Beruflich Dokumente

Kultur Dokumente

Oil Contains Coolant: Troubleshooting

Hochgeladen von

FaresOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oil Contains Coolant: Troubleshooting

Hochgeladen von

FaresCopyright:

Verfügbare Formate

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 1 of 13

Shutdown SIS

Previous Screen

Product: GENERATOR SET

Model: 3512B GENERATOR SET YAM07518

Configuration: 3512B Generator Set YAM00001-UP

Troubleshooting

3500B and 3500C Generator Set Engines

Media Number -RENR5059-11 Publication Date -01/04/2014 Date Updated -16/04/2014

i05711915

Oil Contains Coolant

SMCS - 1348-035; 1395-035

Evidence of the following substances in the results of engine oil analysis are indications of coolant in

the oil:

• Glycol

• Water

• Sodium (Na) when a conventional coolant is used

• Potassium (K) when Extended Life Coolant (ELC) is used

• Silicon (Si) is used in coolant as an anti-foaming agent. Si is also used as an anti-corrosion

agent for aluminum components.

Elevated levels of Na or K and Si can occur in an oil analysis without glycol or water. The glycol or

water is boiled off if the coolant is burned during engine operation.

In some cases, water or glycol can seep into the oil when the engine is not operating.

The presence of Si and glycol or water in the oil indicates direct entry of coolant.

Review the results of the oil analysis before troubleshooting.

Review the service records in order to determine the components that may be more likely to have

caused the coolant contamination.

Oil Analysis Results and Probable Causes

Table 1

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 2 of 13

Oil Analysis Result Probable Cause Additional Notes

High Na or K

Failure of the seal in the

Elevated Si Troubleshoot the more likely jacket water

jacket water pump or

Presence of glycol or pump first

auxiliary water pump

water

The oil pressure is greater than the coolant

pressure during engine operation. The

coolant level will rise as oil enters the

High Na or K

cooling system.

Presence of glycol or Leaking oil cooler

water

Glycol and water can enter the oil if the

engine is unused for days or if the leak is

severe.

With a crack between the coolant passage

and the turbine housing, the coolant is

burned in the exhaust.

High Na or K

No glycol or water

Backpressure of the exhaust gas on the oil

or

Cracked turbocharger system seal enables contamination.

High Na or K

cartridge

Elevated Si

White smoke is in the exhaust.

Presence of glycol or

water

A crack between the coolant passage and

oil passage can allow coolant into the oil

drain.

Glycol and water can appear in the oil

sample after months of burning coolant.

Glycol and water can also appear if the

engine is unused for days.

High Na or K

Cracked cylinder head Small cracks can be hard to find.

No glycol or water

Small cracks only open when the cylinder

head is hot.

A severe crack can enable hydraulic lock,

but the condition is unlikely.

High Na or K Typically rapid progression

No glycol or water if the

engine is operated White smoke for an extended period at start

Cracked aftercooler core

Presence of glycol or -up

water if the engine is not

run for an extended For a severe leak, white smoke continues

period during operation.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 3 of 13

High Na or K Cracked cylinder liner A cracked cylinder liner is unlikely.

No glycol or water

or A cracked cylinder liner allows coolant into

High Na or K the combustion chamber or into the

Presence of glycol or crankcase.

water

Usually, a cracked cylinder liner is

associated with piston seizure.

The crack develops quickly with little

warning or with no warning.

Failure of the lower liner seal is not

High Na or K common.

Damaged lower cylinder

Presence of glycol or

liner seal

water A failed lower seal could be due to an

installation issue or to cavitation erosion.

Sometimes a small amount of burned

coolant is detected in the oil because of a

failed cylinder head gasket.

High Na or K Failed cylinder head

No glycol or water gasket

A more common symptom of a failed

cylinder head gasket is exhaust gas in the

coolant.

A leak from a coolant passage in the air

compressor can allow coolant to flow into

the air system or the lubrication system.

High Na or K Cracked water-cooled air

If the leak occurs in an area where air

Presence of glycol or compressor head (If

pressure can enter the cooling system, the

water equipped)

cooling system can be pressurized.

Air dryers and air filters may plug quickly

if coolant leaks into the air system.

Recommended Actions

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 4 of 13

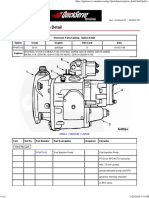

Illustration 1 g02877941

Typical water pump

(1) Weep hole

(2) Felt dust filter

Table 2

Troubleshooting Test Steps Value Result

1. Check the water pumps for leaks Failed Result: There is a

water stream of coolant from

Perform this procedure for the jacket water pump and for the pump seal the weep hole.

auxiliary water pump. Start with the jacket water pump,

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 5 of 13

which is more likely to have a leak. Repair: Replace the

water pump seal or

A. Locate weep hole (1) in the water pump housing. replace the water

Remove felt dust filter (2) (if equipped) from the weep hole. pump.

· If coolant flows from the weep hole, a failed water pump Result: No coolant

seal is probably the cause of coolant in the oil. flows from the weep

hole.

· A slightly damp dust filter is acceptable, but a stream of

coolant indicates excessive leaking of the water pump seal. Repair: Install a new

felt dust filter into the

· A visual inspection of the dust filter is not sufficient. A water pump.

dust filter may appear to be dry, but the pump may have

internally leaked coolant that appears when the filter is Proceed to Test Step 2.

removed.

Illustration 2 g02887699

Typical oil cooler

(3) End sheet

(4) Baffle

Table 3

Troubleshooting Test Step Value Result

2. Visually check for engine oil in the Leaking oil Result: There is an oil slick on top of the

coolant cooler coolant.

A. Remove the radiator cap. Use a Repair:

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 6 of 13

bright flashlight to help look for an oil 1. Drain the engine oil and change the oil

slick on top of the coolant. filters.

2. Disassemble the oil cooler. Look for

fretting or wear between the baffles and the

tubes. Look for a break of the seal at the

end sheet.

3.Repair the oil cooler or replace the oil

cooler. Refill the engine with oil.

Result: There is no oil slick on top of the

coolant.

Proceed to Test Step 3.

Table 4

Troubleshooting Test Step Value Result

Result: There is a loss of air

3. Check the turbocharger for a leak.

pressure.

A. Drain the coolant to a level that is

Repair: Replace the

below the turbocharger.

turbocharger cartridge or

Cracked replace the turbocharger.

B. Plug the coolant return line.

turbocharger

cartridge Result: The air pressure is

C. Pressurize the coolant supply side of

maintained at

the turbocharger with 100 kPa (15 psi) of

100 kPa (15 psi) with no loss of

air pressure.

pressure.

D. Monitor the pressure.

Proceed to Test Step 4.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 7 of 13

Illustration 3 g02887919

(5) Plug in the exhaust side

(6) Hole for the valve cover bolt in the intake side

(7) Inner spring on the exhaust side

Table 5

Troubleshooting Test Step Value Result

4. Check the intake side of the Cracked Result: The end of the bolt is wet or there is

cylinder head for evidence of cylinder residue from coolant on the bolt.

coolant leaks. head

Repair: The cylinder head is probably cracked.

A. Remove the valve cover bolt Replace the cylinder head.

from hole (6) .

Note: After the cylinder head is removed, inspect

Note: The bolt should be the inside of the air inlet elbow for the cylinder.

relatively dry. There may be a Look for coolant residue that is white in color or

slight buildup of carbon on the purple to red. Some residue may have swirled from

bolt, which is normal. the intake valve partly up into the elbow. If the

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 8 of 13

residue coats the entire inside of the elbow, a

B. Inspect the bolt for moisture leaking aftercooler is the problem.

and for residue from coolant.

Result: The bolt is relatively dry. There is no

evidence of coolant residue on the bolt.

Proceed to Test Step 5.

5. Check the exhaust side of the

cylinder head for evidence of

coolant leaks..

A. Remove plug (5) .

Result: One or more of the following conditions

B. Examine the plug with a

are found:

spectrometer to detect the

presence of NA or K.

· NA or K was found on plug (5) .

· Wet, slimy residue was found in the exhaust port.

C. Insert a borescope into the

· Black, gelatinous residue was found on the inner

hole for plug (5) in order to Cracked

springs.

inspect the exhaust port. Look for cylinder

residue that is wet and slimy. head

Repair: The cylinder head is probably cracked.

Replace the cylinder head.

D. Remove the valve cover. Use

a bright flashlight to inspect the

Result: No evidence of coolant was found.

two inner springs (7) on the

exhaust side. Look for black,

Proceed to Test Step 6.

gelatinous material.

The material is the result of

burned coolant mixed with oil

that was pushed up the valve

guide during operation.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 9 of 13

Illustration 4 g02909817

(8) Air inlet elbow

Table 6

Troubleshooting Test Step Value Result

6. Inspect the insides of the air inlet elbows. Leaking Result: One or both of the

aftercooler elbows have residue that is

A. Remove the two air inlet elbows that are core white in color or that is a color

appropriate for the engine model: from purple to red.

- For 16 cylinder engines, the remove elbows for Repair: To locate the leak,

cylinder heads 1 and 16 pressurize the cooling system

to

- For 12 cylinder engines, the remove elbows for 103 kPa (15 psi). Use a bright

cylinder heads 1 and 12 flashlight and look through the

air inlet manifold. Repair the

- For eight cylinder engines, the remove elbows aftercooler core or replace the

for cylinder heads 1 and 8 aftercooler core.

inspect the inside of the elbows. Look for residue Result: The elbows do not

that is white in color or that is a color from purple have residue that is white in

to red. color or that is a color from

purple to red.

Note:If the intake side of the cylinder head is Proceed to Test Step 7.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 10 of 13

cracked, some residue may have swirled from the

intake valve partly up into the elbow. If the

residue coats the entire inside of the elbow, a

leaking aftercooler is the problem.

Illustration 5 g02910497

(9) Lower edge of the cylinder liner

(10) Main bearing cap

Table 7

Troubleshooting Test Step Value Result

7. Pressurize the cylinders. Cracked Result: The cooling system becomes

cylinder liner pressurized and/or the cylinder loses

A. Pressurize each cylinder according to compression rapidly.

Special Instruction, REHS7138, "New

Cylinder Leak Test Procedure Available Repair: Replace the damaged parts.

for 3500 Engines".

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 11 of 13

Result: The cooling system does not

B. Check for pressurization of the become pressurized. The cylinder does

cooling system. Also check for a loss of not lose compression rapidly.

cylinder compression.

Repair: Proceed to Test Step 8.

Note: Usually, a cracked cylinder liner

is associated with damage to the liner

and to the piston rings. A loss of

cylinder compression begins almost

immediately.

8. Look for internal coolant leaks. Result: Coolant is dripping from the

lowest edges of the cylinder liner and

A. Remove the crankcase side covers, as from the main bearing caps.

necessary.

Damaged

Repair: Remove the cylinder liner and

lower

B. Pressurize the cooling system to replace the seals.

cylinder liner

103 kPa (15 psi).

seal

Result: Coolant is not dripping from the

C. Look for coolant dripping from the lowest edges of the cylinder liner and

lowest edges of the cylinder liners (9) from the main bearing caps.

and from the main bearing caps (10) . Proceed to Test Step 9.

9. Check for a leaking cylinder head Leaking Result: A stream of bubbles emerges

gasket. cylinder head from the hose, indicating that exhaust

gasket gas is forced into the coolant..

A. Check for combustion gas in the

coolant. Repair: Use the cylinder cutout test to

cut groups of cylinders out in order to

a. Attach one end of a hose to the isolate the problem cylinder head.

radiator and submerge the other end of Replace the head gasket.

the hose into a container of water.

Result:

b. Run the engine and observe the end

of the hose in the water. When the cylinder head is pressurized,

the level of the jacket water rises and/or

A few isolated bubbles may emerge bubbles emerge from the jacket water..

from the hose, but if a stream of bubbles

emerges. exhaust gas is being forced Repair: Replace the head gasket.

into the coolant.

Result: A stream of bubbles does not

B. Pressurize the cylinder heads. emerge from the hose. When the

cylinder head is pressurized, the level of

a. Install a dummy injector into the the jacket water does not rise. Bubbles

cylinder head. do not emerge from the jacket water.

b. Apply a maximum of Proceed to Test Step 10.

690 kPa (100 psi) of nitrogen pressure

into the cylinder.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 12 of 13

c. Observe the jacket water for an

increase of the level and for the presence

of bubbles..

Illustration 6 g02916296

(11) Coolant supply to the compressor

(12) Coolant drain

(13) Oil drain from the compressor to the oil pan

Table 8

Troubleshooting Test Step Value Result

10. Check the air compressor head for Cracked water- Result: One or more of the

cracks. cooled air following conditions are found:

compressor head

A. Check for additional pressurization of · The pressure of the cooling

the cooling system. system rises when the air

compressor operates.

a. Operate the engine without the air ·Coolant is found in the oil

compressor operating. Monitor the drain from the air compressor.

cooling system pressure. · There is a pressure drop in the

compressor head.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

3512B Generator Set YAM00001-UP(SEBP5402 - 12) - Documentation Page 13 of 13

b. Activate the air compressor and look

for additional pressurization of the Repair: Replace the air

cooling system. compressor.

B. Check for coolant in the oil drain from

the air compressor to the oil pan.

C. Pressurize the air compressor head.

a. Disconnect the coolant hoses from the

air compressor.

b. Plug the coolant inlet or outlet to the

air compressor. Pressurize the other

opening with

100 kPa (15 psi) of air pressure.

c. Monitor the pressure.

Copyright 1993 - 2018 Caterpillar Inc. Mon Apr 2 23:49:14 UTC+0300 2018

All Rights Reserved.

Private Network For SIS Licensees.

An evaluation version of novaPDF was used to create this PDF file.

Purchase a license to generate PDF files without this notice.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/m... 4/2/2018

Das könnte Ihnen auch gefallen

- Engine Oil Pump PM3516 3516B Power Module NBR00001-UP PDFDokument3 SeitenEngine Oil Pump PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Engine Air Cleaner Service Indicator PM3516 3516B Power Module NBR00001-UP PDFDokument2 SeitenEngine Air Cleaner Service Indicator PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Flywheel Housing Cover PM3516 3516B Power Module NBR00001-UPDokument2 SeitenFlywheel Housing Cover PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- PRP LTP: Engine AlternatorDokument8 SeitenPRP LTP: Engine AlternatorFaresNoch keine Bewertungen

- Cylinder Block PM3516 3516B Power Module NBR00001-UPDokument5 SeitenCylinder Block PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Exhaust Manifold PM3516 3516B Power Module NBR00001-UP PDFDokument2 SeitenExhaust Manifold PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Engine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPDokument2 SeitenEngine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Disconnect Switch PM3516 3516B Power Module NBR00001-UPDokument2 SeitenDisconnect Switch PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Engine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UP PDFDokument2 SeitenEngine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Crankcase Pressure Sensor PM3516 3516B Power Module NBR00001-UPDokument1 SeiteCrankcase Pressure Sensor PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Flywheel PM3516 3516B Power Module NBR00001-UPDokument2 SeitenFlywheel PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Poor Fuel Consumption: TroubleshootingDokument3 SeitenPoor Fuel Consumption: TroubleshootingFaresNoch keine Bewertungen

- Exhaust Manifold PM3516 3516B Power Module NBR00001-UPDokument2 SeitenExhaust Manifold PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Fuel Filter PM3516 3516B Power Module NBR00001-UP PDFDokument2 SeitenFuel Filter PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Fuel Filter PM3516 3516B Power Module NBR00001-UP PDFDokument2 SeitenFuel Filter PM3516 3516B Power Module NBR00001-UP PDFFaresNoch keine Bewertungen

- Engine Air Cleaner Service Indicator PM3516 3516B Power Module NBR00001-UPDokument2 SeitenEngine Air Cleaner Service Indicator PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- Engine Oil Pump PM3516 3516B Power Module NBR00001-UPDokument3 SeitenEngine Oil Pump PM3516 3516B Power Module NBR00001-UPFaresNoch keine Bewertungen

- PM3516 3516B Power Module NBR00001-UP (SEBP5738 - 21) - Documentation PDFDokument8 SeitenPM3516 3516B Power Module NBR00001-UP (SEBP5738 - 21) - Documentation PDFFaresNoch keine Bewertungen

- Poor Fuel Consumption: TroubleshootingDokument3 SeitenPoor Fuel Consumption: TroubleshootingFaresNoch keine Bewertungen

- Catalog-A CAP300 PDFDokument2 SeitenCatalog-A CAP300 PDFFaresNoch keine Bewertungen

- Catalog-A CAP300 PDFDokument2 SeitenCatalog-A CAP300 PDFFaresNoch keine Bewertungen

- PM3516 3516B Power Module NBR00001-UP (SEBP5738 - 21) - Documentation PDFDokument8 SeitenPM3516 3516B Power Module NBR00001-UP (SEBP5738 - 21) - Documentation PDFFaresNoch keine Bewertungen

- Getting Started With Dropbox PDFDokument10 SeitenGetting Started With Dropbox PDFJamie DraperNoch keine Bewertungen

- Wa0004Dokument8 SeitenWa0004FaresNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Brayton CycleDokument2 SeitenBrayton CycleemilytNoch keine Bewertungen

- MIT BibliographyDokument6 SeitenMIT BibliographyCBZscribdNoch keine Bewertungen

- M O-352 4all: Mobel Ex-Kmx43Dokument2 SeitenM O-352 4all: Mobel Ex-Kmx43johnny sabinNoch keine Bewertungen

- Selection Table Vetus-Yanmar 2018 enDokument4 SeitenSelection Table Vetus-Yanmar 2018 enSoe Thura NyeinNoch keine Bewertungen

- Mi 1743B TDokument18 SeitenMi 1743B Tamir barekatiNoch keine Bewertungen

- Master Parts Catalog MS4185Dokument218 SeitenMaster Parts Catalog MS4185Carlos Ermácora100% (1)

- AVLDokument112 SeitenAVLroad1212100% (1)

- FIRMAN T08072 10000 or 8000 Watt Tri Fuel Portable Generator User Manual - Manuals+Dokument4 SeitenFIRMAN T08072 10000 or 8000 Watt Tri Fuel Portable Generator User Manual - Manuals+rperezz.agNoch keine Bewertungen

- LM2500 G4 For Oil Gas OperationDokument1 SeiteLM2500 G4 For Oil Gas OperationJose Fernando Barrera Valderrama100% (2)

- 303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainDokument7 Seiten303-01 - 2.3L EcoBoost - Removal and Installation - Timing ChainCARLOS LIMADANoch keine Bewertungen

- Assembly - Guide - Leoncino500.pdf Filename - UTF-8''Assembly Guide Leoncino500Dokument41 SeitenAssembly - Guide - Leoncino500.pdf Filename - UTF-8''Assembly Guide Leoncino500Rahmat TMNoch keine Bewertungen

- New Engine Mercedes 260 Model 177Dokument17 SeitenNew Engine Mercedes 260 Model 177along15102002Noch keine Bewertungen

- Eco Equivalency ChartDokument1 SeiteEco Equivalency ChartEstakoza GoldNoch keine Bewertungen

- Caterpillar Engine Oil Specifications: Astm Section D.02.Bo.02 Heavy-Duty Engine Oil Classification PanelsDokument10 SeitenCaterpillar Engine Oil Specifications: Astm Section D.02.Bo.02 Heavy-Duty Engine Oil Classification PanelsAnjar Setyo NugrohoNoch keine Bewertungen

- Catalogo de Partes Thunder Cat 4NA2 1996Dokument75 SeitenCatalogo de Partes Thunder Cat 4NA2 1996oscartrejoaNoch keine Bewertungen

- D65ex-16 SN81402 UpDokument1.498 SeitenD65ex-16 SN81402 UpVictor Villarroel Vargas Micky100% (1)

- Goods BS II HaulageDokument499 SeitenGoods BS II HaulageMohan Charanchath100% (1)

- Euro III BH117L Engine DL08 Operation Maintenance ManualDokument221 SeitenEuro III BH117L Engine DL08 Operation Maintenance ManualBambang Setyo Utomo88% (17)

- AGCOSISUPOWER 3rd GenerationSeriesDokument6 SeitenAGCOSISUPOWER 3rd GenerationSeriesAutoreisdorferNoch keine Bewertungen

- Fiat 127 1049 CM: Opis Části Servisního ManuáluDokument34 SeitenFiat 127 1049 CM: Opis Části Servisního ManuáluhaithamNoch keine Bewertungen

- Exhaust Muffler Design PDFDokument2 SeitenExhaust Muffler Design PDFAlexNoch keine Bewertungen

- Fuel Pump Spare PartsDokument2 SeitenFuel Pump Spare PartsMohamed MohamedNoch keine Bewertungen

- Delphi Katalog Duesen PDFDokument373 SeitenDelphi Katalog Duesen PDFDavid Lincoln83% (6)

- Um2kc1 Cylinder HeadDokument3 SeitenUm2kc1 Cylinder HeadBurik8Noch keine Bewertungen

- Mercedes Benz M272 EngineDokument28 SeitenMercedes Benz M272 EngineJijo Mercy100% (2)

- Unit 8: Title: Cylinder Block and Cylinder Head General ObjectiveDokument15 SeitenUnit 8: Title: Cylinder Block and Cylinder Head General ObjectiveAdid PunyaNoch keine Bewertungen

- Pulsar 180 Ug4 SPC 31.01.2012Dokument71 SeitenPulsar 180 Ug4 SPC 31.01.2012Bang CokekNoch keine Bewertungen

- Item Description Series NoDokument2 SeitenItem Description Series NoWalter FormigoniNoch keine Bewertungen

- Technical QuestionsDokument8 SeitenTechnical QuestionsKartikBNoch keine Bewertungen