Beruflich Dokumente

Kultur Dokumente

## Public

Hochgeladen von

arjunkoirala0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten1 SeiteActivity Hazard Analysis for Concrete Works

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenActivity Hazard Analysis for Concrete Works

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten1 Seite## Public

Hochgeladen von

arjunkoiralaActivity Hazard Analysis for Concrete Works

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

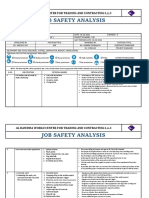

ACTIVITY HAZARD ANALYSIS

Project Name: T/O No:

Contractor: JV of Contractors Location/Site: AHA NO:

AHA Conducted by: Health & Safety Officer Date: Page: 1 of 1

CONCRETE WORK

ACTIVITIES HAZARD IDENTIFICATION HAZARD MITIGATION / CONTROLS

1. Fetching Machine to Site 1. The concrete machine to be fetched, off-load and safely set at right place safely & properly.

2. Access clearance 2. Ensure material (sand & aggregate) is not blocking the safe access,

1. Preparatory Works

3. Site Utilities 3. Make sure construction material not obstruct electric wires, CCTV cables, and telephone line.

4. Storage of Material 4. Better Housekeeping eliminate obstacles, Ensure Access and Egress are free from obestacles.

1. Flying debris 1. All workers on working site shall wear mandatory PPE (Helmet, Safety Shoes, Safety Goggles, Mask)

2. Dust & Smoke Inhalation 2. Dust masks shall be kept on hand to fulfill the immediate requirement at working site.

2. Compliance to Health 3. Foreign body into Eye/Injuries 3. Workers involving in mixing & vibrating work shall wear safety goggles.

and Safety Plan 4. Cuts/scrapes/abrasions 4. Be careful while handling vibrating machine (electric shock and misplacement of vibrator)

5. Struck by machines 5. All workers on site shall wear high-visibility vests, LOTO system to be followed,

6. Fall/Trip/Slip 6. Concreting area to be clean/clear free from obstacles. All workers must use mandatory PPE

1. To avoid cement dust inhalation respirator/mask is mandatory,

1. Dusts 2. Be careful while taking material to prepare slump (handle cement properly).

2. Cement. Sand & Aggregate 3. Concrete shifting pan handle properly, pass hand to hand, do not throw empty pan after delivery.

3. Fetching Material 4. Concreting work will allow only at safe area, unsafe area will be barricaded to stop the access.

5. Toe-guard, mid-rail and top-rail must exist on the working platform.

4. Working Platform

6. As possible make working surface free from slippery, mind your movement during delivery.

5. Toe-guard, Guard rails 7. Sufficient support to be provided against stipulated load and it should be checked before work start.

6. Slippery Surface 8. Make working area free from obstacles, ensuring better housekeeping,

3. Concreting Work

7. Scaffold/support failure 9. Use mandatory PPE, remove all obstacle from the access route.

8. Slip, Trip, Fall 10. Visitors not allow to working area, supervising staff keep themselves in safe distance & Helmet,

9. Falling objects Safety Shoes, Mask and Visibility Vest must be used.

10. Visitor/Supervising staff 11. Concrete mixture to be operate by skill operator, unnecessary person to be avoided at operation area.

Machine to be set properly that should not tilt or move during the motion and pouring time.

11. Mixing Operation

12. Malfunctioning machinery and equipment can cause overheating and fire, follow safe operating

12. Smoke & Fire procedure.

13. Pollution 13. Follow EMEP guideline for environmental mitigation measure, manage dust, empty bags, dirty water

properly

TRAINING REQUIRED EQUIPMENT REQUIRED

Toolbox Health and Safety Plan

Safety Induction on PPE USE Method of Statement & AHA for Concrete Work

Safe Operation Procedure PPE (Helmet, Gumboot, Mask, Earplug, Safety Googles, Gloves, Face Shield)

Emergency Evacuation & First Aid First Aid Box

Das könnte Ihnen auch gefallen

- AHA - Retrofitting WorkDokument1 SeiteAHA - Retrofitting WorkarjunkoiralaNoch keine Bewertungen

- ACTIVITY HAZARD ANALYSIS FOR WELL DIGGINGDokument1 SeiteACTIVITY HAZARD ANALYSIS FOR WELL DIGGINGarjunkoiralaNoch keine Bewertungen

- 01 Job Hazard Analysis For Piling Works (JHA)Dokument3 Seiten01 Job Hazard Analysis For Piling Works (JHA)AmanNoch keine Bewertungen

- Tile WorkDokument1 SeiteTile WorknabeelNoch keine Bewertungen

- Jobs Safety Analysis (JSA)Dokument4 SeitenJobs Safety Analysis (JSA)uttam mishraNoch keine Bewertungen

- Job Safety Analysis - Doc With Penumatic TestingDokument5 SeitenJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Concreting and ShutteringDokument3 SeitenConcreting and ShutteringAnuj Kjoy0% (1)

- Asphalt Paving JsaDokument2 SeitenAsphalt Paving Jsanabeel100% (1)

- Hazard Analysis - Concrete, Cast-In-place (Curbstone)Dokument3 SeitenHazard Analysis - Concrete, Cast-In-place (Curbstone)abdullah ashrafNoch keine Bewertungen

- Construction Manpower Safety: Machinery and Structures Construction Site PremisesDokument5 SeitenConstruction Manpower Safety: Machinery and Structures Construction Site PremisesBlessie Taruc DueñasNoch keine Bewertungen

- Critical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleDokument5 SeitenCritical Steps Hazard(s) Controls/Recommended Action: Concrete Cutting & Breaking Core Cutting On Existing Man HoleSrikanth GandepalliNoch keine Bewertungen

- Jsa For Pilling WorkDokument12 SeitenJsa For Pilling WorkLakhan kumar100% (1)

- SWP BackfillDokument1 SeiteSWP BackfillMohamed Zied ChaariNoch keine Bewertungen

- Jsa HDD DrillingDokument6 SeitenJsa HDD Drillingshaibaz chafekarNoch keine Bewertungen

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDokument9 SeitenJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Tool Box Meeting (New)Dokument44 SeitenTool Box Meeting (New)molokoluki25Noch keine Bewertungen

- Risk Mitigation Plan 1Dokument25 SeitenRisk Mitigation Plan 1Omar BahakimNoch keine Bewertungen

- CHIPPING METHODOLOGYDokument6 SeitenCHIPPING METHODOLOGYChrissa Villaflores GanitNoch keine Bewertungen

- Safety Method StatementDokument11 SeitenSafety Method StatementKamutura Ga TerereNoch keine Bewertungen

- Guidelines Working Aloft ShipsDokument5 SeitenGuidelines Working Aloft ShipsDank100% (1)

- TBT TopicsDokument30 SeitenTBT TopicsmohammedtofiqahmedNoch keine Bewertungen

- Pha ExcavationDokument13 SeitenPha ExcavationirshadNoch keine Bewertungen

- Job Safety AnalysisDokument3 SeitenJob Safety AnalysisDeshbandhu Aman PandeyNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument1 SeiteJob Safety Analysis Worksheetsrinivasa raoNoch keine Bewertungen

- Job Safety Analysis (JSA) - Painting DateDokument2 SeitenJob Safety Analysis (JSA) - Painting DatenabeelNoch keine Bewertungen

- Safety Tool Box TalkDokument30 SeitenSafety Tool Box TalkahmedNoch keine Bewertungen

- Job Safety Analysis Lifting and RiggingDokument17 SeitenJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- STL-HSE Orientation-C-WorkplaceDokument45 SeitenSTL-HSE Orientation-C-Workplacelsm projectNoch keine Bewertungen

- Basic Safety RulesDokument1 SeiteBasic Safety Rulesvaplsawrabh1988Noch keine Bewertungen

- SWP For MBDokument12 SeitenSWP For MBDines VijayadevarNoch keine Bewertungen

- JSA_Scaffolding Erection and dismantling work.(06)Dokument3 SeitenJSA_Scaffolding Erection and dismantling work.(06)hitech.birlacyrNoch keine Bewertungen

- BRIEFING ON HSE DM Water TankDokument7 SeitenBRIEFING ON HSE DM Water Tankssb goddaNoch keine Bewertungen

- JOB Hazard Analysis C: ArpenterDokument2 SeitenJOB Hazard Analysis C: ArpenterUMUTNoch keine Bewertungen

- SAFETY PLAN AND EMERGENCY PROCEDURESDokument4 SeitenSAFETY PLAN AND EMERGENCY PROCEDURESBilal QureshiNoch keine Bewertungen

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDokument2 SeitenRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- Job Hazard Analysis: Amichand Technological Pvt. LTDDokument6 SeitenJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNoch keine Bewertungen

- Behaviour Based Observation ChecklistDokument3 SeitenBehaviour Based Observation ChecklistVaradaraju ThirunavukkarasanNoch keine Bewertungen

- JHADokument8 SeitenJHARayyan ramosNoch keine Bewertungen

- JSA - Field Instruments InstallationDokument4 SeitenJSA - Field Instruments InstallationSagar PadhiyarNoch keine Bewertungen

- Method-Statement SignageDokument4 SeitenMethod-Statement SignageGopan V NairNoch keine Bewertungen

- 4.4.2.4B General OHS Induction VisitorsDokument2 Seiten4.4.2.4B General OHS Induction VisitorsSeeiso MasienyaneNoch keine Bewertungen

- L4C - Working PlatfornDokument3 SeitenL4C - Working PlatfornArif RizwanNoch keine Bewertungen

- Chilled Water Pipe Installation - ACMVDokument4 SeitenChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- JSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Dokument12 SeitenJSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)mehtab uddinNoch keine Bewertungen

- JSA-009a Drilling and Mon Well Construction-SonicDokument4 SeitenJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- General Hazard Identification Form Sample ReportDokument10 SeitenGeneral Hazard Identification Form Sample ReportJavanshir AkbariNoch keine Bewertungen

- PGAT2 MOS CSA 001 - MOS of Plastering WorkDokument4 SeitenPGAT2 MOS CSA 001 - MOS of Plastering WorkViisshnu SilvarajooNoch keine Bewertungen

- Construction Safety & Health Management System: (Accident Prevention Program)Dokument8 SeitenConstruction Safety & Health Management System: (Accident Prevention Program)carlito alvarezNoch keine Bewertungen

- Work Method Statement PDFDokument8 SeitenWork Method Statement PDFUsiwo Abed Soteria Otowa100% (2)

- Crane Jsa TGPDokument2 SeitenCrane Jsa TGPSuryakant SurajNoch keine Bewertungen

- Siemens LTD.: General Work Permit Serial No.Dokument3 SeitenSiemens LTD.: General Work Permit Serial No.Dakshinamurthy PNoch keine Bewertungen

- Binder2 6Dokument1 SeiteBinder2 6Shahid BhattiNoch keine Bewertungen

- BACKFILLINGDokument2 SeitenBACKFILLINGKeith ManansalaNoch keine Bewertungen

- Demobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling AreaDokument3 SeitenDemobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling ArearadeepNoch keine Bewertungen

- SWP-037 Carpentry & Joinery WorksDokument2 SeitenSWP-037 Carpentry & Joinery Worksadrianlim13Noch keine Bewertungen

- Concrete Cutting and Drilling PDFDokument2 SeitenConcrete Cutting and Drilling PDFcityofdarwingis100% (1)

- Job Safety Analysis: Kalco Alu System (P) LTDDokument2 SeitenJob Safety Analysis: Kalco Alu System (P) LTDShekh BabulNoch keine Bewertungen

- HS Summary November 2018Dokument2 SeitenHS Summary November 2018arjunkoiralaNoch keine Bewertungen

- Appendix of Confine SpaceDokument6 SeitenAppendix of Confine SpacearjunkoiralaNoch keine Bewertungen

- Safe Driving ProcedureDokument14 SeitenSafe Driving ProcedurearjunkoiralaNoch keine Bewertungen

- General Inspection ChecklistDokument4 SeitenGeneral Inspection ChecklistarjunkoiralaNoch keine Bewertungen

- Precaution During The EarthquakeDokument11 SeitenPrecaution During The EarthquakearjunkoiralaNoch keine Bewertungen

- Safety Poster of General Rules PDFDokument1 SeiteSafety Poster of General Rules PDFarjunkoiralaNoch keine Bewertungen

- SP 2 General Safety RulesDokument11 SeitenSP 2 General Safety RulesarjunkoiralaNoch keine Bewertungen

- SP 2 General Safety RulesDokument11 SeitenSP 2 General Safety RulesarjunkoiralaNoch keine Bewertungen

- SP 2 General Safety RulesDokument11 SeitenSP 2 General Safety RulesarjunkoiralaNoch keine Bewertungen

- PPE Guide for Construction WorkersDokument9 SeitenPPE Guide for Construction WorkersarjunkoiralaNoch keine Bewertungen

- The Chinese Classic Philosophical TranslationDokument153 SeitenThe Chinese Classic Philosophical Translationarjunkoirala100% (3)

- Para ImprimirDokument2 SeitenPara ImprimirZymafayNoch keine Bewertungen

- Boots Case StudyDokument4 SeitenBoots Case StudyGeorge Lugembe MalyetaNoch keine Bewertungen

- IOE425 Syllabus Winter 2017 002 v1.1Dokument7 SeitenIOE425 Syllabus Winter 2017 002 v1.1jstnjoseNoch keine Bewertungen

- Neuromarketing and The Perception of Knowledge by Michael Butler PDFDokument5 SeitenNeuromarketing and The Perception of Knowledge by Michael Butler PDFcarmldonadoaNoch keine Bewertungen

- Transnational Crimes and Malaysia's Domestic LawsDokument5 SeitenTransnational Crimes and Malaysia's Domestic LawsGlorious El DomineNoch keine Bewertungen

- Globalization Becomes Truly Global: Lessons Learned at LenovoDokument9 SeitenGlobalization Becomes Truly Global: Lessons Learned at LenovormvffrankenbergNoch keine Bewertungen

- How To Use Transaction SOST & SCOT For Chec..Dokument2 SeitenHow To Use Transaction SOST & SCOT For Chec..ghenno18Noch keine Bewertungen

- Irda Act 1999Dokument7 SeitenIrda Act 1999Bhawana SharmaNoch keine Bewertungen

- Serial Card: 377X1-A3-J1-D18-9A7-9B2Dokument1 SeiteSerial Card: 377X1-A3-J1-D18-9A7-9B2troy minangNoch keine Bewertungen

- Review of Literature-Car FinancingDokument5 SeitenReview of Literature-Car FinancingRaj Kumar50% (4)

- Maternity Benefit Act AmendmentsDokument2 SeitenMaternity Benefit Act AmendmentsYogesh BNoch keine Bewertungen

- Oligopoly For MPADokument41 SeitenOligopoly For MPAAshraf Uz ZamanNoch keine Bewertungen

- Suit for Specific Performance of Flat Sale AgreementDokument13 SeitenSuit for Specific Performance of Flat Sale Agreementyash50% (6)

- The coverage details for windstorm, lightning, earthquake, and fire in property insurance policiesDokument1 SeiteThe coverage details for windstorm, lightning, earthquake, and fire in property insurance policiesKim EstalNoch keine Bewertungen

- Banking Industry KYIDokument199 SeitenBanking Industry KYIYasmeen MahammadNoch keine Bewertungen

- 03 - Quality Management SystemDokument12 Seiten03 - Quality Management SystemCharlon Adrian RuizNoch keine Bewertungen

- Oral Communication - Noise Barriers To CommunicationDokument24 SeitenOral Communication - Noise Barriers To Communicationvarshneyankit1Noch keine Bewertungen

- Ias8 PDFDokument3 SeitenIas8 PDFNozipho MpofuNoch keine Bewertungen

- NBN Co: Financial Management SolutionDokument2 SeitenNBN Co: Financial Management SolutionAccentureAustraliaNoch keine Bewertungen

- Organization & EthicsDokument11 SeitenOrganization & EthicsAvijeet ChowdhuryNoch keine Bewertungen

- SAP S/4 HANA Simple Finance Course ContentDokument10 SeitenSAP S/4 HANA Simple Finance Course ContentRakesh GuptaNoch keine Bewertungen

- Transaction Banking Trends in Transaction Banking Report Survey Report v21Dokument16 SeitenTransaction Banking Trends in Transaction Banking Report Survey Report v21Shifat HasanNoch keine Bewertungen

- Training On APQPDokument38 SeitenTraining On APQPSachin Chauhan100% (1)

- 11th Commerce 3 Marks Study Material English MediumDokument21 Seiten11th Commerce 3 Marks Study Material English MediumGANAPATHY.SNoch keine Bewertungen

- Is Wal-Mart Too Powerful - BusinessweekDokument5 SeitenIs Wal-Mart Too Powerful - BusinessweekDavid TanNoch keine Bewertungen

- Apple Vs SamsungDokument10 SeitenApple Vs SamsungREEDHEE2210Noch keine Bewertungen

- Table 2.5 SolutionDokument3 SeitenTable 2.5 SolutionMarghoob AhmadNoch keine Bewertungen

- AccountingDokument4 SeitenAccountinganca9004Noch keine Bewertungen

- De Thi Business Econ K58 CTTT C A Vinh Thi 14h30 Ngày 15.7.2021Dokument2 SeitenDe Thi Business Econ K58 CTTT C A Vinh Thi 14h30 Ngày 15.7.2021Trương Tuấn ĐạtNoch keine Bewertungen

- PlayingByTheRules Apexart PDFDokument178 SeitenPlayingByTheRules Apexart PDFinanna12Noch keine Bewertungen