Beruflich Dokumente

Kultur Dokumente

FCU Installation

Hochgeladen von

Krishna PatilCopyright

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFCU Installation

Hochgeladen von

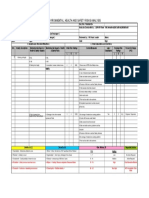

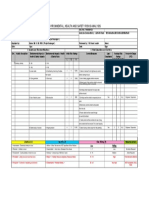

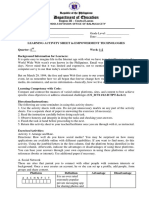

Krishna PatilENVIRONMENTAL, HEALTH AND SAFETY RISKS ANALYSIS

Title: FCU Installation Doc. No. / Revision:00

Company: Voltas LTD Analysis Conducted by: L&W-RA

Mr.Venkatesh,Mr.Sathish,Mr.Muthalli

Team

Site: L&W-I- Gate-Airoli

Approved by: Name: Mr.Ritesh ( MEP Project manager )

Approved by: Name: Mr. U. M. Patil ( Project manager ) Reviewed by: RA Team Leader Name:

Date: Sign: Date: Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Environmental Impacts / Health Initial Risk Ratings Control Measures Law / Residual Risk Person-In-Charge

Health & Safety Hazards & Safety Risks Compliance Ratings (PIC)

L S R L S R

1 Mobilization of Manpower E - Nil E - Nil

H - Nil H - Nil

S- Unskilled Worker S- Personal Injury 4 2 8(M) 1. Only trained person should be deployed Yes 2 2 4(L) Engineer / Supervisor

on this work.

2.Use of required PPEs such as Safety Helmet, jacket

Safety shoes, Hand Gloves, ear plugs, nose mask,

safety goggles, lather apron, Shoulder Pad.

3.Tool box talk should be conduct before start the .

activity.

4.Work permit should be taken before start the work.

5.Work activity should be carried out under

adequate & continues supervision.

2 Beginning of the job E - Nil E - Nil

H - Nil H - Nil

S- Improper communication S-Accidents, Personal Injuries 4 2 8(M) 1.Training should be conducted regarding Material Yes 2 2 4(L) Engineer / Supervisor

handling, Loading & Unloading

3 Manual handling& E - Nil E - Nil

Shifting of FCU to it H

S--caught

Nil in between H - Nil to Limbs

S-Injuries

Location. 4 2 8(M) 1.Use proper type of hand gloves Yes 2 2 4(L) Engineer / Supervisor

Dropping the load Personal Injuries 2.Too heavy get help from others

3.Use correct posture of lifting

4. A group leader for the group lifting

5.Prior tool box talk to the workmen.

4 Working at height E - Nil E - Nil

(scaffolding) H- Nil H- Nil

S- Fall of material from height. S-Damage to other material, 3 4 12(M) 1.No storage of material on working platform. Yes 2 2 4(L) Engineer / Supervisor

fracture ,injuries. 2.Area underneath should be barricaded..

3.Prior tool box talk to the workmen.

S- Fall of person from height. S-Laceration bruises, fracture,injuries 1.Ensure use of PPE's like Safety shoes,. Yes 2 2 4(L) Engineer / Supervisor

safety helmet.

2.Use of double lanyard safety belt.

5 Drilling E - Nil E - Nil

H- Dust Exposure H- Heart Dieseas 3 3 9(M) 1. Work Permit System. Yes 2 2 4(L) Engineer / Supervisor

2. Ensure Worker use dust control nose mask.

3. Proper Ppes should be Provided.

4. Explain to all workers related hazard & Safety

Measures.

S- Driliing work at height S-Laceration bruises, fracture,injuries 4 2 8(M) 1.Working platform shall be made of minimum Yes 2 2 4(L) Engineer / Supervisor

600mm width and secured both side and

with hand rail.

2.Use of full body harness with double lanyards'

S- Use of electricity S-Electrocution 4 2 8(M) 1.All the power cable shall be routed through . Yes 2 2 4(L) Engineer / Supervisor

30mA RCCB

2.Inspection of drilling machine prior to use .

3.No cable joints with out cable connector.

4.Daily inspection of cables and cable joints

by site safety stewards and electricians.

S-Flying particles S-Eye injury 4 2 8(M) 1.Usage of safety goggles shall be ensured. Yes 2 2 4(L) Engineer / Supervisor

Barricading area underneath &

stand by person to restrict unauthorized entry.

6 Transferring of FCU E - Nil E - Nil

from ground to Supports. H- Nil H- Nil

1..Area where FCU installation is in progress has to

S-Hit by falling object S-Damage to other material, 4 2 8(M) Yes 2 2 4(L) Engineer / Supervisor

fracture ,injuries, fatal be barricaded with proper warning signage in

place.

2.Conduct safety briefing to workers before work

starts.

3.One Supervisor to be stationed below at all time.

4.Adequate manpower to Lift the load

5. Chain pulley to be used for lifting of FCU.

6.Inspection certification of equipment.

Check the lifting appliance and gears prior to work.

7. All rigging, slinging and lifting to be done by

competent person.

8. Load weight to be identified before lifting.

9.All persons to be made aware of dangers through

tool box talk.

S-Non involved Personnel S-Serious Injuries 4 2 8(M) 1..Area where installation is in progress has to be Yes 2 2 4(L) Engineer / Supervisor

barricaded with proper warning signage in

coming under the path of load

being moved. place.

2.One Supervisor to be stationed below at

all time.

3.Clear the area before lifting starts. If necessary,

cordon the area.

4.All persons to be made aware of dangers

through tool box talk.

Likelihood (L) Severity (S) Risk Rating (R) Required Action

1 <Improbable> - Extremely unlikely to occur 1 <Minor> - Minor: No lost time / NOT significant, Minor Pollution Index Rating

2 <Remote> - Unlikely to occur 2 <Appreciable> - minor injury; Damage to flora ,fauna 1-7 Low No Action Required

3 <Occasional> - Could possibly or known to occur 3 <Serious> - serious injury; Kills flora , fauna 8 - 14 Medium Action Required

4 <Probable> - Likely to occur more than once 4 <Major> - 1 fatality; Resource depletion, Resource Waste 15 - 19 High Find Alternative Method

5 <Frequent> - Common or repeating occurrences 5 <Catastrophic> - Multiple fatality; > 20 - 25 Very High NOT Acceptable / Stop

Work

Das könnte Ihnen auch gefallen

- Method Statement: QC InspectorDokument7 SeitenMethod Statement: QC InspectorCobbinah MarkNoch keine Bewertungen

- MS-WL-117 Wrapping D.I. PipesDokument5 SeitenMS-WL-117 Wrapping D.I. PipesburereyNoch keine Bewertungen

- Method Statement-Ext Pipe FittingsDokument13 SeitenMethod Statement-Ext Pipe FittingsSam JoseNoch keine Bewertungen

- Maaden-JSA - Piping Erection 1Dokument1 SeiteMaaden-JSA - Piping Erection 1Santos RexNoch keine Bewertungen

- Boq Piping Materials RaDokument4 SeitenBoq Piping Materials RaHerruSetiawanNoch keine Bewertungen

- Project Title: TBA: Client: ContractorDokument3 SeitenProject Title: TBA: Client: ContractorIzza HalimNoch keine Bewertungen

- Demolition of ShadesDokument6 SeitenDemolition of ShadesahmadNoch keine Bewertungen

- DT # 0232 Metod Statement For Steel ErectionDokument16 SeitenDT # 0232 Metod Statement For Steel ErectionPangky AbasoloNoch keine Bewertungen

- Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)Dokument4 SeitenMethod Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)poovazhaganNoch keine Bewertungen

- Detailed MsDokument17 SeitenDetailed MsDinesh CandassamyNoch keine Bewertungen

- HSE Plan RevDokument263 SeitenHSE Plan RevUdayan ChakrabortyNoch keine Bewertungen

- 08 Hirarc Form (r02)Dokument2 Seiten08 Hirarc Form (r02)Aizat Sera SuwandiNoch keine Bewertungen

- QATAR Pin Braze pdfr1Dokument14 SeitenQATAR Pin Braze pdfr1Karunanithi NagarajanNoch keine Bewertungen

- Method Statement For Installation and Relocation of Isolation FenceDokument13 SeitenMethod Statement For Installation and Relocation of Isolation FenceAnantha PadmanabhanNoch keine Bewertungen

- Manpower ListDokument4 SeitenManpower ListgkNoch keine Bewertungen

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Dokument6 SeitenMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectNoch keine Bewertungen

- Job Procedure For Hydrotest/Water Fillup Test: 1. ScopeDokument3 SeitenJob Procedure For Hydrotest/Water Fillup Test: 1. ScopeRebecca SchultzNoch keine Bewertungen

- Data Monitor Fast FoodDokument38 SeitenData Monitor Fast FoodMelvin Yeo0% (1)

- Dyer JSA - Brazing CopperDokument2 SeitenDyer JSA - Brazing Copperdawn yatesNoch keine Bewertungen

- Lifting Equipment Thorough Examination Register: Almansoori Inspection ServicesDokument5 SeitenLifting Equipment Thorough Examination Register: Almansoori Inspection ServicesMohamed YasirNoch keine Bewertungen

- Work Method StatementDokument10 SeitenWork Method StatementMdNasruddin shaikhNoch keine Bewertungen

- Lift Plan-Wilco Extenral StairsDokument25 SeitenLift Plan-Wilco Extenral StairsEdgar ChecaNoch keine Bewertungen

- MOS - Steel StructureDokument15 SeitenMOS - Steel StructuredennisNoch keine Bewertungen

- IC Workshop Materials 09 - Construction WorkshopDokument81 SeitenIC Workshop Materials 09 - Construction WorkshoptrndemNoch keine Bewertungen

- Compliance Statement - PPR CopraxDokument1 SeiteCompliance Statement - PPR CopraxAhmed HelmyNoch keine Bewertungen

- JSA Backfilling, Leveling, (Night Shift)Dokument14 SeitenJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNoch keine Bewertungen

- Program of Works: 02 QuirinoDokument14 SeitenProgram of Works: 02 QuirinoAYSON N. DELA CRUZNoch keine Bewertungen

- Tool Box Meeting AttendancesDokument1 SeiteTool Box Meeting AttendancesPT LD ServisNoch keine Bewertungen

- Erection Method StatementDokument30 SeitenErection Method StatementmustafaNoch keine Bewertungen

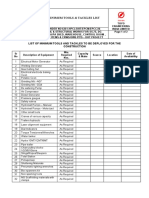

- List of Minimum Tools and Tackles To Be Deployed For The ConstructionDokument2 SeitenList of Minimum Tools and Tackles To Be Deployed For The ConstructionRashid Ahmed SiddiquiNoch keine Bewertungen

- 439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water LineDokument16 Seiten439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water Linearshad iqbalNoch keine Bewertungen

- Test Pack Flow / Control Log: Punch List / Inspection Prior For Hydro TestDokument2 SeitenTest Pack Flow / Control Log: Punch List / Inspection Prior For Hydro Testsyedahmad39Noch keine Bewertungen

- Summary of PPP Projects: Stage Mode of Procurement Number Project Cost (In PHP Billion)Dokument8 SeitenSummary of PPP Projects: Stage Mode of Procurement Number Project Cost (In PHP Billion)Oliver ZuñigaNoch keine Bewertungen

- Method Statement Excavation Civil WorksDokument9 SeitenMethod Statement Excavation Civil WorksRanjith GabrielNoch keine Bewertungen

- Project (APOT)Dokument43 SeitenProject (APOT)Alaa RajabiNoch keine Bewertungen

- Minutes of MeetingDokument3 SeitenMinutes of MeetingNoriel BueranoNoch keine Bewertungen

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksDokument26 Seiten30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eNoch keine Bewertungen

- TCF 1 - Daily Safety Report 01-Sep-2021Dokument4 SeitenTCF 1 - Daily Safety Report 01-Sep-2021Sabre AlamNoch keine Bewertungen

- MOS For Installation of Drainage Pipes and FittingsDokument14 SeitenMOS For Installation of Drainage Pipes and FittingsHubaibNoch keine Bewertungen

- Vpci PMC NCR 0026 PDFDokument51 SeitenVpci PMC NCR 0026 PDFDarrel Espino AranasNoch keine Bewertungen

- Project Execution PlanDokument31 SeitenProject Execution PlanCedie Sietereales100% (1)

- Itp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)Dokument2 SeitenItp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)wagwahkiabatheNoch keine Bewertungen

- q11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitDokument77 Seitenq11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitJobish ManikulathNoch keine Bewertungen

- Building Works at Hougang Town Daily Site Record: Thursday, March 12, 2020Dokument1 SeiteBuilding Works at Hougang Town Daily Site Record: Thursday, March 12, 2020ALFREDO JR. ARIOS CLARONoch keine Bewertungen

- 2016-06-20 ACX-APL5 Installation Time Schedule Rev06Dokument17 Seiten2016-06-20 ACX-APL5 Installation Time Schedule Rev06julio arroyoNoch keine Bewertungen

- Method Statement For Installation of Emt Conduit-OldDokument13 SeitenMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNoch keine Bewertungen

- Method Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteDokument10 SeitenMethod Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteJethin SurendranNoch keine Bewertungen

- Sop of StringingDokument7 SeitenSop of Stringingshubham shindeNoch keine Bewertungen

- MOS 2x15T EOTC Robotic ShopDokument17 SeitenMOS 2x15T EOTC Robotic ShopJohn Rey PerlasNoch keine Bewertungen

- Jacking Procedurefor Construction of Tanks NEWDokument9 SeitenJacking Procedurefor Construction of Tanks NEWVikram RangasamyNoch keine Bewertungen

- Karnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpDokument16 SeitenKarnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpJahangir AlamNoch keine Bewertungen

- Power and Control Cable Laying, Glading and TerminationDokument9 SeitenPower and Control Cable Laying, Glading and Terminationsalman100% (1)

- 3.2 Method - Statement - For - Construction - of - Civil - WorksDokument23 Seiten3.2 Method - Statement - For - Construction - of - Civil - WorksJoseph EgonaNoch keine Bewertungen

- Method Statement With Job Safety Analysis For Process Units Foundation Works (Rev 1) (13-08-2019)Dokument38 SeitenMethod Statement With Job Safety Analysis For Process Units Foundation Works (Rev 1) (13-08-2019)Pradip PaulNoch keine Bewertungen

- Method Statement For Cable Terminaton (CP3)Dokument20 SeitenMethod Statement For Cable Terminaton (CP3)Jacky TamNoch keine Bewertungen

- Qcs 2010 Section 21 Part 1 General Provisions For Electrical InstallaDokument15 SeitenQcs 2010 Section 21 Part 1 General Provisions For Electrical Installabryanpastor106100% (1)

- DS 40 Full SubmittalDokument50 SeitenDS 40 Full Submittalahmed100% (1)

- VRF InstallationDokument3 SeitenVRF InstallationKrishna PatilNoch keine Bewertungen

- Duct InstallationDokument2 SeitenDuct InstallationKrishna PatilNoch keine Bewertungen

- Welding and Gas CuttingDokument2 SeitenWelding and Gas CuttingKrishna Patil100% (2)

- Environmental, Health and Safety Risks AnalysisDokument2 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument1 SeiteEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument1 SeiteEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- JET Fan InstallationDokument2 SeitenJET Fan InstallationKrishna Patil100% (2)

- Grinding ActivityDokument1 SeiteGrinding ActivityKrishna Patil100% (2)

- Insulation of Ducting and PipingDokument1 SeiteInsulation of Ducting and PipingKrishna Patil100% (1)

- VRF InstallationDokument3 SeitenVRF InstallationKrishna PatilNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument2 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- AHU AssemblyDokument3 SeitenAHU AssemblyKrishna Patil100% (1)

- Environmental, Health and Safety Risks AnalysisDokument2 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument3 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument3 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- Testing and CommisioningDokument2 SeitenTesting and CommisioningKrishna PatilNoch keine Bewertungen

- VRF InstallationDokument3 SeitenVRF InstallationKrishna PatilNoch keine Bewertungen

- JHA Chain HoistDokument1 SeiteJHA Chain HoistKrishna Patil100% (2)

- Insulation of Ducting and PipingDokument1 SeiteInsulation of Ducting and PipingKrishna PatilNoch keine Bewertungen

- Electrical Panel InstallationDokument2 SeitenElectrical Panel InstallationKrishna PatilNoch keine Bewertungen

- Fan InstallationDokument2 SeitenFan InstallationKrishna PatilNoch keine Bewertungen

- Duct InstallationDokument2 SeitenDuct InstallationKrishna PatilNoch keine Bewertungen

- Copper PipingDokument2 SeitenCopper PipingKrishna PatilNoch keine Bewertungen

- The-Stakeholders-of-Education-and-Funding-CapabilitiesDokument15 SeitenThe-Stakeholders-of-Education-and-Funding-CapabilitiesKaren May Urlanda80% (5)

- Wits Lesson PlanDokument2 SeitenWits Lesson Planapi-317043268Noch keine Bewertungen

- Cruise MissileDokument17 SeitenCruise MissileAli KhanNoch keine Bewertungen

- WEEK1 - Computer AppreciationDokument11 SeitenWEEK1 - Computer AppreciationMarvin DeinlaNoch keine Bewertungen

- Thesis Chapter1-3Dokument76 SeitenThesis Chapter1-3Arveeh AvilesNoch keine Bewertungen

- Epfo Test ScheduleDokument7 SeitenEpfo Test SchedulePawan KumarNoch keine Bewertungen

- Course Manual Venice, Byzantium, Greek World - 2021-2022Dokument3 SeitenCourse Manual Venice, Byzantium, Greek World - 2021-2022SP CNoch keine Bewertungen

- Principles of Management Mg2351 Anna University Question BankDokument4 SeitenPrinciples of Management Mg2351 Anna University Question BankjeebalaNoch keine Bewertungen

- The Resistible Rise of Benito Mussolini and Fighting Fascism in Britain TodayDokument5 SeitenThe Resistible Rise of Benito Mussolini and Fighting Fascism in Britain TodayIgor CrnoboriNoch keine Bewertungen

- Krieger Family HandbookDokument62 SeitenKrieger Family Handbooksweetkim0515Noch keine Bewertungen

- Understanding The Reliability Block DiagramDokument5 SeitenUnderstanding The Reliability Block DiagramHugh cabNoch keine Bewertungen

- Punjab 2016Dokument4.298 SeitenPunjab 2016Yanamandra Radha Phani ShankarNoch keine Bewertungen

- Supply Chain - Introduction: Rosalin RubaraniDokument17 SeitenSupply Chain - Introduction: Rosalin RubaranipremNoch keine Bewertungen

- Empowerment TechnologiesDokument30 SeitenEmpowerment Technologiesskz blueprintNoch keine Bewertungen

- 09 - San Juan vs. People, May 30, 2011Dokument2 Seiten09 - San Juan vs. People, May 30, 2011Nica Cielo B. Libunao100% (1)

- Bend, Curl, Hold, Lift, Lower, Pull, PushDokument3 SeitenBend, Curl, Hold, Lift, Lower, Pull, Pushapi-595082074Noch keine Bewertungen

- Healthwire Proposal - CWPDokument12 SeitenHealthwire Proposal - CWPSyedArslanAttaNoch keine Bewertungen

- Hass Planning Year 3 Term 2Dokument3 SeitenHass Planning Year 3 Term 2api-505532021Noch keine Bewertungen

- 1.loyola Grand Villas Homeowners South Association Inc. Vs CaDokument5 Seiten1.loyola Grand Villas Homeowners South Association Inc. Vs CaLalaine FelixNoch keine Bewertungen

- Anju Thapa: Human Resource School Administrator & TeacherDokument1 SeiteAnju Thapa: Human Resource School Administrator & TeacherKishore KumarNoch keine Bewertungen

- grBKmJyRKC - Tata Motor Finance JDDokument7 SeitengrBKmJyRKC - Tata Motor Finance JDVanya AroraNoch keine Bewertungen

- Communication SkillsDokument1 SeiteCommunication SkillsSalmaBagulNoch keine Bewertungen

- Performance Management, 57 (5), Pp. 420-423. Doi: 10.1108/17410400810881863Dokument2 SeitenPerformance Management, 57 (5), Pp. 420-423. Doi: 10.1108/17410400810881863Mrigendra MishraNoch keine Bewertungen

- Fbs Week 7 Exemplar 2Dokument4 SeitenFbs Week 7 Exemplar 2Maureen Latayan AgbingNoch keine Bewertungen

- RMC - Hiware Bazar - Mamaearth - Rural Marketing StrategyDokument18 SeitenRMC - Hiware Bazar - Mamaearth - Rural Marketing StrategySwati MalpaniNoch keine Bewertungen

- Ski Resort in Manang Project: Salient FeaturesDokument3 SeitenSki Resort in Manang Project: Salient Featuresmarab12Noch keine Bewertungen

- Max's Restaurants in Metro Manila" For The Partial Fulfillment of Our Thesis Writing SubjectDokument3 SeitenMax's Restaurants in Metro Manila" For The Partial Fulfillment of Our Thesis Writing SubjectMark Gelo WinchesterNoch keine Bewertungen

- Reengineering Retail Stephens en 32925Dokument5 SeitenReengineering Retail Stephens en 32925Deep MannNoch keine Bewertungen

- MAPEH8 Arts q2 Mod1 v2Dokument59 SeitenMAPEH8 Arts q2 Mod1 v2Nicolee Leah IINoch keine Bewertungen

- Research On Influences On Maintenance Management EDokument10 SeitenResearch On Influences On Maintenance Management EMacammad Qabdu WasamaNoch keine Bewertungen