Beruflich Dokumente

Kultur Dokumente

Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2

Hochgeladen von

Ahmad DanielOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2

Hochgeladen von

Ahmad DanielCopyright:

Verfügbare Formate

A.

WELDING PROCEDURE SPECIFICATION (WPS)

B.ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition

2014 & ABS 2016 PART 2

Organization Name: By:

C. Welding Procedure Specification No.: 117.SOFEL-GTAW-316L(5SCH20)-6G-SELECTARC Revision No.: 00 Date:

D. Supporting PQR No(s): 117.SOFEL-PQR-GTAW-316L(5SCH20)-6G-SELECTAR Revision No.: 00

E. Welding Process(es): GTAW F. Type (s): Manual

Attached Details

G. JOINTS (QW – 402)

Joint Design: Single V Groove, Single Bevel, Fillet

Backing: with/ without See attached sketches at page 3

Backing Material (Type): Ceramic, weld metal, same as base metal. etc.

Metal Nonfusing Metal

Nonmetallic Other

Retainer: None

H. BASE METAL (QW-403)

P-No.8, Group-No.: All

(If Notch Toughness required; P – No.8, Group-No.1)

Material Specification: SA-312 Type/ grade: TP316L UNS Number: S31603

to Material Specification: SA-312 Type/ grade: TP316L UNS Number: S31603

OR

Chem. Analysis and Mech. Prop.: None

to Chem. Analysis and Mech. Prop.: None

Thickness Range:

Base Metal:

Groove: 1 .5 - 10mm (If Notch Toughness required: 2.5-10mm) Fillet: All

T limits (S.cir.arc): N/A

Diameter Range: All diameter

Other: None

GTAW

I. FILLER METALS (QW-404) SFA5.9

Spec. No. (SFA): ER316L

AWS No (Class) : 6

F-No. : N/A

A-No. : 1.6mm

Size of Filler Metals : Solid Rod

Filler metal Product Form: TIG 20/10M

Filler metal Trade Name: Selectarc

Manufacturer N/A

Supplemental Filler Metal:

Weld Metal Deposited Thickness Range Max. 10 mm

Groove : All

Fillet : N/A

Electrode-Flux (Class) : N/A

Flux Type : N/A

Flux Trade Name : Without

Consumable Insert : None

Other

Organization:

Prepare by welding Engineer Certified by QA/QC Manager Approved by Class Approved by Client

Name: Name: Name: Name:

Date: Date: Date: Date:

Page 1 of 3 Date 13/09/2016

WELDING PROCEDURE SPECIFICATION (WPS)

ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition

2014 & ABS 2016 PART 2

QW-482 (Back)

WPS No. 117.SOFEL-GTAW-316L(5SCH20)-6G-SELECTARC Rev. 00

J. POSITIONS (QW-405) K. POST WELD HEAT TREATMENT (QW-407)

Position (s) of groove: All Temperature Range: N/A

Welding Progression: Uphill/ Downhill Time Range: N/A

Position (s) of Fillet: All Other: N/A

Other: None

M. GAS (QW-408)

L. PREHEAT (QW-406) Percent Composition

Preheat Temp. Min: > 0oC Classification Gas(es) (Mixture) Flow Rate

Shielding SFA 5.32 SG-A Ar 99.99% 14-25L/min

Interpass Temp. Max: 150 oC

Trailing None None None None

(If Notch toughness required 127oC) Backing SFA 5.32 SG-A Ar 99.99% 14-25L/min

Preheat Maintenance: None Other None None None None

Checked by: Digital pyrometer or applicable tools

Other: None

N. ELECTRICAL CHARACTERISTIC (QW–409)

Travel Speed Max. Heat Input

Filler Metal Current Amps Energy

Volt (Mm/Min) (If notch toughness

Weld Type & or Other

required)

Pass(es) Process Dia. Polarity Min. Max. Min. Max. Min. Max. Power

Class. (kJ/mm)

Root GTAW A5.9 ER316L 1.6 DCEN 60 90 7 15 15 40 N/A 1.50

Fill GTAW A5.9 ER316L 1.6 DCEN 70 110 7 15 40 100 N/A 0.80

Cap GTAW A5.9 ER316L 1.6 DCEN 70 100 7 15 40 90 N/A 0.81

Tungsten Electrode Size and Type: EWTh-2 (2% Thoriated-red colour)

Mode of Metal Transfer : N/A

Other: None

P. TECHNIQUE (QW – 410) NOTED

String or weave bead: Weave/Stringer

Orifice, Nozzle or Gas Cup Size: ½” 1. Neither the depth nor the maximum width in the cross section of

Initial and Interpass cleaning: Brush/Grinding weld metal deposited in each weld pass shall exceed the width at

Method of Back Gouging: Air-Arc gouging and/or Grinding the surface of weld pass.

Oscillation: N/A 2. Preheat and subsequent minimum inter-pass temperature shall

Closed to out chamber: both be checked just prior to initiating the arc and shall be maintained

Multiple or Single Pass (per side): multi-pass during welding operation for a distance at least equal to the

Multiple or Single Electrodes: Single thickness of the thickest welded part (but not less than 75mm) in

Electrode Spacing: N/A all directions from the points of welding.

Peening: N/A 3. No welding over dirt, mill scale, oil, moisture or other foreign

Other: None matter.

Organization:

Prepare by welding Engineer Certified by QA/QC Manager Approved by Class Approved by Client

Name: Name: Name: Name:

Date: Date: Date: Date:

Page 2 of 3 Date 13/09/2016

WELDING PROCEDURE SPECIFICATION (WPS)

ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition

2014 & ABS 2016 PART 2

WPSNo. 117.SOFEL-GTAW-316L(5SCH20)-6G-SELECTARC Rev. 00

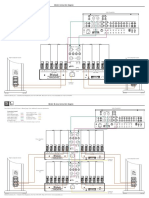

R. SKETCHES OF JOINT DESIGN (QW-402)

Organization:

Prepare by welding Engineer Certified by QA/QC Manager Approved by Class Approved by Client

Name: Name: Name: Name:

Date: Date: Date: Date:

Page 3 of 3 Date 13/09/2016

Das könnte Ihnen auch gefallen

- WPS - 024Dokument4 SeitenWPS - 024MAT-LIONNoch keine Bewertungen

- Stainless steel welding procedure qualification recordDokument1 SeiteStainless steel welding procedure qualification recordchandraNoch keine Bewertungen

- Weld Checklist PQRDokument2 SeitenWeld Checklist PQRScott Trainor100% (1)

- Weldspec ASME PQRDokument2 SeitenWeldspec ASME PQRSunil KumarNoch keine Bewertungen

- WELDER QUAL TEST REPORTDokument1 SeiteWELDER QUAL TEST REPORTtantri.hellyanti100% (1)

- Piping WPS SMAWDokument2 SeitenPiping WPS SMAWJk KarthikNoch keine Bewertungen

- WELDING PROCEDURE SPECIFICATIONSDokument6 SeitenWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- WPSDokument1 SeiteWPSNidhinkorothNoch keine Bewertungen

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Dokument14 SeitenList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNoch keine Bewertungen

- Dynamic Balancing Machines Measure and Correct UnbalanceDokument9 SeitenDynamic Balancing Machines Measure and Correct UnbalanceAmmar Al-Aghbari100% (1)

- For Fillet Weld Joint Project:Production ManifoldDokument1 SeiteFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- PQRDokument2 SeitenPQRafqzfieNoch keine Bewertungen

- Welding Procedure Specification (WPS)Dokument2 SeitenWelding Procedure Specification (WPS)Abdulmecit YetisNoch keine Bewertungen

- WPS FormatDokument2 SeitenWPS FormatAmit SarkarNoch keine Bewertungen

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokument3 SeitenWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Dokument1 SeiteQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNoch keine Bewertungen

- CEng Pink BookDokument46 SeitenCEng Pink BookAhmad DanielNoch keine Bewertungen

- WpsDokument3 SeitenWpsPankaj KumarNoch keine Bewertungen

- Welding and Gas CuttingDokument2 SeitenWelding and Gas CuttingKrishna Patil100% (1)

- HAZID Workshop PDFDokument45 SeitenHAZID Workshop PDFNora Afzam Abd Wahab100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDokument6 SeitenWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- Playing Arpeggios Over Changes Ex in DmajDokument4 SeitenPlaying Arpeggios Over Changes Ex in DmajMiguel PereiraNoch keine Bewertungen

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- 1000 Most Common Words in English - Numbers Vocabulary For 1Dokument12 Seiten1000 Most Common Words in English - Numbers Vocabulary For 1izmitlimonNoch keine Bewertungen

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokument3 SeitenWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNoch keine Bewertungen

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokument2 Seiten(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Specification for Vertical Storage TanksDokument6 SeitenWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNoch keine Bewertungen

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDokument1 SeiteWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNoch keine Bewertungen

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Dokument2 SeitenWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNoch keine Bewertungen

- Tax Review (Taxrev) BSA 4th Year (Saturday, 8:00AM - 11:00AM) I - Multiple ChoiceDokument8 SeitenTax Review (Taxrev) BSA 4th Year (Saturday, 8:00AM - 11:00AM) I - Multiple ChoiceDavidson Galvez0% (1)

- Surge TankDokument2 SeitenSurge TankBilel MarkosNoch keine Bewertungen

- WPS PQR Procedure PDFDokument31 SeitenWPS PQR Procedure PDFsudeesh kumarNoch keine Bewertungen

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDokument3 SeitenWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNoch keine Bewertungen

- Guidance To Prepare Wps PQR For WeldingDokument1 SeiteGuidance To Prepare Wps PQR For WeldingHamid MansouriNoch keine Bewertungen

- Proposed WPSDokument2 SeitenProposed WPSChisom Ikengwu100% (2)

- Hardness Test Report: Test Details Machine DetailsDokument1 SeiteHardness Test Report: Test Details Machine DetailsESHWAR CHARYNoch keine Bewertungen

- PQR 01 PDFDokument2 SeitenPQR 01 PDFVijay BhaleraoNoch keine Bewertungen

- Aws 001Dokument1 SeiteAws 001akshay sarfareNoch keine Bewertungen

- API 570 FormulasDokument2 SeitenAPI 570 FormulasArif Mokhtar89% (9)

- Piping WpsDokument37 SeitenPiping WpsZulfokar FahdawiNoch keine Bewertungen

- Aws d1.1 WPS, PQR & WQTDokument4 SeitenAws d1.1 WPS, PQR & WQTWeld Bro SandeepNoch keine Bewertungen

- Nonequilibrium Statistical MechanicsDokument299 SeitenNonequilibrium Statistical MechanicsKshitij LauriaNoch keine Bewertungen

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Dokument2 SeitenWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNoch keine Bewertungen

- Wps Mma PipeDokument2 SeitenWps Mma PipeDimitris NikouNoch keine Bewertungen

- Welders CertDokument11 SeitenWelders CertAhmed GomaaNoch keine Bewertungen

- WPQ-1083 3G PDFDokument2 SeitenWPQ-1083 3G PDFduendex360100% (1)

- QW 483Dokument2 SeitenQW 483delta lab sangliNoch keine Bewertungen

- Physics: OxfordDokument224 SeitenPhysics: OxfordMusic Life100% (1)

- WPQR Welding Procedure Qualification RecordsDokument3 SeitenWPQR Welding Procedure Qualification Recordsramesh rajaNoch keine Bewertungen

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Dokument2 SeitenWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNoch keine Bewertungen

- WPQ WeldCanada PDFDokument1 SeiteWPQ WeldCanada PDFAhmad DanielNoch keine Bewertungen

- GTAW Welding Process ParametersDokument12 SeitenGTAW Welding Process Parametersmiteshpatel191Noch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDokument31 SeitenALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNoch keine Bewertungen

- Report on Welding Procedure Specifications for Single V-Groove JointsDokument15 SeitenReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDokument4 SeitenWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Company Logo Added to QAP DocumentDokument4 SeitenCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDokument2 SeitenQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetDokument4 SeitenPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNoch keine Bewertungen

- WOPQ Form English1Dokument2 SeitenWOPQ Form English1oaperuchenaNoch keine Bewertungen

- Welding Procedure Specification For GTAW & GMAWDokument4 SeitenWelding Procedure Specification For GTAW & GMAWanh thoNoch keine Bewertungen

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDokument1 SeiteSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcNoch keine Bewertungen

- WPQ Is 2062 Haresh Shah W1Dokument1 SeiteWPQ Is 2062 Haresh Shah W1Anand KesarkarNoch keine Bewertungen

- Welder Operators Qualification TestDokument2 SeitenWelder Operators Qualification Testlokifarad100% (1)

- WPS API1104 A516 GR 70Dokument1 SeiteWPS API1104 A516 GR 70Erick HoganNoch keine Bewertungen

- Aic Asf PQR 133Dokument3 SeitenAic Asf PQR 133AHMED MEDANYNoch keine Bewertungen

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Dokument3 SeitenNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNoch keine Bewertungen

- Welding Procedure SpecificationDokument4 SeitenWelding Procedure SpecificationBhargav BbvsNoch keine Bewertungen

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Dokument3 SeitenNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNoch keine Bewertungen

- PWPS CS To SS446-3Dokument5 SeitenPWPS CS To SS446-3BIIS QAQC Babu SivaNoch keine Bewertungen

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Dokument9 Seiten(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNoch keine Bewertungen

- MT 10 Om 02 LDokument20 SeitenMT 10 Om 02 LAhmad DanielNoch keine Bewertungen

- WPS PQR PDFDokument23 SeitenWPS PQR PDFAhmad Daniel100% (1)

- API Exams CalculationsDokument20 SeitenAPI Exams CalculationssyedsayeediNoch keine Bewertungen

- LP Formulation MITDokument27 SeitenLP Formulation MITAhmad DanielNoch keine Bewertungen

- BLOB AnalysisDokument9 SeitenBLOB AnalysisAhmad DanielNoch keine Bewertungen

- Periodic Table IsotopesDokument1 SeitePeriodic Table IsotopeslamantreveurNoch keine Bewertungen

- NRC - 10 CFR Part 20-Standards For Protection Against RadiationDokument81 SeitenNRC - 10 CFR Part 20-Standards For Protection Against RadiationAhmad DanielNoch keine Bewertungen

- NRC Regulations for Industrial RadiographyDokument24 SeitenNRC Regulations for Industrial RadiographyAhmad DanielNoch keine Bewertungen

- UgCalculator V1.1Dokument1 SeiteUgCalculator V1.1Ahmad DanielNoch keine Bewertungen

- Target Band 7 Trial Listening Edition4Dokument3 SeitenTarget Band 7 Trial Listening Edition4Ahmad DanielNoch keine Bewertungen

- NRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialDokument70 SeitenNRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialAhmad DanielNoch keine Bewertungen

- Alessandro Amp ArticleDokument1 SeiteAlessandro Amp ArticleAhmad DanielNoch keine Bewertungen

- MT 10 Om 02 LDokument20 SeitenMT 10 Om 02 LAhmad DanielNoch keine Bewertungen

- WA Sabrina Hi Fi News 08-15Dokument3 SeitenWA Sabrina Hi Fi News 08-15Ahmad DanielNoch keine Bewertungen

- MC452 Connection DiagramDokument2 SeitenMC452 Connection DiagramAhmad DanielNoch keine Bewertungen

- Blues Scale W/tapping: 3-Notes Per Strings Mayones School #5Dokument1 SeiteBlues Scale W/tapping: 3-Notes Per Strings Mayones School #5Ahmad DanielNoch keine Bewertungen

- XLogic X-Desk Install GuideDokument48 SeitenXLogic X-Desk Install GuideAhmad DanielNoch keine Bewertungen

- X-Desk X-Panded Recall SheetDokument1 SeiteX-Desk X-Panded Recall SheetAhmad DanielNoch keine Bewertungen

- Audeze LCD-X PathosDokument3 SeitenAudeze LCD-X PathosAhmad DanielNoch keine Bewertungen

- Funk Guitar Rhythms Pt1 PDFDokument2 SeitenFunk Guitar Rhythms Pt1 PDFAlvaro RodriguesNoch keine Bewertungen

- Bigsby Parts 2010Dokument85 SeitenBigsby Parts 2010Ahmad DanielNoch keine Bewertungen

- Hamka Dibawah Lindungan KabahDokument1 SeiteHamka Dibawah Lindungan KabahAhmad DanielNoch keine Bewertungen

- HFN Pro-JectClassic LowresDokument3 SeitenHFN Pro-JectClassic LowresAhmad DanielNoch keine Bewertungen

- WA Sabrina Hi Fi News 08-15Dokument3 SeitenWA Sabrina Hi Fi News 08-15Ahmad DanielNoch keine Bewertungen

- HFN Pro-JectClassic LowresDokument3 SeitenHFN Pro-JectClassic LowresAhmad DanielNoch keine Bewertungen

- 3 Goshu 3Dokument18 Seiten3 Goshu 3nega cheruNoch keine Bewertungen

- Bachelor of Engineering (Hons) Chemical Course OutlineDokument2 SeitenBachelor of Engineering (Hons) Chemical Course OutlineWan Mohammad Faris FahmiNoch keine Bewertungen

- Rotational Motion Engineering Mechanics IIT KanpurDokument67 SeitenRotational Motion Engineering Mechanics IIT KanpurNitin SharmaNoch keine Bewertungen

- Sliit L Epdc 15Dokument108 SeitenSliit L Epdc 15sulochana priyashanNoch keine Bewertungen

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDokument5 SeitenTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNoch keine Bewertungen

- Produktkatalog 2019 WebDokument280 SeitenProduktkatalog 2019 WebbagastcNoch keine Bewertungen

- 1 - WTE Forum - Info About WTE in The PhilippinesDokument2 Seiten1 - WTE Forum - Info About WTE in The PhilippinesMatti Grey Celestial DG IINoch keine Bewertungen

- O Level Physics 2018 Past PaperDokument20 SeitenO Level Physics 2018 Past PaperfordalNoch keine Bewertungen

- Downstream - Processing - Lecture 5rnjDokument8 SeitenDownstream - Processing - Lecture 5rnjqwertyuNoch keine Bewertungen

- Generate Electricity From Park Revolving DoorDokument39 SeitenGenerate Electricity From Park Revolving Doortariq7660% (5)

- 1st PU Chemistry May 2015 PDFDokument2 Seiten1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- EV Technology QPDokument3 SeitenEV Technology QPvcetnaac c6Noch keine Bewertungen

- 400TheoryTest AcrobatDokument4 Seiten400TheoryTest AcrobatRiahi RezegNoch keine Bewertungen

- Na-S BatteryDokument12 SeitenNa-S Batterymeseret simachewNoch keine Bewertungen

- Bridge Rectifier - Definition, Construction and WorkingDokument14 SeitenBridge Rectifier - Definition, Construction and WorkingRamKumarNoch keine Bewertungen

- Profile ForgingDokument17 SeitenProfile ForgingMahipal ChandanNoch keine Bewertungen

- Operation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesDokument178 SeitenOperation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesHéctor AraujoNoch keine Bewertungen

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsDokument3 SeitenAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoNoch keine Bewertungen

- Parts Crane Hitachi FK600 - PRDokument2 SeitenParts Crane Hitachi FK600 - PRDefly Gusti100% (1)

- ME1130 Mechanism of SolidificationDokument15 SeitenME1130 Mechanism of SolidificationShivam RajNoch keine Bewertungen

- Internship ReportDokument58 SeitenInternship ReportSamay Dhirwani100% (1)

- Hybrid Safety and Service Procedures: Automotive Technology, Fifth EditionDokument40 SeitenHybrid Safety and Service Procedures: Automotive Technology, Fifth EditionSkyAnimal ChannelNoch keine Bewertungen