Beruflich Dokumente

Kultur Dokumente

Fallsem2018-19 Mee2003 Eth Mb309a Vl2018191003591 Quiz-I Answer Key Tes Cat1 Key Fs 2018-19

Hochgeladen von

Vedant KarnatakOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fallsem2018-19 Mee2003 Eth Mb309a Vl2018191003591 Quiz-I Answer Key Tes Cat1 Key Fs 2018-19

Hochgeladen von

Vedant KarnatakCopyright:

Verfügbare Formate

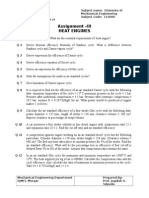

School of Mechanical Engineering

CAT- I, Fall Semester 2018-19

B.Tech

Course Name : Thermal Engineering Systems Duration : 90 min.

Course Code : MEE2003 Max. Marks : 50

Faculty Name : Dr. Nantha Gopal K, Dr. Bibhuti Bhusan Sahoo, Dr. Saboor S, Dr. Bibin

John, Dr. Immanuel Selwyn Raj A, Dr. Vinod Kumar Sharma

Slot : C1

Answer all Questions

Part - A (7x 2 = 14 Marks)

1. How to control knocking in CI engine? Ans: Low self ignition temperature of fuel,

High cylinder wall temperature, High inlet temperature and pressure, High

compression ratio.

2. List out anti-knocking additives used for petrol? Ans: Tetraethyl lead, Toluene,

xylene, methanol, ethanol, alcohol, tertiary butyl alcohol, tertiary butyl ether.

3. Briefly explain lubrication system of 2-Stroke engine? Ans: Mixed lubrication system:

the lubricating oil of 2-3% is directly admitted into engine cylinder along with fuel

from crankcase. Fuel-oil ratio is 50:1.

4. What are the technical aspects to phase out two-stroke vehicles by RTO in major

cities of India? Ans: 1.) Pollution from combustion of oil along with fuel 2.) leak out

of fresh air-fuel mixture with exhaust gases (Hydrocarbon leakage)

5. What are the requirements of a good ignition system? Ans: 1.) it has to transform the

normal battery voltage (6-12V) to 20,000-25,000 V. 2.) Ignition system has to provide

spark in each cylinder at appropriate time 3.) Distributor of ignition system has to

direct high voltage to proper spark plug

6. What is the purpose of ballast resistor in battery ignition system? Ans: Under

prolonged conditions of engine operation, the temperature of ignition coil increases

which can be dangerous. To prevent this ballast resistor made up of iron wire provided

in series with primary winding. Iron has the property of increasing electrical resistance

with increasing temperature. Hence ballast resistor keeps the current down to safe

value.

7. How do you prevent freezing of water in water cooling system of IC engine in cold

regions? Ans: ethylene glycol, propylene glycol, hexylene glycol and glycerine.

Part - B (36 Marks)

1. The following observations were recorded during a trial of a four stroke single

cylinder oil engine. Duration of the trial is 30 min, oil consumption is 4 litres,

calorific value of the oil is 43,000 kJ/kg, specific gravity of the fuel = 0.8, average

area of indicator diagram and length are 8.5 cm2 and 8.5 cm, respectively. The spring

constant = 5.5 bar/cm, Brake load = 1500N, spring balance reading = 200N, effective

brake wheel diameter = 1.5 m, speed= 200 rpm, cylinder diameter = 300 mm, stroke =

450 mm. Calculate i) Indicated power 29.158 kW (2M) ii) Brake power 20.42 kW

(2M) iii) Mechanical efficiency 70.03% (2M) iv) Brake specific fuel consumption

0.3134 kg/kWh (2M) v) Indicated thermal efficiency 38.14% (2M) vi) Brake thermal

efficiency 26.71% (2M)

2. The following observations were made during a trial of a single cylinder, four stroke

gas engine having cylinder diameter of 18 cm and stroke 24 cm.

Duration of trial = 30 min

Total number of revolution = 9000

Total number of explosion = 4450

Mean effective pressure = 5 bar

Net load on the brake wheel = 40 kg

Effective diameter of brake wheel = 1 m

Total gas used at NTP = 2.4 m3

Calorific value of gas at NTP = 19 MJ/m3

Total air used = 36 m3

Pressure of air = 720 mm Hg

Temperature of air = 17°C

Density of air at NTP = 1.29 kg/m3

Temperature of exhaust gas = 350°C

Room temperature = 17°C

Specific heat of exhaust gases = 1 kJ/kg K

Cooling water circulated = 80 kg

Rise in temperature of cooling water = 30°C

Draw up a heat balance sheet in percentage. Take R = 287 J/kg K. (12M)

Heat Input kJ Heat (kJ) (%)

Expenditure

(per min)

Heat supplied by 1520 (2M) 1.Heat 369.6 24.31% (2M)

fuel equivalent to bp

2. heat lost to 334.4 22% (2M)

cooling medium

3. heat lost in 493.5 32.46% (2M)

exhaust

4. unaccounted 322.5 21.21% (2M)

losses

TOTAL 1520 100% (2M)

3. A Morse test on a 12 cylinder, two stroke compression ignition engine of bore 40 cm and

stroke 50 cm running at 200 rpm gave the following readings

CONDITION BRAKE LOAD (N) CONDITION BRAKE LOAD (N)

All firing 2040 7th cylinder 1835

1st cylinder 1830 8th cylinder 1860

2nd cylinder 1850 9th cylinder 1820

3rd cylinder 1850 10th cylinder 1840

4th cylinder 1830 11th cylinder 1850

5th cylinder 1840 12th cylinder 1830

6th cylinder 1855 All firing 2060

The output is found from the dynamometer using the following relation

𝑾𝑵

𝒃𝒑 = 𝟏𝟖𝟎 in kW

Where, W: brake load in Newton, N: speed in rpm.

Calculate:

1.) Total indicated power 2789.2 kW (4M)

2.) Mechanical efficiency 81.66% (4M)

3.) Brake mean effective pressure 9.06 bar (4M) (12M)

Das könnte Ihnen auch gefallen

- Piano Chords PracticeDokument30 SeitenPiano Chords PracticeEd Vince89% (9)

- Mitsubishi Evo Vii Workshop ManualDokument1.471 SeitenMitsubishi Evo Vii Workshop ManuallimaynardNoch keine Bewertungen

- Technical Data Speedmaster SM 102: Printing Stock Blanket CylinderDokument1 SeiteTechnical Data Speedmaster SM 102: Printing Stock Blanket CylinderAHMED MALALNoch keine Bewertungen

- Case Study - Food Services - Business Opportunities Analysis - Presales InternshipDokument2 SeitenCase Study - Food Services - Business Opportunities Analysis - Presales InternshipVedant Karnatak20% (5)

- Case Study - Food Services - Business Opportunities Analysis - Presales InternshipDokument2 SeitenCase Study - Food Services - Business Opportunities Analysis - Presales InternshipVedant Karnatak0% (1)

- Unitized Curtain Wall SystemDokument38 SeitenUnitized Curtain Wall Systems.senthil nathan100% (1)

- D5092 - Design and Installation of Ground Water Monitoring Wells in AquifersDokument14 SeitenD5092 - Design and Installation of Ground Water Monitoring Wells in Aquifersmaxuelbestete100% (1)

- Case Study On Transportation ProblemDokument3 SeitenCase Study On Transportation ProblemVedant Karnatak50% (2)

- THD3602 Major Test 1 2023Dokument3 SeitenTHD3602 Major Test 1 2023LeighNoch keine Bewertungen

- ATD - I IA QP FinalDokument1 SeiteATD - I IA QP FinalSarita UmadiNoch keine Bewertungen

- VIT University SMEC Thermal Engineering Systems assignmentDokument4 SeitenVIT University SMEC Thermal Engineering Systems assignmentVedant KarnatakNoch keine Bewertungen

- Coaching - I TEDokument2 SeitenCoaching - I TEtagoreboopathyNoch keine Bewertungen

- NR-222001-Thermal Engineering and Heat TransferDokument8 SeitenNR-222001-Thermal Engineering and Heat TransferSrinivasa Rao GNoch keine Bewertungen

- THERMAL ENGINEERING-IIDokument2 SeitenTHERMAL ENGINEERING-IIraisa1Noch keine Bewertungen

- Heat Balance Diesel Rope Brake-6Dokument3 SeitenHeat Balance Diesel Rope Brake-6Arup NaskarNoch keine Bewertungen

- Question Bank: Department of Mechanical EngineeringDokument7 SeitenQuestion Bank: Department of Mechanical EngineeringArul Murugan SNoch keine Bewertungen

- Thermodynamics ReportDokument6 SeitenThermodynamics ReportHarsh Vora100% (1)

- Ii Mech ThermalDokument8 SeitenIi Mech ThermalRameez FaroukNoch keine Bewertungen

- Rajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringDokument7 SeitenRajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringPunith YadavNoch keine Bewertungen

- Thermodynamics (MME 2201) RCSDokument2 SeitenThermodynamics (MME 2201) RCSsanyam KanungaNoch keine Bewertungen

- ME 416 (ME 4) Internal Combustion Engine Practice ProblemsDokument3 SeitenME 416 (ME 4) Internal Combustion Engine Practice ProblemsMark MagdaleNoch keine Bewertungen

- TE Assignment IDokument6 SeitenTE Assignment Iragunath LakshmananNoch keine Bewertungen

- Fallsem2013-14 Cp0084 Asgn03 Assignment3Dokument2 SeitenFallsem2013-14 Cp0084 Asgn03 Assignment3Agnibh PrakashNoch keine Bewertungen

- QP 2010Dokument25 SeitenQP 2010samy_175Noch keine Bewertungen

- Thermal Engineering QP AuDokument14 SeitenThermal Engineering QP AusaisenthNoch keine Bewertungen

- Politecnico di Milano Energy Systems exam problemDokument2 SeitenPolitecnico di Milano Energy Systems exam problemEliot KhNoch keine Bewertungen

- Heat engines assignment solutionsDokument6 SeitenHeat engines assignment solutionsSaniya Jumani0% (1)

- Thermal Questions KonguDokument9 SeitenThermal Questions Konguabu19870% (1)

- Birla Institute of Technology and Science, PilaniDokument2 SeitenBirla Institute of Technology and Science, Pilanip vsNoch keine Bewertungen

- MCE 508 Tutorial Answers 2Dokument11 SeitenMCE 508 Tutorial Answers 2David AkinrinolaNoch keine Bewertungen

- Angelo S. Tamaño: Power Plant EngineeringDokument22 SeitenAngelo S. Tamaño: Power Plant EngineeringNeil RubsNoch keine Bewertungen

- MCE 508 Problem SetDokument4 SeitenMCE 508 Problem SetDavid AkinrinolaNoch keine Bewertungen

- Properties From Steam Table Are Given Below:: Q. No. Question Description MarksDokument2 SeitenProperties From Steam Table Are Given Below:: Q. No. Question Description MarksShivamNoch keine Bewertungen

- Nhom 10 - Chuong 4Dokument10 SeitenNhom 10 - Chuong 4Alfie StacyNoch keine Bewertungen

- Air Standard CycleDokument6 SeitenAir Standard CycleBishOy NasrNoch keine Bewertungen

- WWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 ThermodynamicsDokument8 SeitenWWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 Thermodynamicsashoku24007Noch keine Bewertungen

- SY - Thermal Engineering - Dec 2018Dokument3 SeitenSY - Thermal Engineering - Dec 2018Paras kapoorNoch keine Bewertungen

- Applied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreDokument4 SeitenApplied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreMatthew Smith0% (1)

- A. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGDokument5 SeitenA. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGal hasan kanonNoch keine Bewertungen

- Instructions:: No of Pages: 2 Course Code: 15M405Dokument2 SeitenInstructions:: No of Pages: 2 Course Code: 15M405CRAZY PIANO PLAYERNoch keine Bewertungen

- Tutorial - ICEDokument4 SeitenTutorial - ICESuchi Suchi SuchiNoch keine Bewertungen

- ETD - III 2nd AssignmentDokument7 SeitenETD - III 2nd Assignmentmallesh mendaNoch keine Bewertungen

- Thermal CAT 2012Dokument5 SeitenThermal CAT 2012samy_175Noch keine Bewertungen

- Final Exam Set A Cpd30303 July2020 081220 CompleteDokument10 SeitenFinal Exam Set A Cpd30303 July2020 081220 CompleteAzhan FikriNoch keine Bewertungen

- Performance Testing of A Diesel Engine From No Load To Full Load (At Constant Speed) For A SiDokument3 SeitenPerformance Testing of A Diesel Engine From No Load To Full Load (At Constant Speed) For A SiNavneet KumarNoch keine Bewertungen

- Ic Assignment 2Dokument1 SeiteIc Assignment 2Nilven GastardoNoch keine Bewertungen

- ICE Assignment 30072016 043902AM PDFDokument6 SeitenICE Assignment 30072016 043902AM PDFJayPatelNoch keine Bewertungen

- Maximizing Efficiency in IC Engines and Gas TurbinesDokument15 SeitenMaximizing Efficiency in IC Engines and Gas TurbinesVishnu DasNoch keine Bewertungen

- THERMODYNAMICS Oct-Nov 2019Dokument8 SeitenTHERMODYNAMICS Oct-Nov 2019Karthik CruiseNoch keine Bewertungen

- Problems On Performance Testing of Ic Engines: WXN BPDokument4 SeitenProblems On Performance Testing of Ic Engines: WXN BPaldrin sardillaNoch keine Bewertungen

- Applied Thermodynamics Practice QuestionsDokument4 SeitenApplied Thermodynamics Practice QuestionsAshish KumarNoch keine Bewertungen

- Thermal EngineeringDokument1 SeiteThermal EngineeringSoumya BsoumyaNoch keine Bewertungen

- Applied Thermodynamics Otto Dual Ic EnginesDokument2 SeitenApplied Thermodynamics Otto Dual Ic EnginesAkshay A KumarNoch keine Bewertungen

- 16marks QueusionDokument19 Seiten16marks QueusionprasanthprpNoch keine Bewertungen

- Section - B (Attempt All The Questions) - 50 MarksDokument2 SeitenSection - B (Attempt All The Questions) - 50 MarksYash ShuklaNoch keine Bewertungen

- At AssignmentDokument3 SeitenAt AssignmentYogesh PatilNoch keine Bewertungen

- Thermal Engineering - QBDokument2 SeitenThermal Engineering - QBMaxNoch keine Bewertungen

- Thermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsDokument26 SeitenThermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsSuhas G MNoch keine Bewertungen

- r05220304 Thermal Engineering IDokument8 Seitenr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- 78HE-1 Sr. No. 7 Examination of Marine Engineer OfficerDokument4 Seiten78HE-1 Sr. No. 7 Examination of Marine Engineer Officeryosh gurtNoch keine Bewertungen

- 3 - IcDokument28 Seiten3 - Icمصطفى العباديNoch keine Bewertungen

- Tutorial AssignmentDokument5 SeitenTutorial AssignmentAnup ChauhanNoch keine Bewertungen

- Energy Auditing and Volumetric Efficiency of A C.I EngineDokument4 SeitenEnergy Auditing and Volumetric Efficiency of A C.I EngineSIDDHARTH JAINNoch keine Bewertungen

- Apg1000 Specs 74hc595 NXPDokument7 SeitenApg1000 Specs 74hc595 NXPNatgas WebmasterNoch keine Bewertungen

- 20Th National Certification Examination FOR Energy Managers & Energy Auditors - September, 2019Dokument13 Seiten20Th National Certification Examination FOR Energy Managers & Energy Auditors - September, 2019Albert SekarNoch keine Bewertungen

- ME2402 Final Examination 2020 (Mechanical)Dokument3 SeitenME2402 Final Examination 2020 (Mechanical)Dilshan VimukthiNoch keine Bewertungen

- Mid SemDokument2 SeitenMid SemVivekananda NandamNoch keine Bewertungen

- Jio CCIDokument3 SeitenJio CCIVedant KarnatakNoch keine Bewertungen

- Marketing Research Topics Section 3Dokument1 SeiteMarketing Research Topics Section 3Vedant KarnatakNoch keine Bewertungen

- Should CCI Act Against JioDokument1 SeiteShould CCI Act Against JioVedant KarnatakNoch keine Bewertungen

- DRM02Dokument4 SeitenDRM02Vedant KarnatakNoch keine Bewertungen

- Personal Learning Paper PDFDokument3 SeitenPersonal Learning Paper PDFIshmeet SinghNoch keine Bewertungen

- Qualitative Research Note UpdatedDokument9 SeitenQualitative Research Note UpdatedVedant KarnatakNoch keine Bewertungen

- Consolidated Outputs PGDMDokument52 SeitenConsolidated Outputs PGDMVedant KarnatakNoch keine Bewertungen

- Radial Turbines Problem Set Efficiency StageDokument10 SeitenRadial Turbines Problem Set Efficiency StageSiddharth S NarayananNoch keine Bewertungen

- EY WFA Analytics Interns JD 2022Dokument1 SeiteEY WFA Analytics Interns JD 2022Vedant KarnatakNoch keine Bewertungen

- Sars-Cov-2 (Covid 19) Detection (Qualitative) by Real Time RT PCRDokument3 SeitenSars-Cov-2 (Covid 19) Detection (Qualitative) by Real Time RT PCRVedant KarnatakNoch keine Bewertungen

- Letter Form of Undertaking & IndemnityDokument1 SeiteLetter Form of Undertaking & IndemnityVedant KarnatakNoch keine Bewertungen

- MEE1018 Facilities-and-Process-Planning TH 1 AC40Dokument2 SeitenMEE1018 Facilities-and-Process-Planning TH 1 AC40Vedant KarnatakNoch keine Bewertungen

- USE OF BIOMETHANE AS A SUSTAINABLE FUELDokument35 SeitenUSE OF BIOMETHANE AS A SUSTAINABLE FUELVedant KarnatakNoch keine Bewertungen

- Business Model Canvas For 'The Vanity Fur' - Pet Care StartupDokument2 SeitenBusiness Model Canvas For 'The Vanity Fur' - Pet Care StartupVedant KarnatakNoch keine Bewertungen

- Mee1027 Instrumentation-And-Control-Engineering Eth 2.2 47 Mee1027Dokument2 SeitenMee1027 Instrumentation-And-Control-Engineering Eth 2.2 47 Mee1027Vedant KarnatakNoch keine Bewertungen

- 17BEM0049DA1Dokument12 Seiten17BEM0049DA1Vedant KarnatakNoch keine Bewertungen

- Business Model Canvas For 'The Vanity Fur' - Pet Care StartupDokument2 SeitenBusiness Model Canvas For 'The Vanity Fur' - Pet Care StartupVedant KarnatakNoch keine Bewertungen

- Plant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016Dokument18 SeitenPlant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016Vedant KarnatakNoch keine Bewertungen

- The Union Cabinet On Wednesday Unveiled A Comprehensive Biofuels Policy WhichDokument2 SeitenThe Union Cabinet On Wednesday Unveiled A Comprehensive Biofuels Policy WhichVedant KarnatakNoch keine Bewertungen

- Evs Da#2: 17BEM0049 VITDokument11 SeitenEvs Da#2: 17BEM0049 VITVedant KarnatakNoch keine Bewertungen

- Mee1024 - Operations Research: Transportation Problem Case Study: Ultratech CementDokument18 SeitenMee1024 - Operations Research: Transportation Problem Case Study: Ultratech CementVedant KarnatakNoch keine Bewertungen

- Cogeneration Systems Literature ReviewDokument46 SeitenCogeneration Systems Literature ReviewVedant KarnatakNoch keine Bewertungen

- Estimation of Calcium Hardness in Water by Flame Photometry: Expt No. 2 Date: PrincipleDokument3 SeitenEstimation of Calcium Hardness in Water by Flame Photometry: Expt No. 2 Date: PrincipleVedant Karnatak100% (1)

- Cogeneration Systems Literature ReviewDokument46 SeitenCogeneration Systems Literature ReviewVedant KarnatakNoch keine Bewertungen

- 17BEM0049DA1Dokument12 Seiten17BEM0049DA1Vedant KarnatakNoch keine Bewertungen

- Thank You For Your Purchase!: Wwl89Tj Rs.587.82Dokument2 SeitenThank You For Your Purchase!: Wwl89Tj Rs.587.82Vedant KarnatakNoch keine Bewertungen

- Guide To Program EVK1100 With AVR32studioDokument2 SeitenGuide To Program EVK1100 With AVR32studioRobert T. WursterNoch keine Bewertungen

- Urea CycleDokument2 SeitenUrea CycleyoungdandareNoch keine Bewertungen

- Optimize Your Portfolio With Modern TheoriesDokument65 SeitenOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mNoch keine Bewertungen

- Embodied experience at the core of Performance StudiesDokument10 SeitenEmbodied experience at the core of Performance StudiesVictor Bobadilla ParraNoch keine Bewertungen

- CHAPTER 8 SULLIVAN MyReviewerDokument7 SeitenCHAPTER 8 SULLIVAN MyReviewerFrances LouiseNoch keine Bewertungen

- GHB FactsheetDokument2 SeitenGHB FactsheetABC Action NewsNoch keine Bewertungen

- Sujet Dissertation Sciences PolitiquesDokument7 SeitenSujet Dissertation Sciences PolitiquesDoMyPaperSingapore100% (1)

- Excel File - Business Computing - End Term (To Be Shared Vide Email)Dokument301 SeitenExcel File - Business Computing - End Term (To Be Shared Vide Email)Aman SankrityayanNoch keine Bewertungen

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDokument8 SeitenICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- Preferred Vendors For CoilDokument4 SeitenPreferred Vendors For CoildeepakNoch keine Bewertungen

- Turning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewDokument12 SeitenTurning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewfajaqaNoch keine Bewertungen

- 1 Session1 DRR ConceptsDokument43 Seiten1 Session1 DRR ConceptsHoneylet Ü FerolNoch keine Bewertungen

- Understanding the Difference Between Positive and Normative EconomicsDokument21 SeitenUnderstanding the Difference Between Positive and Normative EconomicsKevin Fernandez MendioroNoch keine Bewertungen

- Shrub - Wikipedia, The Free EncyclopediaDokument5 SeitenShrub - Wikipedia, The Free EncyclopediabmxengineeringNoch keine Bewertungen

- 53 Midas-Xr Analysis enDokument33 Seiten53 Midas-Xr Analysis encristiNoch keine Bewertungen

- Ozone Layer EssayDokument7 SeitenOzone Layer Essayb71bpjha100% (2)

- AA Practice Problems on Amino Acids and Peptides (less than 40 charsDokument20 SeitenAA Practice Problems on Amino Acids and Peptides (less than 40 charsNurlaeli NaelulmunaMajdiyahNoch keine Bewertungen

- Complex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDokument8 SeitenComplex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsJorge Luis SotoNoch keine Bewertungen

- 1 - Introducing Your SelfDokument31 Seiten1 - Introducing Your SelfAbdurrahmanNoch keine Bewertungen

- DP4XXX PricesDokument78 SeitenDP4XXX PricesWassim KaissouniNoch keine Bewertungen

- English NotesDokument39 SeitenEnglish NotesNorAini MohamadNoch keine Bewertungen

- Mr. Sanjeev Nanda - Devoted Son and GrandsonDokument1 SeiteMr. Sanjeev Nanda - Devoted Son and GrandsonSanjeev NandaNoch keine Bewertungen

- The Syntactic Alignments Across Three-Ar PDFDokument441 SeitenThe Syntactic Alignments Across Three-Ar PDFabiskarNoch keine Bewertungen

- Oracle Fusion Middleware: CloningDokument25 SeitenOracle Fusion Middleware: CloningSwathiPatluriNoch keine Bewertungen

- Handouts For Semantics GradDokument8 SeitenHandouts For Semantics GradPhuong Thao DangNoch keine Bewertungen