot be substituted by a high

creases the setting temperature and results in a viscosity. Indeed, a high viscosity delays the

Rheology and Sensorics: Section I: yield point at a higher temperature. rising of fruits but will not prevent it.

In a given formulation, which means that su- The calcium concentration in section I is very

gars and sugar concentration, pectin concen- low: fruit preparations in this area are highly In resting condition, once the jams have been

tration and type of fruits and fruit quantity are viscous or slightly gelled. filled in containers and are no longer stirred or

constant, gels become increasingly more firm

with higher amounts of calcium. Section II:

The firmness may be assessed by testing the Gels in this area have only just started gelation

breaking strength with the Herbstreith or are already gelled. The gels are very smooth

Pektinometer. and spreadable. Rheologically speaking, they

may be characterized by their visco-elasticity as

However, an increase in calcium concentration follows:

does not only raise the breaking strength of

26 the gels but also affects the rheological and

sensory properties such as spreadability, stabi-

lity, tendency to syneresis, regeneration poten-

Pectin gels have visco-elastic properties which

means elastic as well as viscous properties. 27

tial, setting temperature of the gels and mouth The elastic component is responsible for high

feel. breaking strength, even reaching brittle tex-

tures and for low mechanical stability together

These properties will be described in the follo- with poor spreadability and a tendency to

wing in sections I-IV, into which the curve in syneresis. The viscous component, on the other

chart 10 is divided. These sections characterize hand, prevents brittleness and causes good

certain areas in which varying calcium-pectin spreadability and a low tendency to syneresis.

ratios exist.

Jams, Jellies and Marmalades

Section III: Low Methylester, Amidated Pectins – Gelling As the bondings are additionally stabilised due occurs. Fine gel particles are formed, the gel

In section III the calcium concentration is very Behaviour: to the presence of amid groups and with that arrangement looses its elastic character, the

high with a lot of calcium bridges which cause by the formation of hydrogen bonds, low texture becomes pasty and with that the gel-

the pectin molecules to approach each other Influence of Calcium Ion Concentration methylester, amidated pectins are able to gel ling strength is reduced. At mechanical treat-

closely. The pectin network is very tightly In the case of low methylester, amidated homogeneously and relatively independent ment the gel looses water, syneresis occurs.

structured, originally bound water molecules pectins, the calcium ion concentration which is from calcium ion concentration over a wide This process of pre-gelation is reversible. If pre-

are now easily squeezed out of the gel net- necessary for gelation, depends on different range. gelled gels made of amidated pectins are

work. product parameters such as soluble solids con- heated again to a temperature which is higher

tent, pH-value of the product or the buffer If the calcium dosage is raised intensely, pre- than their setting temperature and then cooled

The gel texture is dominantly elastic, the concentration. gelation, that means an over-reaction between down again, an elastic and firm gel will be ob-

viscous phase is suppressed. This provides gels the pectin molecules and the calcium ions, tained.

with a very high breaking strength, on the Already at a low calcium ion concentration the

other hand, these gels are unstable against pectin chains start to cluster via calcium bonds.

mechanical stressing. Once they have been pro- Here the calcium ion concentration which is

cessed, e.g. stirred or pumped, they are not necessary for gelation, may yet come from the

able to regenerate or at least require a very natural calcium content which is brought in by

long time to do so. The inclination to syneresis the fruits or the water contained in the recipe. Natural calcium

increases, the yield point or the fruit retention content of the

fruits

property also increases and the setting tempe- The amid groups stabilise the network by

rature is also raised. hydrogen bonds resulting in elastic gel pro-

ducts already at a low calcium ion concentra-

Section IV: tion. Besides the degree of esterification, the

In this section, the calcium concentration is too amount of amid groups determine the sensiti-

Gel strength

high and at the given filling temperature pre- vity and with that the calcium need for forming

gelling will occur. The gel strength decreases, a gel network and the resulting setting tempe-

the consistency is mushy or pasty, syneresis rature.

occurs and the yield point is lowered. The tex-

28 ture of such products is very unappealing. It is

not recommended to apply this area to jams,

jellies and marmalades.

With increasing the calcium ion concentration

the gels become stronger until reaching an

optimum, the texture of the gels becomes

Low methylester amidated pectin

Low methylester Classic Apple pectin 29

more elastic and more brittle.

Increasing the filling temperature may prevent

Calcium concentration

pre-gelling up to a certain point. However, the

gels remain very firm and are brittle with a Fig. 11:

high tendency to syneresis. Gelation of low methylester, amidated pectins in dependence from calcium ion concentration

Jams, Jellies and Marmalades

b) Gelling properties of low methylester,

Elastic-brittle texture

Sensitivity levels of low methylester, amidated pectins with differing calcium sensiti-

amidated pectins: vity at different filling temperature

Low sensitivity: The texture and the firmness of the final pro-

Low methylester, amidated Pectin Amid AF 005, Pectin Amid CF 005 duct can be decisively influenced by the selec-

citrus pectin ted filling temperature.

Low methylester, amidated Medium sensitivity:

apple pectin Pectin Amid AF 010, Pectin Amid CF 010 By means of two low methylester, amidated

pectins with differing calcium sensitivity fig. 14

High sensitivity: (page 32) shows, under comparable recipe

Pectin Amid AF 020, Pectin Amid CF 020 parameters, the changing of firmness and tex-

Calcium concentration

ture of the final product, if the product was

Fig. 12: Gelation of low methylester, amidated pectins in dependence from calcium ion concentration For special applications also H&F pectins with filled at different temperatures.

very high sensitivity are available. Furthermore,

H&F offer tailor-made low methylester, amida- If a product, for example a fruit preparation

ted pectins which are already standardized (e.g. 45% ss, pH-value 3.3), is manufactured

with specific buffer salts to a defined gelling with a reactive pectin and then filled, elastic

Influence of the raw material on the gelation behaviour. gels with a constantly high gelling strength

of low methylester, amidated pectins will be obtained as long as the filling tempera-

Low methylester, amidated pectins can be setting temperature and the formation of a a) Setting time/setting temperature of low ture is higher than the setting temperature of

made from apple pomace as well as from citrus particular gel texture, are decisively deter- methylester, amidated pectins with differing this fruit preparation. If the filling temperature

peels. mined by the calcium sensitivity. calcium sensitivity is decreased and reaches a level beneath the

setting temperature, pre-gelation will occur

The raw material used has also an influence on Therefore the behaviour of low methylester, The higher the calcium sensitivity of the low resulting in the partial loss of the maximal

the texture of the manufactured gels. At com- amidated pectins in dependence from calcium methylester, amidated pectin, the shorter the reachable gelling strength. At the same time

parable degree of esterification and degree of ion concentration is not only influenced by the setting time resp. the higher the setting tem- the texture of the pre-gelled fruit preparation

amidation, low methylester, amidated apple fixed recipe parameters such as soluble solids perature in a gel preparation, produced with becomes more and more viscous, the lower the

pectins form elastic-viscous textures which are content, pH-value of the product and the this pectin, is. filling temperature is chosen.

30 easy to spread, show a high mouthfeel (”body”)

and low tendency to syneresis. Gels, which are

manufactured with low methylester, amidated

amount of present/added buffer salts, but

additionally by the particular calcium sensitivity

of the pectin. Due to this property low methyl-

31

citrus pectins, have higher setting temperatures ester, amidated pectins can be specifically

and result in elastic-brittle products. selected that, also under most different pro-

duct parameters, they gel homogeneously and

Increase of calcium reactivity

Gelling properties of low methylester, amida- relatively independent from calcium ion con-

Increase of setting speed/setting temperature

ted pectins with differing calcium sensitivity centration for reaching the desired texture in

The gelling properties of low methylester, the particular final product.

amidated pectins, that means, the setting time/

Pectin Amid AF 005 Pectin Amid AF 010 Pectin Amid AF 020

Pectin Amid CF 005 Pectin Amid CF 010 Pectin Amid CF 020

Fig. 13

Jams, Jellies and Marmalades

Due to the relatively high setting temperature c) Gelling properties of low methylester, ami- At comparable calcium ion concentration the ture of this gel preparation is high in a way

of the fruit preparation manufactured with dated pectins with differing calcium sensitivity gel strength decreases from pH 3.2 to pH 3.6 that pre-gelation will occur under the given

reactive pectin, the final gelling strength de- at different product pH-values which means that the gels become weaker with conditions. With that the texture looses its

creases relatively quick with falling filling tem- The product pH-value has an important in- rising pH-value, the viscous shares increase. elasticity and becomes more and more viscous.

perature. If finally this fruit preparation is filled fluence on the gelling behaviour of low

at a low temperature (e.g. 60°C), a pasty texture methylester, amidated pectins. With rising pH-value of the final product the In contrast to that, elastic gels are formed over

with higher tendency to syneresis will result calcium need increases. That means to obtain a wide range at a pH-value of pH 3.6 by using a

due to the pre-gelation occured. With the example of two pectins with differing comparably firm gels, gels with a higher pH- reactive pectin. The curve progression is plain,

sensitivity fig. 15 shows the breaking strength value need more calcium ions than gels with that means the breaking strength of these gels

If the same fruit preparation is manufactured in dependence from calcium dosage at two lower pH-value. changes only little with increasing calcium

with a pectin with less calcium sensitivity, the different product pH-values of the gel prepara- dosage.

gelling strength will be constant within a wider tion. The breaking strength of the gels which are

temperature range as this fruit preparation manufactured with a pectin with high sensiti- A plain curve progression means to the user,

shows a lower setting temperature. Products The breaking strength, which is reached by vity, at first also increases with rising calcium that the working area under these conditions

which are manufactured with pectins with low using the pectin with low calcium sensitivity in ion concentration. is wide, as the gels are very tolerant towards

calcium sensitivity, can therefore also be pro- dependence from the calcium dosage, increases fluctuations of the calcium content. With that a

cessed and filled at lower temperatures. The for the two product pH-values with increasing In comparison, the absolute values in this range high flexibility and production safety are

products show only very low tendency to calcium ion concentration. are higher than for the pectin with low sensiti- guaranteed.

syneresis. vity. At the same time the texture of the gels

which are manufactured with a more reactive Low methylester, amidated pectins with high

pectin, are more elastic at a comparable pH- sensitivity such as Pectin Amid CF 020 or Pectin

value. Amid AF 020 are therefore especially well suited

for the use at higher pH-values, whereas for

With a defined calcium ion concentration, how- products with lower pH-value rather pectins

ever, the gel strength of the gels with a pH- with a lower sensitivity such as Pectin Amid

value of 3.2 decreases, as the setting tempera- CF 005 or Pectin Amid AF 005 are used.

LMA Pectin with high reactivity

LMA Pectin with low reactivity

Gel strength

32 33

Falling filling temperature

Fig. 14: Texture of gels, manufactured with low methylester, amidated pectins with differing calcium sensitivity in

dependence from filling temperature

Jams, Jellies and Marmalades

Breaking strength [HPU]

To form elastic gels, gel preparations which are calcium ions for gelation, however then it

manufactured with pectins with medium and shows a high tolerance towards fluctuations of

low reactivity require a certain amount of the calcium content resulting in a homogenous

LMA pectin with high calcium

calcium ions whereas gels, which are manufac- gelation over a wide working range.

reactivity

tured with a reactive pectin, already form an

LMA pectin with low calcium

reactivity elastic gel at minor addition of calcium ions As a result, low methylester, amidated pectins

which might come from the fruits or the drin- with high calcium reactivity such us Pectin

Increasing calcium concentration king water. Amid CF 020 or Pectin Amid AF 020 are excel-

pH 3.2 pH 3.6 lently suited for the use in products with a low

In contrast to pectins with low and medium sugar content such as sugar reduced fruit pre-

Fig. 15: Breaking strength (Herbstreith Pektinometer Mark IV) of gels (40% ss, 1.0% pectin), manufactured at diffe-

reactivity, the curve progression of pectin with parations or delicatessen products.

rent pH-values with low methylester, amidated pectins with differing calcium reactivity in dependence from calcium

ion concentration high reactivity is plain and the breaking

strength of the gels changes over a wide range Pectins with very high reactivity such as Pectin

only little. Amid CF 025 or Pectin Amid CB 025 are suited

d) Gelling properties of low methylester, ami- Gelling behaviour at 20% ss among others for glaze, spray nappage or jelly.

dated pectins with differing calcium reactivity With rising calcium ion concentration the At low soluble solids contents (0-20% ss) the

at different soluble solids content breaking strength, determined with the reactive pectin requires a certain amount of

Besides the pH-value of the product also the Herbstreith Pektinometer Mark IV, increases,

soluble solids content is an important parame- the texture of the gels becomes firmer and

ter for choosing low methylester, amidated more elastic.

pectins. When altering the soluble solids con- 20% ss

tent, low methylester, amidated pectins show Over the whole range investigated the high

different gelling properties in dependence reactive pectin results in firmer gels at compa-

from their calcium reactivity. Thus, depending rable calcium ion concentration than pectins

Breaking strength [HPU]

on the product and its soluble solids content, with medium resp. low reactivity do.

34 the required gelling behaviour can be reached

by choosing the suitable pectin. In order to reach a comparable breaking

strength of the gels, pectins with medium and

35

The following figures show at the example of low reactivity require higher calcium dosages LMA pectin with high

three pectins with differing reactivity the than pectins with high reactivity. reactivity

breaking strength of gel preparations in LMA pectin with

medium reactivity

dependence from calcium dosage at different

LMA pectin with low

soluble solids ranges (20%, 40%, 60% ss). reactivity

Increasing calcium concentration

Fig. 16: Breaking strength of gels (20% ss, 1.0% pectin, pH-value 3.2), manufactured with low methylester, amidated

pectins with differing calcium reactivity in dependence from calcium ion concentration

Jams, Jellies and Marmalades

40% ss

Breaking strength [HPU]

Gelling behaviour at 60% ss

At a soluble solids content of 60% pectins with solids content of 60% already without separate

high and medium calcium reactivity already calcium addition. In contrast to pectins with

Fig. 17: Breaking strength gel without the separate addition of calcium high and medium reactivity, the curve progres-

LMA pectin with high

of gels (40% ss, 1.0% pectin,

reactivity ions. When adding calcium ions, the breaking sion of the pectin with low reactivity is plain

pH-value 3.2), manufactu-

red with low methylester, LMA pectin with medium strength values increase at first, the texture of and the breaking strength of the gels changes

amidated pectins with diffe- reactivity the gel becomes firmer and more elastic-brittle. only little over a wide range. Even at high

ring calcium reactivity in LMA pectin with low

calcium dosages pre-gelation will not occur.

dependence from calcium reactivity

ion concentration With a further raise of the calcium ion concen-

Increasing calcium concentration

tration pre-gelation will occur relatively quick Therefore low methylester, amidated pectins

and, as a consequence, the gel strength decrea- with low calcium reactivity such as Pectin Amid

Gelling behaviour at 40% ss ses. At a soluble solids content of 60% ss the CF 005 or Pectin Amid AF 005 are very well

If the soluble solids content is raised to 40% ss, As pectins with high calcium reactivity and setting temperature of these pectins increases suited for the use in products with high sugar

low methylester, amidated pectins with medium especially pectins with medium calcium reacti- with increasing calcium ion concentration very content, as for example jams, fruit spreads and

and higher calcium reactivity will form elastic vity show, at a soluble solids content of 40%, a intensely, the preparation gels already during fruit preparations for yogurt.

gels already at a low concentration of calcium homogeneous gelation over a wide range and the boiling process and the gel can no longer

ions. Especially for gels which are manufactu- with that a high tolerance towards calcium be filled without being destroyed. Due to the The high setting temperature of the low

red with a pectin with medium reactivity, the ions, these medium reactive pectins are excel- pre-gelation, the obtained gels are pasty with methylester, amidated pectins with high reacti-

breaking strength is homogeneously high over lently suited for the use in products in this decreasing firmness and increased tendency to vity such as Pectin Amid CF 020 or Pectin Amid

a very wide range and relatively independent soluble solids range. snyeresis. AF 020 can be used for technological reasons

from calcium ion concentration. At a defined, to prevent floating. The gelation process starts

relatively high calcium ion concentration the For example, in applications with gelling sugar As the setting temperature of gels increases already during the boiling process and is addi-

gel strength of gels, which are manufactured (2:1) most different fruits are used at approx. with increasing reactivity of the pectins, the tionally enhanced by the addition of acid. This

with the high reactive pectin, slightly decreases, 40% ss, which mainly differ regarding their calcium ion concentration at which pre-gelation gelation results in an increase of viscosity

as here the setting temperature is high in a calcium and acid content. starts, is the lower, the higher the reactivity of because of which the fruits in the preparation

way, that pre-gelation occurs under the given the low methylester, amidated pectin is. The do not separate during the filling process.

conditions. Then the texture becomes more Additionally the household production condi- pectin with the low reactivity gels at a soluble

and more viscous resulting in falling breaking tions vary depending from the user. Despite

strength values. this fact, products with homogeneous gelation

and sufficient firmness are expected. Low

On the contrary, the pectin with low calcium methylester, amidated pectins with medium

reactivity requires a certain amount of calcium reactivity are a guarantee for the successful 60% ss

36 ions to form elastic gels. Then the breaking

strength values rise with increasing calcium ion

manufacture of these preparations. Further-

more, low methylester, amidated pectins with 37

Breaking strength [HPU]

concentration and the gels become firmer. medium calcium reactivity such us Pectin Amid

CF 010 or Pectin Amid AF 010 are used for

At comparable gel strength the pectin with example for calorie-reduced fruit preparations,

LMA pectin with high reactivity

high calcium reactivity forms an elastic-brittle fruit preparations for yoghurts or to stabilise Fig. 18: Breaking strength of

gels (60% ss, 1.0% pectin,

texture, whereas gels manufactured with a fruit cream.

LMA pectin with medium pH-value 3.2), manufactured

pectin with low reactivity are elastic-viscous reactivity with low methylester, ami-

and pasty. LMA pectin with low reactivity dated pectins with differing

calcium reactivity in depen-

dence from calcium ion con-

Increasing calcium concentration centration

Jams, Jellies and Marmalades

Pectins form visco-elastic gels, i.e. gels with carboxyl groups are statistically distributed

Syneresis Behaviour elastic as well as viscous phases. The greater throughout the molecule due to the production

the elastic and the smaller the viscous phase in method. Enzymes, which cause a clustered

a gel, the greater the sensitivity of gel textures demethoxylation, are not active in the raw

to mechanical stressing and their inclination to material pomace, contrary to other raw mate-

In general, syneresis is an undesired phenome- High Methylester Pectins (HM Pectins): syneresis are. rials, e.g. citrus peels.

non for jams and other fruit preparations and

depends on many factors. It is described more Gelled products with HM pectins have, as a The ratio of elastic and viscous phases in pectins The most frequent cause for syneresis is the

closely in the following: rule, a soluble solids content of at least 60%. is determined by the degree of esterification series of unsuitable production conditions

At these high soluble solids, the manufactured and their sensitivity to multivalent ions. which may be summarized by the term

Pectin is supposed to immobilize the free water products should not show any syneresis under ”pre-gelling”.

in the product. If the desired water binding optimal conditions, that is if the gel is not Very high methylester pectins form very elastic

effect is not completely achieved in gel produc- destroyed. gels with high setting temperatures. Medium Pre-gelling will always occur if the filling

tion or during further processing of the gel, methylester pectins form elastic gels with temperature for the gel has been set too low.

gels show a tendency to shrink and to release Syneresis to a minor extent may occur in the greater viscous phases and lower setting tem- The reason for this may be (at correct pectin

fluid, which is called syneresis (the pectin normal consumption of gelled products, e.g. in peratures. Due to the greater viscous phase, dosage):

chains approach each other too closely and household consumption and especially if a gel medium methylester pectins are less sensitive

squeeze the originally bound water out of the is stirred or pumped. to mechanical stressing, show less inclination

gel network). to syneresis and result in more spreadable gels. ● that the sugar concentration is too high

HM pectin gels are not able to regenerate their ● that the acid dosage (which causes the pH

Based on the different gelling mechanisms, gel texture after mechanical destruction. Once Another reason for high gel elasticity is ion in the product to be too low) is too high or

syneresis must be differently assessed in high the texture of these gels has been damaged, sensitivity, which occurs also in high methyl- ● an unsuitable type of pectin, e.g. a pectin

and low methylester pectins. syneresis sets in and becomes more pronounced ester pectins as a function of raw materials and that sets too fast.

during a longer storage period. production methods. Ion sensitivity is probably

also influenced by the way the free carboxyl This may be remedied by correcting the sugar

groups are distributed in the pectin molecule. and acid concentrations, and by matching the

A clustered appearance of free carboxyl groups filling temperature and the type of pectin.

38 due to the corresponding enzyme activity in

the raw material results in high ion sensitivity.

This makes gels highly elastic, up to being even

Another reason for syneresis may be an insuffi-

cient sugar exchange between fruits and the

39

brittle with a stronger inclination to syneresis. liquid medium, which might be due to a too

short cooking time for fruits with very hard

High methylester Classic Apple Pectins are skins or firm fruit pulp.

comparatively insensitive to ions since the

A fluid separation will also occur if the pectin

dosage is too small or the pectin has not been

completely dissolved. This means, the available

water cannot be sufficiently immobilized.

Jams, Jellies and Marmalades

Low Methylester Pectins (LM Pectins):

Whether or not syneresis in gels with low The suitable pectin and calcium dosage

methylester pectins occurs, depends on the depends, as already described, on the pH-value,

ratio between selected pectin and calcium for a ion strength, sugars and sugar quantities,

certain formulation. which follows that all these parameters have

to be exactly matched. An important factor,

The proper dosage of low methylester pectin very difficult to assess in its impact, is the ion

and relatively few calcium ions result in thixo- composition of fruits, because this can even

tropic gels with a high regeneration rate. This vary within one and the same type and variety

means that after mechanical stressing of a gel, of fruit.

e.g. spooning jam from a pot, the destroyed

gel can regenerate quickly and liquid does not It is recommended to use a calcium insensitive

seep from the pectin network; the tendency to pectin in such cases.

syneresis is relatively low in these gels.

Strong syneresis in jams, marmalades and jellies

An increased amount of calcium, in comparison does not only make an unappealing impression

to the selected pectin dosage, renders gels but is also considered as a quality defect by

more elastic, the viscous phase is smaller, the jam manufacturers and consumers and should

texture becomes even brittle and is no longer thus be avoided.

spreadable and thixotropic gels with a very

low regeneration rate are the result. After

destruction, these gels take much longer to

restructure their texture and fluids may be

released.

40 41

Fig. 19: Determination of

syneresis behaviour of fruit

preparations

Jams, Jellies and Marmalades

The Standardization

of H&F Pectins

A sugar-pectin-water gel with 65% soluble For determining the breaking strength and the

solids and a pH-range of about 2.0 is manufac- texture with the Herbstreith Pektinometer a

tured for this purpose. The gel is cooled under nearly optional gel is put on strain up to the

defined conditions (25°C [77°F] 24 hours). After destruction of the gel network. The force

cooling, the gel is released from its mould and necessary for this effect is measured in depen-

the percentage of sagging under its specific dence from time.

gravity is measured with the so-called Exchan-

ge Ridgelimeter after exactly 2 minutes. A Gel The simple handling, good reproducibility and

with a 23.5% sagging is considered a standard above all the great flexibility regarding the

gel. recipe are the advantages of this method. With

that gels can be assessed which are exactly

The grading of pectin is calculated according to adjusted to the particular application.

the following formula:

Fxa But, fruit spreads containing fruit components

°USA-Sag =

b can only be assessed reproducibly if the fruits

a = amount of sugar in the gel (650g) are finely ground or at least relatively small

b = amount of pectin in the gel (4.33g) and distributed homogeneously.

A sagging of 23.5% is equal to factor F = 1 and For determination of the breaking strength and

the °USA-Sag = 150. Gels which sag more the texture with the Herbstreith Pektinometer

strongly (weaker gels) are corrected by a factor the gel preparation is filled into a standardized

< 1; gels which sag less strongly are calculated measuring beaker with shear insert. After a

with the correcting factor > 1. A table has been defined time this shear insert is pulled out of

compiled with these factors. the gel and the force necessary herefore is

measured. From the resulting force-time-dia-

The method described has served as commercial gram the following information is obtained:

Fig. 20: Ridgelimeter (USA-Sag-Method)

basis for high methylester pectins for many

years. However, this method is not undisputed, The maximum value is the force which is neces-

42 As pectin is extracted from natural, vegetable

raw materials, its properties may be different

Different methods of standardization are used

depending on the intended application of the

it is frequently criticized that the extremely

low pH-value in the gel is not practice oriented.

This means, that pectin is assessed by the gela-

sary for disrupting the gel and which is called

breaking strength. This breaking strength resp.

inner firmness correlates very well with the

43

depending on the quality of the raw materials pectins. tion of a product which would not be produced firmness which is perceived during the first

used. Due to this fact, the pectins are analyzed in this way in practice. The so-called ”internal swallowing or first spooning up for sensory

and standardized to their defined properties in The standardization of high methylester pectins strength”, also termed ”breaking strength”, assessment.

order to reach ever a constant texture with the to constant grade value is internationally done correlates more directly with the sensory stabi-

application of pectin. by way of a Ridgelimeter according to the lity perception than the USA-Sag-values do.

”USA-Sag-Method”. Therefore, lately efforts have been increased to

assess high methylester pectins not only accor-

ding to the USA-Sag-Method, but additionally

to their breaking strength.

Jams, Jellies and Marmalades

Fig. 21: Herbstreith Pektinometer

Elastic-viscous gels for example require a smal- Determination of Texture Properties using the

ler force to be disrupted resp. broken and Oscillating Rheometer

therefore their breaking strength is relatively The above mentioned texture constant K

low. which is used together with the Herbstreith

As elastic-viscous gels have an inner cohesion, Pektinometer Mark IV for determining the tex-

a low but steady power input is necessary to ture properties of pectin gels correlates very

pull the shear insert out of the gel. Therefrom well with the so-called dynamic Weißenberg

a relatively large integral area in the force- number W’ (Windhab, 1990) which can be

time-curve results. determined by using the oscillating rheometer.

From the ratio of breaking strength, i.e. the The determination of the dynamic Weißenberg

maximum force, and integral of the force-time- number W’ is a comparatively extensive rheo-

curve a relatively low value for the texture metric method in which the ratio between

constant K is obtained. Sensorily the gels are elastic (G’) and viscous shares (G’’) of a pectin

assessed very easy to spread and homoge- gel is determined by a special oscillating

neously firm with high mouthfeel. measurement mode (W’ = G’ : G‘’).

Elastic gels show high breaking strength values, Pectin gels are visco-elastic substances, which

thus they require a high power input for means they are predominantly elastic. How-

breaking. Elastic gels break into single frag- ever, they additionally possess more or less

ments when ruptured. Therefore after breaking high viscous shares which have a very signifi-