Beruflich Dokumente

Kultur Dokumente

14H, 22H Details

Hochgeladen von

mshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

14H, 22H Details

Hochgeladen von

mshCopyright:

Verfügbare Formate

Section 10

Useful Information

PROPERTY CLASS DATA

Threaded Fasteners not under Tensile Stresses

Ref: ISO 898/5-1980

This International Standard concerning the mechanical properties of set screws and similar fasteners not under tensile stresses, does not apply to

screws requiring special properties such as: -Specified tensile stresses -Weldability -Corrosion resistance -Ability to withstand

temperatures above plus 300ºC (572ºF) or below minus 50ºC (58ºF)

*Please note: Screws made of free-cutting steel should not be used above plus 250ºC (482ºF)

DESIGNATION SYSTEM: 14 H, 17 H, 22 H, 33 H, 45 H

The numerical part of the symbol represents 1/10 of the minimum Vickers hardness. The letter H of the symbol refers to Vickers hardness.

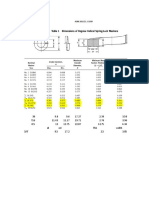

PROPERTY CLASS 14 H 17 H 22 H 33 H 45 H

VICKERS HARDNESS HV min. 140 170 220 330 450

MATERIAL SPECIFICATIONS:

CHEMICAL COMPOSITIONS %

PROPERTY C P S

MATERIAL HEAT TREATMENT

CLASS

max. min. max. max.

14 H Carbon Steel 1, 2 - 0.50 - 0.11 0.15

17 H Carbon Steel - 0.58 - 0.06 0.15

17 H Free Machine Steel - 0.50 - 0.12 0.34

22 H Carbon Steel 3 Quenched and Tempered 0.50 - 0.05 0.05

33 H Carbon Steel 3 Quenched and Tempered 0.50 - 0.05 0.05

45 H Alloy Steel 3, 4 Quenched and Tempered 0.50 0.19 0.05 0.05

1. Free Cutting Steel may be used with lead content 0.35% max., phosphorous content 0.11% and sulphur content 0.34% max.

2. Case hardening is allowed in the case of square-head set screws.

3. Steel with lead content 0.35% max. may be used.

4. Shall contain one or more of alloying elements: chromium, nickel, molybdenum, vanadium or boron.

MECHANICAL PROPERTIES:

PROPERTY CLASS* DIN 267/4-1975-P.87

MECHANICAL PROPERTIES

14 H 17 H 22 H 33 H 45 H PROPERTY CLASS

Vickers Hardness min. 140 170 220 330 450 OLD NEW

HV max. 290 245 300 440 560 4D 11 H

Brinell Hardness min. 133 162 209 314 428 5D 5S 14 H

HB, F = 30 D² max. 276 233 285 418 532 6G 6S 17 H

min. 75 85 95 - - 8G 22 H

HRB

Rockwell max. 105 - - - -

Hardness min. - - - 33 45

HRC

max. - - 30 44 53

*Classes 14 H, 17 H, 22 H AND 33 H are not for hexagon socket set screws.

HARDNESS TESTS:

Hardness reading for the surface hardness shall be taken on the end of the screw, which will be prepared by slightly grinding or polishing to ensure

reproducible readings. In case of doubt, the Vickers hardness test is decisive for acceptance.

© Copyright Metric & Multistandard Components Corp. 2000 10-1019

Das könnte Ihnen auch gefallen

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDokument2 SeitenSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Lss-A286 Astm A453 PDFDokument2 SeitenLss-A286 Astm A453 PDFmazolasboNoch keine Bewertungen

- Iso 9717 2010 en FR - PDF Phosphate CoatingDokument11 SeitenIso 9717 2010 en FR - PDF Phosphate CoatingGANESH ANoch keine Bewertungen

- Asme Section II A-2 Sa-638 Sa-638mDokument4 SeitenAsme Section II A-2 Sa-638 Sa-638mAnonymous GhPzn1xNoch keine Bewertungen

- 2370 Ed1 ENDokument5 Seiten2370 Ed1 ENanhthoNoch keine Bewertungen

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDokument4 SeitenForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNoch keine Bewertungen

- NAS1169Dokument2 SeitenNAS1169Yong-il Kim0% (1)

- Sae j429. Vs Astm A354 BDDokument2 SeitenSae j429. Vs Astm A354 BDOswaldo Leyva RNoch keine Bewertungen

- WSS M1P94 ADokument9 SeitenWSS M1P94 AAleks SenaNoch keine Bewertungen

- Sae J496 1972 (En)Dokument5 SeitenSae J496 1972 (En)Oh No PotatoNoch keine Bewertungen

- Sae J81-2012Dokument10 SeitenSae J81-2012Marcos RosenbergNoch keine Bewertungen

- Astm A31 (1995)Dokument4 SeitenAstm A31 (1995)gsb2100% (1)

- SB 271Dokument4 SeitenSB 271AnilNoch keine Bewertungen

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Dokument5 SeitenTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Noch keine Bewertungen

- Asme B 446Dokument5 SeitenAsme B 446Ramon AraujoNoch keine Bewertungen

- Aerospace Material SpecificationDokument6 SeitenAerospace Material Specificationvsraju2Noch keine Bewertungen

- KAMAXDokument19 SeitenKAMAXNathan PaulNoch keine Bewertungen

- Aisi 4340 Alloy Steel (Uns g43400)Dokument4 SeitenAisi 4340 Alloy Steel (Uns g43400)LamhotFernandoSihombingNoch keine Bewertungen

- Asme B18.13-2017Dokument30 SeitenAsme B18.13-2017윤규섭100% (1)

- Standard Specification For: Designation: B574 17Dokument6 SeitenStandard Specification For: Designation: B574 17raulNoch keine Bewertungen

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDokument6 SeitenSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForAnıl ZiylanNoch keine Bewertungen

- A304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsDokument48 SeitenA304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsAlejandro Valdes100% (1)

- A434Dokument3 SeitenA434alirioNoch keine Bewertungen

- GMW3359Dokument4 SeitenGMW3359lev501Noch keine Bewertungen

- A493 00 PDFDokument3 SeitenA493 00 PDFJohano AraújoNoch keine Bewertungen

- 304 DDQ SpecificationDokument1 Seite304 DDQ Specificationdac_angelovNoch keine Bewertungen

- Mil STD 1312BDokument44 SeitenMil STD 1312BgreatsteelNoch keine Bewertungen

- AMS2303 - Steel Cleanliness, Aircraft Quality PDFDokument14 SeitenAMS2303 - Steel Cleanliness, Aircraft Quality PDFRATHNAKUMARANoch keine Bewertungen

- Aerospace Material SpecificationDokument6 SeitenAerospace Material SpecificationadiNoch keine Bewertungen

- Astm A47-99Dokument5 SeitenAstm A47-99romerobernaNoch keine Bewertungen

- Aerospace Material SpecificationDokument6 SeitenAerospace Material SpecificationAnonymous T6GllLl0Noch keine Bewertungen

- IS 5517 - 1993-Hardening & Tempering GradesDokument15 SeitenIS 5517 - 1993-Hardening & Tempering GradesMohanrajMJ100% (1)

- Astm F 436-04Dokument6 SeitenAstm F 436-04JORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsDokument4 SeitenCold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property Requirementssharon blushteinNoch keine Bewertungen

- Sa 325 PDFDokument12 SeitenSa 325 PDFMo'men Abu-SmaihaNoch keine Bewertungen

- Asme Section Ii A-2 Sa-675 Sa-675mDokument6 SeitenAsme Section Ii A-2 Sa-675 Sa-675mdavid perezNoch keine Bewertungen

- A 29 - A 29M - 16Dokument17 SeitenA 29 - A 29M - 16Isabel Christina Gonzalez MoralesNoch keine Bewertungen

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDokument17 SeitenLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjNoch keine Bewertungen

- B 171Dokument7 SeitenB 171manuel flores100% (1)

- Fed STD H28aDokument11 SeitenFed STD H28amurphygtNoch keine Bewertungen

- Steel Rivets and Bars For Rivets, Pressure VesselsDokument4 SeitenSteel Rivets and Bars For Rivets, Pressure VesselsxaviereduardoNoch keine Bewertungen

- ASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsDokument7 SeitenASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsJuan Luis FerretNoch keine Bewertungen

- Sae Ams 5556H-2008Dokument8 SeitenSae Ams 5556H-2008Mehdi MokhtariNoch keine Bewertungen

- 1 - Din 1683-1e - 0Dokument4 Seiten1 - Din 1683-1e - 0Joaquin AlvarezNoch keine Bewertungen

- Copper-Beryllium Alloy Rod and Bar: Standard Specification ForDokument5 SeitenCopper-Beryllium Alloy Rod and Bar: Standard Specification ForAyvid HgnisNoch keine Bewertungen

- Sae J933 1998 (En)Dokument8 SeitenSae J933 1998 (En)Oh No PotatoNoch keine Bewertungen

- Hardness Conversion TableDokument3 SeitenHardness Conversion TableRavindra KirangeNoch keine Bewertungen

- SteelDokument44 SeitenSteelDevendra SinghNoch keine Bewertungen

- 219-Asme-Sec-Ii-B-Sb-211 Alu AlloyDokument14 Seiten219-Asme-Sec-Ii-B-Sb-211 Alu AlloyGRIPHOLD Engineering ServicesNoch keine Bewertungen

- Aerospace Material SpecificationDokument5 SeitenAerospace Material SpecificationAnonymous T6GllLl0Noch keine Bewertungen

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDokument4 SeitenA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNoch keine Bewertungen

- ASME B18-2-4-6M Metric Heavy Hex NutsDokument16 SeitenASME B18-2-4-6M Metric Heavy Hex Nutsronaldoge100% (1)

- Astm A311 - 2015 - ObsoletoDokument4 SeitenAstm A311 - 2015 - ObsoletoRicardo Ricardo100% (1)

- Iso 683-2-2016 2Dokument7 SeitenIso 683-2-2016 2Saju ShajuNoch keine Bewertungen

- WSS-M1A346-A - Calidad de ChapaDokument12 SeitenWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNoch keine Bewertungen

- Astm B487Dokument2 SeitenAstm B487Srinivasa RaghavanNoch keine Bewertungen

- 17-4 Fi Us enDokument10 Seiten17-4 Fi Us ennaeem akramNoch keine Bewertungen

- BS1400 HTB1Dokument2 SeitenBS1400 HTB1Atul KulkarniNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Martin DuarteNoch keine Bewertungen

- Material Characteristics PDFDokument4 SeitenMaterial Characteristics PDFELTIPAZONoch keine Bewertungen

- Performance Thickness Ratio at Its BestDokument2 SeitenPerformance Thickness Ratio at Its BestmshNoch keine Bewertungen

- SAI - Company ProfileDokument34 SeitenSAI - Company ProfilemshNoch keine Bewertungen

- IFI Book of Fastener Standards 2021 Edition - TOCDokument7 SeitenIFI Book of Fastener Standards 2021 Edition - TOCmoises cordoba100% (1)

- QTN1Dokument1 SeiteQTN1mshNoch keine Bewertungen

- Catalogue 2911Dokument12 SeitenCatalogue 2911mshNoch keine Bewertungen

- Military FastenersDokument17 SeitenMilitary Fastenersmsh100% (1)

- Heavy Hex Nut Inch SizeDokument1 SeiteHeavy Hex Nut Inch SizemshNoch keine Bewertungen

- Estimate 14 08 21Dokument1 SeiteEstimate 14 08 21mshNoch keine Bewertungen

- Dental Tips 1Dokument4 SeitenDental Tips 1mshNoch keine Bewertungen

- Price List No. 164 Price List No. 164Dokument12 SeitenPrice List No. 164 Price List No. 164mshNoch keine Bewertungen

- With GST 022Dokument1 SeiteWith GST 022mshNoch keine Bewertungen

- Aa331220069157k - Rc21012021-Industrial Eng WorksDokument3 SeitenAa331220069157k - Rc21012021-Industrial Eng WorksmshNoch keine Bewertungen

- Price List - MM - Dated 20-04-2021Dokument1 SeitePrice List - MM - Dated 20-04-2021mshNoch keine Bewertungen

- Banyan HydraulicsDokument1 SeiteBanyan HydraulicsmshNoch keine Bewertungen

- Aff Declaration EngDokument1 SeiteAff Declaration Engmsh0% (1)

- Fastener Markings BoltsDokument2 SeitenFastener Markings BoltsmshNoch keine Bewertungen

- State Code: 33 Tin: 33550040141 Gstin: 33aaaph9911p1ziDokument1 SeiteState Code: 33 Tin: 33550040141 Gstin: 33aaaph9911p1zimshNoch keine Bewertungen

- High Strength STructural BoltsDokument10 SeitenHigh Strength STructural BoltsmshNoch keine Bewertungen

- Experimental Research and Method For Calculation of 'Upsetting-with-Buckling' Load at The Impression-Free (Dieless) Preforming of WorkpieceDokument11 SeitenExperimental Research and Method For Calculation of 'Upsetting-with-Buckling' Load at The Impression-Free (Dieless) Preforming of WorkpiecemshNoch keine Bewertungen

- Inch Washer Dimensions-Wajid BhaiDokument2 SeitenInch Washer Dimensions-Wajid BhaimshNoch keine Bewertungen

- FF S 85DDokument20 SeitenFF S 85DmshNoch keine Bewertungen

- Aar M 101 PDFDokument180 SeitenAar M 101 PDFRafael Schelbauer100% (2)

- Daily Mis Report For Heat Treatment (Feb)Dokument40 SeitenDaily Mis Report For Heat Treatment (Feb)YashJhunjhunwalaNoch keine Bewertungen

- ASTM A480-A480M-99bDokument24 SeitenASTM A480-A480M-99bmgmqro100% (1)

- Strength of Materials Lab Manual - MechanicalDokument41 SeitenStrength of Materials Lab Manual - MechanicalNallappan Rajj A100% (2)

- Bradken Fixed Plant BrochureDokument29 SeitenBradken Fixed Plant BrochurepinkypachoNoch keine Bewertungen

- Nanotechnology in Civil EngineeringDokument34 SeitenNanotechnology in Civil EngineeringA R Senthil ArumugamNoch keine Bewertungen

- European Steel and Alloy Grades: Nicr20Co18Ti (2.4632)Dokument2 SeitenEuropean Steel and Alloy Grades: Nicr20Co18Ti (2.4632)farshid KarpasandNoch keine Bewertungen

- Importance of Heat TreatmentDokument5 SeitenImportance of Heat TreatmentArgha DasNoch keine Bewertungen

- Induction Hardening - Interpretation of Drawing & Testing PDFDokument4 SeitenInduction Hardening - Interpretation of Drawing & Testing PDFrajesh DESHMUKHNoch keine Bewertungen

- Purging While WeldingDokument16 SeitenPurging While Weldingchapulincolorado100% (1)

- ASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFDokument4 SeitenASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFmitchialiNoch keine Bewertungen

- The Iron-Iron Carbide (Fe-Fe3C) PhaseDokument8 SeitenThe Iron-Iron Carbide (Fe-Fe3C) PhaseRecep VatanseverNoch keine Bewertungen

- 4140 PDFDokument28 Seiten4140 PDFShariq KhanNoch keine Bewertungen

- Astm A565-1Dokument4 SeitenAstm A565-1MICHELNoch keine Bewertungen

- Sanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsDokument35 SeitenSanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsChaitanya YengeNoch keine Bewertungen

- Steel Castings, Carbon, For General ApplicationDokument4 SeitenSteel Castings, Carbon, For General ApplicationHussein BeqaiNoch keine Bewertungen

- Sa 517Dokument2 SeitenSa 517sepackltdaNoch keine Bewertungen

- Difference ASTM A106 and A333 Grade 6.Dokument2 SeitenDifference ASTM A106 and A333 Grade 6.Qaisir MehmoodNoch keine Bewertungen

- ASTM A333 Grade 6 SpecificationDokument9 SeitenASTM A333 Grade 6 SpecificationmaldonadohansNoch keine Bewertungen

- Ferrography Overview PDFDokument16 SeitenFerrography Overview PDFfido aloneNoch keine Bewertungen

- Trade Fitter 1 ST Semester Multiple Choice Questions: About The Institute & SafetyDokument42 SeitenTrade Fitter 1 ST Semester Multiple Choice Questions: About The Institute & SafetyAnonymous n7jQFvW7rNoch keine Bewertungen

- Effects of Residual Elements in SteelDokument2 SeitenEffects of Residual Elements in SteelPRABHUNoch keine Bewertungen

- MDSP Elements 02 (Prime)Dokument100 SeitenMDSP Elements 02 (Prime)RommelNoch keine Bewertungen

- J Conbuildmat 2019 117109Dokument12 SeitenJ Conbuildmat 2019 117109CIVIL ENGINEERINGNoch keine Bewertungen

- Forging - Mechanical Test SA 105 SA 266 SA 350 SA 765Dokument3 SeitenForging - Mechanical Test SA 105 SA 266 SA 350 SA 765manisami7036Noch keine Bewertungen

- Astm B 570Dokument4 SeitenAstm B 570Telmo VianaNoch keine Bewertungen

- Astm A 770Dokument5 SeitenAstm A 770Patricia MenaNoch keine Bewertungen

- A Report On Placement Training at Peekay Steels PVT LTD CalicutDokument63 SeitenA Report On Placement Training at Peekay Steels PVT LTD CalicutDilrupa JmNoch keine Bewertungen

- DS482Dokument3 SeitenDS482mariomatoNoch keine Bewertungen

- AISI 301 Stainless Steel vs. AISI 304 Stainless SteelDokument8 SeitenAISI 301 Stainless Steel vs. AISI 304 Stainless SteelFSAAVEDRAFNoch keine Bewertungen