Beruflich Dokumente

Kultur Dokumente

Inspection Queries

Hochgeladen von

muhammad qasim0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten3 SeitenOriginaltitel

Inspection queries.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten3 SeitenInspection Queries

Hochgeladen von

muhammad qasimCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Dated: 04/09/2018

Point Raised By Inspection Team

1. Door of washing area must be permanently closed

2. Diagrammatic SOP for Sanitizer (70% IPA must be used without any smell)

3. Provision of Corridor cleaning manager

4. Maintaining Logbook for daily cleaning

5. Door closer are not working properly

6. Vacuum cleaner

7. Standard weights for internal calibration (RMS Balances)

8. Bulb or light should be in a proper place, so dust couldn’t accumulate on it

9. Containers must be of SS Steel.

10. Factory name mentioned outside on main gate

11. Anti microbial paints in FBD area

12. Aluminum foil should be kept in Controlled temperature and in proper packing

13. Stability chamber for QC

14. HPLC for QC

15. Carl Fischer analyzer for QC

16. RMS and Finished Goods store tem/humidity record

17. Capsule shells should be kept in its proper place in capsule filling area

18. Use of cone mixer for final mixing

19. One machine for one product

20. Fans are not allowed in production area

21. Manufacturing in Lots are not allowed

22. Maintaining of QC records

23. Scopes

24. Dispensing Area discrepancy

25. Completion of all relevant documents (QC/Production)

26. Hygrometers must be working properly in all sections

27. HVAC Returns grills should be changed

28. Bay area

29. Raw material must be placed at least 4 inches away from wall

30. Usage of Methylene Chloride should be stopped

Record provision to inspection team

Copy of Receipt of Technical staff documents submitted to DRAP

QC equipments and Production machinery list

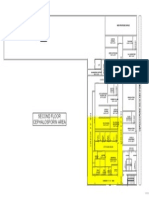

Lay out plan

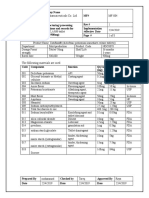

List of Registered products

List of QC Instruments

S.No. Name Made

1. UV- Visible spectrophotometer Shimadzu, Japan

2. Hot Air oven

3. Moisture analyzer China

4. Melting point apparatus China

5. Analytical balance AND, Japan

6. pH meter China

7. Flame photometer China

8. Conductivity meter China

9. Stirrer +Heater China

10. Sanicator China

11. Dissolution test apparatus Local

12. Disintegration apparatus Local

13. Water bath Local

14. Muffle furnace China

15. Distillation unit China

16. Hardness tester China

17. Vernier Caliper China

18. screw gauge China

19. Polarimeter China

20. Friabilator Local

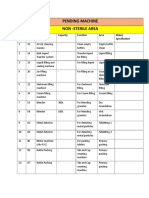

List of Production Machinery

S.No. Name

1. Balance 300 kg max

2. Balance 200 kg max

3. Balance 07 kg max

4. Balance 300Gm max

5. Balance 01 kg max max

6. Horizontal mixer

7. Fluidized Bed Dryer

8. Oscillating granulator

9. Compression machine ZP-17

10. Compression machine ZP-19

11. Coating pan

12. Capsule filling machine

13. Cone mixer

14. Blister Machine (Alu-PVC)

15. Blister Machine (Alu-Alu)

16. Strip packing machine

17. Strip packing machine

18. Printer( laser jet)

19. Dehumidifier # 1

20. Dehumidifier #2

21. R.O Plant

Das könnte Ihnen auch gefallen

- Validation TableDokument11 SeitenValidation TableAlison LewisNoch keine Bewertungen

- XYZ Tablet 20mg FCTDokument123 SeitenXYZ Tablet 20mg FCTAnonymous jzlKNORNoch keine Bewertungen

- Cefepime For Injection USP (Dossier) PDFDokument66 SeitenCefepime For Injection USP (Dossier) PDFsofiaNoch keine Bewertungen

- Unilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryDokument92 SeitenUnilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryMhike EcoNoch keine Bewertungen

- Siddhi Vinayak Industries.: Batch Manufacturing RecordDokument11 SeitenSiddhi Vinayak Industries.: Batch Manufacturing RecordPANKAJNoch keine Bewertungen

- Equipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreDokument1 SeiteEquipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreMuhammad Rizwan KhanNoch keine Bewertungen

- B-Block B Iii Area Clean Room Entry & Exit Pictorial DisplayDokument24 SeitenB-Block B Iii Area Clean Room Entry & Exit Pictorial DisplaySanathNoch keine Bewertungen

- Format Ahu ValDokument3 SeitenFormat Ahu ValKrishna RajNoch keine Bewertungen

- IQ Risk AnalysisDokument1 SeiteIQ Risk AnalysisNadine LilleNoch keine Bewertungen

- Summary Caldece 112.8 KG NewDokument23 SeitenSummary Caldece 112.8 KG NewfajarRS69Noch keine Bewertungen

- QC TestsDokument12 SeitenQC Testsembermich100% (1)

- Flow Chart Neozep F Exp TabletDokument4 SeitenFlow Chart Neozep F Exp TabletRio FebriansyahNoch keine Bewertungen

- Purified Water User PointDokument1 SeitePurified Water User PointMuhammadAmdadulHoqueNoch keine Bewertungen

- Check List Regarding Documents Submitted For Drug Registration PurposesDokument8 SeitenCheck List Regarding Documents Submitted For Drug Registration PurposesMayson Bali100% (1)

- List of Licenses / Certificates: As Per List Attached Here WithDokument2 SeitenList of Licenses / Certificates: As Per List Attached Here Withkanji63Noch keine Bewertungen

- Related Substances of Cefipime IPDokument4 SeitenRelated Substances of Cefipime IPBhawani singhNoch keine Bewertungen

- DOEH Pesticide FilesDokument20 SeitenDOEH Pesticide FilesMichael_Lee_RobertsNoch keine Bewertungen

- Pending Machine Non - Sterile Area: S. NO. Room No. Equipment Name Capacity Function Area Make/ SpecificationDokument3 SeitenPending Machine Non - Sterile Area: S. NO. Room No. Equipment Name Capacity Function Area Make/ Specificationjpmaurya77Noch keine Bewertungen

- Chemical Analysis of Soft WaterDokument4 SeitenChemical Analysis of Soft WaterBhawani singhNoch keine Bewertungen

- Index of QA WorkingDokument2 SeitenIndex of QA WorkingsajidNoch keine Bewertungen

- Propose Modification For Change Room (BLS) First Change (Officer For Primary Area) : Sl. No Modification Responsible Dept Timeline RemarksDokument4 SeitenPropose Modification For Change Room (BLS) First Change (Officer For Primary Area) : Sl. No Modification Responsible Dept Timeline RemarksshdphNoch keine Bewertungen

- Monthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthDokument31 SeitenMonthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthFajarRachmadiNoch keine Bewertungen

- Bhaluka Equipment, Utilities and QC Instrument DetailsDokument15 SeitenBhaluka Equipment, Utilities and QC Instrument DetailsRamboNoch keine Bewertungen

- Annexure - VIDokument19 SeitenAnnexure - VIKiran KumarNoch keine Bewertungen

- TENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletDokument2 SeitenTENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletGaFf ArNoch keine Bewertungen

- Lab Ledger PhyDokument287 SeitenLab Ledger PhyMumtazAhmadNoch keine Bewertungen

- Docs h06 FM 018Dokument2 SeitenDocs h06 FM 018ArchanNoch keine Bewertungen

- Siphar Bod-03-06-2011Dokument4 SeitenSiphar Bod-03-06-2011Indra NeelNoch keine Bewertungen

- Vidya Bharti College, Seloo Requirement of Chemical and Media For Microbiology PracticalDokument11 SeitenVidya Bharti College, Seloo Requirement of Chemical and Media For Microbiology PracticalYogesh BanginwarNoch keine Bewertungen

- Acene CreamDokument2 SeitenAcene CreamJai MurugeshNoch keine Bewertungen

- 2nd Floor Ceph Area Hilton PharmaDokument1 Seite2nd Floor Ceph Area Hilton PharmamhmaharNoch keine Bewertungen

- Microbiology Available Equipments Data As Per NABL FormatDokument8 SeitenMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaNoch keine Bewertungen

- Product Spect - VPODokument2 SeitenProduct Spect - VPOKomathi BalasupramaniamNoch keine Bewertungen

- Raw Data Report of TabletDokument11 SeitenRaw Data Report of TabletShubam SharmaNoch keine Bewertungen

- 161 ListDokument8 Seiten161 ListAnnie KhanNoch keine Bewertungen

- Premix Jordan (VAPCO®)Dokument2 SeitenPremix Jordan (VAPCO®)Tayyab TahirNoch keine Bewertungen

- Concentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfateDokument6 SeitenConcentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfatesajidNoch keine Bewertungen

- Requirements For NABLDokument1 SeiteRequirements For NABLSiva ShankarNoch keine Bewertungen

- Product Cost-Pharma (1.2.16)Dokument406 SeitenProduct Cost-Pharma (1.2.16)EmranNoch keine Bewertungen

- Calibration of ExperimentsDokument48 SeitenCalibration of ExperimentsNgocThuc LeNoch keine Bewertungen

- No. of SOP Pending in All Cross Functional DepartmentDokument64 SeitenNo. of SOP Pending in All Cross Functional DepartmentNishit SuvaNoch keine Bewertungen

- Sop ZetasizerDokument3 SeitenSop ZetasizerP SWETHANoch keine Bewertungen

- New ProjectDokument4 SeitenNew Projectjpmaurya77Noch keine Bewertungen

- Calibration Curve: Tartaric Acid: Peak AreaDokument10 SeitenCalibration Curve: Tartaric Acid: Peak Areajanesalazar3369Noch keine Bewertungen

- CTD (Form 5F) : Section Sub-Section HeadingDokument19 SeitenCTD (Form 5F) : Section Sub-Section Headinganon_3034696030% (1)

- Filter IDsDokument4 SeitenFilter IDsopd pharmacyNoch keine Bewertungen

- Bag Filter: NO Client Site Location Application Capacity Q'Ty Completion RemarksDokument6 SeitenBag Filter: NO Client Site Location Application Capacity Q'Ty Completion Remarksbasavaraju535Noch keine Bewertungen

- Raya Pharmaceuticals Co. LTD: Cataflam®Dokument8 SeitenRaya Pharmaceuticals Co. LTD: Cataflam®Mayson BaliNoch keine Bewertungen

- Attachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)Dokument6 SeitenAttachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)PAWAN KUMARNoch keine Bewertungen

- PH Measurement Protocol For Lenwin SuspensionDokument5 SeitenPH Measurement Protocol For Lenwin Suspensionnaeem186Noch keine Bewertungen

- Miss. Garima Shroty Contact No.: 08006740284: Curriculum VitaeDokument3 SeitenMiss. Garima Shroty Contact No.: 08006740284: Curriculum VitaePragya SharmaNoch keine Bewertungen

- Lovex RegistrDokument64 SeitenLovex RegistrbishopshehadehNoch keine Bewertungen

- Certificate of Quality: Cayman Pharma S.R.O. Ul. Práce 657, 277 11 NERATOVICE Czech Republic Tel. +420 315 665 360Dokument3 SeitenCertificate of Quality: Cayman Pharma S.R.O. Ul. Práce 657, 277 11 NERATOVICE Czech Republic Tel. +420 315 665 360amin138irNoch keine Bewertungen

- Master Listof Watertreatment PlantDokument2 SeitenMaster Listof Watertreatment PlantHarpal SainiNoch keine Bewertungen

- ListDokument18 SeitenListits4krishna3776Noch keine Bewertungen

- Analysis Request Form 2014Dokument52 SeitenAnalysis Request Form 2014Mohamad ArtaNoch keine Bewertungen

- Print 24.1.18 Sop LlistDokument11 SeitenPrint 24.1.18 Sop Llistkalaiarasi ravichandranNoch keine Bewertungen

- 01 Disintegration Test For Tablets and CapsulesDokument30 Seiten01 Disintegration Test For Tablets and CapsulesmefroNoch keine Bewertungen

- Guidelines For Minimum Infrastructure Facilities To Be Created by The Manufacturers of BiopesticidesDokument7 SeitenGuidelines For Minimum Infrastructure Facilities To Be Created by The Manufacturers of BiopesticidesKanthimathinathan KrishnanNoch keine Bewertungen

- (C) 2.3 Guidelines For Minimum Infrastructure Facilities To Be Created by The Manufacturers of Botanical Biopesticides (Pyrethrum, Azadirachtin, Cymbopogon Etc.)Dokument2 Seiten(C) 2.3 Guidelines For Minimum Infrastructure Facilities To Be Created by The Manufacturers of Botanical Biopesticides (Pyrethrum, Azadirachtin, Cymbopogon Etc.)Kl SarathNoch keine Bewertungen

- The Khyber Pakhtunkhwa Drugs Rules 1982 PDFDokument8 SeitenThe Khyber Pakhtunkhwa Drugs Rules 1982 PDFmuhammad qasimNoch keine Bewertungen

- House Rent SlipDokument1 SeiteHouse Rent Slipmuhammad qasimNoch keine Bewertungen

- House Rent SlipDokument1 SeiteHouse Rent Slipmuhammad qasimNoch keine Bewertungen

- Self InspectionDokument2 SeitenSelf Inspectionmuhammad qasimNoch keine Bewertungen

- Fluidized-Bed Reactors - Kuralay TilegenDokument16 SeitenFluidized-Bed Reactors - Kuralay TilegenKuralay TilegenNoch keine Bewertungen

- Compression Lab ReportDokument8 SeitenCompression Lab ReportfatinzalilaNoch keine Bewertungen

- Structure and Classification of LipidsDokument50 SeitenStructure and Classification of LipidsLEILA MARIPOROC100% (2)

- 17BEM0049DA1Dokument12 Seiten17BEM0049DA1Vedant KarnatakNoch keine Bewertungen

- BatteriesDokument29 SeitenBatteriesgihan5dhananjaya5katNoch keine Bewertungen

- SMC EIA Final Report - Baseline ReportDokument54 SeitenSMC EIA Final Report - Baseline ReportGary JopsonNoch keine Bewertungen

- Brochure EN Ver - Thai Parkerizing Company ProfileDokument4 SeitenBrochure EN Ver - Thai Parkerizing Company ProfileTAEWARAT RAKRUANGNoch keine Bewertungen

- Solid Waste Management For HouseholdDokument70 SeitenSolid Waste Management For HouseholdsonNoch keine Bewertungen

- Safety Data Sheet - Perfect Coat Flea & Tick Dog Shampoo PDFDokument7 SeitenSafety Data Sheet - Perfect Coat Flea & Tick Dog Shampoo PDFhoneybelNoch keine Bewertungen

- Carbon & It's Compounds (X)Dokument27 SeitenCarbon & It's Compounds (X)Pakhi MauryaNoch keine Bewertungen

- Claus Process: Claus, The Claus Process Has Become The Industry StandardDokument23 SeitenClaus Process: Claus, The Claus Process Has Become The Industry StandardNhan Nguyen VanNoch keine Bewertungen

- Rolling Threads DetailsDokument0 SeitenRolling Threads DetailsfastenersworldNoch keine Bewertungen

- NW6Dokument10 SeitenNW6Mamidala HarithaNoch keine Bewertungen

- Mole Concept Extra Practice ProblemsDokument3 SeitenMole Concept Extra Practice ProblemsSouvik NandiNoch keine Bewertungen

- GGBSDokument20 SeitenGGBSratnakar0% (1)

- Workplace HazardsDokument26 SeitenWorkplace HazardsPageduesca RouelNoch keine Bewertungen

- Latex & RubberDokument4 SeitenLatex & RubberLựuLiềuLìNoch keine Bewertungen

- Pollutants and Its MeasurementDokument70 SeitenPollutants and Its MeasurementECRDNoch keine Bewertungen

- Unit Cells PDFDokument3 SeitenUnit Cells PDFel_tano33Noch keine Bewertungen

- Abn Abwa 8s eDokument8 SeitenAbn Abwa 8s efrancis eugenioNoch keine Bewertungen

- C in 110 PDFDokument7 SeitenC in 110 PDFRezaNoch keine Bewertungen

- Food PoisoningDokument20 SeitenFood PoisoningNgọcNoch keine Bewertungen

- Ionic EquilibriumDokument4 SeitenIonic EquilibriumFu HongNoch keine Bewertungen

- Introduction To TextileDokument30 SeitenIntroduction To Textileumar.niift3049100% (1)

- LPG Standards PDFDokument115 SeitenLPG Standards PDFhandoyo_eko20017573Noch keine Bewertungen

- SealXtra PU FR - BaseDokument3 SeitenSealXtra PU FR - BasehazelNoch keine Bewertungen

- BOQ Fountain Water Body (1) .XLSXBDokument6 SeitenBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- Chemical Control of Turfgrass Diseases 2020Dokument34 SeitenChemical Control of Turfgrass Diseases 2020Zakhar PikulytskyiNoch keine Bewertungen

- Guideline For Butt Saddle and Socket FusionDokument10 SeitenGuideline For Butt Saddle and Socket FusionKenNoch keine Bewertungen

- Gas Cylider Technical Regulation PDFDokument37 SeitenGas Cylider Technical Regulation PDFVinod Varadan SNoch keine Bewertungen