Beruflich Dokumente

Kultur Dokumente

TABLE 1 Physical Properties of The Binders: Transportation Research Record 1492

Hochgeladen von

varun persadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TABLE 1 Physical Properties of The Binders: Transportation Research Record 1492

Hochgeladen von

varun persadCopyright:

Verfügbare Formate

2 TRANSPORTATION RESEARCH RECORD 1492

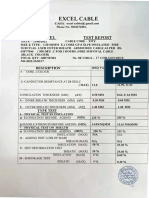

TABLE 1 Physical Properties of the Binders

Binder After

Virgin Thin-Film

Binder Oven Test

AC-20 Binder (FHWA Code: B6090)

Thin-Film Oven Test, percent loss 0.07

Penetration, 25 C (lOOg, 5s), 0.1 mm 87 60

Absolute Viscosity, 60C, dPa-s 2 042 4 349

Kinematic Viscosity, 135C, mm2/s 480 660

Specific Gravity, 25/25C 1. 038

Solubility in Trichloroethyline, % 99.99

Inorganic Material or Ash, percent 0.06

Flash Point, COC, C 2.88

Styrelf Binder

(FHWA Code· B-6096)

Thin-Film Oven Test, percent loss 0.13

Penetration, 25 C (lOOg, 5s), 0.1 mm 51 39

Absolute Viscosity, 60C, dPa-s 40 958 126 826

·Kinematic Viscosity, 135C, µm2/s 2 260 3 463

Specific Gravity, 25/25C 1.026

Solubility in Trichloroethyline, % 99.92

Inorganic Material or Ash, percent 0.12

Flash Point, COC, C 271

stiffer than the AC-20 asphalt, according to capillary viscosities and SMA TWG. The diabase aggregate satisfied the recommendation.

penetration. The supplier modified a different AC-20 asphalt in for- Aggregates with different weight losses were included in this study

mulating the Styrelf binder. (Note: The absolute viscosities of the to determine whether weight loss affects mixture performance.

Styrelf binder may not be correct. ASTM D2 l 71 is valid for New- The percent water absorptions for the three diabase gradations

tonian flow, but many modified binders exhibit non-Newtonian flow were below the recommended maximum of 2 percent; they were

at 60°C. The industry currently recommends ASTM D4957 for mod- slightly greater than 1 percent. The percent water absorptions for the

ified binders, but FHW A did not have the viscometer needed for the three limestone gradations ranged from 2.56 to 2.88 percent. This

test.) indicated that the limestone SMA mixtures would have high binder

absorptions. The ramifications of not meeting the absorption speci-

fication are unknown, except that specified minimum binder con-

Aggregates tents for .SMA mixtures based on mass will be easier to meet.

Minimum binder contents should be based on volume. This

Crushed diabase and limestone aggregates were used in this study. specification was adopted from European practice, in which most

The diabase was used in constructing dense-graded pavement aggregates have low water absorptions and absorption is a minor

sections tested by the accelerated loading facility at the Tumer- concern.

Fairbank Highway Research Center (TFHRC). The limestone was The percentage of aggregate particles having greater than 3: 1 and

used in the SHRP studies and was designated "RC." Aggregate 5: I length-to-thickness, width-to-thickness, or length-to-width ratios

properties are presented in Table 2. were measured by mass and by number using 100 particles for each

Three different aggregate gradations were used. The gradations coarse aggregate size. The results are presented in Tables 3 and 4.

were designed to meet the SMA TWG aggregate gradation require- The diabase aggregate did not meet the SMA TWG recommenda-

ments and the German specifications, except for the percentages of tions for flat and elongated particles in the coarse aggregate. Assum-

material passing the 4.75- and 2.36-mm sieves. The three gradations ing that the recommendations are valid, there may be some breaking

were designated Gradations I, II, and III. The percent passing all of the diabase aggregate particles in the hot-mixture plant or under

sieves greater than 4.75 mm and smaller than 2.36 mm were equal traffic. The limestone aggregate met the recommendations.

for the three gradations. Gradations I, II, and III consisted of 80, 70,

and 60 percent retained on the 4.75-mm sieve, respectively.

The aggregate gradations are presented in Table 2 and illustrated in Mixture Design

Figure 1.

The percent L.A. abrasion weight loss for the coarse fraction of Marshall mix designs were performed to determine the optimum

the limestone was above the maximum percent recommended by the asphalt contents (OACs). The mixtures were designed to sustain

Das könnte Ihnen auch gefallen

- TDS - Premix Marine ThixotropeDokument3 SeitenTDS - Premix Marine ThixotropegmNoch keine Bewertungen

- Technical Data Sheet Product 406: Worldwide Version, February 1996Dokument3 SeitenTechnical Data Sheet Product 406: Worldwide Version, February 1996Muhammad irtizaNoch keine Bewertungen

- Ultramid A3WG7 IsoDokument3 SeitenUltramid A3WG7 IsoRiccardoNoch keine Bewertungen

- Tests Astm Test Method Requirements Min. MaxDokument12 SeitenTests Astm Test Method Requirements Min. Maxhisham gawishNoch keine Bewertungen

- Multipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water SuitabilityDokument2 SeitenMultipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water Suitabilityjulius hasan33Noch keine Bewertungen

- UltrasonS6010 IsoDokument2 SeitenUltrasonS6010 IsoKablayialijanNoch keine Bewertungen

- Chryso Cwa 10Dokument2 SeitenChryso Cwa 10Kiran KumarNoch keine Bewertungen

- Technical Data Sheet Chryso Cwa10 6039 1322Dokument3 SeitenTechnical Data Sheet Chryso Cwa10 6039 1322velmurug_balaNoch keine Bewertungen

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDokument84 SeitenConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDokument2 SeitenKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNoch keine Bewertungen

- Datenblaetter A4 C-4324 eDokument2 SeitenDatenblaetter A4 C-4324 eGeneration GrowthNoch keine Bewertungen

- LLDPE-218BJ EditDokument3 SeitenLLDPE-218BJ EditChu ChuNoch keine Bewertungen

- Specifications Asfalto 50-80-2023Dokument1 SeiteSpecifications Asfalto 50-80-2023H JNoch keine Bewertungen

- Crystic PD9359 EN Dec17Dokument2 SeitenCrystic PD9359 EN Dec17MoutikNoch keine Bewertungen

- Loctite Stycast 2651MM Cat 9 TDS 1Dokument2 SeitenLoctite Stycast 2651MM Cat 9 TDS 1steffan.henryNoch keine Bewertungen

- Protective & Marine Coatings: Polysiloxane 1KDokument4 SeitenProtective & Marine Coatings: Polysiloxane 1KAna CabreraNoch keine Bewertungen

- Soil Test Report: Materials Testing LaboratoryDokument6 SeitenSoil Test Report: Materials Testing LaboratoryVero YonduaiNoch keine Bewertungen

- Brushable Abrasion Resistant Composite Epigen 806BR: ProfileDokument2 SeitenBrushable Abrasion Resistant Composite Epigen 806BR: Profileputra gradaxNoch keine Bewertungen

- Product Technical Data Sheet: Unit Value MethodDokument2 SeitenProduct Technical Data Sheet: Unit Value Methodhamza OUADINoch keine Bewertungen

- Epoxy Asphalt ConcreteDokument4 SeitenEpoxy Asphalt Concretefatemeh.ahmadkhaniNoch keine Bewertungen

- MTC VG-40-9080942Dokument1 SeiteMTC VG-40-9080942vyzjhxypdcNoch keine Bewertungen

- Ultraform N2320 003 BK120 Q600Dokument2 SeitenUltraform N2320 003 BK120 Q600JoelNoch keine Bewertungen

- Epoxy Backing Grout Epigen 0301: Typical Applications ProfileDokument2 SeitenEpoxy Backing Grout Epigen 0301: Typical Applications ProfileDianWidodoNoch keine Bewertungen

- 25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Dokument3 Seiten25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Mithun RaulNoch keine Bewertungen

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignDokument17 SeitenPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedNoch keine Bewertungen

- H Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFDokument14 SeitenH Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFŞăźàdă MùhămmãdNoch keine Bewertungen

- CRS 60 Emulsified BitumenDokument1 SeiteCRS 60 Emulsified BitumenEng Venance MasanjaNoch keine Bewertungen

- ULTRADUR B4300G6 (03p023)Dokument3 SeitenULTRADUR B4300G6 (03p023)ayala castroNoch keine Bewertungen

- 1 s2.0 S1877042812010403 MainDokument7 Seiten1 s2.0 S1877042812010403 MainKarolinaNoch keine Bewertungen

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDokument2 SeitenSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- SABIC® HDPE - P6006 - Global - Technical - Data - SheetDokument2 SeitenSABIC® HDPE - P6006 - Global - Technical - Data - Sheetjemish limbaniNoch keine Bewertungen

- 3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171Dokument2 Seiten3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171UEL IndNoch keine Bewertungen

- Influence of Waxes On BitumenDokument24 SeitenInfluence of Waxes On BitumenJuan CamposNoch keine Bewertungen

- Synthetic Rubber Putty Ultra: Technical Reference InformationDokument2 SeitenSynthetic Rubber Putty Ultra: Technical Reference InformationAbdul RafiiNoch keine Bewertungen

- Improving Slurry Seal Performance in Eastern Saudi Arabia Using Steel SlagDokument7 SeitenImproving Slurry Seal Performance in Eastern Saudi Arabia Using Steel SlagAlejandro MorenoNoch keine Bewertungen

- Legato Limra TCDokument2 SeitenLegato Limra TCRAHIL NISHATNoch keine Bewertungen

- Tds Panaoil Amon SHCDokument1 SeiteTds Panaoil Amon SHCMuhammad FarhanNoch keine Bewertungen

- High Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueDokument1 SeiteHigh Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueRivky Haris RizaldyNoch keine Bewertungen

- TDS - Vinyl 901-3 (En)Dokument2 SeitenTDS - Vinyl 901-3 (En)OXY Composite TechNoch keine Bewertungen

- Sir - Tds.siropol 8340-PLV-180.v03.202012.no2Dokument3 SeitenSir - Tds.siropol 8340-PLV-180.v03.202012.no2Yousef LotfyNoch keine Bewertungen

- 128 FPDokument6 Seiten128 FPRajesh KumarNoch keine Bewertungen

- Concrete Characteristics Design and ValuationDokument8 SeitenConcrete Characteristics Design and ValuationIrshad HussainNoch keine Bewertungen

- Datasheet MomentiveDokument5 SeitenDatasheet Momentivehuynh thi y viNoch keine Bewertungen

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDokument1 SeiteIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNoch keine Bewertungen

- Lee1997 Article TheDeterminationOfTheFlexuralCDokument9 SeitenLee1997 Article TheDeterminationOfTheFlexuralChghghg3Noch keine Bewertungen

- Ficha Técnica Hdpe (Sabic)Dokument2 SeitenFicha Técnica Hdpe (Sabic)Luis LiraNoch keine Bewertungen

- Technical Data Sheet Product 3421: Research, Development & Engineering PreliminaryDokument3 SeitenTechnical Data Sheet Product 3421: Research, Development & Engineering PreliminaryAfzal ImamNoch keine Bewertungen

- KLINGERSIL C-4430plus Data SheetDokument3 SeitenKLINGERSIL C-4430plus Data SheetMichael PhamNoch keine Bewertungen

- Crystic Ve671Dokument2 SeitenCrystic Ve671M Taufik WijayaNoch keine Bewertungen

- Loctite 495Dokument3 SeitenLoctite 495Rammstein GottNoch keine Bewertungen

- Solid Surface Resin - SpecsDokument3 SeitenSolid Surface Resin - SpecsAmr Abdelmegid abdelsalam husseinNoch keine Bewertungen

- Normas para Análisis TérmicoDokument23 SeitenNormas para Análisis TérmicoFernando Chacmana LinaresNoch keine Bewertungen

- DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENDokument3 SeitenDOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENMisikEENoch keine Bewertungen

- ArticleDokument6 SeitenArticletotojul1Noch keine Bewertungen

- Ultramid B3WG6 NYLON PDFDokument3 SeitenUltramid B3WG6 NYLON PDFrenebbNoch keine Bewertungen

- M705-ULT369 Technical Data - 1.0EDokument12 SeitenM705-ULT369 Technical Data - 1.0EQuýNguyễnNoch keine Bewertungen

- DBM Gupta ConstructionDokument24 SeitenDBM Gupta Constructionimran khanNoch keine Bewertungen

- Asphalt Mix Design Submittal: Project DescriptionDokument11 SeitenAsphalt Mix Design Submittal: Project DescriptionjovindhaNoch keine Bewertungen

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDokument2 SeitenSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNoch keine Bewertungen

- TABLE 3 Percent Flat and Elongated Particles: Ihi KnessDokument1 SeiteTABLE 3 Percent Flat and Elongated Particles: Ihi Knessvarun persadNoch keine Bewertungen

- TABLES Mixture Design Properties: Mogawer and StuartDokument1 SeiteTABLES Mixture Design Properties: Mogawer and Stuartvarun persadNoch keine Bewertungen

- Length TQ: Mogawer and StuartDokument1 SeiteLength TQ: Mogawer and Stuartvarun persadNoch keine Bewertungen

- Asphalt Fines From AASHTO FP96Dokument1 SeiteAsphalt Fines From AASHTO FP96varun persadNoch keine Bewertungen

- Inc VmaDokument1 SeiteInc Vmavarun persadNoch keine Bewertungen

- SMADokument1 SeiteSMAvarun persadNoch keine Bewertungen

- Mixing and Compaction Temperature ChartDokument1 SeiteMixing and Compaction Temperature Chartvarun persadNoch keine Bewertungen

- X 2 X ! 2 1 5 2 N X 2 1 5 2 ! 2 1: 5. Basis of Statistical Criteria For OutliersDokument1 SeiteX 2 X ! 2 1 5 2 N X 2 1 5 2 ! 2 1: 5. Basis of Statistical Criteria For Outliersvarun persadNoch keine Bewertungen

- Effect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain DownDokument1 SeiteEffect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain Downvarun persadNoch keine Bewertungen

- FIG. X1.1 Power Law Shear Stress Versus Shear Rate RelationshipDokument1 SeiteFIG. X1.1 Power Law Shear Stress Versus Shear Rate Relationshipvarun persadNoch keine Bewertungen

- Material Transfer VehicleDokument1 SeiteMaterial Transfer Vehiclevarun persadNoch keine Bewertungen

- Marshall Teoria y Ejercicios PDFDokument30 SeitenMarshall Teoria y Ejercicios PDFYuliana Meriño TNoch keine Bewertungen

- Pages From Structural Behavior of Asphalt PavementsDokument13 SeitenPages From Structural Behavior of Asphalt Pavementsvarun persadNoch keine Bewertungen

- 10.2.2 Repeated Shear Test at Constant HeightDokument1 Seite10.2.2 Repeated Shear Test at Constant Heightvarun persadNoch keine Bewertungen

- Asphalt Volumetric AnalysisDokument6 SeitenAsphalt Volumetric Analysisvarun persadNoch keine Bewertungen

- Stockpile CalculationsDokument6 SeitenStockpile Calculationsvarun persad100% (2)

- FHWA KS 12 8 - FinalDokument29 SeitenFHWA KS 12 8 - FinalNatalieNoch keine Bewertungen

- Faa Ac150-5370-2gDokument95 SeitenFaa Ac150-5370-2gvarun persadNoch keine Bewertungen

- Feb 15 TLA Asphalt Cement Viscosity - Temp CHARTDokument1 SeiteFeb 15 TLA Asphalt Cement Viscosity - Temp CHARTvarun persadNoch keine Bewertungen

- C 3-GD - Highway CS Elements PDFDokument48 SeitenC 3-GD - Highway CS Elements PDFvarun persadNoch keine Bewertungen

- Marshall Method of Asphalt-Concrete Mix DesignDokument16 SeitenMarshall Method of Asphalt-Concrete Mix DesignfitrianiNoch keine Bewertungen

- Prime Tack Coats FHWA July 2005Dokument18 SeitenPrime Tack Coats FHWA July 2005mzaimNoch keine Bewertungen

- Xavier High SchoolDokument1 SeiteXavier High SchoolHelen BennettNoch keine Bewertungen

- 2019 09 20 New Balance Harvard Business CaseDokument7 Seiten2019 09 20 New Balance Harvard Business CaseFrans AdamNoch keine Bewertungen

- SET UP Computer ServerDokument3 SeitenSET UP Computer ServerRicHArdNoch keine Bewertungen

- Aero - 2013q2 Apu On DemandDokument32 SeitenAero - 2013q2 Apu On DemandIvan MilosevicNoch keine Bewertungen

- Alcatraz Analysis (With Explanations)Dokument16 SeitenAlcatraz Analysis (With Explanations)Raul Dolo Quinones100% (1)

- Physiology PharmacologyDokument126 SeitenPhysiology PharmacologyuneedlesNoch keine Bewertungen

- List of Vocabulary C2Dokument43 SeitenList of Vocabulary C2Lina LilyNoch keine Bewertungen

- Pre T&C Checklist (3 Language) - Updated - 2022 DavidDokument1 SeitePre T&C Checklist (3 Language) - Updated - 2022 Davidmuhammad farisNoch keine Bewertungen

- LiverDokument6 SeitenLiverMiguel Cuevas DolotNoch keine Bewertungen

- Field Assignment On Feacal Sludge ManagementDokument10 SeitenField Assignment On Feacal Sludge ManagementSarah NamyaloNoch keine Bewertungen

- A Beautiful Mind - Psychology AnalysisDokument15 SeitenA Beautiful Mind - Psychology AnalysisFitto Priestaza91% (34)

- Learner's Material: ScienceDokument27 SeitenLearner's Material: ScienceCarlz BrianNoch keine Bewertungen

- Michael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Dokument55 SeitenMichael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Sosa VelazquezNoch keine Bewertungen

- TN Vision 2023 PDFDokument68 SeitenTN Vision 2023 PDFRajanbabu100% (1)

- Curriculum Vitae Mukhammad Fitrah Malik FINAL 2Dokument1 SeiteCurriculum Vitae Mukhammad Fitrah Malik FINAL 2Bill Divend SihombingNoch keine Bewertungen

- Apple Festival Program 2017Dokument3 SeitenApple Festival Program 2017Elizabeth JanneyNoch keine Bewertungen

- Roman Roads in Southeast Wales Year 3Dokument81 SeitenRoman Roads in Southeast Wales Year 3The Glamorgan-Gwent Archaeological Trust LtdNoch keine Bewertungen

- KBC Autumn Regatta 2023 Saturday Race ScheduleDokument2 SeitenKBC Autumn Regatta 2023 Saturday Race SchedulezainNoch keine Bewertungen

- LM213 First Exam Notes PDFDokument7 SeitenLM213 First Exam Notes PDFNikki KatesNoch keine Bewertungen

- Custom Belt Buckles: Custom Brass Belt Buckles - Hand Made in The USA - Lifetime Guarantee of QualityDokument1 SeiteCustom Belt Buckles: Custom Brass Belt Buckles - Hand Made in The USA - Lifetime Guarantee of QualityAndrew HunterNoch keine Bewertungen

- (Methods in Molecular Biology 1496) William J. Brown - The Golgi Complex - Methods and Protocols-Humana Press (2016)Dokument233 Seiten(Methods in Molecular Biology 1496) William J. Brown - The Golgi Complex - Methods and Protocols-Humana Press (2016)monomonkisidaNoch keine Bewertungen

- Network Function Virtualization (NFV) : Presented By: Laith AbbasDokument30 SeitenNetwork Function Virtualization (NFV) : Presented By: Laith AbbasBaraa EsamNoch keine Bewertungen

- Florida v. DunnDokument9 SeitenFlorida v. DunnJustice2Noch keine Bewertungen

- Philippine Housing Industry: Regulatory ReviewDokument42 SeitenPhilippine Housing Industry: Regulatory ReviewAl MarzolNoch keine Bewertungen

- CrisisDokument13 SeitenCrisisAngel Gaddi LarenaNoch keine Bewertungen

- Meike SchalkDokument212 SeitenMeike SchalkPetra BoulescuNoch keine Bewertungen

- Contoh RPH Ts 25 Engish (Ppki)Dokument1 SeiteContoh RPH Ts 25 Engish (Ppki)muhariz78Noch keine Bewertungen

- Wetlands Denote Perennial Water Bodies That Originate From Underground Sources of Water or RainsDokument3 SeitenWetlands Denote Perennial Water Bodies That Originate From Underground Sources of Water or RainsManish thapaNoch keine Bewertungen

- 9francisco Gutierrez Et Al. v. Juan CarpioDokument4 Seiten9francisco Gutierrez Et Al. v. Juan Carpiosensya na pogi langNoch keine Bewertungen

- Caregiving Learning Activity Sheet 3Dokument6 SeitenCaregiving Learning Activity Sheet 3Juvy Lyn CondaNoch keine Bewertungen