Beruflich Dokumente

Kultur Dokumente

SWX - 110 Iso 14174

Hochgeladen von

wiOriginaltitel

Copyright

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSWX - 110 Iso 14174

Hochgeladen von

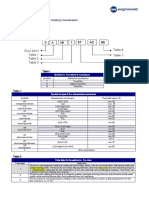

wiProduct Data Sheet

SWX 110 EN ISO 14174: S A AB 1 67 AC H5

Page: 1/4 Type no: 110

Features Benefits

• Agglomerated flux • Very versatile

• Aluminate-basic type • Excellent slag detachability

• Slightly Si and Mn alloying • Good deposition rate

• For mild and medium tensile steels • Impact toughness down to -46°C (-50°F)

• For single and multi wire applications • Supplied in moisture proof packaging

Applications

• General construction • Pressure vessel fabrication

• Double jointing of pipes • Heavy beams

• Heavy equipment • Tank building

• Structural and bridge fabrication • Water and sewage pipes

• Shipbuilding

Flux Characteristics Metallurgical Behaviour

Flux type Aluminate-Basic The diagrams show the typical weld metal analysis in relation to wire

Basicity index 1.4 (Boniszewski) analysis for silicon and manganese.

Alloy transfer Slightly Si and Mn alloying

Density 1.2 kg/litre

Grain size 0.2-2.0 mm / 10-70 mesh

HDM < 5 ml/100 g weld metal

Current DC+/AC

Re-drying unopened bag Not required

Re-drying opened bag See storage and handling recommendations

Flux Main Components

Al2O3 + MnO CaO + MgO SiO2 + TiO2 CaF2

~35% ~25% ~20% ~15%

Single wire, ø 4.0 mm, DC+, 30 V, 60 cm/min

Hobart Brothers Company

101 Trade Square East - Troy, OH 45373, USA

+1 (937) 332 4000 +1 (800) 424-1543 www.hobartbrothers.com

Product Data Sheet

SWX 110 EN ISO 14174: S A AB 1 67 AC H5

Page: 2/4 Type no: 110

Flux/Wire - Combination Classifications Mechanical Properties - Typical Values

With wire EN ISO AWS Re/Rp0.2 Rm A CVN

MPa Mpa % J

0°C -20°C -30°C -40°C -46°C

SDX EM13K AW A5.17: F7A4-EM13K

SDX S2 AW 14171-A: S 38 4 AB S2 420 500 26 130 110 65

SDX S2Si-EM12K AW 14171-A: S 38 4 AB S2Si A5.17: F7A5-EM12K 420 500 26 130 100 60

SDX S3Si-EH12K* AW 14171-A: S 42 4 AB S3Si A5.17: F7A6-EH12K 450 560 28 110 65 50

1

SR A5.17: F7P6-EH12K 440 550 28 100 55 40

SDX S2Mo-EA2 AW 14171-A: S 46 2 AB S2Mo A5.23: F7A4-EA2-A4 510 590 24 90 70 50

SR1 A5.23: F7P4-EA2-A4 470 560 24 70 40

TR 14171-A: S 4T 2 AB S2Mo 50

SDX S4-EH14* AW 14171-A: S 46 4 AB S4 A5.17: F7A4-EH14 520 620 21 80 60

SR2 A5.17: P7A4-EH14 480 580 27 90 65

SDX S3Ni1Mo0.2-ENi5 AW 14171-A: S 50 4 AB S3Ni1Mo0.2 A5.23: F8A6-ENi5-Ni5 570 640 24 90 75 65 40

SDX S2Ni1Cu AW 14171-A: S 46 3 AB S2Ni1Cu 485 570 26 70 55

SubCOR EM12K-S AW A5.17: F7A4-EC1

SubCOR EM13K-S AW A5.17: F7A6-EC1

SR1 A5.17: F7P6-EC1

SubCOR EM13K-S MOD AW A5.17: F7A6-EC1

1

SR A5.17: F7P6-EC1

SubCOR SL 731 AW 14171-A: S 46 4 AB T3 490 600 29 150 115

1

SR 490 600 29 150 115

SubCOR SL 281 Cr AW 14171-A: S 46 4 AB TZ 490 590 25 100 80

AW: as welded, all weld metal. SR: stress relieved, all weld metal. TR: two-run. SR 1: PWHT 620°C (1150°F)/1h. SR2: PWHT 580°C (1080°F)/2h

Metric values are typical of EN ISO testing and imperial values are typical of AWS testing.

*Use with precaution. In certain applications, the manganese content may reach critical levels, leading to hot cracking.

Hobart Brothers Company

101 Trade Square East - Troy, OH 45373, USA

+1 (937) 332 4000 +1 (800) 424-1543 www.hobartbrothers.com

Product Data Sheet

SWX 110 EN ISO 14174: S A AB 1 67 AC H5

Page: 3/4 Type no: 110

Flux/Wire - Combination Classifications Mechanical Properties - Typical Values

With wire EN ISO AWS YS TS E CVN

ksi ksi % ft-lbf

0°F -40°F -60°F -80°F -100°F

SDX EM13K AW A5.17: F7A4-EM13K 75 87 28 22

SDX S2 AW 14171-A: S 38 4 AB S2

SDX S2Si-EM12K AW 14171-A: S 38 4 AB S2Si A5.17: F7A5-EM12K 71 83 29 48 35

SDX S3Si-EH12K* AW 14171-A: S 42 4 AB S3Si A5.17: F7A6-EH12K 76 88 27 54 38

1

SR A5.17: F7P6-EH12K 67 83 28 58 29

SDX S2Mo-EA2 AW 14171-A: S 46 2 AB S2Mo A5.23: F7A4-EA2-A4 80 90 26 58 33

1

SR A5.23: F7P4-EA2-A4 74 86 27 49 33

TR 14171-A: S 4T 2 AB S2Mo

SDX S4-EH14* AW 14171-A: S 46 4 AB S4 A5.17: F7A4-EH14 75 89 21 59 45

2

SR A5.17: P7A4-EH14 69 84 27 67 48

SDX S3Ni1Mo0.2-ENi5 AW 14171-A: S 50 4 AB S3Ni1Mo0.2 A5.23: F8A6-ENi5-Ni5 88 97 25 63 37

SDX S2Ni1Cu AW 14171-A: S 46 3 AB S2Ni1Cu

SubCOR EM12K-S AW A5.17: F7A4-EC1 60 71 30 45

SubCOR EM13K-S AW A5.17: F7A6-EC1 64 73 28 97 75

SR1 A5.17: F7P6-EC1 64 77 32 95

SubCOR EM13K-S MOD AW A5.17: F7A6-EC1 76 84 29 115

1

SR A5.17: F7P6-EC1 68 80 31 143 105

SubCOR SL 731 AW 14171-A: S 46 4 AB T3

SR1

SubCOR SL 281 Cr AW 14171-A: S 46 4 AB TZ

AW: as welded, all weld metal. SR: stress relieved, all weld metal. TR: two-run. SR 1: PWHT 1150°F (620°C)/1h. SR2: PWHT 1080°F (580°C)/2h

Metric values are typical of EN ISO testing and imperial values are typical of AWS testing.

*Use with precaution. In certain applications, the manganese content may reach critical levels, leading to hot cracking.

Chemical Composition All Weld Metal - Typical Values

With wire %C %Si %Mn %Cr %Ni %Mo %Cu

SDX EM13K 0.06 0.3 1.2

SDX S2 0.06 0.3 1.2

SDX S2Si-EM12K 0.06 0.5 1.3

SDX S2Mo-EA2 0.06 0.3 1.3 0.5

SDX S3Si-EH12K 0.07 0.5 1.9

SDX S4-EH10K 0.09 0.3 2.1

SDX S3Ni1Mo0.2-ENi5 0.09 0.3 1.4 0.9 0.2

SDX S2Ni1Cu 0.08 0.4 1.3 0.7 0.5

SubCOR EM12K-S 0.05 0.2 1.2

SubCOR EM13K-S 0.06 0.3 1.2

SubCOR EM13K-S MOD 0.07 0.4 1.3

SubCOR SL 731 0.05 0.3 2.1

SubCOR SL 281 Cr 0.12 0.6 1.3 0.5 0.6 0.5

Standard Packages

Description Item number No of bags/pallet Net weight/pallet

25 kg (55 lbs) Aluminium/PE Bag EAE 110022500H 42 1050 kg (2310 lbs)

1000 kg (2200 lbs) Double Bag 110071T00H 1 1000 kg (2200 lbs)

Hobart Brothers Company

101 Trade Square East - Troy, OH 45373, USA

+1 (937) 332 4000 +1 (800) 424-1543 www.hobartbrothers.com

Product Data Sheet

SWX 110 EN ISO 14174: S A AB 1 67 AC H5

Page: 4/4 Type no: 110

Approvals

With wire ABS BV DNV/GL LR CWB DB TÜV CE

SDX S1-EL12 √

SDX S2 √ √

SDX S2Si-EM12K 4Y400M 4Y40M IVY40M 4Y40M F49A4-EM12K √ √ √

SDX S2Mo-EA2 3YTM IIIYTM 3YTM F8A6-EA2-A4 √ √

SDX S3Si-EH12K F49A6-EH12K √

SDX S2Ni1Cu √

SubCOR EM13K-S MOD F49A6-EC1

SubCOR SL 731 √

SubCOR SL 281 Cr √

Limitations (diameter, position, etc.) may exist. Please refer to product approval certificates for more information.

Storage, recycling and re-drying

HOBART welding fluxes from undamaged moisture proof packaging can be used without costly re-drying. The flux recycling system must be free

from moisture and oil. Slag and millscale must be removed from the recycled flux. At least one part of new flux to three parts of recycled flux must

be added. From open packaging and if the flux has been exposed to moist conditions, re-drying is recommended. Agglomerated fluxes should be

re-dried at a temperature of 300-350°C (570-660°F) for a minimum of 2 hours. Re-dried flux must be stored at 150±25°C (300±45°F) before

use. Re-drying should be made maximum three times.

Maintaining a proper welding procedure - including pre-heat and interpass temperatures - may be critical depending

on the type and thickness of steel being welded.

TECHNICAL QUESTIONS? For technical support of Hobart Filler Metals products please visit www.hobartbrothers.com/where-to-buy to

find your closest Hobart representative or send an e-mail to subarc@itw-welding.com for further assistance.

DISCLAIMER:

The information contained or otherwise referenced herein is for reference purposes only and is presented only as “typical.” Typical data are those obtained when welding and testing

are performed in accordance with applicable AWS and/or EN ISO specification(s). Other tests and procedures may produce difference results and typical data should not be assumed

to yield similar results in a particular application or weldment. No data is to be constructed as a recommendation for any welding condition or technique not controlled by ITW Welding.

ITW Welding does not assume responsibility for any results obtained by persons over whose methods it has no control. It is the user’s responsibility to determine the suitability of any

products or methods mentioned herein for a particular purpose. In light of the foregoing, ITW Welding specifically disclaims any liability incurred from reliance on such information, and

disclaims all guarantees and warranties, express or implied, including warranties of merchantability and fitness for a particular purpose, and further disclaims any liability for

consequential or incidental damages of any kind, including lost profits.

CAUTION:

Consumers should be thoroughly familiar with the safety precautions on the warning label posted in each shipment and in the American National Standard Z49.1, “Safety in Welding

and Cutting,” published by the American Welding Society, 8669 NW 36 St, # 130, Miami, FL 33166-6672 (can also be downloaded online at www.aws.org); OSHA Safety and Health

Standards 29 CFR 1910 is available from the U.S. Department of Labor, Washington, D.C. 20210.

Safety Data Sheets on any Hobart Brothers Company product may be obtained from Hobart Customer Service or at www.hobartbrothers.com.

Because Hobart Brothers Company is constantly improving products, Hobart reserves the right to change design and/or specifications without notice.

SubCOR is a trademark of Hobart Brothers Company, Troy Ohio.

Hobart is a registered trademark of Hobart Brothers Company, Troy, Ohio.

Specification: PDS110 // Type Number: 110 // Revision: 9 // Replaces: 8 // Approved By: R.Fox, P.Jeirud

Prepared By: I.Oziewicz // Reason For Issue: Flux and wire combinations added.

Hobart Brothers Company

101 Trade Square East - Troy, OH 45373, USA

+1 (937) 332 4000 +1 (800) 424-1543 www.hobartbrothers.com

Das könnte Ihnen auch gefallen

- Adiabatic Shear Localization: Frontiers and AdvancesVon EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNoch keine Bewertungen

- EN 760 (Flux-SAW)Dokument2 SeitenEN 760 (Flux-SAW)HoangNoch keine Bewertungen

- A 48 Gray Iron CastingsDokument5 SeitenA 48 Gray Iron Castingswasatiah05Noch keine Bewertungen

- Friction Stir Welding of Dissimilar Alloys and MaterialsVon EverandFriction Stir Welding of Dissimilar Alloys and MaterialsBewertung: 3 von 5 Sternen3/5 (1)

- Astm G 101Dokument8 SeitenAstm G 101El_Proesor100% (1)

- ISO 9692 1 2013 Welding and Allied ProcessesDokument20 SeitenISO 9692 1 2013 Welding and Allied Processesluisgonzalezf95Noch keine Bewertungen

- Astm A204 A204m PDFDokument3 SeitenAstm A204 A204m PDFKaterynaNoch keine Bewertungen

- WABO Welding 27-13 Full VersionDokument73 SeitenWABO Welding 27-13 Full Versionalajev17Noch keine Bewertungen

- Mechanical Testing 01B: Part 2 Charpy Impact TestingDokument25 SeitenMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- En 10025-2Dokument4 SeitenEn 10025-2Sebastián Araya MoraNoch keine Bewertungen

- S355 European Standard SteelDokument7 SeitenS355 European Standard SteelmaiquelernNoch keine Bewertungen

- Welding Metallurgy and Weldability of Stainless SteelsDokument6 SeitenWelding Metallurgy and Weldability of Stainless SteelsoifhiudsnfNoch keine Bewertungen

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Dokument16 SeitenVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNoch keine Bewertungen

- Metales de Aporte EsabDokument556 SeitenMetales de Aporte EsabAndres Felipe GutierrezNoch keine Bewertungen

- InteractiveFormQB 482Dokument1 SeiteInteractiveFormQB 482Afriadi Budi PrasetyoNoch keine Bewertungen

- RepairDokument0 SeitenRepairPatricio TamayoNoch keine Bewertungen

- Steel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Dokument10 SeitenSteel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Sama UmateNoch keine Bewertungen

- Sfa-5.7Dokument10 SeitenSfa-5.7vannie_yundaNoch keine Bewertungen

- The Role of Niobium in Austenitic and Duplex Stainless SteelsDokument25 SeitenThe Role of Niobium in Austenitic and Duplex Stainless SteelsZoe SideriNoch keine Bewertungen

- ISO - TR - 15608 - Welding Guide Line PDFDokument10 SeitenISO - TR - 15608 - Welding Guide Line PDFDacher DanielNoch keine Bewertungen

- BS2789 Grade 700-2 SG Iron: Form of SupplyDokument2 SeitenBS2789 Grade 700-2 SG Iron: Form of SupplySama UmateNoch keine Bewertungen

- 206WKS 17 Health and Safety Welding August 2019Dokument46 Seiten206WKS 17 Health and Safety Welding August 2019louis donyNoch keine Bewertungen

- BS EN ISO 17637 - 2003 - WeldingDokument20 SeitenBS EN ISO 17637 - 2003 - WeldingYang GaoNoch keine Bewertungen

- Astm A27Dokument4 SeitenAstm A27MAX ALBERTO JUAREZ AVALOSNoch keine Bewertungen

- A572 50 TY1 KrakatauposcoplateASTMproductDokument1 SeiteA572 50 TY1 KrakatauposcoplateASTMproductSteel BridgeNoch keine Bewertungen

- Astm A209 PDFDokument3 SeitenAstm A209 PDFgaminNoch keine Bewertungen

- Temper Embrittlement - J and X FactorDokument2 SeitenTemper Embrittlement - J and X Factorgovimano100% (2)

- ALuminium MIG Welding of All Series With Filler MetalsDokument37 SeitenALuminium MIG Welding of All Series With Filler MetalsSuresh G KumarNoch keine Bewertungen

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Dokument16 SeitenNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNoch keine Bewertungen

- Astm e 2218 - 02Dokument15 SeitenAstm e 2218 - 02Jaime Rafael Patron PrioloNoch keine Bewertungen

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDokument19 SeitenSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNoch keine Bewertungen

- Iso 683 1 2012Dokument13 SeitenIso 683 1 2012Haluk TOKGÖZNoch keine Bewertungen

- EN 288-3xDokument38 SeitenEN 288-3xSyah Reza Maulana0% (1)

- SN200-4 2016-05 eDokument37 SeitenSN200-4 2016-05 emochocerNoch keine Bewertungen

- Astm e 112 Ebook - enDokument46 SeitenAstm e 112 Ebook - enyostar 232Noch keine Bewertungen

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Dokument13 SeitenNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNoch keine Bewertungen

- Rimmed Vs Killed SteelDokument1 SeiteRimmed Vs Killed SteelMuthuKumarNoch keine Bewertungen

- En 10029 PDFDokument1 SeiteEn 10029 PDFJan AmersfNoch keine Bewertungen

- AISI 1018 Mild Low Carbon Steel PDFDokument3 SeitenAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNoch keine Bewertungen

- 2370 Ed1 ENDokument5 Seiten2370 Ed1 ENanhthoNoch keine Bewertungen

- Test Report 11 Pcs Padeyes THR Room GCIIIDokument6 SeitenTest Report 11 Pcs Padeyes THR Room GCIIIJurand Juri100% (1)

- A5 32-A5 32M-97Dokument5 SeitenA5 32-A5 32M-97mon3embo7Noch keine Bewertungen

- EN 15085 Program Evaluation TestDokument2 SeitenEN 15085 Program Evaluation TestSatish KeskarNoch keine Bewertungen

- Advance StructuresDokument6 SeitenAdvance StructuresManju NishaNoch keine Bewertungen

- Iso 14343-2017Dokument24 SeitenIso 14343-2017getatodicaNoch keine Bewertungen

- Microinclusion Evaluation Using Various StandardsDokument12 SeitenMicroinclusion Evaluation Using Various StandardsSinan Chen100% (1)

- Sa 213Dokument11 SeitenSa 213gst ajahNoch keine Bewertungen

- Sfa-5 31Dokument10 SeitenSfa-5 31Sarvesh MishraNoch keine Bewertungen

- Astm A245 2020Dokument5 SeitenAstm A245 2020CK CkkouNoch keine Bewertungen

- ASME SA213 T9 Seamless Alloy Steel TubesDokument7 SeitenASME SA213 T9 Seamless Alloy Steel TubesJayminNoch keine Bewertungen

- QW 442 A Number PDFDokument1 SeiteQW 442 A Number PDFMadidj_2014Noch keine Bewertungen

- Aws d1.1 WPQR GuidesDokument3 SeitenAws d1.1 WPQR GuidesDo XuanNoch keine Bewertungen

- Bavaria Flux BF 5.1Dokument3 SeitenBavaria Flux BF 5.1Filipe CordeiroNoch keine Bewertungen

- BOM List Converter 60-12VDC - 18.05.20 - FinalDokument9 SeitenBOM List Converter 60-12VDC - 18.05.20 - FinalNguyễn TínNoch keine Bewertungen

- Hickok 600A-605ADokument98 SeitenHickok 600A-605Ajose torresNoch keine Bewertungen

- Industrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationDokument16 SeitenIndustrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationglukkerNoch keine Bewertungen

- 05 - 14 Steel RepairsDokument1 Seite05 - 14 Steel Repairsmaxuya2001Noch keine Bewertungen

- 05 - 14 Steel RepairsDokument1 Seite05 - 14 Steel Repairsmaxuya2001Noch keine Bewertungen

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDokument8 SeitenSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubeswiNoch keine Bewertungen

- Impact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CDokument9 SeitenImpact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CwiNoch keine Bewertungen

- WPS PqrchecklistDokument1 SeiteWPS PqrchecklistrodofgodNoch keine Bewertungen

- Asnt-Tc1a Cambios PDFDokument20 SeitenAsnt-Tc1a Cambios PDFwiNoch keine Bewertungen

- AWS D10 4 86R Recommended Practices PDFDokument44 SeitenAWS D10 4 86R Recommended Practices PDFwi100% (1)

- Effect of PH, Temperature and Chloride Concentrations 316lDokument17 SeitenEffect of PH, Temperature and Chloride Concentrations 316lwiNoch keine Bewertungen

- TOFD PA Procedure For 301 PDFDokument49 SeitenTOFD PA Procedure For 301 PDFwiNoch keine Bewertungen

- Hobart Subarc CatalogDokument2 SeitenHobart Subarc CatalogwiNoch keine Bewertungen

- Techalloy 276 ERNiCrMo-4Dokument2 SeitenTechalloy 276 ERNiCrMo-4wiNoch keine Bewertungen

- Inconel 622 Ernicrmo-10 Uns n06022Dokument1 SeiteInconel 622 Ernicrmo-10 Uns n06022wiNoch keine Bewertungen

- BendTestJig LowerBody 1 PDFDokument1 SeiteBendTestJig LowerBody 1 PDFwiNoch keine Bewertungen

- BendTestJig UpperBody 1 PDFDokument1 SeiteBendTestJig UpperBody 1 PDFwiNoch keine Bewertungen

- Repairing The Roller of A Rolling Machine Used in SMAW Welding ProcessesDokument7 SeitenRepairing The Roller of A Rolling Machine Used in SMAW Welding ProcesseswiNoch keine Bewertungen

- General PA Procedure For Detection and SizingDokument46 SeitenGeneral PA Procedure For Detection and Sizingwi100% (5)

- Order 114-3711903-9862655 Colonia PDFDokument1 SeiteOrder 114-3711903-9862655 Colonia PDFwiNoch keine Bewertungen

- Order 114-1661038-0533809 Baterry PDFDokument1 SeiteOrder 114-1661038-0533809 Baterry PDFwiNoch keine Bewertungen

- Improving Surface Mine Profitability With Phased Array UltrasonicsDokument14 SeitenImproving Surface Mine Profitability With Phased Array Ultrasonicswi100% (1)

- 1998 Zhang Biodegradability ofDokument8 Seiten1998 Zhang Biodegradability ofAlejandro Castro YaruroNoch keine Bewertungen

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Dokument38 SeitenStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi67% (3)

- Midas Concrete DamageDokument9 SeitenMidas Concrete DamageShishir Kumar Nayak100% (1)

- Installation PracticesDokument28 SeitenInstallation PracticesKelly QuicenoNoch keine Bewertungen

- Canning of FoodDokument4 SeitenCanning of Foodkolita kamalNoch keine Bewertungen

- Steel HandbookDokument276 SeitenSteel HandbookYu chung yin100% (2)

- Wiring Cable StandardDokument6 SeitenWiring Cable StandardAli AhmadNoch keine Bewertungen

- Chapt02 PDFDokument21 SeitenChapt02 PDFAdi SuwandiNoch keine Bewertungen

- LB Aw Arc SPT - enDokument62 SeitenLB Aw Arc SPT - enWaldir Donatti JuniorNoch keine Bewertungen

- Inorganic Chemistry Practice Booklet-1Dokument65 SeitenInorganic Chemistry Practice Booklet-1godlanshul32Noch keine Bewertungen

- Slide 11 Extrusion and Wire DrawingDokument53 SeitenSlide 11 Extrusion and Wire Drawingjohn doeNoch keine Bewertungen

- The Thermal Expansion of The Fireclay BricksDokument38 SeitenThe Thermal Expansion of The Fireclay BricksanuarsgNoch keine Bewertungen

- Water Purification Using Solar Still: A Technical Seminar OnDokument18 SeitenWater Purification Using Solar Still: A Technical Seminar Onashna latheefNoch keine Bewertungen

- ASTM A449 Tech InfoDokument2 SeitenASTM A449 Tech InfoBoz Van DuynNoch keine Bewertungen

- SAFT Msds Nicd Europe 2003-10 enDokument7 SeitenSAFT Msds Nicd Europe 2003-10 enDiego Francisco Castañeda ViñasNoch keine Bewertungen

- Rubber JointDokument1 SeiteRubber JointAymen AyedNoch keine Bewertungen

- 712-1010-001 - Avkcms - en 2205Dokument6 Seiten712-1010-001 - Avkcms - en 2205Vieru GabrielNoch keine Bewertungen

- Luminate PDS BF 10609 USLDokument2 SeitenLuminate PDS BF 10609 USLArash AbbasiNoch keine Bewertungen

- GORE Automotive Vents Exterior Lighting Datasheet ENDokument4 SeitenGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangNoch keine Bewertungen

- Pif 00 Forms Final ListDokument8 SeitenPif 00 Forms Final Listkaty leeNoch keine Bewertungen

- FIRE Extinguisher / FIRE Igniter LAB: NAME - PER - MAILBOX # - DUE DATEDokument9 SeitenFIRE Extinguisher / FIRE Igniter LAB: NAME - PER - MAILBOX # - DUE DATEMacaraeg, Janea MaeNoch keine Bewertungen

- Concrete ClothDokument20 SeitenConcrete ClothShrinivasNoch keine Bewertungen

- KALORIMETERDokument8 SeitenKALORIMETERSeliyaNoch keine Bewertungen

- Deltech DK60 and AboveDokument4 SeitenDeltech DK60 and Abovesales-admin.bdgNoch keine Bewertungen

- Retrofitting of RC Structure Using FRP Laminate: AbstractDokument10 SeitenRetrofitting of RC Structure Using FRP Laminate: AbstractYo Yo AkNoch keine Bewertungen

- Irostic para Adhesivo PCVDokument3 SeitenIrostic para Adhesivo PCVlobocerna0% (1)

- Phase Equilibrium Study in The CaODokument5 SeitenPhase Equilibrium Study in The CaOsattiricNoch keine Bewertungen

- Ashrae 62-73Dokument20 SeitenAshrae 62-73Jose Luis ZIMICNoch keine Bewertungen

- NMR Solvents - Unsurpassed Quality For Peak PerformanceDokument12 SeitenNMR Solvents - Unsurpassed Quality For Peak PerformanceSigma-Aldrich100% (1)

- Nida Metal BrazingDokument4 SeitenNida Metal Brazingapi-115534435Noch keine Bewertungen

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsVon EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNoch keine Bewertungen

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsVon EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNoch keine Bewertungen

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastVon EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastBewertung: 5 von 5 Sternen5/5 (1)

- Edward's Menagerie: Dogs: 50 canine crochet patternsVon EverandEdward's Menagerie: Dogs: 50 canine crochet patternsBewertung: 3 von 5 Sternen3/5 (5)

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesVon Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNoch keine Bewertungen

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreVon EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreBewertung: 4 von 5 Sternen4/5 (6)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeVon EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeBewertung: 5 von 5 Sternen5/5 (1)

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsVon EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsBewertung: 5 von 5 Sternen5/5 (3)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldVon EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldBewertung: 4.5 von 5 Sternen4.5/5 (30)

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookVon EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Textiles Transformed: Thread and thrift with reclaimed textilesVon EverandTextiles Transformed: Thread and thrift with reclaimed textilesNoch keine Bewertungen

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsVon EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNoch keine Bewertungen

- Edward's Menagerie: Over 40 Soft and Snuggly Toy Animal Crochet PatternsVon EverandEdward's Menagerie: Over 40 Soft and Snuggly Toy Animal Crochet PatternsBewertung: 5 von 5 Sternen5/5 (10)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearVon EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearBewertung: 5 von 5 Sternen5/5 (1)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsVon EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsNoch keine Bewertungen

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesVon EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesBewertung: 5 von 5 Sternen5/5 (3)

- Build Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreVon EverandBuild Your Skills Crochet Tops: 26 Simple Patterns for First-Time Sweaters, Shrugs, Ponchos & MoreBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesVon EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNoch keine Bewertungen

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtVon EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtNoch keine Bewertungen