Beruflich Dokumente

Kultur Dokumente

AGN 065 - Technical Guidance on Air Inlet Filters

Hochgeladen von

P.p. Arul IlancheeranOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AGN 065 - Technical Guidance on Air Inlet Filters

Hochgeladen von

P.p. Arul IlancheeranCopyright:

Verfügbare Formate

Application Guidance Notes: Technical Information from Cummins Generator Technologies

AGN 065 – Air Inlet Filters

DESCRIPTION

There are two types of Air Inlet Filter used on AvK and STAMFORD alternators. The type of

filter design will be selected for specific environmental conditions. The two types are:

Dry Dust Filter

Moisture Filter

Both types of filters are manufactured by companies specialising in air filtration systems and

each type of filter kit is a proprietary package from that company’s standard range of

appropriate products.

ENVIRONMENTAL CONDITIONS

When considering a proposed operational site with a contaminated atmosphere, careful

consideration must be given to the design and operational functionality of the Generating Set

housing, with special attention to air inlet and air outlet apertures. The next area of concern

must be the internal airflow management system in conjunction with the type of contamination

that will inevitably enter the Generating Set housing. Finally, the type of supplementary filter

required at point of entry to the alternator, the engine and its cooling system.

The decision making process regarding the need to consider an abnormal site and associated

contaminated atmosphere must be a controlled function within the Generating Set

manufacturer’s commercial operation, where direct contact exists with the end user, their

needs and required duty for any proposed Generating Set.

AGN 065 ISSUE B/1/6

It is expected that this commercial team will have the necessary experience to identify

troublesome applications at time of quotation and further expected that there will be Generating

Set company technical documentation in place to help their commercial team work through a

process of:

Requirements

Recommendations

Application Checklist

Such a procedure will ensure the Generating Set supplier and installer are fully aware of the

risk they place on the Generating Set company, if operational problems occur related to site

conditions, when a correctly specified Generating Set equipment package has not been

supplied or correctly installed and operationally managed.

Air inlet filters are constructed into a specially fitted filter framework at the factory. Each filter

assembly is designed specifically for a particular alternator frame size and should be fitted at

the factory during alternator manufacture. Retrofitting at the customer’s site is complicated

and is to be avoided.

It is strongly recommends that all alternators fitted with air inlet filters are specified to be factory

fitted with stator winding temperature detection devices, thereby providing an automatic control

system that can be employed to ensure that blocked air filters are detected before a winding

overheats, with the risk of burn-out occurring.

FILTER TYPES

Dry Dust Filters

STAMFORD Alternators

The Dry Dust Filters used on STAMFORD alternators are made to a specific size to fit each of

the frame size air inlet apertures. The type of filter medium used is known as P250 type.

The filter assembly is constructed from ferrous metals and is; therefore, liable to rust if the filter

assembly is used in a damp/wet environment. Desert conditions or excessively dusty

environments should be carefully considered by the designer of the Generating Set housing.

Such conditions require the housing to have air inlet apertures with large areas, therefore very

low air speed and incorporate a tortuous path that includes a ‘sand-trap’. The ‘sand-trap’ must

be regularly inspected and emptied and the access and method for doing this should be a

design feature of the Generating Set housing.

S0/S1 and P0/P1: Air inlet filters are not available for these small alternators.

UC 224 (S2) and UC 274 (S3): A pair of dry dust filter assemblies are fitted, one at each side

of the terminal box.

AGN 065 ISSUE B/2/6

S4, HC5 (S5) and S6: A pair of dry dust filter assemblies are fitted, one at each side of the

terminal box.

P7 (S7): A single dry dust filter assembly is located at the NDE of the terminal box. When the

filter is fitted to the P7 (S7) alternator, a grommet is fitted to the slots at the DE of the frame.

AvK Alternators

The Dry Dust Filters used on AvK alternators are made to a specific size to fit each of the frame

size air inlet apertures. The type of filter medium used will be determined during negotiations

on the complete alternator specification.

The filter assembly may be constructed from steel with zinc coated mesh wire or stainless steel

with stainless steel mesh wire, depending on the application conditions.

Moisture Filters

Dry dust filters do have some capability to take moisture from the cooling air stream, but their

effectiveness is very limited. In damp/wet environments, moister filters are recommended.

STAMFORD Alternators

Moisture Filters may be fitted to the HC6 (S6) or P7 (S7) alternator as part of the IP44 upgrade

package. This upgrade package is not available on other STAMFORD alternators. The moister

filter used in a Premaburg type and is made to a specific size to fit the HC6 (S6) or P7 (S7)

frame size air inlet aperture. The Premaburg filter is designed for removing airborne water

droplets from the cooling air stream.

This type of filter is designed to function by a fundamental principle known as a ‘torturous path’.

Here the cooling air stream is passed through a filter system providing large area therefore,

relatively low air speed. The cooling air is then made to turn through many 90º changes of

direction around multiple vertical aluminium vanes. At each directional change the heavier than

air water droplet collides with a vane and is then held against a barb formed as part of the

extruded aluminium vane. The water droplets then drain under gravity to a designed drain point

and drip to atmosphere away from the cooling air flow path. The clearance between the vanes

is typically 10mm, which is ideal for the filtration of water droplets, but renders these filters

virtually useless for dry dust filtration.

When IP44 requirements are specified and the alternator is supplied with IP44 Premaburg air

inlet filters, then the alternator will also be fitted with IP23 air outlet louvers at the alternator’s

air outlet apertures.

S6: A pair of Premaburg filter assemblies are fitted, one at each side of the terminal box base,

as part of the IP44 protection upgrade.

AGN 065 ISSUE B/3/6

P7 (S7): When the Premaburg type of filter is fitted to any type of P7 (S7) alternators, then a

grommet will be fitted to the slots at the DE of the frame. A single Premaburg filter assembly

is fitted to the terminal box side opposite to cable entry, as part of the IP44 protection upgrade.

AvK Alternators

Moisture Filters are available for all AvK alternators. The type of filter will be determined by the

application conditions and the IP protection afforded to the alternator. The Premaburg type

filter, as used on STAMFORD HC6 (S6) and P7 (S7) alternators is regularly used on AvK

alternators. Whichever moister filter is used, it will be made to a specific size to fit the alternator

frame size air inlet aperture. Refer to the information above, for details of the Premaburg filter

design.

ALTERNATOR DE-RATES

Any air inlet filtration system will restrict air flow, reducing the volume and so thermal heat

transfer characteristic, of the cooling air as it passes through the alternator. For this reason the

following guidance is offered;

Dry Dust Filters invoke a 5% de-rate

This 5% ‘rule’ is applicable to all STAMFORD alternators and is based on an expectation of

good on-site filter maintenance. With good maintenance, the pressure drop across the filter

should never exceed 10% of the total pressure drop across the complete alternator. The

necessary de-rate will be factored in to the size of AvK alternator nominated for a particular

application.

Moisture Filters

Moisture Filters may be fitted to STAMFORD HC6 (S6) or P7 (S7) alternators as part of the

IP44 upgrade package. The IP44 upgrade package invokes a 10% de-rate. No further de-rate

is necessary. The necessary de-rate will be factored in to the size of AvK alternator nominated

for a particular application.

MAINTENANCE

Dry Dust Filters

The dry dust filter assemblies used on AvK and STAMFORD alternators were chosen after

due discussions with reliable and reputable suppliers concerning technical aspects in terms of

airspeed, air volume and choice of a media material. Also with due consideration for

serviceability and worldwide supply structure.

It must be accepted that the major influence for continual in-service filter performance is filter

maintenance, where the principle responsibility is with the Generating Set operator. However,

the Generating Set manufacturer must supply appropriate Installation, Service and

Maintenance Instructions to ensure that all operational requirements regarding the cooling

AGN 065 ISSUE B/4/6

airflow system, for both the engines and alternators air filtration systems, are regularly checked

and cleaned by an appropriate method. The dry dust filter is washable and the following

procedure should be carried out to prevent damage to the high efficiency fine particle filtration

media:

Remove the filter assembly from the alternator.

Immerse the filter in water containing a mild household detergent (washing up liquid or

similar).

Agitate the filter to remove dirt particles from the media.

If necessary, use a soft brush and gently brush off any remaining dirt particles.

Thoroughly rinse the filter using clean water.

Reverse flush the filter – rinse the filter with clean water in the opposite direction to the

airflow through the filter when in normal service. This will ensure that dirt particles are

not collected on the clean air side of the filter.

Ensure the filter is completely dry before refitting it to the alternator.

The chosen dry dust filter media must not be soaked in oil prior to use. This is an outdated

requirement for older type filters. The dry dust filters used on AvK and STAMFORD alternators

are not designed to operate under conditions of water saturated cooling air situations. The

media becomes saturated and then large globules of water will enter the alternator with

disastrous results. It should be noted that even when the Generating Set is not running,

exposing the filter to prevailing wet weather conditions is not acceptable, as the filter media

will absorb water and could become saturated. Subsequent natural convection of air through

the alternator will encourage air flow through the filter and this could easily result in moist air

entering the alternator. This will introduce the risk of reducing the alternator’s Insulation

Resistance (IR) values, thereby promoting the risk of winding failure occurring when the

alternator is next started.

Moisture Filters

Although the openings between the Premaburg filter’s vanes is some 10mm, the filter still

needs to be regularly checked for any obstruction, such as leaves or plastic bags etc. and clear

silt from the water drain area along with ensuring the drain hole is not restricted.

A maintenance regime similar to that for the dry dust filters may be used for these moisture

filters. The fitting of a water gauge is recommended to measure pressure drop through the

filter.

With the appropriate de-rate applied, the alternator will have an allowance for the restriction to

air flow when the filter is becoming clogged with dirt and operating with an air restriction

pressure drop of 0.5 inch water gauge. When the pressure drop across the filter reaches this

critical 0.5 inch pressure drop, the alternator should be taken out of service. The filter element

should be removed and thoroughly washed clean, dried and then refitted.

If a situation occurs whereby the filter element pressure drop exceeds the 0.5 inch pressure

drop, but it is not immediately possible to take the alternator out of service, then the Generating

Set’s output should be reduced below its nameplate rating by a factor that makes good

AGN 065 ISSUE B/5/6

allowance for the reduction of air flow quantity and the prevailing site ambient temperature

conditions, when compared with the alternator’s nameplate data.

Application Guidance Notes are for information purposes only. Cummins Generator Technologies reserves the right to change the contents of

Application Guidance Notes without notice and shall not be held responsible for any subsequent claims in relation to the content.

AGN 065 ISSUE B/6/6

Das könnte Ihnen auch gefallen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- IP Protection Ratings and Upgrades for Cummins Generator AlternatorsDokument7 SeitenIP Protection Ratings and Upgrades for Cummins Generator AlternatorsariwibowoNoch keine Bewertungen

- Air Intake Systems: Application and Installation GuideDokument36 SeitenAir Intake Systems: Application and Installation Guiderudey18Noch keine Bewertungen

- Drip Irrig Guide 06-03-24Dokument15 SeitenDrip Irrig Guide 06-03-24MisgatesNoch keine Bewertungen

- LT32599 10Dokument38 SeitenLT32599 10Angela BaileyNoch keine Bewertungen

- Service InformationDokument2 SeitenService InformationMarcelo GiussaniNoch keine Bewertungen

- Pneumatic Actuator InformationDokument24 SeitenPneumatic Actuator Informationsapperbravo52Noch keine Bewertungen

- PQT Rheem Rlmb-A150clDokument92 SeitenPQT Rheem Rlmb-A150clGerardo ZamoranoNoch keine Bewertungen

- Application & Installation Guide Air Intake Systems: LEBW4969-07Dokument34 SeitenApplication & Installation Guide Air Intake Systems: LEBW4969-07ryan fernandezNoch keine Bewertungen

- Csa 10 To 20Dokument6 SeitenCsa 10 To 20peterpunk75Noch keine Bewertungen

- 38aum 50hz PDC v4Dokument36 Seiten38aum 50hz PDC v4khaled salahNoch keine Bewertungen

- Jet FansDokument8 SeitenJet FansTin ThanNoch keine Bewertungen

- Exhaust Systems LEBW4970 05Dokument46 SeitenExhaust Systems LEBW4970 05Nick TotNoch keine Bewertungen

- Special Air Services: Aerial Application Agricultural SystemDokument28 SeitenSpecial Air Services: Aerial Application Agricultural Systemviorelu99Noch keine Bewertungen

- Compressed Air Interchangeable Elements: Engineering SuccessDokument66 SeitenCompressed Air Interchangeable Elements: Engineering SuccesscarlosNoch keine Bewertungen

- LT36499_Hydraulic_Filters_0Dokument43 SeitenLT36499_Hydraulic_Filters_0khans21840Noch keine Bewertungen

- 38AUM 60Hz PDC V9Dokument40 Seiten38AUM 60Hz PDC V9hgogoriyaNoch keine Bewertungen

- REHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFDokument18 SeitenREHS0883 - Installation and Maintenance of The Fumes Disposal Filter PDFvoivod6Noch keine Bewertungen

- K30Dokument48 SeitenK30mlachenal5237Noch keine Bewertungen

- DR 633 833 1233 (1) BarraDokument15 SeitenDR 633 833 1233 (1) BarraJhonatan Bejarano BazanNoch keine Bewertungen

- Air Compressor SpecDokument11 SeitenAir Compressor Specyoi_123Noch keine Bewertungen

- Air Ejector PDFDokument66 SeitenAir Ejector PDFSebastianNoch keine Bewertungen

- RB Manual For North America EnglishDokument21 SeitenRB Manual For North America EnglishEduardo FeitosaNoch keine Bewertungen

- Maintenance of HVACDokument47 SeitenMaintenance of HVACab_s5036Noch keine Bewertungen

- York EspecificacionesDokument34 SeitenYork EspecificacionesblasspascalNoch keine Bewertungen

- Racor DieselFuelFilterDokument9 SeitenRacor DieselFuelFilterigize2Noch keine Bewertungen

- Ycjd18 Thru 60Dokument20 SeitenYcjd18 Thru 60Alberto NavarroNoch keine Bewertungen

- Filters Ingersoll-RandDokument4 SeitenFilters Ingersoll-RandAnonymous bcdUbxoNoch keine Bewertungen

- Jet Fans for Smoke Extraction & Basement VentilationDokument10 SeitenJet Fans for Smoke Extraction & Basement Ventilationabc3579Noch keine Bewertungen

- VRV Maintenance ChecklistDokument8 SeitenVRV Maintenance Checklistredshoes1981Noch keine Bewertungen

- Filtration Bulletin Nov 2017 EI17 074Dokument12 SeitenFiltration Bulletin Nov 2017 EI17 074Samuel ArantesNoch keine Bewertungen

- Specification - Screw Chiller - DraftDokument8 SeitenSpecification - Screw Chiller - DraftSupriya RoyNoch keine Bewertungen

- TRC Unit SpecDokument12 SeitenTRC Unit SpecJohn ChirinosNoch keine Bewertungen

- Informacion TecnicaDokument20 SeitenInformacion Tecnicasandra fiorelaNoch keine Bewertungen

- SB LT32575Dokument14 SeitenSB LT32575zzapiecheNoch keine Bewertungen

- Aftercooler - Test: Shutdown SIS Previous ScreenDokument7 SeitenAftercooler - Test: Shutdown SIS Previous ScreenKeron Trotz100% (1)

- PM SeriesDokument36 SeitenPM SeriesmrthanhspktNoch keine Bewertungen

- Atlas Copco ZT55Dokument14 SeitenAtlas Copco ZT55benlineyNoch keine Bewertungen

- OM005 Halton CaptureJetOperationMaintenanceDokument26 SeitenOM005 Halton CaptureJetOperationMaintenanceRaul Jaime Flores GuardiaNoch keine Bewertungen

- Filtro de AireDokument7 SeitenFiltro de AirejlfyNoch keine Bewertungen

- Why An Air Filtration System Is So ImportantDokument8 SeitenWhy An Air Filtration System Is So ImportantSujoy BanikNoch keine Bewertungen

- Bulletin 114 IOM Manual GP Steam DsfilterDokument4 SeitenBulletin 114 IOM Manual GP Steam DsfiltervextersNoch keine Bewertungen

- ABAC Formula 5.5 22kWDokument6 SeitenABAC Formula 5.5 22kW1976gt500Noch keine Bewertungen

- MANUAL DezumidificatorDokument98 SeitenMANUAL DezumidificatorcivodulNoch keine Bewertungen

- AP003j Auto PurgerDokument20 SeitenAP003j Auto Purgerchris jonesNoch keine Bewertungen

- Sepura Oil Water Separator 4ppDokument4 SeitenSepura Oil Water Separator 4ppmuppetscrapNoch keine Bewertungen

- Air Filter Leaflet 2009Dokument2 SeitenAir Filter Leaflet 2009karthikraja21Noch keine Bewertungen

- Gas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06Dokument4 SeitenGas Filtration Sterile Micro Filtration For Bio Reactors F & S Vol 43, #4, May 06michael_payne3532Noch keine Bewertungen

- 50P Series: High Pressure FiltersDokument10 Seiten50P Series: High Pressure FiltersPartsGopher.comNoch keine Bewertungen

- Installing A Centrifugal Air Compressor: by Rick Stasyshan and Ian Macleod, Compressed Air & Gas InstituteDokument5 SeitenInstalling A Centrifugal Air Compressor: by Rick Stasyshan and Ian Macleod, Compressed Air & Gas Institutehamedia83Noch keine Bewertungen

- PR BW600Dokument8 SeitenPR BW600tata_77Noch keine Bewertungen

- G Series Industrial and Chemical Owners ManualDokument20 SeitenG Series Industrial and Chemical Owners ManualbayuNoch keine Bewertungen

- Altair Product and Filter System UpdateDokument51 SeitenAltair Product and Filter System UpdateabelsgNoch keine Bewertungen

- Goodman Ductos - Inst OperaciónDokument8 SeitenGoodman Ductos - Inst OperaciónlafsNoch keine Bewertungen

- By Rick Stasyshan and Ian Macleod, Compressed Air & Gas InstituteDokument5 SeitenBy Rick Stasyshan and Ian Macleod, Compressed Air & Gas InstituteRaul BautistaNoch keine Bewertungen

- Aftercooler - Test PDFDokument6 SeitenAftercooler - Test PDFDaniel Castillo Peña100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentVon EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Land Market Solutions: Drawworks Rotary TablesDokument2 SeitenLand Market Solutions: Drawworks Rotary TablesP.p. Arul IlancheeranNoch keine Bewertungen

- Ojus Ol 5d Portable Genset PDFDokument2 SeitenOjus Ol 5d Portable Genset PDFP.p. Arul IlancheeranNoch keine Bewertungen

- ECM Calibration Download Instructions PDFDokument11 SeitenECM Calibration Download Instructions PDFArtemio Garcia BarrientosNoch keine Bewertungen

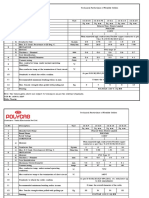

- Polycab Cables Pricelist (New)Dokument8 SeitenPolycab Cables Pricelist (New)P.p. Arul IlancheeranNoch keine Bewertungen

- Diesel Trouble PDFDokument5 SeitenDiesel Trouble PDFzona amrullohNoch keine Bewertungen

- Koel AmfDokument4 SeitenKoel AmfChetan GuptaNoch keine Bewertungen

- 3 CementsDokument43 Seiten3 CementsChan Pisith de Phal100% (1)

- 128 - GS Level Industrial Level Sensor - LD4174-M Issue 2Dokument2 Seiten128 - GS Level Industrial Level Sensor - LD4174-M Issue 2P.p. Arul IlancheeranNoch keine Bewertungen

- 128 - GS Level Industrial Level Sensor - LD4174-M Issue 2Dokument2 Seiten128 - GS Level Industrial Level Sensor - LD4174-M Issue 2P.p. Arul IlancheeranNoch keine Bewertungen

- 056-017 PC Configuration Interfacing PDFDokument2 Seiten056-017 PC Configuration Interfacing PDFCarlitos MenesNoch keine Bewertungen

- Coolant Filter, Spin-On Sca Plus: AttributesDokument2 SeitenCoolant Filter, Spin-On Sca Plus: AttributesP.p. Arul IlancheeranNoch keine Bewertungen

- Specification BurdenDokument3 SeitenSpecification BurdensarokrisNoch keine Bewertungen

- 0 5PX1CBLKFLX100Dokument4 Seiten0 5PX1CBLKFLX100P.p. Arul IlancheeranNoch keine Bewertungen

- ECU 100, GCU 100, Engine Communication, 4189340804 UKDokument60 SeitenECU 100, GCU 100, Engine Communication, 4189340804 UKJoaquin Andres Boilet Huerta100% (1)

- Agri Price List 01jan2019 PDFDokument32 SeitenAgri Price List 01jan2019 PDFParas VaghasiyaNoch keine Bewertungen

- 2 X1.3TAA G7 - 20kVA - Rev 2Dokument4 Seiten2 X1.3TAA G7 - 20kVA - Rev 2P.p. Arul IlancheeranNoch keine Bewertungen

- GSM 2 RELAY v3Dokument2 SeitenGSM 2 RELAY v3P.p. Arul IlancheeranNoch keine Bewertungen

- 15LD400 GBDokument4 Seiten15LD400 GBP.p. Arul IlancheeranNoch keine Bewertungen

- ECU 100, GCU 100, Engine Communication, 4189340804 UKDokument60 SeitenECU 100, GCU 100, Engine Communication, 4189340804 UKJoaquin Andres Boilet Huerta100% (1)

- Pluggable and Miniature Relays PDFDokument10 SeitenPluggable and Miniature Relays PDFP.p. Arul IlancheeranNoch keine Bewertungen

- Analog Timer1Dokument4 SeitenAnalog Timer1P.p. Arul IlancheeranNoch keine Bewertungen

- GSM Security System Ac230v New PDFDokument3 SeitenGSM Security System Ac230v New PDFP.p. Arul IlancheeranNoch keine Bewertungen

- GSM Motor Model 2Dokument2 SeitenGSM Motor Model 2P.p. Arul IlancheeranNoch keine Bewertungen

- CTS2 5unDokument3 SeitenCTS2 5unP.p. Arul IlancheeranNoch keine Bewertungen

- Stanadyne Lock Timing PerkinsDokument1 SeiteStanadyne Lock Timing PerkinsP.p. Arul IlancheeranNoch keine Bewertungen

- Vashi Electricals BrochureDokument26 SeitenVashi Electricals BrochureP.p. Arul Ilancheeran100% (1)

- 2011-08-04 114144 Fl70cumisbiscwiring PDFDokument6 Seiten2011-08-04 114144 Fl70cumisbiscwiring PDFVM Elliott II100% (1)

- Diesel Trouble PDFDokument5 SeitenDiesel Trouble PDFzona amrullohNoch keine Bewertungen

- 2-Basic - Feb 12 ONGC - Cleaned PDFDokument36 Seiten2-Basic - Feb 12 ONGC - Cleaned PDFP.p. Arul Ilancheeran100% (1)

- GSM 6 Relay Switch 2019Dokument2 SeitenGSM 6 Relay Switch 2019P.p. Arul IlancheeranNoch keine Bewertungen

- Analysis of Rake Angle Effect To Stress Distributi PDFDokument13 SeitenAnalysis of Rake Angle Effect To Stress Distributi PDFYvan BravoNoch keine Bewertungen

- Term Paper On Black Cotton SoilDokument21 SeitenTerm Paper On Black Cotton SoilGideon100% (1)

- Effect of Foliar Copper Fertilizer On Pi PDFDokument5 SeitenEffect of Foliar Copper Fertilizer On Pi PDFAmmarGhazaliNoch keine Bewertungen

- Investigatory Project On FertilizersDokument5 SeitenInvestigatory Project On Fertilizersvishwa jayanthi80% (5)

- Smart Farm ManagementDokument4 SeitenSmart Farm ManagementInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- D2487 Clasificacion SUCS PDFDokument12 SeitenD2487 Clasificacion SUCS PDFAlejandro OrtegaNoch keine Bewertungen

- Aggregate Testing StandardsDokument4 SeitenAggregate Testing StandardsDastaggir KarimiNoch keine Bewertungen

- UNIT 2 - (LE-2 Landscape Pattern and Structure)Dokument14 SeitenUNIT 2 - (LE-2 Landscape Pattern and Structure)palaniNoch keine Bewertungen

- Cultural PracticesDokument3 SeitenCultural PracticesrexazarconNoch keine Bewertungen

- Urban Forestry & Urban Greening: A A B BDokument11 SeitenUrban Forestry & Urban Greening: A A B BBarış KaraNoch keine Bewertungen

- Irrigation Engineering FundamentalsDokument26 SeitenIrrigation Engineering FundamentalsMinn Thu NaingNoch keine Bewertungen

- Key Note LecturesDokument353 SeitenKey Note LecturesKUMAR SHUBHAMNoch keine Bewertungen

- Drain DesignDokument106 SeitenDrain DesignBilal Ahmed Barbhuiya100% (2)

- Suelo Limoso Estabilizado Con Lignina Recuperado Resistencia Al Corte Sin Drenaje PDFDokument9 SeitenSuelo Limoso Estabilizado Con Lignina Recuperado Resistencia Al Corte Sin Drenaje PDFnilron savedraNoch keine Bewertungen

- Soil and Water ConservationDokument23 SeitenSoil and Water ConservationHitesh YadavNoch keine Bewertungen

- Development of Landslide Monitoring and Early Warning System in IndonesiaDokument4 SeitenDevelopment of Landslide Monitoring and Early Warning System in IndonesiaBramantyo AirlanggaNoch keine Bewertungen

- breakwater-DESIGN CALCULATION PDFDokument11 Seitenbreakwater-DESIGN CALCULATION PDFHerdi Salvatore100% (2)

- Soil Water ConservationDokument98 SeitenSoil Water Conservationsakshirithe32Noch keine Bewertungen

- The Tatacoa DesertDokument3 SeitenThe Tatacoa Desertlina trujilloNoch keine Bewertungen

- Latvia-Univ-Agriculture Landscape Architecture Art VOL4 2014Dokument84 SeitenLatvia-Univ-Agriculture Landscape Architecture Art VOL4 2014Nicolas PanaiteNoch keine Bewertungen

- Remote Sensing and Gis Application in Agro-Ecological ZoningDokument21 SeitenRemote Sensing and Gis Application in Agro-Ecological ZoningDelizius Nathalis KolopNoch keine Bewertungen

- Bajra Cultivation Information (Pearl Millet) Guide - AgrifarmingDokument2 SeitenBajra Cultivation Information (Pearl Millet) Guide - AgrifarmingSonuNoch keine Bewertungen

- PRHTA Compliance ResponseDokument10 SeitenPRHTA Compliance ResponseCORALationsNoch keine Bewertungen

- The Clayworker's Hand-Book.Dokument418 SeitenThe Clayworker's Hand-Book.Barry Bj Shaide50% (2)

- Growing Adeniums in The Rainy Season PDFDokument4 SeitenGrowing Adeniums in The Rainy Season PDFNorberto R. Bautista50% (2)

- DFI Wick Drain Guide Specifications-February 2014Dokument10 SeitenDFI Wick Drain Guide Specifications-February 2014andresmelodNoch keine Bewertungen

- Ae Board Exam 2017 060917Dokument80 SeitenAe Board Exam 2017 060917trishaNoch keine Bewertungen

- De Gasit Standardele.Dokument2 SeitenDe Gasit Standardele.Buliga MarianNoch keine Bewertungen

- Specific Gravity: QuestionsDokument2 SeitenSpecific Gravity: QuestionsSmruti RanjanNoch keine Bewertungen

- Teaching Guide for Secondary Social Studies in PakistanDokument124 SeitenTeaching Guide for Secondary Social Studies in PakistanQurrat ul ain100% (1)