Beruflich Dokumente

Kultur Dokumente

Power House: Schedule of Equipment

Hochgeladen von

Billy Joe BreakfastOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Power House: Schedule of Equipment

Hochgeladen von

Billy Joe BreakfastCopyright:

Verfügbare Formate

4000

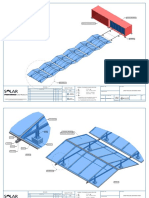

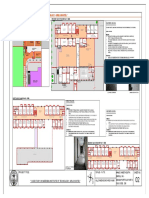

SCHEDULE OF EQUIPMENT

1000 2000 1000

DIESEL ENGINE GENERATING SET

GENERATOR SPECIFICATIONS ENGINE SPECIFICATIONS

AREA

DESIGNATION QUANTITY DUTY REMARKS

SERVED CAPACITY CAPACITY FUEL FUEL

RPM VOLTAGE FREQUENCY PHASE RPM COOLING

( KVA ) ( KW ) CONSUMPTION TYPE

UNITS SHALL BE FOR OUTDOOR INSTALLATION WITH 12 HOUR

STANDBY CAPACITY, SERVICE/ DAY TANK, PIPING, INDUSTRIAL TYPE,

GEN SET 1 ALL AREA 25 1800 230 60 SINGLE 20 5.4 L / h DIESEL 1800 RADIATOR

1200

850

UNIT WITH SILENCER COMPLETE WITH STANDARD

3000

ACCESSORIES AND READY FOR SERVICE.

1500 250

25 KVA NOTES :

GENSET

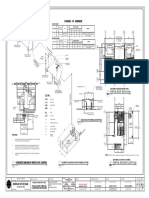

1. FOUNDATION BOLT TEMPLATE - THE BOLTS SHOULD BE SUPPORTED BY A TEMPLATE, CAREFULLY LEVELED, RESTING ON THE FOUNDATION FORMS. EACH BOLT SHOULD BE SURROUNDED WITH IRON PIPE,

SUPPORTED BY THE BOTTOM WASHER, AND STOPPER WITH WASHER AT THE UPPER END TO PREVENT ENTRANCE OF CONCRETE.

2. LEVELING THE ENGINE - THE ENGINE SHOULD BE LEVELED BY WEDGES RESTING ON STEEL PLATES ON TOP OF THE FOUNDATION, AND GROUTED IT WITH A THIN MIXTURE OF ONE PART CEMENT AND TWO PARTS

SAND. THE GROUT SHOULD FILL THE PIPES AROUND THE FOUNDATION BOLTS. THE LEVELING WEDGES SHOULD BE REMOVED AFTER GROUT HAS THOROUGHLY SET.

1 POWER HOUSE 3. SERVICE TANKS / DAY TANK ABOVE THE FLOOR LINE SHOULD HAVE GAUGE GLASSES TO PERMIT MEASUREMENT OF FUEL CONSUMED.

M-2 SCALE 1:50 M.

4. PIPING - SHOULD BE LOCATED IN TRENCHES WITH SIDE WALLS AND FLOORS OF CONCRETE AT LEAST 4 INCHES THICK AND COVERED BY REMOVABLE STEEL PLATES.

PIPE SLEEVE

4000 CONTINOUS WELD INSIDE FACE OF WALL

EXHAUST MUFFLER

SEAL WATERTIGHT

WITH MASTER OR ASPHALT ESCUTCHEON

PIPE SUPPORT

EXHAUST AIR DUCT

25 KVA

GRAVITY DAMPER

3000

GENSET

FUEL PIPE

SEALING & SEAL SLEEVE WITH TIGHTLY

ANCHORING COLLAR PACKED OAKUM & PLASTIC 2" DEEP LEAD

1200

WATER PROOF RESISTANT SQUARE STEEL PLATE

CAULKING COMPOUND

OAKUM

CENTER PIPE

IN SLEEVE

200

WHERE PIPING PENETRATES WALL AND FLOOR SLABS, THE PIPE WORK SHALL

COAT EXTERIOR SURFACES BE SLEEVED WITH 1" THICK FIBERGLASS THE FULL LENGHT OF THE

STANDARD WEIGHT STEEL

2 ELEVATION PIPE POURED IN PLACE WITH TAR COMPOUND PENETRATION AND SEALED WITH J.M. DUXSEAL OR UNISEAL. FIBERGLASS

SLEEVE TO BE INSTALLED WIDER THAN THICKNESS OF SLAB AFTER IS MADE UP

SCALE 1:50 M. EXTERIOR WALLS TIGHT TO FIBERGLASS AND THE MORTAR SET TRIM EXTENDING FIBERGLASS

M-2 AND SEAL EACH END WITH A NON-HARDENING COMPOUND SIMILAR TO J.M.

VIBRATION ISOLATOR CONCRETE SLAB DUXSEAL OR UNISEAL.

4 DETAIL SECTION OF GENERATOR 5 EXHAUST PIPE SLEEVE DETAIL 6 PIPE SLEEVE DETAIL

SCALE NTS SCALE NTS SCALE NTS

M-2 M-2 M-2

25 KVA

GENSET

LOCKING NUT SHEET METAL SCREWS

COLLAR

U-STRAP

60.30mm

LOCKING NUT HOLE DUCT

60mm FLEXIBLE FABRIC

VIBRATION ISOLATOR

NEOPRENE RUBBER MATERIAL

44 ANCHOR BOLT HOLE

6

130mm

19 19

ANCHOR BOLT 5" MIN

BASE ( RUBBER & STEEL MATERIAL ) PLAN

SECTION

3 SCHEMATIC DIAGRAM 7 VIBRATION ISOLATOR MOUNTING DETAIL 8 FLEXIBLE CONNECTION DETAIL

M-2 SCALE 1:50 M.

M-2 SCALE NTS SCALE NTS

M-2

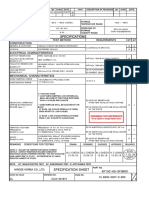

PROJECT : SHEET CONTENTS: SUBMITTED: REVIEWED: (AS TO THE DESIGN CONCEPT) RECOMMENDING APPROVAL: APPROVED: SHEET NO.

ALLAN B. PADILLA

PROFESSIONAL MECHANICAL ENGINEER PROPOSED:

SCHEDULE OF EQUIPMENT (SEE COVERSHEET FOR SIGNATURE) (SEE COVERSHEET FOR SIGNATURE) (SEE COVERSHEET FOR SIGNATURE)

REG. No. : 0103022 DATE ISSUED :

ICD 4B COMMUNICATION NETWORK

POWER HOUSE

DETAIL SECTION OF GENERATOR

M-2

EXHAUST PIPE SLEEVE DETAIL ARNOLD I. DAGDAG MARIANO C. DEL CASTILLO B. ELIZABETH E. YAP GILBERTO S. REYES RAUL C. ASIS

PTR No. : PLACE ISSUED :

VIBRATION ISOLATOR MOUNTING DETAIL OIC, BUILDINGS DIVISION DIRECTOR III DIRECTOR IV

2 13

LOCATION: DPWH DISTRICT ENGINEERING OFFICE GENERAL PROJECT MANAGER UNDERSECRETARY

TIN : 941-524-085 FLEXIBLE CONNECTION DETAIL BOD, DPWH MIS, DPWH BOD, DPWH

NERA PHIL INC. DPWH

Das könnte Ihnen auch gefallen

- ITP - Painting & SandBlasting Rev00Dokument2 SeitenITP - Painting & SandBlasting Rev00Sulist N Wahyudie80% (5)

- Pilot Operations Handbook C182 (1970-182N)Dokument44 SeitenPilot Operations Handbook C182 (1970-182N)Fabrício Torres PeixotoNoch keine Bewertungen

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDokument6 SeitenSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNoch keine Bewertungen

- Surface Mining Extraction Equipment v1.1 03.13.14 Part DDokument59 SeitenSurface Mining Extraction Equipment v1.1 03.13.14 Part DRyan Abubakar Obili PakayaNoch keine Bewertungen

- Aisi 4130Dokument3 SeitenAisi 4130Rajesh R BhavsarNoch keine Bewertungen

- Marine Diesel Engine Products Guide Marine Diesel Engine Products Guide Marine Diesel Engine Products Guide Marine Diesel Engine Products GuideDokument26 SeitenMarine Diesel Engine Products Guide Marine Diesel Engine Products Guide Marine Diesel Engine Products Guide Marine Diesel Engine Products GuideVlad GerzogNoch keine Bewertungen

- Amief-2693 0Dokument1 SeiteAmief-2693 0wangkai01.sneiNoch keine Bewertungen

- Century Addt - New Layout 1Dokument1 SeiteCentury Addt - New Layout 1lazer stormNoch keine Bewertungen

- TSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WDokument4 SeitenTSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WFrigia IsudibyoNoch keine Bewertungen

- Carlyle Semi-Hermetic Compressors: Guide To 06D Part Numbering SystemDokument26 SeitenCarlyle Semi-Hermetic Compressors: Guide To 06D Part Numbering Systemjorge alberto roca susanoNoch keine Bewertungen

- DW HCVersion FINAL WebsiteDokument36 SeitenDW HCVersion FINAL WebsiteSikandar Haidar KhanNoch keine Bewertungen

- Hyw 13 M5Dokument6 SeitenHyw 13 M5myint zawNoch keine Bewertungen

- YANMAR - Guía de Productos Marinos de Alta VelocidadDokument32 SeitenYANMAR - Guía de Productos Marinos de Alta VelocidadAngel Jesús Agapito CortezNoch keine Bewertungen

- BL2.0 Mechanical Diaphragm Price ListDokument1 SeiteBL2.0 Mechanical Diaphragm Price Listarijit mukhkerjeeNoch keine Bewertungen

- Century Addt - New Layout 5 A2Dokument1 SeiteCentury Addt - New Layout 5 A2lazer stormNoch keine Bewertungen

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDokument6 SeitenSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNoch keine Bewertungen

- 20kwp Railing Container 40ftDokument4 Seiten20kwp Railing Container 40ftTurinto MarjonoNoch keine Bewertungen

- 3 DfoundrylayoutplanviewDokument1 Seite3 Dfoundrylayoutplanviewnayan205Noch keine Bewertungen

- Carlyle Semi-Hermetic Compressors: Guide To 06D Part Numbering SystemDokument26 SeitenCarlyle Semi-Hermetic Compressors: Guide To 06D Part Numbering Systemmauricio duberger lopesNoch keine Bewertungen

- Start Fuel Station Page 2Dokument1 SeiteStart Fuel Station Page 2EDGARDO JR. DIGALNoch keine Bewertungen

- Schedule of Equipment: Partial Roof Deck PlanDokument1 SeiteSchedule of Equipment: Partial Roof Deck PlanJuan IstilNoch keine Bewertungen

- MTU Marine Flyer 4000M55N GasDokument5 SeitenMTU Marine Flyer 4000M55N GasAmin GuiNoch keine Bewertungen

- General Notes:: Schedule of EquipmentDokument1 SeiteGeneral Notes:: Schedule of EquipmentBilly Joe BreakfastNoch keine Bewertungen

- Proyecto Salina Cruz Mediana TensionDokument1 SeiteProyecto Salina Cruz Mediana TensionCarlos SalvadorNoch keine Bewertungen

- Front Elevation Escalator Section: General NoteDokument1 SeiteFront Elevation Escalator Section: General NoteHabibulla BavajiNoch keine Bewertungen

- General Notes and Specifications: Generator Set Specification DataDokument1 SeiteGeneral Notes and Specifications: Generator Set Specification DataErwin Bernard NionesNoch keine Bewertungen

- LIW Feeder BrochureDokument5 SeitenLIW Feeder BrochurebnzelectricianshopNoch keine Bewertungen

- AA-4L6-L501-80mm: Legend For LimitsDokument4 SeitenAA-4L6-L501-80mm: Legend For Limitsmina fawzyNoch keine Bewertungen

- Api 610, 8Th Edition Centrifugal Pump Data Sheet Si Units / Iso Standards Us Units / Us Standards (Short Version by Ecopetrol - VIT, Ago-97)Dokument2 SeitenApi 610, 8Th Edition Centrifugal Pump Data Sheet Si Units / Iso Standards Us Units / Us Standards (Short Version by Ecopetrol - VIT, Ago-97)jojagucaNoch keine Bewertungen

- F-VG-39 Control de Programación V2Dokument4 SeitenF-VG-39 Control de Programación V2Mauro BlazkexNoch keine Bewertungen

- Property: Minedry Building Floor Plan SCALE 1:150Dokument1 SeiteProperty: Minedry Building Floor Plan SCALE 1:150Iveel PurevdorjNoch keine Bewertungen

- Ratings and Specifications: Allison TransmissionDokument2 SeitenRatings and Specifications: Allison TransmissionSarra ChoucheneNoch keine Bewertungen

- KP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngDokument2 SeitenKP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngIgor LeeNoch keine Bewertungen

- Delivery Note For Team AfourDokument1 SeiteDelivery Note For Team AfourshoaibNoch keine Bewertungen

- Loctite® Retaining Compounds Properties Chart: ProductDokument1 SeiteLoctite® Retaining Compounds Properties Chart: ProductSreenivas TalariNoch keine Bewertungen

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDokument6 SeitenSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNoch keine Bewertungen

- Design Notes: 132Kv Radial Switchyard Major EquipmentDokument1 SeiteDesign Notes: 132Kv Radial Switchyard Major EquipmentBharath KumarNoch keine Bewertungen

- Layout AED, SID, STAR & Map RNAV 2Dokument8 SeitenLayout AED, SID, STAR & Map RNAV 2oka nNoch keine Bewertungen

- Attachment#4 DatasheetDokument13 SeitenAttachment#4 DatasheetzhangNoch keine Bewertungen

- N.domingo Proposed Pump Motor (Manila Water A-3 Size)Dokument7 SeitenN.domingo Proposed Pump Motor (Manila Water A-3 Size)Charlemagne VillarbaNoch keine Bewertungen

- Civil&Industrial Acgen 01032018Dokument18 SeitenCivil&Industrial Acgen 01032018esameldeen mhmoudNoch keine Bewertungen

- Moser Specsheet DRC400Dokument4 SeitenMoser Specsheet DRC400ebow powerNoch keine Bewertungen

- 4 Amp Silicon Bridge Rectifiers: Ul Recognized - File #E124962 Rohs CompliantDokument2 Seiten4 Amp Silicon Bridge Rectifiers: Ul Recognized - File #E124962 Rohs CompliantSero StivNoch keine Bewertungen

- 12-10G GH-3VCMDokument1 Seite12-10G GH-3VCMMamiherintsoa Issaia RanaivoarimananaNoch keine Bewertungen

- Typical Second and Third Floor Plan: Schedule of EquipmentDokument1 SeiteTypical Second and Third Floor Plan: Schedule of EquipmentJuan IstilNoch keine Bewertungen

- Front Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Dokument1 SeiteFront Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Habibulla BavajiNoch keine Bewertungen

- Carrier 06D 06E SeriesDokument40 SeitenCarrier 06D 06E SerieskuatifansyahNoch keine Bewertungen

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDokument6 SeitenSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNoch keine Bewertungen

- 4TNV88 BGGE Bro PDFDokument1 Seite4TNV88 BGGE Bro PDFSamsung KalimantanNoch keine Bewertungen

- FOOTING FORMWORK-ModelDokument1 SeiteFOOTING FORMWORK-Modelpupuk wahyuonoNoch keine Bewertungen

- Option 4Dokument1 SeiteOption 4manu guptaNoch keine Bewertungen

- CCDokument9 SeitenCCvomicih221Noch keine Bewertungen

- Evertson Rig 10 Equipment ListDokument6 SeitenEvertson Rig 10 Equipment ListPablo Rivas RNoch keine Bewertungen

- JCB Rough Terrain Fork Lift 926, 930, 940Dokument4 SeitenJCB Rough Terrain Fork Lift 926, 930, 940DarrenNoch keine Bewertungen

- Hyw 175T6Dokument13 SeitenHyw 175T6LMN ArchitectNoch keine Bewertungen

- 2011 Bombardier Challenger 605Dokument12 Seiten2011 Bombardier Challenger 605Joaquin IoccaNoch keine Bewertungen

- 2 MBIT CASE STUDY-ModelDokument1 Seite2 MBIT CASE STUDY-ModelSekh SamimNoch keine Bewertungen

- SRD800LDokument1 SeiteSRD800LArsene LupinNoch keine Bewertungen

- RE739434001-Produced Water Injection PumpsDokument7 SeitenRE739434001-Produced Water Injection PumpsBilel MahjoubNoch keine Bewertungen

- Persan RenaultDokument9 SeitenPersan RenaultGerman AngueraNoch keine Bewertungen

- 1967 C150G Owners Manual PDFDokument28 Seiten1967 C150G Owners Manual PDFalexred89Noch keine Bewertungen

- Dampers PDFDokument14 SeitenDampers PDFBilly Joe BreakfastNoch keine Bewertungen

- Tire Bath Plan and Details: F'C 3500psi at 28 Days Fy 228 MpaDokument1 SeiteTire Bath Plan and Details: F'C 3500psi at 28 Days Fy 228 MpaBilly Joe BreakfastNoch keine Bewertungen

- Design of Septic TankDokument1 SeiteDesign of Septic TankBilly Joe Breakfast100% (1)

- Item No. Description Qty Unit Unit Cost Amount: I Site WorksDokument5 SeitenItem No. Description Qty Unit Unit Cost Amount: I Site WorksBilly Joe BreakfastNoch keine Bewertungen

- LFO Canopy - SpecificationDokument16 SeitenLFO Canopy - SpecificationBilly Joe BreakfastNoch keine Bewertungen

- SEC Capex FormDokument3 SeitenSEC Capex FormBilly Joe BreakfastNoch keine Bewertungen

- PCEE15 MNv2 Rev2Dokument9 SeitenPCEE15 MNv2 Rev2Billy Joe BreakfastNoch keine Bewertungen

- Plumbing Bank 4Dokument19 SeitenPlumbing Bank 4Billy Joe Breakfast100% (1)

- Updated Standard Qap 14.07.22Dokument6 SeitenUpdated Standard Qap 14.07.22Karna Satish KumarNoch keine Bewertungen

- Top Emerging Bio Based ProductsDokument29 SeitenTop Emerging Bio Based ProductsArunNoch keine Bewertungen

- High Quality Dispersing Agents For MasterbatchDokument28 SeitenHigh Quality Dispersing Agents For MasterbatchEsthikar khanNoch keine Bewertungen

- Artificial Rocks, NaturallyDokument2 SeitenArtificial Rocks, NaturallyMichael BrownNoch keine Bewertungen

- Tata Magizinc EnglischDokument4 SeitenTata Magizinc EnglischIbtissam EL HaiNoch keine Bewertungen

- Probuild RP110Dokument2 SeitenProbuild RP110osama mohNoch keine Bewertungen

- Rene Industries Limited General Test ProcedureDokument2 SeitenRene Industries Limited General Test ProcedureMubarak PatelNoch keine Bewertungen

- K26 Concrete Deterioration and RepairDokument68 SeitenK26 Concrete Deterioration and RepairPaul LunaNoch keine Bewertungen

- Leaf Filter Press: Flores, Dharyl Martin, Alvin Mar Tagalog, ShairaDokument21 SeitenLeaf Filter Press: Flores, Dharyl Martin, Alvin Mar Tagalog, ShairaMartin AlvinNoch keine Bewertungen

- 3613Dokument31 Seiten3613youuuuyNoch keine Bewertungen

- CD 361 Weathering Steel For Highway Structures-WebDokument19 SeitenCD 361 Weathering Steel For Highway Structures-WebAbinashNoch keine Bewertungen

- Porosity in Gold Coatings On Metal Substrates by Paper ElectrographyDokument5 SeitenPorosity in Gold Coatings On Metal Substrates by Paper ElectrographyDanZel DanNoch keine Bewertungen

- Recycling of Finished Leather Wastes: A Novel ApproachDokument11 SeitenRecycling of Finished Leather Wastes: A Novel ApproachMohammed HussienNoch keine Bewertungen

- ASM Subject Guide - Aluminum PDFDokument5 SeitenASM Subject Guide - Aluminum PDFzeeshaniqbalNoch keine Bewertungen

- Extraction and Uses of Metals 1 QP PDFDokument12 SeitenExtraction and Uses of Metals 1 QP PDFAngus AnizNoch keine Bewertungen

- Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingDokument2 SeitenMonth Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month& Year Code For CastingJatin SharmaNoch keine Bewertungen

- U-Seal /Z-Seal Casing Seals: For Cased CrossingsDokument4 SeitenU-Seal /Z-Seal Casing Seals: For Cased CrossingsChegg ChemNoch keine Bewertungen

- W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDokument1 SeiteW.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDouglas CortezziNoch keine Bewertungen

- Dura Flow IND Spec SheetDokument2 SeitenDura Flow IND Spec SheetForum PompieriiNoch keine Bewertungen

- DatabaseDokument112 SeitenDatabaseamirulamirNoch keine Bewertungen

- Chemical Principles 6th Edition Atkins Solutions ManualDokument12 SeitenChemical Principles 6th Edition Atkins Solutions Manualpaullopez22021999cke100% (21)

- Surface Protective Systems: Oxydur VE-ARDokument3 SeitenSurface Protective Systems: Oxydur VE-ARfrancisca ferrerNoch keine Bewertungen

- Effective Grouting Materials For Tunneling Through Unconsolidated GroundDokument8 SeitenEffective Grouting Materials For Tunneling Through Unconsolidated GroundDuvan RuedaNoch keine Bewertungen

- Weight List of Various Laminated SheetsDokument1 SeiteWeight List of Various Laminated SheetsAli HashemiNoch keine Bewertungen

- Rotary Drum SpecsDokument16 SeitenRotary Drum SpecsArrianne Jaye MataNoch keine Bewertungen

- Invoice-WPQT Welder PTMDokument5 SeitenInvoice-WPQT Welder PTMFerdie OSNoch keine Bewertungen

- Membrane SystemDokument16 SeitenMembrane SystemAulia syafiraNoch keine Bewertungen

- Lecture 1 Pulp and Paper Technology CHE 510Dokument12 SeitenLecture 1 Pulp and Paper Technology CHE 510Christian Nweke100% (2)