Beruflich Dokumente

Kultur Dokumente

RP Technical Paper NPSH Reciprocating Pumps v2 PDF

Hochgeladen von

balajiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RP Technical Paper NPSH Reciprocating Pumps v2 PDF

Hochgeladen von

balajiCopyright:

Verfügbare Formate

Calculating NPSH for reciprocating plunger pumps

must account for losses due to acceleration head for

a reliable design that will meet the required duty

Ruhrpumpen Reciprocating plunger pumps accelerate the pumped fluid as the plunger

moves through its stroke and this acceleration of the fluid has an impact on

Ruhrpumpen is a global supplier of

the calculation for NPSH which must be accounted for in the design and

innovative centrifugal and

selection of reciprocating plunger pumps to avoid potentially catastrophic

reciprocating pump solutions for the

consequences

oil and gas, petrochemical,

chemical, process, industrial, water,

Net Positive Suction Head (NPSH) is a measure of the pressure of the fluid

power and mining markets.

being presented to the pump in the suction line. NPSHA is the Available head,

Pumps are designed and that is the absolute pressure at the suction port of the pump, and NPSHR is the

manufactured to the most pressure of fluid Required by the pump to avoid cavitation (see Figure 1) and so

demanding quality standards and perform to the required specification.

industry specifications, including

API, ANSI, ISO and Hydraulic

NPSHA must always be greater NPSHR in a system for the

Institute Standards. When a

pump to operate reliably otherwise the pump may suffer

standard pump is not suitable for a

from erratic performance, reduced flow, high levels of

challenging application or duty,

noise and vibration, cavitation of the pumped fluid, undue

Ruhrpumpen engineers will design

wear and ultimately premature failure.

and manufacture a bespoke

pumping solution, drawing on the

company’s breadth and depth of

skills, expertise and technology.

Quality is managed and controlled

through the company’s own

integrated foundries, machine

shops, service centres, and

manufacturing plants located

around the world.

Reciprocating Plunger Pumps

The Ruhrpumpen RDP series of

high-quality triplex and quintuplex

reciprocating plunger pumps are

designed in the United Kingdom and

used for high-pressure duties across

the oil and gas, petrochemical,

process, industrial and mining

markets where low leakage, high

reliability and reduced running noise

are paramount.

The pumps fully meet API 674 3rd

edition and ISO13710, and can

handle pressures up to 1,000 bar

(14,500 psi) at temperatures Figure 1– Cavitation is the result of a drop in pressure of a moving

between -40C (-104°F) and 200C liquid. This reduced pressure causes bubbles to form, then as the

(392°F). Bespoke pumps can be pressure of the liquid increases again, the bubbles close to surface

engineered to meet customer collapse generating an extremely high pressure jet of liquid for that is

specific requirements and duties. capable of eroding the surface material.

Ruhrpumpen Reciprocating Plunger Pumps T: +44 (0)1273 782240

22 Commerce Way, Lancing BN15 8TA E: salesuk@ruhrpumpen.com

United Kingdom www.ruhrpumpen.com

Calculating NPSHA for centrifugal pumps

The calculation of NPSHA takes into account the static head from the supply tank and factors in various losses and

adjustments. NPSHA is calculated for the system and it is the customer’s responsibility to provide this to the pump

manufacturer in the specifications for a pump. NPSHR is provided by the pump manufacturer for each pump and an

acceptable margin between NPSHA and NPSHR is agreed, normally greater than 1m.

Most engineers specifying pumps are familiar with the calculation for NPSHA for centrifugal pumps which is

expressed as:

NPSHA = pg + pz - pvp - pf

where:

pg is the static head from the supply tank

pz is the head due to height difference

pvp is the margin needed for vapour pressure

pf is the head loss due to frictional losses

Accounting for acceleration head in reciprocating plunger pumps

Centrifugal pumps and reciprocating plunger pumps

operate on entirely different principles. In its simplest

form a centrifugal pump is a velocity generator in which

the fluid moves through a pipeline at constant velocity,

but a reciprocating plunger pump is a flow generator in

that the fluid flow accelerates in sine wave as it moves

through the pipeline. This acceleration and associated

with the fluid being moved by a reciprocating pump

introduces pulsation into the pumped fluid as the

plungers displace a discrete volume of fluid for each

stroke, which can be represented as a series of pressure

waves.

The resistance of the flow acceleration in a particular

system is known as impedance. The loss in NPSHA due to

this impedance is also known as the acceleration head

and must be accounted for when determining NPSHA for

a system that will incorporate a reciprocating plunger

pump, otherwise the NPSHA given by the customer to the

pump manufacturer will be overstated with the result

that the actual NPSHA in the system may be lower than Figure 2—Illustration of how head losses are added

the NPSHR of the selected pump with undesirable and subtracted in a closed supply

consequences.

The acceleration head for reciprocating pumps pac is subtracted from calculation of NPSHA used for centrifugal

pumps as follows (and see Figure 2):

NPSHA = pg + pz - pvp - pf - pac

Ruhrpumpen Reciprocating Plunger Pumps T: +44 (0)1273 782240

22 Commerce Way, Lancing BN15 8TA E: salesuk@ruhrpumpen.com

United Kingdom www.ruhrpumpen.com

Effect of pipeline diameter on NPSHA for reciprocating plunger pumps

Fluid moving through a large bore pipe will result in low pressure waves and so have a low impedance whereas a

small diameter bore will result in high pressure waves in the fluid and a high impedance. As such, the impedance of

pumped fluid is proportional to the bore diameter of the pipeline (see Figure 3).

Figure 3 - Relative pressure waves between large bore and small bore pipe

The acceleration head pac used in the calculation of NPSHA is therefore related to the bore diameter of the suction

pipe, and in addition the length of suction pipe and the reciprocating pump speed and displacement. The

calculation of the acceleration head pac (in metres) is made as follows:

pac = C1LNQS

D2

where:

C1 is the constant for the type of pump and specified in the ANSI standard for Reciprocating Power Pumps

(ANSI 6.1-6.5-2000) as 0.066 for triplex pumps and 0.040 for quintuplex pumps

L is the length of suction pipe, m

N is the pump speed, rpm

Q is the pump displacement, m3/s

S is the specific gravity of liquid

D is the inner diameter of the suction pipe, m

Ruhrpumpen Reciprocating Plunger Pumps T: +44 (0)1273 782240

22 Commerce Way, Lancing BN15 8TA E: salesuk@ruhrpumpen.com

United Kingdom www.ruhrpumpen.com

The key point to note in the above calculation of the acceleration head is that the bore diameter of the suction pipe

is squared and so increasing or decreasing the bore diameter of the suction pipe has a large impact on the

acceleration head that must subtracted from the NPSHA. A small bore diameter suction pipe will generate

significantly more acceleration losses than a large bore diameter suction pipe and so a much greater reduction in

the resulting NPSHA, which if not accounted for correctly could easily be greater than the margin between NPSHA

and NPSHR normally agreed resulting in catastrophic consequences for the pump.

Furthermore, as increasing the bore diameter decreases the impedance this also has the positive effect of reducing

the pulsation in the pump and associated pipework which may eliminate or reduce the need for pulsation

dampeners.

Summary

The customer is responsible for providing the NPSHA for a given system to the pump manufacturer so that the

pump manufacturer ensure that a pump with a lower NPSHR is selected. In the case of reciprocating pumps,

Ruhrpumpen should check that the NPSHA provided by the end-user fully accounts for the acceleration head losses

when using reciprocating plunger pumps, particularly if the end-user is not familiar with reciprocating pumps or the

duty could be performed by both a centrifugal and reciprocating pump, in which cases the customer may have

mistakenly used the NPSHA calculation for centrifugal pumps.

Using the correct NPSHA, which fully accounts for the acceleration head loss, will ensure that a suitable

reciprocating plunger pump for the duties is selected that will deliver the required performance with low noise and

vibration levels and long-term reliability.

Ruhrpumpen Reciprocating Plunger Pumps T: +44 (0)1273 782240

22 Commerce Way, Lancing BN15 8TA E: salesuk@ruhrpumpen.com

United Kingdom www.ruhrpumpen.com

Das könnte Ihnen auch gefallen

- Accomplishment Report in ESPDokument7 SeitenAccomplishment Report in ESPAldrin Perez85% (39)

- Suction Specific Speed FromDokument18 SeitenSuction Specific Speed FromAlda EnglandNoch keine Bewertungen

- A Exercises SolutionsDokument13 SeitenA Exercises SolutionsuxNoch keine Bewertungen

- Report On SURFACE CONSTRUCTION OF THE REICHSTAGDokument19 SeitenReport On SURFACE CONSTRUCTION OF THE REICHSTAGkylikeschoco100% (3)

- Wind LoadDokument1 SeiteWind Loadvikramjain66Noch keine Bewertungen

- CFM56-5A-5B CO-063 Basic Engine Feb2014Dokument27 SeitenCFM56-5A-5B CO-063 Basic Engine Feb2014Kelik Arif100% (1)

- A Look at Centrifugal Pump Suction Hydraulic - Part 1Dokument4 SeitenA Look at Centrifugal Pump Suction Hydraulic - Part 1Said Ahmed SalemNoch keine Bewertungen

- Applying NPSH To Metering PumpsDokument3 SeitenApplying NPSH To Metering PumpsJoce88888100% (1)

- White Paper - Calculating Safe NPSH (A)Dokument3 SeitenWhite Paper - Calculating Safe NPSH (A)Stephen BeasleyNoch keine Bewertungen

- NPSH For Metering PumpsDokument7 SeitenNPSH For Metering PumpsRahul S. ChandrawarNoch keine Bewertungen

- NPSH Pump OperatingDokument4 SeitenNPSH Pump OperatingJanneth Herrera FloresNoch keine Bewertungen

- Guia de Diseño de BombeoDokument33 SeitenGuia de Diseño de BombeoNelson Vargas100% (1)

- Wilfley BrochureDokument8 SeitenWilfley BrochureCarlos de la TorreNoch keine Bewertungen

- Restriction Orifice RO Flow Control Instrument PDFDokument8 SeitenRestriction Orifice RO Flow Control Instrument PDFRaphael212219Noch keine Bewertungen

- VTP October 22Dokument8 SeitenVTP October 22Hidroterm Plantas Electricas-Bombas De Agua-Maquinaria Pesada100% (1)

- Presentation On - : Horizontal Centrifugal PumpDokument78 SeitenPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Workshop 1Dokument429 SeitenWorkshop 1Vijay Rajaindran100% (1)

- Nitro Nic 50 BookDokument18 SeitenNitro Nic 50 Booka100acomNoch keine Bewertungen

- System OneDokument4 SeitenSystem OnerasottoNoch keine Bewertungen

- Gas Jet Pump Paper Oct03 Ipa03 e 059Dokument11 SeitenGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadNoch keine Bewertungen

- FDA Det Flame ArrestorsDokument2 SeitenFDA Det Flame Arrestorsali kararNoch keine Bewertungen

- Mantenimiento SruDokument22 SeitenMantenimiento SruDaineris HernandezNoch keine Bewertungen

- CT2 2012 Poor Pump Design ConsiderationsDokument2 SeitenCT2 2012 Poor Pump Design ConsiderationsKroya HunNoch keine Bewertungen

- Cenários Sobrepressão Conforme API RP 521Dokument3 SeitenCenários Sobrepressão Conforme API RP 521Adilmar E. NatãnyNoch keine Bewertungen

- NPSH - Net Positive Suction HeadDokument9 SeitenNPSH - Net Positive Suction Headlokeshjaddu6Noch keine Bewertungen

- Cavitational FlowDokument11 SeitenCavitational FlowriemannNoch keine Bewertungen

- Specification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessDokument30 SeitenSpecification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessFrancisco Gonzalez100% (1)

- Facts at Your Fingers - Positive-Displacement-Pumps PDFDokument1 SeiteFacts at Your Fingers - Positive-Displacement-Pumps PDFjohn VilladaNoch keine Bewertungen

- Vane Pump SelectionDokument25 SeitenVane Pump SelectionGirlish JackieNoch keine Bewertungen

- Rupturedisk CheresourcesDokument9 SeitenRupturedisk Cheresourcessammar_10100% (1)

- Cooling Water Pump - Rev 1Dokument3 SeitenCooling Water Pump - Rev 1Parag ThakkarNoch keine Bewertungen

- ChecklistDokument3 SeitenChecklistAndy Noven KrisdiantoNoch keine Bewertungen

- How Pump Speed and Impeller Diameter Affect NPSHRDokument2 SeitenHow Pump Speed and Impeller Diameter Affect NPSHRdk4monjure100% (3)

- Correction Factors For Centrifugal Pump Water Performance Due To ViscosityDokument5 SeitenCorrection Factors For Centrifugal Pump Water Performance Due To ViscositynasirmuzaffarNoch keine Bewertungen

- Pulsation Dampeners For Smooth Flow in Pipes: The K FactorDokument3 SeitenPulsation Dampeners For Smooth Flow in Pipes: The K FactorEdisonReisNoch keine Bewertungen

- BFP ARC Valve FunctionDokument6 SeitenBFP ARC Valve FunctionVenkat ShanNoch keine Bewertungen

- Elastec TDS-118 Skimmer Brochure PDFDokument2 SeitenElastec TDS-118 Skimmer Brochure PDFGiorgiana RosuNoch keine Bewertungen

- Reciprocating Pumps - NDPDDokument2 SeitenReciprocating Pumps - NDPDDhanny MiharjaNoch keine Bewertungen

- Tips For Layout1Dokument3 SeitenTips For Layout1amitrai86Noch keine Bewertungen

- b3311 722-2Dokument7 Seitenb3311 722-2Arnaldo BenitezNoch keine Bewertungen

- Pocket API 682 4th Edition Piping Plans - EN Burgmann PDFDokument131 SeitenPocket API 682 4th Edition Piping Plans - EN Burgmann PDFPoncho RmzNoch keine Bewertungen

- Pump CurvesDokument3 SeitenPump CurvesMahmoud NaelNoch keine Bewertungen

- DeepFlex BrochureDokument4 SeitenDeepFlex Brochureribeiro30Noch keine Bewertungen

- Aurora Pump School 101Dokument87 SeitenAurora Pump School 101metropumpsNoch keine Bewertungen

- DeepFlex Overview March-2014Dokument32 SeitenDeepFlex Overview March-2014bzkxt100% (1)

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDokument9 SeitenControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımNoch keine Bewertungen

- Impulse 4.0 Users Guide SI PDFDokument554 SeitenImpulse 4.0 Users Guide SI PDFalberto fuentealbaNoch keine Bewertungen

- 8100 Series Fire Pumps: Replacement Parts ForDokument10 Seiten8100 Series Fire Pumps: Replacement Parts ForAlvialvarezNoch keine Bewertungen

- How Liquid Ring Vacuum Pumps Work - EnggcyclopediaDokument3 SeitenHow Liquid Ring Vacuum Pumps Work - EnggcyclopediaJAGADEESHNoch keine Bewertungen

- CV1Dokument47 SeitenCV1Sridhar GudapatiNoch keine Bewertungen

- 41000Dokument36 Seiten41000tetiospamNoch keine Bewertungen

- PRV ScenariosDokument5 SeitenPRV Scenariosaugur886Noch keine Bewertungen

- MOGAS Refining Valve Application GuideDokument28 SeitenMOGAS Refining Valve Application Guidecristi_molinsNoch keine Bewertungen

- CH 5 Control ValvesDokument42 SeitenCH 5 Control ValvesFelix LaraNoch keine Bewertungen

- Reciprocating Compressor 11p Vs 618Dokument4 SeitenReciprocating Compressor 11p Vs 618karehmanNoch keine Bewertungen

- Blackmer Autogas HandbookDokument32 SeitenBlackmer Autogas HandbookMuhammad ImranNoch keine Bewertungen

- Single Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Dokument47 SeitenSingle Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Karoline EnríquezNoch keine Bewertungen

- Bomba CPKDokument20 SeitenBomba CPKPatricio Andres Silva SanzanaNoch keine Bewertungen

- Pump VSPDokument12 SeitenPump VSPMiguel V. PalNoch keine Bewertungen

- Multiphase Flow 1995Von EverandMultiphase Flow 1995A. SerizawaNoch keine Bewertungen

- NPSHDokument7 SeitenNPSHsateesh chandNoch keine Bewertungen

- PC PumpDokument5 SeitenPC Pumpphantanthanh100% (1)

- Pumps & NPSH-Avoid ProblemsDokument4 SeitenPumps & NPSH-Avoid ProblemsChem.EnggNoch keine Bewertungen

- Specification - Importance of Getting Them RightDokument6 SeitenSpecification - Importance of Getting Them RightAnonymous QSfDsVxjZNoch keine Bewertungen

- FP 6 6 UpdateDokument233 SeitenFP 6 6 Updatebalaji100% (1)

- MIMOUTDokument96 SeitenMIMOUTbalajiNoch keine Bewertungen

- Boiler PresentationDokument1 SeiteBoiler PresentationbalajiNoch keine Bewertungen

- Jun 97Dokument349 SeitenJun 97homer hullezaNoch keine Bewertungen

- JanuaryDokument1 SeiteJanuaryRiduan ChehalimNoch keine Bewertungen

- 2 DoutDokument2 Seiten2 DoutbalajiNoch keine Bewertungen

- Pressure VesselDokument40 SeitenPressure VesselPrt00789% (18)

- NewFeatures FPv10 NPv12Dokument8 SeitenNewFeatures FPv10 NPv12junhyolNoch keine Bewertungen

- CWXSTR2017R1Dokument6 SeitenCWXSTR2017R1balajiNoch keine Bewertungen

- Oil and GasDokument1 SeiteOil and GasbalajiNoch keine Bewertungen

- Readme PDFDokument6 SeitenReadme PDFbalajiNoch keine Bewertungen

- PR VesselDokument9 SeitenPR Vesselsheikhyasir11Noch keine Bewertungen

- HAZOPDokument66 SeitenHAZOPMartin Shija100% (2)

- PR VesselDokument9 SeitenPR Vesselsheikhyasir11Noch keine Bewertungen

- Install NotesDokument1 SeiteInstall NotesbalajiNoch keine Bewertungen

- PR VesselDokument9 SeitenPR Vesselsheikhyasir11Noch keine Bewertungen

- Horiz OutDokument73 SeitenHoriz OutbalajiNoch keine Bewertungen

- Mechanical-Engineering Gate2016.InfoDokument3 SeitenMechanical-Engineering Gate2016.InfoHenryNoch keine Bewertungen

- Info Iec60079-7 (Ed5.0) enDokument19 SeitenInfo Iec60079-7 (Ed5.0) enbalajiNoch keine Bewertungen

- PR VesselDokument9 SeitenPR Vesselsheikhyasir11Noch keine Bewertungen

- The Latest Welding TechnologiesDokument4 SeitenThe Latest Welding TechnologiesbalajiNoch keine Bewertungen

- Introduction To Project Management: Malcolm KearDokument56 SeitenIntroduction To Project Management: Malcolm KearRaj ShravanthiNoch keine Bewertungen

- DOW Code of ConductDokument24 SeitenDOW Code of ConductLaurynNoch keine Bewertungen

- DoubtsDokument1 SeiteDoubtsbalajiNoch keine Bewertungen

- Iec 42Dokument1 SeiteIec 42balajiNoch keine Bewertungen

- Podhum DaDokument42 SeitenPodhum DabalajiNoch keine Bewertungen

- 311 Ehrhardt PDFDokument12 Seiten311 Ehrhardt PDFbalajiNoch keine Bewertungen

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDokument28 SeitenInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNoch keine Bewertungen

- MN PV 001 Installation Operation and Maintenance Manual Pig Valve Model F PDokument17 SeitenMN PV 001 Installation Operation and Maintenance Manual Pig Valve Model F PbalajiNoch keine Bewertungen

- Saep 3103Dokument6 SeitenSaep 3103Anonymous 4IpmN7OnNoch keine Bewertungen

- Fluid MechDokument2 SeitenFluid MechJade Kristine CaleNoch keine Bewertungen

- West Point Partners Project - OverviewDokument11 SeitenWest Point Partners Project - OverviewhudsonvalleyreporterNoch keine Bewertungen

- DatasheetDokument2 SeitenDatasheetTesfay Zemuy GebrekidanNoch keine Bewertungen

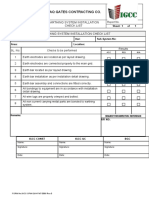

- IGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETDokument1 SeiteIGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETAhmedNoch keine Bewertungen

- Valve Operation and System DesignDokument208 SeitenValve Operation and System DesignWalter José de Miranda100% (8)

- Philips AZ 1839 Service ManualDokument7 SeitenPhilips AZ 1839 Service ManualEdwardNoch keine Bewertungen

- Updated Resume Kelly oDokument2 SeitenUpdated Resume Kelly oapi-254046653Noch keine Bewertungen

- Civil Engineering and SocietyDokument23 SeitenCivil Engineering and Societyyeah100% (3)

- CONTRIBN MADE by Deming, Juran and CrosbyDokument14 SeitenCONTRIBN MADE by Deming, Juran and CrosbySachin Methree100% (1)

- SAFMC 2023 CAT B Challenge Booklet - V14novDokument20 SeitenSAFMC 2023 CAT B Challenge Booklet - V14novJarrett LokeNoch keine Bewertungen

- Sony CFD s100lDokument11 SeitenSony CFD s100lGeremias KunohNoch keine Bewertungen

- 01 - Motor Protection Circuit Breakers - 01 - 20 PDFDokument20 Seiten01 - Motor Protection Circuit Breakers - 01 - 20 PDFMostafa ShannaNoch keine Bewertungen

- Scarabeo 200 I e 0910Dokument66 SeitenScarabeo 200 I e 0910ΧΑΡΑΛΑΜΠΟΣΣΕΛΙΜΗΣNoch keine Bewertungen

- 10 MIPS Floating Point ArithmeticDokument28 Seiten10 MIPS Floating Point ArithmeticHabibullah Khan MazariNoch keine Bewertungen

- Oil-Less Decal Transfer: Copyfun WhiteDokument1 SeiteOil-Less Decal Transfer: Copyfun WhiteIgor Cece GigoNoch keine Bewertungen

- 575 Tech Specs Placenta Pit FinalDokument9 Seiten575 Tech Specs Placenta Pit FinalJohn Aries Almelor SarzaNoch keine Bewertungen

- ALR Compact Repeater: Future On DemandDokument62 SeitenALR Compact Repeater: Future On DemandmickycachoperroNoch keine Bewertungen

- 2016 Smart City PresentationDokument22 Seiten2016 Smart City PresentationDeshGujarat80% (5)

- New Generation Shaft KilnDokument2 SeitenNew Generation Shaft Kilndocument nugrohoNoch keine Bewertungen

- Capr-I En229Dokument13 SeitenCapr-I En229Anonymous WglGv0GNoch keine Bewertungen

- Rukovodstvo Atlas Copco Xahs 447 CDDokument99 SeitenRukovodstvo Atlas Copco Xahs 447 CDradamantus100% (1)

- Modern Love - The New York TimesDokument23 SeitenModern Love - The New York TimesPearl Sky100% (1)

- Logic Families and Their Characteristics CharacteristicsDokument26 SeitenLogic Families and Their Characteristics CharacteristicsanunilaNoch keine Bewertungen

- Pooja CVDokument3 SeitenPooja CVEl Cajon de AmeliaNoch keine Bewertungen

- Failure Mechanisms of C-Steels (API 571)Dokument90 SeitenFailure Mechanisms of C-Steels (API 571)Abdul Gafoor Shaikh50% (2)