Beruflich Dokumente

Kultur Dokumente

Oil Gallery

Hochgeladen von

rburtonshawCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oil Gallery

Hochgeladen von

rburtonshawCopyright:

Verfügbare Formate

Project Proposal

(Bme122 / Issue 2)

Providing safety through mechanical excellence

Introduction

In the event of engine failure, it is necessary to clean the oil galleries of an engine to

ensure foreign particles and engine failure debris is not present upon engine rebuild as

this could have catastrophic consequences.

Oil Flow Direction Explanation

Looking at Figure 1 the engine oil is lifted through the oil pump strainer and is then sent to

the filter housing where it travels through the oil filters before passing through the oil

cooler.

From the oil cooler the oil then flows through the main crankcase oil gallery where there

are several take offs.

The first take off is the oil feed to the Geislinger coupling and A1 & B1 crank pin journal.

This enters the crankshaft at the drive end and flows into the Geislinger damper coupling

and flows in the direction of the free end to cylinders A1 & B1, these are first to receive oil

on the crankshaft with cylinder A4 & B4 last to receive engine oil. The oil from the

crankshaft drains directly into the sump where the above process starts again.

The next take off from the main oil gallery is the turbo charger and fuel pump oil feed,

which then feed the turbos and fuel pump with engine oil and drain back directly into the

sump.

Following on from this, the next take offs are the piston cooling jets and camshaft and

rocker gear oil ways and remaining 5 main bearings, all returning directly to the sump.

Each big end bearing is fed oil from the main bearing oil feed as in fig 2, this shows an

example of the oil flow.

Vat No: GB 4635797 08

Tel: +44 (0) 1206 791552

Company No: 02154196

Fax: +44 (0) 1206 225241

Registered Office:

Email: info@bartechmarine.com

Unit D E & F, Chandlers Row,

Web: www.bartechmarine.com

Colchester, Essex, CO1 2HG

Lapline Ltd trading as Bartech Marine. All business is transacted subject to the general conditions of Lapline Ltd.

Project Proposal

(Bme122 / Issue 2)

Providing safety through mechanical excellence

Fig 1 – Engine oil flow schematic

Vat No: GB 4635797 08

Tel: +44 (0) 1206 791552

Company No: 02154196

Fax: +44 (0) 1206 225241

Registered Office:

Email: info@bartechmarine.com

Unit D E & F, Chandlers Row,

Web: www.bartechmarine.com

Colchester, Essex, CO1 2HG

Lapline Ltd trading as Bartech Marine. All business is transacted subject to the general conditions of Lapline Ltd.

Project Proposal

(Bme122 / Issue 2)

Providing safety through mechanical excellence

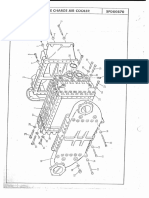

Fig 2 – Oil flow from main bearings to big end bearings

Cleaning Method

With the above description and the engine damage being localised to the A2 & B2

crankshaft journals, it is highly doubtful that material debris from the failure has been

transferred to the rest of the engine, with the only points of transfer being the oil pump

and filter assembly with debris unable to pass through the filters.

With the engine dismantled it is not possible to rig up an external pump and filter system

to flush through the oil ways.

The oil filter assembly and cooler are to be returned to Bartech for ultrasonic cleaning.

A new oil pump, crankshaft, 2x connecting rods and all new main and big end bearings

are to be fitted this will drastically reduce the amount of cleaning required to be

undertaken on the platform.

Tooling Requirements:

Brake & Clutch Cleaner x5 litres

Paraffin pressure spray gun (Fig 3) x1

Bag of white cotton rag x1

Oil spill matting

Air line and gun x1

Vat No: GB 4635797 08

Tel: +44 (0) 1206 791552

Company No: 02154196

Fax: +44 (0) 1206 225241

Registered Office:

Email: info@bartechmarine.com

Unit D E & F, Chandlers Row,

Web: www.bartechmarine.com

Colchester, Essex, CO1 2HG

Lapline Ltd trading as Bartech Marine. All business is transacted subject to the general conditions of Lapline Ltd.

Project Proposal

(Bme122 / Issue 2)

Providing safety through mechanical excellence

Full PPE must be worn to include gloves and full-face mask to protect face, eyes and

breathing.

Fig 3 – Paraffin Spray Gun

Compressed air should be blown through the rocker gear oil feed tubes (Fig 4), it is

recommended brake and clutch cleaner is not used here so as not to wash the camshaft

bearings completely of oil.

Fig 4 – Rocker gear oil feeds

It is recommended the oil gallery plug on the drive end is removed (item 4 on Fig 5).

Vat No: GB 4635797 08

Tel: +44 (0) 1206 791552

Company No: 02154196

Fax: +44 (0) 1206 225241

Registered Office:

Email: info@bartechmarine.com

Unit D E & F, Chandlers Row,

Web: www.bartechmarine.com

Colchester, Essex, CO1 2HG

Lapline Ltd trading as Bartech Marine. All business is transacted subject to the general conditions of Lapline Ltd.

Project Proposal

(Bme122 / Issue 2)

Providing safety through mechanical excellence

The piston cooling oil jets should then be removed (item 10 Fig 5)

The oil cooler to main oil gallery (highlighted red in Fig 5) should be blocked, this can be

done by inserting cotton rag into the hole.

The spray gun should be filled with brake & clutch cleaner and inserted into the oil gallery

via the hole from which the blanking plug was removed (Item 4, Fig 5).

White cotton rag should be laid underneath the engine block on top of oil spill matting to

collect dirt and debris and fluid.

Fig 5 – Engine block

Brake and clutch cleaner should then be sprayed up through the piston cooling jet feeds

and the main bearing feeds,

Finally, brake and clutch fluid should be sprayed once more through the main oil gallery

plug hole and then blown dry using compressed air.

Once the engine is rebuilt, we recommend running the engine on idle for 15 minutes and

then change the engine oil and filters, this will ensure a totally clean engine.

Vat No: GB 4635797 08

Tel: +44 (0) 1206 791552

Company No: 02154196

Fax: +44 (0) 1206 225241

Registered Office:

Email: info@bartechmarine.com

Unit D E & F, Chandlers Row,

Web: www.bartechmarine.com

Colchester, Essex, CO1 2HG

Lapline Ltd trading as Bartech Marine. All business is transacted subject to the general conditions of Lapline Ltd.

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- STORK 6SE280 Overhaul ReportDokument32 SeitenSTORK 6SE280 Overhaul Reportrburtonshaw100% (2)

- Data and InformationDokument15 SeitenData and InformationrburtonshawNoch keine Bewertungen

- Delegate Access DetailsDokument1 SeiteDelegate Access DetailsrburtonshawNoch keine Bewertungen

- Budgets & ResourcesDokument16 SeitenBudgets & ResourcesrburtonshawNoch keine Bewertungen

- Communication & Building Relatio.Dokument16 SeitenCommunication & Building Relatio.rburtonshawNoch keine Bewertungen

- Detroit Diesel MBE4000 Service Manual PDFDokument76 SeitenDetroit Diesel MBE4000 Service Manual PDFrburtonshawNoch keine Bewertungen

- Macduff - Isla S - Stork 6SW280 Version 1.3Dokument6 SeitenMacduff - Isla S - Stork 6SW280 Version 1.3rburtonshawNoch keine Bewertungen

- I'm Affiliative - What's Your Management StyleDokument3 SeitenI'm Affiliative - What's Your Management StylerburtonshawNoch keine Bewertungen

- Bartech MarineDokument8 SeitenBartech MarinerburtonshawNoch keine Bewertungen

- 98240-WB000 - Parts Catalogue S12R-MPTA, MPTK - May 2005 PDFDokument181 Seiten98240-WB000 - Parts Catalogue S12R-MPTA, MPTK - May 2005 PDFrburtonshaw100% (1)

- 31 Series Trouble ShootingDokument4 Seiten31 Series Trouble ShootingrburtonshawNoch keine Bewertungen

- Systems OperationDokument51 SeitenSystems Operationrburtonshaw100% (2)

- Sapphire Aqua-SilDokument6 SeitenSapphire Aqua-SilrburtonshawNoch keine Bewertungen

- Waukesha Bosch Fuel PumpsDokument3 SeitenWaukesha Bosch Fuel PumpsrburtonshawNoch keine Bewertungen

- Bartech MarineDokument8 SeitenBartech MarinerburtonshawNoch keine Bewertungen

- Engaging & Motivating TeamsDokument25 SeitenEngaging & Motivating Teamsrburtonshaw100% (1)

- TD610V Manual PDFDokument184 SeitenTD610V Manual PDFrburtonshaw100% (7)

- HD9063 Installation Manual PDFDokument4 SeitenHD9063 Installation Manual PDFrburtonshawNoch keine Bewertungen

- 98240-31970 - Parts Catalogue S12r-Pta, Mpta, MPTK - Aug.1999Dokument373 Seiten98240-31970 - Parts Catalogue S12r-Pta, Mpta, MPTK - Aug.1999Ricky Burtonshaw78% (9)

- FL6051 Maint Kit 358Dokument3 SeitenFL6051 Maint Kit 358rburtonshawNoch keine Bewertungen

- Engaging & Motivating TeamsDokument21 SeitenEngaging & Motivating Teamsrburtonshaw100% (1)

- Delivery Note2 - 0000012704 - EnQuestDokument3 SeitenDelivery Note2 - 0000012704 - EnQuestrburtonshawNoch keine Bewertungen

- Kato Spec PDFDokument30 SeitenKato Spec PDFrburtonshaw0% (1)

- PAXMAN 12VP185 High Pressure Charge Air CoolerDokument2 SeitenPAXMAN 12VP185 High Pressure Charge Air Coolerrburtonshaw0% (1)

- Paxman VP185 Low Pressure Charge Air CoolerDokument2 SeitenPaxman VP185 Low Pressure Charge Air CoolerrburtonshawNoch keine Bewertungen

- Poly Gaurd Brake Cleaner MSDSDokument16 SeitenPoly Gaurd Brake Cleaner MSDSrburtonshawNoch keine Bewertungen

- Iveco Workshop ManualDokument378 SeitenIveco Workshop ManualMariam100% (6)

- 97821-02031 - Shop Manual 6D1 (For Industrial Use) - Sep.2004 PDFDokument572 Seiten97821-02031 - Shop Manual 6D1 (For Industrial Use) - Sep.2004 PDFrburtonshaw88% (8)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 1050 Operations ManualDokument14 Seiten1050 Operations ManualEd da SilvaNoch keine Bewertungen

- Briggs and Straton Operators Manual 1Dokument136 SeitenBriggs and Straton Operators Manual 1Robert DelafosseNoch keine Bewertungen

- LV05 - Routine Maintenance - Issue 1Dokument53 SeitenLV05 - Routine Maintenance - Issue 1Đức Hòang100% (1)

- Heritage CatalogDokument44 SeitenHeritage CatalogHaitem FarganiNoch keine Bewertungen

- Cat 120H - Motor GraderDokument20 SeitenCat 120H - Motor GraderWhisnu Ryan H100% (2)

- The Mechanism of Lubricants Protective Layers Formation in Friction SlidingDokument6 SeitenThe Mechanism of Lubricants Protective Layers Formation in Friction SlidingTuribio SunnyNoch keine Bewertungen

- Volvo Penta MD2020 - Operation ManualDokument64 SeitenVolvo Penta MD2020 - Operation ManualToby Page100% (1)

- Lubricant Viscosities - Fluids Recommendations (M0087328)Dokument6 SeitenLubricant Viscosities - Fluids Recommendations (M0087328)mauricio100% (1)

- Craftsman Pressure Washer Model No. 580.752400Dokument52 SeitenCraftsman Pressure Washer Model No. 580.752400Javier LopezNoch keine Bewertungen

- 5w 30 Synthetic Oil ComparisonDokument12 Seiten5w 30 Synthetic Oil ComparisonindeskeyNoch keine Bewertungen

- Cummins Fluids 5411406 - 2017 VersionDokument32 SeitenCummins Fluids 5411406 - 2017 VersionRushikesh SawantNoch keine Bewertungen

- Bell Lubricant BrochureDokument68 SeitenBell Lubricant BrochureAfandiquokkaNoch keine Bewertungen

- Choosing the Right High-Speed Grease for Faster Rotating EquipmentDokument34 SeitenChoosing the Right High-Speed Grease for Faster Rotating EquipmentArtur MkrtchyanNoch keine Bewertungen

- Lubes Induction ProgramDokument26 SeitenLubes Induction ProgramTanmoy SahaNoch keine Bewertungen

- Hyundai SERVO Premium Engine Oil 10 Jan 07Dokument2 SeitenHyundai SERVO Premium Engine Oil 10 Jan 07nivi_sharma11Noch keine Bewertungen

- ICT Project Report on Maintenance of Measuring InstrumentsDokument8 SeitenICT Project Report on Maintenance of Measuring InstrumentsKim AvilesNoch keine Bewertungen

- 774 ArmioniMirunaDiana PublishedDokument8 Seiten774 ArmioniMirunaDiana PublishedCaiMep GemalinkNoch keine Bewertungen

- Manual Hidraulico Montacargas Yale Gp060rcDokument52 SeitenManual Hidraulico Montacargas Yale Gp060rcPepe AlNoch keine Bewertungen

- Aerospace and Military Lubrication SolutionsDokument6 SeitenAerospace and Military Lubrication SolutionsbvteoNoch keine Bewertungen

- International 7400 Parts Manual 2006Dokument1.886 SeitenInternational 7400 Parts Manual 2006Gustavo92% (26)

- PAO 5W30: Product DescriptionDokument1 SeitePAO 5W30: Product DescriptionJhonatan PerezNoch keine Bewertungen

- Yamaha F15B Service Manual (En)Dokument180 SeitenYamaha F15B Service Manual (En)Roberto Flores GuerreroNoch keine Bewertungen

- Powertech™ E 4.5 L and 6.8 L Oem Diesel Engines (Tier 3 / Stage Iii A Platform)Dokument176 SeitenPowertech™ E 4.5 L and 6.8 L Oem Diesel Engines (Tier 3 / Stage Iii A Platform)MENDEZ POWER SERVICE E.I.R.L VENTASNoch keine Bewertungen

- Volvo Penta D3 Workshop ManualDokument186 SeitenVolvo Penta D3 Workshop Manualm.kelleci724890% (67)

- PT Nitrogen Pumper 180000Dokument1 SeitePT Nitrogen Pumper 180000Mind Nasrin KadirNoch keine Bewertungen

- Havoline Formula 15W 40 20W 50 API SN 1406Dokument2 SeitenHavoline Formula 15W 40 20W 50 API SN 1406Dewa NataNoch keine Bewertungen

- Periodic Maintenance: Tier 2 Emission EngineDokument58 SeitenPeriodic Maintenance: Tier 2 Emission EnginehoiNoch keine Bewertungen

- Ceccato CompressorDokument29 SeitenCeccato Compressorpeterpunk7586% (7)

- Diesel Engine Valve Failures: April 2002Dokument15 SeitenDiesel Engine Valve Failures: April 2002Rajnish PotdarNoch keine Bewertungen

- FORD WX200 Rev2014Dokument4 SeitenFORD WX200 Rev2014Amandeep SinghNoch keine Bewertungen